फ़िलीपींस ओवरहेड क्रेन ख़रीदने की गाइड 2025: हर ख़रीदार को क्या पता होना चाहिए

विषयसूची

बुनियादी ढाँचे, रसद और भारी उद्योग क्षेत्र में वृद्धि के कारण, फिलीपींस में ओवरहेड क्रेन समाधानों की माँग बढ़ रही है। हालाँकि, फिलीपींस में ओवरहेड क्रेन से संबंधित अधिकांश ऑनलाइन सामग्री या तो पुरानी है, अत्यधिक सामान्य है, या स्थानीय प्रासंगिकता का अभाव है।

यह मार्गदर्शिका खरीदारों को फिलीपींस ओवरहेड क्रेन बाजार में नेविगेट करने में मदद करती है - चाहे आप आपूर्तिकर्ता की तलाश कर रहे हों, चीन से आयात कर रहे हों, या स्थानीय समर्थन की तलाश कर रहे हों।

संयुक्त राष्ट्र कॉमट्रेड के आंकड़ों के अनुसार 2023 में फिलीपींस में ट्रांसपोर्टर या ब्रिज क्रेन का आयात देशवार2014-15 में, फिलीपींस ने चीन से 24,533,160 अमेरिकी डॉलर मूल्य के ओवरहेड क्रेन आयात किए, जो सभी स्रोत देशों में अब तक का सबसे अधिक है।

