Паслугі па ўсталёўцы маставых кранаў Dafang Crane: забеспячэнне бяспечнага, эфектыўнага і якаснага выканання праектаў

Змест

Мы прапануем прафесійныя паслугі па ўсталёўцы маставых кранаў на месцы. Дасведчаныя інжынеры непасрэдна прыедуць на аб'ект кліента, каб завяршыць увесь працэс: ад распакавання абсталявання, зборкі канструкцыі, каліброўкі пуцей да электраправодкі, уводу ў эксплуатацыю і прыёмкі і г.д., каб забяспечыць бяспечную і эфектыўную працу абсталявання. Калі вы хочаце ўсталяваць яго самастойна, мы можам прадаставіць падрабязную тэхнічную інфармацыю і забяспечыць дыстанцыйнае відэа-інструкцыі або анлайн-падтрымку ў выпадку ўзнікнення тэхнічных праблем. Незалежна ад таго, ці гэта ўстаноўка на месцы, ці дыстанцыйная дапамога, мы заўсёды імкнемся забяспечыць кліентам эфектыўнае і бяспечнае абслугоўванне.

Паслугі па ўсталёўцы маставых кранаў ад вопытных інжынераў

Нашы паслугі па ўсталёўцы маставых кранаў на месцы ўключаюць наступнае:

Адпраўка інжынераў па ўсталёўцы

Як правіла, у залежнасці ад складанасці ўстаноўкі маставога крана і канкрэтных патрэб кліента, мы прызначым ад аднаго да трох інжынераў для выканання паслуг па ўсталёўцы на месцы.

Нашы інжынеры-мантажнікі спецыялізуюцца ў розных галінах, такіх як машынабудаванне, машынабудаванне і электрычная аўтаматызацыя. Яны маюць кваліфікацыю ад сярэдняга да старэйшага ўзроўню, добра разбіраюцца ў працэсах мантажу і ўводу ў эксплуатацыю розных тыпаў маставых кранаў і маюць шырокі практычны вопыт як у айчынных, так і ў міжнародных праектах.

Наша інжынерная каманда паспяхова завяршыла праекты па ўсталёўцы маставых кранаў у такіх краінах, як Егіпет, Саудаўская Аравія, Аргенціна, Узбекістан і Алжыр, атрымаўшы шырокае прызнанне і пахвалу ад нашых кліентаў.

Устаноўка маставога крана

- Падрыхтоўка да ўстаноўкі: перад пачаткам пад'ёмных работ мы праводзім комплексную тэхнічную падрыхтоўку. Гэта ўключае ў сябе агляд зоны пад'ёму на месцы, прагляд будаўнічых чарцяжоў, арганізацыю пад'ёмнай брыгады для азнаямлення з працэдурамі ўстаноўкі, а таксама правядзенне інструктажаў па тэхніцы бяспекі і тэхнічных інструктажаў для ўсяго персаналу на месцы.

- Пад'ём і мантаж галоўнай і канцавой бэлек: у залежнасці ад умоў на будаўнічай пляцоўцы распрацоўваецца адпаведны план пад'ёму. Галоўная і канцавыя бэлькі падымаюцца і ўсталёўваюцца паслядоўна, пасля чаго выконваецца зварка або балтавыя злучэнні. Інжынеры-мантажнікі кантралююць крутоўны момант балтоў і якасць зваркі на будаўнічай пляцоўцы, каб забяспечыць цэласнасць канструкцыі. Памеры і вышыні канструкцыі правяраюцца на адпаведнасць праектным патрабаванням.

- Зборка каляскі і ўстаноўка рэек: кампаненты каляскі збіраюцца секцыямі або цалкам у адпаведнасці з планам зборкі. Рэйкі каляскі ўсталёўваюцца з дакладнасцю, з карэкціроўкай адлегласці паміж рэйкамі і вышыні для забеспячэння бесперабойнай працы. Дыяметр колаў, каляіна і стан ходу правяраюцца на месцы, і пазіцыянавальныя прылады адпаведна наладжваюцца.

- Мантаж і падключэнне электрычных сістэм: кабелі пракладваюцца, а электрычныя шафы і блокі кіравання ўсталёўваюцца ў адпаведнасці з праектнымі чарцяжамі. Падключэнне на месцы забяспечвае належныя і стандартызаваныя падключэнні, якія адпавядаюць патрабаванням бяспекі. Узровень абароны і меры зазямлення электраабсталявання старанна правяраюцца.