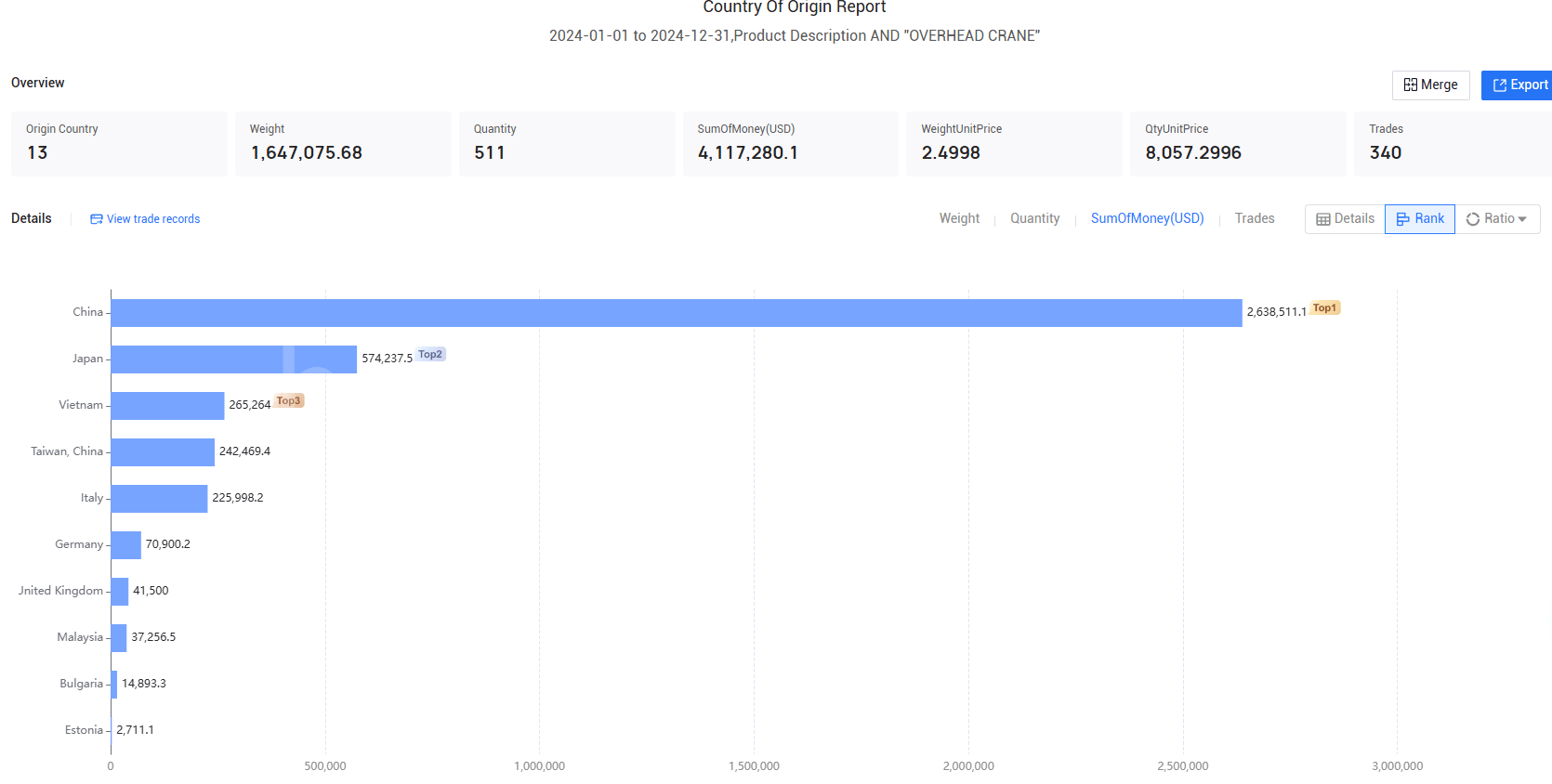

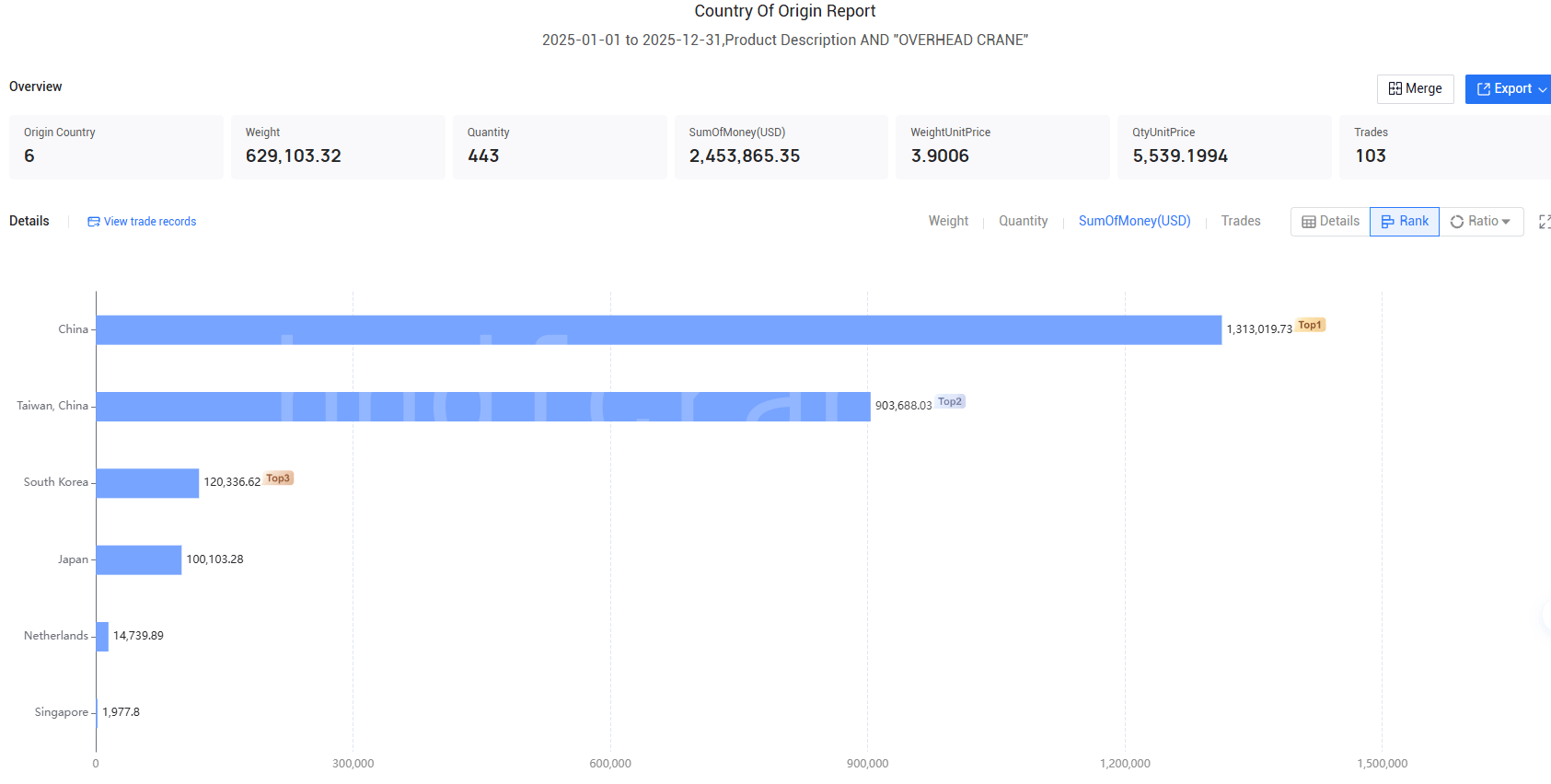

जबकि आधिकारिक वैश्विक व्यापार डेटाबेस ने अभी तक 2024 और 2025 के लिए पूरे वर्ष के आंकड़े प्रकाशित नहीं किए हैं, हमारी आंतरिक सीमा शुल्क ट्रैकिंग से पता चलता है कि चीन से आयात 2024 में 2,638,511.10 अमरीकी डॉलर और 2025 के पहले आठ महीनों में 1,313,019.73 अमरीकी डॉलर तक पहुंच गया।

ये स्थिर आँकड़े चीनी ओवरहेड क्रेन आपूर्तिकर्ताओं पर मज़बूत और निरंतर निर्भरता को दर्शाते हैं। लगातार तीन वर्षों से, चीन फिलीपींस को ओवरहेड क्रेन का शीर्ष निर्यातक बना हुआ है, और अन्य देशों से काफ़ी बेहतर प्रदर्शन कर रहा है।

फिलीपींस में प्रमुख उद्योगों में ओवरहेड क्रेन का अनुप्रयोग

हालाँकि ओवरहेड क्रेन का वैश्विक उद्योगों में व्यापक रूप से उपयोग किया जाता है, फ़िलीपींस के ओवरहेड क्रेन बाज़ार के कुछ क्षेत्रों में इनकी माँग विशेष रूप से मज़बूत और बढ़ती हुई है। इन वास्तविक अनुप्रयोगों को समझने से खरीदारों को अधिक उपयुक्त क्रेन विन्यास चुनने, अधिक खर्च से बचने और परिचालन दक्षता में सुधार करने में मदद मिलती है।

सही क्रेन चुनना सिर्फ़ उठाने की क्षमता से नहीं, बल्कि उसके संचालन संबंधी उपयुक्तता से भी जुड़ा है। फिलीपींस में ओवरहेड क्रेन के संदर्भ में, जलवायु, जगह की कमी और स्थानीय ऊर्जा की स्थिति जैसे कारक क्रेन के प्रदर्शन को बहुत प्रभावित करते हैं। उद्योग की ज़रूरतों के साथ क्रेन के विनिर्देशों का मिलान जोखिम को कम करता है, सुरक्षा में सुधार करता है और जीवनकाल की लागत को कम करता है।

फिलीपीन स्टील और धातु उद्योग में ओवरहेड क्रेन अनुप्रयोग

हालाँकि फ़िलीपींस अभी भी अपना अधिकांश स्टील आयात करता है, लेकिन स्थानीय उत्पादन तेज़ी से बढ़ रहा है। स्टीलएशिया अकेले देश भर में कई मिलों का संचालन करती है। इसमें बटांगास, कॉम्पोस्टेला वर्क्स, सेबू और दावाओ शामिल हैं—और कई अन्य मिलों का विकास कार्य चल रहा है। इसका एक प्रमुख उदाहरण है बटांगास में लेमेरी वर्क्स परियोजनाजो हॉट-रोल्ड स्टील सेक्शन का उत्पादन करने वाला पहला स्थानीय संयंत्र होगा, जिसकी नियोजित क्षमता 500,000 मीट्रिक टन वार्षिक होगी, जिसे 1 मिलियन टन तक बढ़ाया जा सकेगा।