Увогуле, устаноўка однобалочный мостовой кран займае каля 15-20 дзён.

Фактычны тэрмін усталёўкі можа адрознівацца ў залежнасці ад некалькіх фактараў, такіх як складанасць канструкцыі крана, колькасць устаноўленых адзінак, даўжыня пад'ёмнай паласы і тое, ці адказваем мы таксама за ўстаноўку рэек. Акрамя таго, на графік могуць паўплываць знешнія фактары, такія як умовы надвор'я. Мы распрацуем практычны і добра арганізаваны план усталёўкі ў залежнасці ад канкрэтнай сітуацыі, каб забяспечыць эфектыўны, бяспечны і арганізаваны працэс усталёўкі.

Кантроль якасці ўстаноўкі

Пасля завяршэння ўстаноўкі маставога крана мы правядзем комплексную праверку ўсіх ключавых кампанентаў, каб пераканацца, што абсталяванне адпавядае стандартам бяспечнай, стабільнай і надзейнай працы. Праверка ахоплівае наступныя аспекты:

- Якасць зборкі злучэнняў металічнай канструкцыі крана

- Якасць мантажу тралейбусных рэек, сабраных на месцы

- Якасць мантажу механізмаў перамяшчэння каляскі і моста, сабраных на месцы

- Усталёўка і функцыянальнасць прылад бяспекі

Выпрабаванне маставых кранаў

Каб пераканацца ў надзейнай працы і адпаведнасці стандартам бяспекі маставога крана перад яго ўводам у эксплуатацыю, пасля паспяховай устаноўкі праводзіцца серыя выпрабаванняў:

- Выпрабаванне: пераканайцеся, што кірунак кіравання кожным прывадным механізмам адпавядае фактычнаму кірунку руху. Кожны рухавік правяраецца асобна, каб забяспечыць нармальную працу, прычым тармазы, канцавыя выключальнікі і прылады бяспекі працуюць дакладна і надзейна. Калі крук апускаецца ў самае ніжняе становішча, на барабане павінна заставацца не менш за два поўныя віткі троса. Прылады абароны ад сутыкнення, буферы і падобныя сістэмы павінны працаваць правільна.

- Выпрабаванне на статычную нагрузку: Гэта выпрабаванне правярае ўстойлівасць і грузападымальнасць крана. Кран падымае груз, які ў 1,25 раза перавышае намінальны, пры гэтым груз падвешваецца на вышыні 100–200 мм над зямлёй на працягу 10 хвілін. Пасля зняцця нагрузкі канструкцыя моста правяраецца на наяўнасць рэшткавай дэфармацыі.

- Выпрабаванне на дынамічную нагрузку: Гэта выпрабаванне ацэньвае працу ўсіх механізмаў і тармазных сістэм. Кран падымае груз, які ў 1,1 раза перавышае намінальны, і пасля выпрабавання ўсе кампаненты не павінны мець расколін або пашкоджанняў, а ўсе злучэнні павінны заставацца надзейнымі, каб кран лічыўся прыдатным для эксплуатацыі.

Каардынацыя мае значэнне

Каб забяспечыць бесперабойны ход мантажу крана, кліенту прапануецца загадзя выканаць фундаментныя работы ў адпаведнасці з чарцяжамі, пераканаўшыся, што ключавыя канструкцыі, такія як размяшчэнне рэек, адпавядаюць тэхнічным патрабаванням.

Кошт нашай паслугі па ўсталёўцы на месцы складае 1200 юаняў за інжынера ў дзень. Кліент нясе адказнасць за авіябілет і назад, візу, пражыванне і харчаванне інжынераў.

Калі ласка, загадзя ўзгадніце ўмовы на месцы і падрыхтуйце неабходныя рэсурсы, у тым ліку пад'ёмнае абсталяванне, электразабеспячэнне, інструменты і персанал, каб забяспечыць эфектыўны і арганізаваны працэс усталёўкі.