विद्युत चुम्बकीय ओवरहेड क्रेन गर्म स्टील बिलेट को स्थानांतरित करने के लिए उपयोग किया जाता है

गर्म रोलिंग के बाद, लाल-गर्म बिलेट्स को तुरंत शीतलन क्षेत्रों में स्थानांतरित किया जाना चाहिए।

क्रेनों को 800°C से अधिक तापमान वाली बिलेट लाइनों के पास सुरक्षित रूप से संचालित किया जाना चाहिए। इसके लिए विशेष ताप-प्रतिरोधी केबल और नियंत्रण पैनल की आवश्यकता होती है।

ओवरहेड क्रेन पकड़ो स्टील सामग्री हथियाने के लिए प्रयोग किया जाता है

स्क्रैप हैंडलिंग या रीबार छंटाई वाले क्षेत्रों में अक्सर दक्षता और सुरक्षा बढ़ाने के लिए ग्रैब ओवरहेड क्रेन का उपयोग किया जाता है।

फिलीपीन खनन उद्योग में ओवरहेड क्रेन अनुप्रयोग

फिलीपींस निकल, तांबा और सोने का एक प्रमुख उत्पादक है, और पलावन, मिंडानाओ और ज़म्बालेस में सक्रिय खनन गतिविधियाँ हैं। साथ ही, कोयला, जलविद्युत और नवीकरणीय ऊर्जा संयंत्रों को उपकरणों के रखरखाव, स्थापना और पुर्जों के प्रतिस्थापन के लिए भारी-भरकम उठाने वाले उपकरणों की आवश्यकता होती है।

सिंगल गर्डर ओवरहेड क्रेन खदान कार्यशाला उपकरण रखरखाव के लिए उपयोग किया जाता है

खदान रखरखाव दुकान में नियमित उपकरण रखरखाव और स्पेयर पार्ट्स प्रतिस्थापन के लिए।

धमाका प्रूफ ओवरहेड क्रेन खनन सामग्री के हस्तांतरण के लिए उपयोग किया जाता है

खनन सामग्री को बंद प्रसंस्करण कार्यशालाओं में स्थानांतरित करना

धूल-प्रूफ, नमी-प्रूफ और विस्फोट-प्रूफ, विशेष रूप से खनन क्षेत्रों में, हवा में धूल मोटर पर बहुत प्रभाव डालती है।

फिलीपीन विद्युत अवसंरचना उद्योग में ओवरहेड क्रेन अनुप्रयोग

फिलीपींस में बिजली की खपत सालाना लगभग 4-5% की दर से बढ़ रही है, खासकर लूजोन और विसाय में। औद्योगीकरण और शहरीकरण के साथ, ऊर्जा अवसंरचना का विस्तार हो रहा है। इसमें जलविद्युत और ताप विद्युत संयंत्रों का रखरखाव और विस्तार; सौर और पवन ऊर्जा जैसी स्वच्छ ऊर्जा परियोजनाओं का उदय (जैसे, इलोकोस नॉर्टे में पवन फार्म); और उन सबस्टेशनों और ट्रांसमिशन लाइनों का निर्माण और नवीनीकरण शामिल है जिनमें ट्रांसफार्मर जैसे भारी पुर्जों को उठाने के लिए क्रेन की आवश्यकता होती है। फिलीपींस जैसे द्वीपसमूह देशों में, जहाँ कई बिजलीघर जटिल भूभाग और सघन क्षेत्रों में स्थित हैं, कुशल और सुरक्षित उठाने के कार्यों के लिए ब्रिज क्रेन जैसे उपकरणों पर अधिक निर्भरता है।

डबल गर्डर ओवरहेड क्रेन जेनरेटो उठाने के लिए उपयोग किया जाता है

कार्यशाला रखरखाव, जेनरेटो या ट्रांसफार्मर कोर को उठाना और रखरखाव करना।

फिलीपींस के कुछ भागों में बिजली आपूर्ति अस्थिर है, और वहां आवृत्ति रूपांतरण नियंत्रण प्रणाली की आवश्यकता है।

अंडरहंग ओवरहेड क्रेन पावर स्टेशन उपकरणों के ओवरहाल के लिए उपयोग किया जाता है

जब किसी सबस्टेशन में स्विचगियर, इंसुलेटर, बसबार सिस्टम, डिस्कनेक्टिंग नाइफ गेट और अन्य उपकरणों की नियमित रूप से ओवरहालिंग की जाती है, तो भागों को जमीन पर या कार्य प्लेटफॉर्म पर उठाने के लिए अंडरहंग ओवरहेड क्रेन का उपयोग किया जाता है।

सीमित स्थान, उच्च परिचालन परिशुद्धता और क्रेन की स्थिति और सुरक्षा संरक्षण के लिए सख्त आवश्यकताएं।

पोर्ट्स वेयरहाउसिंग और फ्रीपोर्ट ज़ोन में ओवरहेड क्रेन फिलीपींस

7,000 से ज़्यादा द्वीपों वाला फ़िलीपींस समुद्री रसद पर काफ़ी हद तक निर्भर है, जिससे बंदरगाह और गोदाम केंद्र उसकी अर्थव्यवस्था के लिए बेहद अहम हो जाते हैं। मनीला नॉर्थ हार्बर, सेबू पोर्ट, सुबिक फ़्रीपोर्ट और दावाओ पोर्ट जैसे प्रमुख बंदरगाह बड़ी मात्रा में आयातित निर्माण सामग्री, इस्पात उत्पाद, मशीनरी और उपकरणों का संचालन करते हैं। ओवरहेड क्रेन का इस्तेमाल अक्सर जहाज़ से किनारे तक के काम के लिए नहीं, बल्कि भंडारण डिपो और बॉन्डेड गोदामों में किया जाता है, जहाँ ओवरहेड क्रेन मोबाइल या गैन्ट्री क्रेन की तुलना में ज़्यादा सटीक और सुरक्षित सामग्री प्रबंधन प्रदान करते हैं।

यूरोपीय प्रकार ओवरहेड क्रेन बंदरगाह माल के हस्तांतरण के लिए प्रयोग किया जाता है

ढके हुए गोदामों में कंटेनरों से ट्रेलरों तक माल का स्थानांतरण।

बंदरगाह के ग्राहक अक्सर आसान रखरखाव के लिए यूरोपीय शैली के कॉम्पैक्ट होइस्ट को पसंद करते हैं।

समुद्र तट के निकट उपयोग किए जाने वाले ओवरहेड क्रेनों को जंगरोधी उपचार और समुद्री-ग्रेड कोटिंग की आवश्यकता होती है।

कम हेडरूम ओवरहेड क्रेन कम निकासी वाले गोदाम के लिए उपयोग किया जाता है

कम छत ऊंचाई वाले गोदामों में कम हेडरूम ओवरहेड क्रेन की आवश्यकता होती है।

कारखाने की इमारत की ऊंचाई अक्सर 8 मीटर से कम होती है, और उपकरण का चयन कम हेडरूम डिजाइन के अनुरूप होना चाहिए।

फिलीपींस में शीर्ष 10 ओवरहेड क्रेन निर्माता

फिलीपींस के विभिन्न उद्योगों में फिलीपींस ओवरहेड क्रेन की मांग लगातार बढ़ रही है, इसलिए सही ओवरहेड क्रेन आपूर्तिकर्ता की पहचान करना खरीद प्रक्रिया का एक महत्वपूर्ण पहलू बन गया है। चाहे आप किसी स्थानीय वितरक के साथ काम कर रहे हों या सीधे चीन से आयात कर रहे हों, खरीदार अपनी फिलीपींस ओवरहेड क्रेन की ज़रूरतों के लिए तेज़ सहायता और बेहतर मूल्य सुनिश्चित करने के लिए "मेरे आस-पास ओवरहेड क्रेन निर्माता" की खोज में तेज़ी से बढ़ रहे हैं।