Устаноўка маставога крана кліентам

Для кліентаў, якія маюць магчымасць самастойна ўсталёўваць абсталяванне, мы можам па запыце прадаставіць тэхнічную дакументацыю, у тым ліку інструкцыю па ўсталёўцы, электрычныя схемы, чарцяжы маставых кранаў і спіс неабходных інструментаў для ўстаноўкі. Для вырашэння любых тэхнічных праблем, якія ўзніклі падчас усталёўкі, даступныя дыстанцыйныя відэаінструкцыі або анлайн-падтрымка.

- Кіраўніцтва па ўсталёўцы: У гэтым кіраўніцтве падрабязна апісаны кожны этап працэсу ўстаноўкі маставога крана, у тым ліку падрыхтоўка і меры засцярогі перад усталёўкай, падключэнне галоўнай і канцавых бэлек, карэкціроўка выраўноўвання пасля зборкі канцавой бэлькі, месцы і метады ўстаноўкі электрычнага блока кіравання, канцавых выключальнікаў і сістэм кабельных гірлянд, а таксама патрабаванні да ўстаноўкі буфера ў канцы падкрановага шляху. Падрабязны змест прапануе зразумелыя і практычныя рэкамендацыі для персаналу па ўсталёўцы, эфектыўна мінімізуючы памылкі пры ўсталёўцы.

- Падключэнне правадоў: Для крана, пад'ёмніка або каляскі прадстаўлены схемы электрычных блокаў кіравання, а таксама падрабязныя інструкцыі па падключэнні. У кіраўніцтве таксама тлумачацца метады падключэння прылад бяспекі, такіх як канцавыя выключальнікі ходу, абмежавальнікі перагрузкі і абмежавальнікі процівагі, што забяспечвае бяспечны і стандартызаваны працэс усталёўкі.

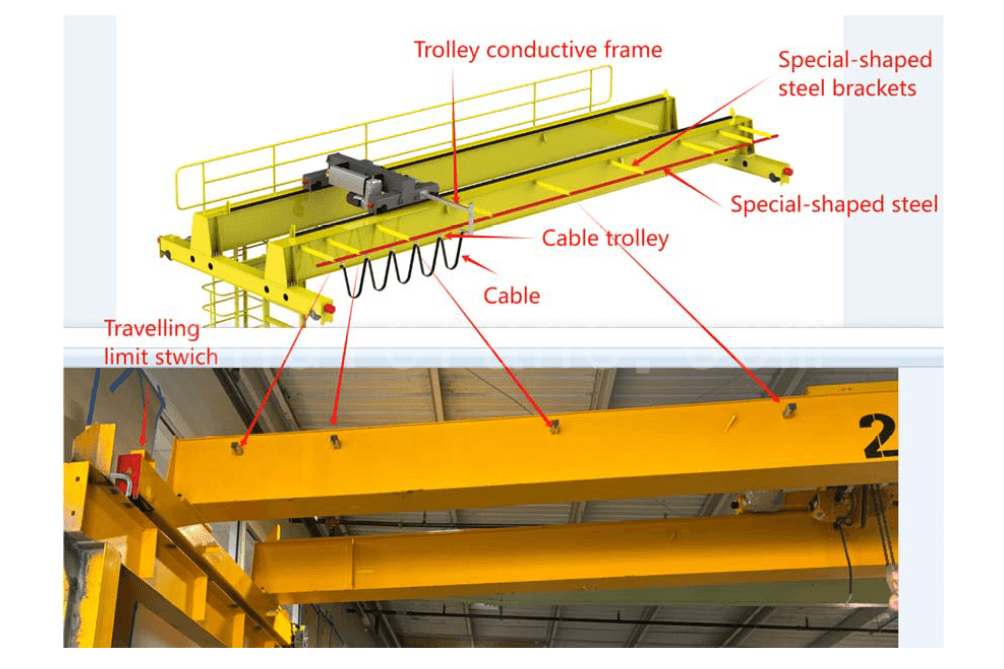

- Чарцёж маставога крана: На чарцяжы агульнай зборкі паказана структурная схема крана і асноўныя памерныя параметры, у тым ліку контур абсталявання, максімальна дапушчальная адлегласць паміж цэнтрам крука і цэнтрам кранавай рэйкі, агульная шырыня крана, каляіна і максімальная нагрузка на кола. Гэты чарцёж дапамагае карыстальнікам зразумець агульную логіку ўстаноўкі і дапамагае мантажнікам дакладна вызначыць месцазнаходжанне галоўнай бэлькі, канцавых бэлек, праходу, кабельнай каляскі і іншых кампанентаў, што спрашчае папярэдняе планаванне працоўнай прасторы пляцоўкі і паслядоўнасці ўстаноўкі.