2023 से 2025 तक फिलीपींस के सीमा शुल्क आयात आंकड़ों की हमारी समीक्षा, गूगल सर्च ट्रेंड्स और हालिया परियोजना गतिविधियों के संयोजन के आधार पर, हमने फिलीपींस के बाजार में सक्रिय रूप से आपूर्ति करने वाले 10 शीर्ष ओवरहेड क्रेन निर्माताओं की पहचान की है। ये कंपनियां विविध क्रेन कॉन्फ़िगरेशन, प्रतिस्पर्धी मूल्य निर्धारण और बिक्री के बाद सहायता प्रदान करती हैं—कुछ के पास सिद्ध डिलीवरी रिकॉर्ड या पहले से मौजूद स्थानीय सेवा साझेदार हैं।

(निम्नलिखित सूची को क्रम में रैंक नहीं किया गया है, और चयन वास्तविक निर्यात रिकॉर्ड, ऑनलाइन उपस्थिति और इस्पात, जहाज निर्माण, बंदरगाहों और भंडारण जैसे प्रमुख उद्योगों में परियोजना भागीदारी पर आधारित है।)

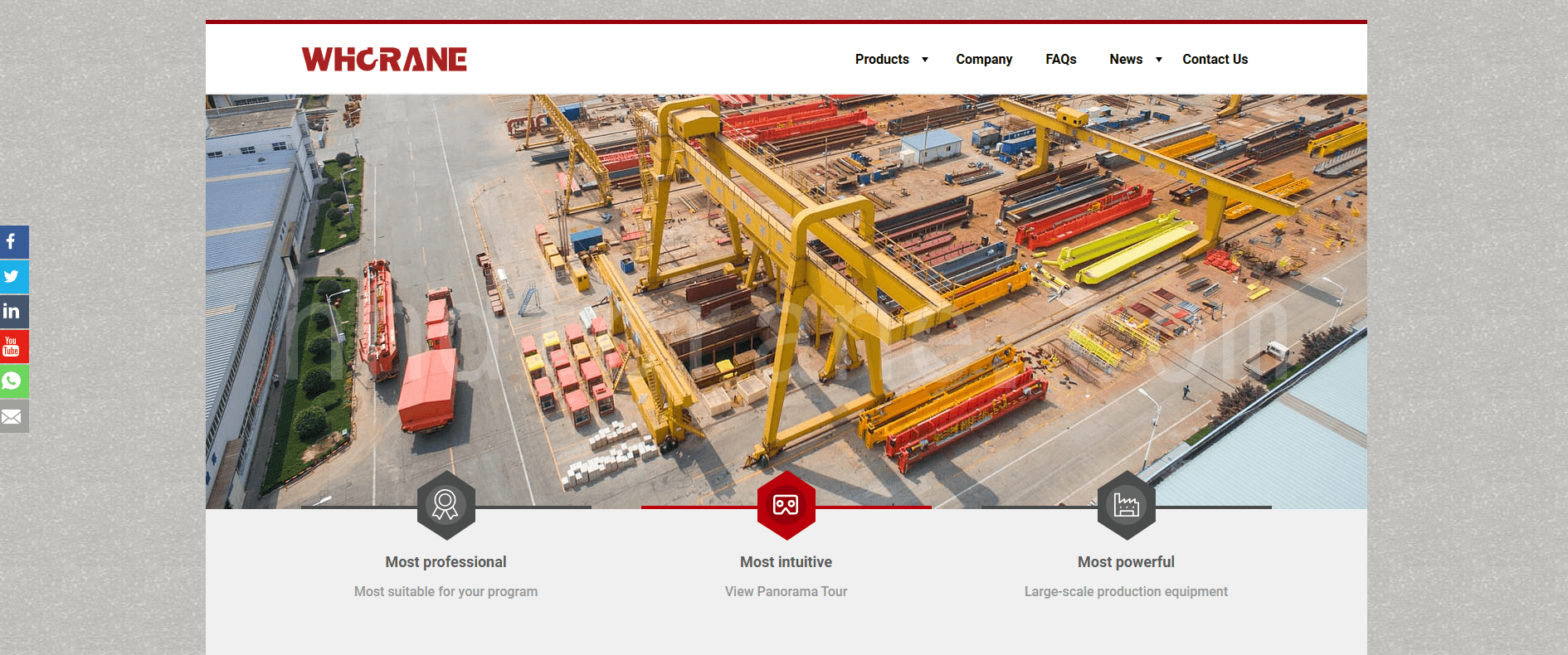

डब्ल्यूएचक्रेन

✅ आईएसओ और सीई प्रमाणित

✅ दक्षिण पूर्व एशिया परियोजना का अनुभव

✅ पूर्ण उत्पाद रेंज

वेइहुआ चीन के सबसे बड़े ब्रिज क्रेन निर्माताओं में से एक है, जिसके पास 35 वर्षों से भी अधिक का अनुभव और वैश्विक पहुँच है। अपनी टिकाऊ संरचना, स्मार्ट नियंत्रण प्रणालियों और विस्तृत क्षमता रेंज (800 टन तक) के लिए प्रसिद्ध, वेइहुआ क्रेन का व्यापक रूप से इस्पात, रसद और निर्माण उद्योगों में उपयोग किया जाता है।

फिलीपीन बाजार में, WEIHUA को इसके अनुकूलन योग्य डिजाइन, संक्षारण-रोधी उपचार और तेज लीड टाइम के लिए पसंद किया जाता है - जो इसे तटीय बंदरगाहों, भारी कार्यशालाओं और औद्योगिक क्षेत्रों के लिए एक मजबूत विकल्प बनाता है।