- Спіс неабходных інструментаў для ўстаноўкі: У спісе інструментаў указаны як стандартныя, так і спецыяльныя інструменты, неабходныя для поўнай устаноўкі крана, у тым ліку гаечныя ключы, дамкраты, ручныя ланцуговыя талі, цягавыя тросы, аўтапагрузчыкі, мабільныя краны і многае іншае. Гэты спіс дапамагае кліентам належным чынам падрыхтавацца перад устаноўкай, каб пазбегнуць перапынкаў у працы або пераробкі з-за адсутнасці інструментаў на будаўнічай пляцоўцы.

Справа аб абслугоўванні ўстаноўкі маставога крана Dafang Crane

Устаноўка двухбалкавага маставога крана 30/5T

Мы паставілі кліенту двухбалкавы маставы кран грузападымальнасцю 30/5 тон з пралётам 25 метраў. У адпаведнасці з патрабаваннямі кліента, мы накіравалі на аб'ект вопытных інжынераў для ўдзелу ў мантажы. Цесна супрацоўнічаючы з мясцовымі рабочымі, яны выканалі ўвесь працэс ад механічнай зборкі і электрычнай праводкі да поўнага ўводу абсталявання ў эксплуатацыю, забяспечыўшы бесперабойны ўвод абсталявання ў эксплуатацыю ў майстэрні кліента.

Працэс усталёўкі на месцы

На ранняй стадыі праекта нашы інжынеры кіруюць і дапамагаюць у зборцы галоўнай бэлькі, канцавых бэлек, кабіны аператара, каляскі і іншых механічных кампанентаў, грунтуючыся на прадастаўленых чарцяжах і ўмовах будаўнічай пляцоўкі. Усе злучэнні і мантажныя аперацыі былі выкананы ў адпаведнасці са стандартамі, каб забяспечыць трываласць канструкцыі і бесперабойную працу.

Пасля завяршэння мантажу канструкцыі інжынеры сумесна з электрыкамі на месцы выканалі электрычную праводку і падключэнні, у тым ліку асноўную крыніцу харчавання, шафу кіравання, канцавыя выключальнікі і сігнальныя кабелі, забяспечыўшы належную праводку і разумную планіроўку.

Увод у эксплуатацыю электраабсталявання і інтэграцыя праграм

Адным з найбольш адказных этапаў праекта была ўвод у эксплуатацыю электрычнай сістэмы крана. Пасля завяршэння праводкі на месцы нашы інжынеры ўнеслі карэктывы ў сістэму кіравання кранам у адпаведнасці з патрабаваннямі заказчыка, што дазволіла ёй інтэгравацца з існуючай аперацыйнай логікай пад'ёмна-транспартнага абсталявання ў майстэрні.

Падчас пусканаладачных работ мы супрацоўнічалі са звязанымі пастаўшчыкамі для вырашэння ўзніклых тэхнічных праблем. Па просьбе заказчыка мы паспяхова інтэгравалі праграму кіравання пад'ёмна-транспартным абсталяваннем у сістэму крана, забяспечыўшы скаардынаваную працу і належную рэакцыю кіравання ўсяго абсталявання.

Завяршэнне праекта

Пасля некалькіх этапаў пусканаладачных работ і выпрабавальнай эксплуатацыі ўсе функцыі маставога крана працавалі нармальна і стабільна, цалкам задавальняючы патрэбы кліента ў перавозках і тэхніцы. Пасля завяршэння праекта кліент высока ацаніў наша абслугоўванне на месцы і асабліва высока ацаніў наша прафесійнае супрацоўніцтва падчас мантажу і нашы тэхнічныя магчымасці падчас пусканаладачных работ.

Кіраўніцтва па ўсталёўцы 2-тоннага двухбалкавага маставога крана

Мы паставілі кліенту двухтонны двухбалкавы маставы кран з пралётам 10,5 метраў. Згодна з дамоўленасцю з кліентам, нашы інжынеры не наведвалі аб'ект, а дапамагалі ў мантажы дыстанцыйна. З этапу падрыхтоўкі мы падтрымлівалі цесную сувязь з кліентам і прадастаўлялі падрабязныя інструкцыі па мантажы на кітайскай і англійскай мовах. Матэрыялы ўключалі фатаграфіі і пісьмовыя інструкцыі, каб палегчыць кліенту разуменне і эксплуатацыю. На працягу ўсяго працэсу ўстаноўкі мы прапаноўвалі кругласутачную дыстанцыйную тэхнічную падтрымку, аператыўна адказваючы на кожнае пытанне кліента і актыўна супрацоўнічаючы для забеспячэння бесперабойнага завяршэння ўстаноўкі.

Падрыхтоўка праекта

Перад адгрузкай мы абмеркавалі з кліентам яго патрабаванні да ўстаноўкі і даведаліся, што ён аддае перавагу самастойна арганізаваць устаноўку на месцы. Таму пры дастаўцы мы падрыхтавалі інструкцыі па ўсталёўцы, электрычныя схемы, чарцяжы агульнага размяшчэння і спіс неабходных інструментаў, каб дапамагчы кліенту выканаць устаноўку ў адпаведнасці з чарцяжамі і дакументацыяй.

Аддаленая падтрымка падчас усталёўкі

На працягу ўсёй устаноўкі нашы інжынеры падтрымлівалі анлайн-кантакт з кліентам, своечасова адказваючы на ўсе тэхнічныя пытанні. Напрыклад, калі кліент сутыкаўся з незнаёмымі дэталямі падключэння, этыкеткамі правадоў або нумарамі абсталявання, ён дасылаў нам фатаграфіі або паведамленні, а нашы інжынеры адказвалі тлумачэннямі, спасылаючыся на чарцяжы або пісьмовыя інструкцыі.

Мы абавязаліся рэагаваць кругласутачна ў працоўныя дні і падчас ключавых этапаў усталёўкі, каб гарантаваць аператыўныя адказы на пытанні кліентаў. Нягледзячы на розніцу ў часе, наша каманда арганізавала зменную працу, каб падтрымліваць бесперабойную сувязь і своечасовую падтрымку.

Вынік праекта

Абсталяванне было паспяхова ўсталявана, і кліент паведаміў, што ўвесь працэс усталёўкі быў зразумелым і кіраваным, інструкцыі былі практычнымі, а дыстанцыйная сувязь праходзіла бесперабойна. Нягледзячы на тое, што мы фізічна не знаходзіліся на месцы, падрыхтаваўшы вычарпальную тэхнічную дакументацыю і забяспечыўшы пастаянную дыстанцыйную падтрымку, мы дапамаглі кліенту паспяхова завяршыць усталёўку.

Выберыце кран Dafang для надзейнай устаноўкі маставых кранаў

Кампанія Dafang Crane атрымала шырокае прызнанне за сваю комплексную і арыентаваную на кліента сістэму абслугоўвання па ўсталёўцы маставых кранаў. Мы прапануем прафесійныя паслугі па ўсталёўцы на месцы ад вопытных інжынераў, што забяспечвае бяспечную, дакладную і своечасовую ўстаноўку абсталявання. Для кліентаў, якія вырашылі ўсталяваць абсталяванне самастойна, мы прадастаўляем падрабязную тэхнічную дакументацыю і дыстанцыйнае кіраўніцтва, каб дапамагчы ў бесперабойнай зборцы і ўводзе ў эксплуатацыю. Наша інжынерная каманда прытрымліваецца строгіх галіновых стандартаў і гнутка адаптуецца да розных умоў на месцы, дапамагаючы кліентам скараціць час прастою і пазбегнуць памылак пры ўсталёўцы. Незалежна ад таго, ці гэта руцінныя задачы па ўсталёўцы, ці складаная інтэграцыя сістэм, Dafang забяспечвае эфектыўныя і надзейныя вынікі ўстаноўкі.

Адпраўце свой запыт

- электронная пошта: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Тэлеграма: +86 191 3738 6654

- Тэл.: +86-373-581 8299

- Факс: +86-373-215 7000

- Дадаць: прамысловы раён Чаннао, горад Сіньсян, правінцыя Хэнань, Кітай

WeChat

WeChat