योंगली

✅ पूर्ण-सेवा क्षमता वाला स्थानीय आपूर्तिकर्ता

✅ तेज़ बदलाव और कम सेवा लागत

✅ फिलीपींस में सिद्ध परियोजना रिकॉर्ड

योंगली फिलीपींस स्थित एक ओवरहेड क्रेन आपूर्तिकर्ता है जो डिज़ाइन और आपूर्ति से लेकर स्थापना और रखरखाव तक, संपूर्ण सेवा समाधान प्रदान करता है। 2015 में स्थापित और बटांगस में मुख्यालय वाली इस कंपनी ने औद्योगिक क्षेत्रों में 50 से ज़्यादा क्रेन परियोजनाएँ पूरी की हैं।

इसकी स्थानीय उपस्थिति आयातित प्रणालियों की तुलना में तेज़ डिलीवरी, त्वरित समर्थन और कम रखरखाव लागत की अनुमति देती है। YONGLI कस्टम डिज़ाइन, ऑपरेटर प्रशिक्षण और सुरक्षा-मानक परीक्षण के साथ सिंगल/डबल गर्डर क्रेन प्रदान करता है।

दफांग क्रेन

✅ पूर्ण क्रेन लाइसेंस प्रणाली

✅ मजबूत निर्माण आधार

✅ बड़ी परियोजनाओं के लिए प्रतिस्पर्धी मूल्य निर्धारण

दफांग क्रेन, जिसे आधिकारिक तौर पर हेनान दफांग हेवी मशीनरी कंपनी लिमिटेड के रूप में जाना जाता है, चीन की एक अग्रणी ओवरहेड क्रेन निर्माता है, जो अपने इन-हाउस उत्पादन शक्ति और सख्त गुणवत्ता नियंत्रण के लिए जानी जाती है।

सभी प्रकार के क्रेन के लिए प्रमाणित लाइसेंस और सटीक विनिर्माण उपकरणों की एक विस्तृत श्रृंखला के साथ, DAFANG लागत प्रभावी ओवरहेड क्रेन प्रदान करता है जो विनिर्माण, रसद और बुनियादी ढांचा परियोजनाओं की मांगों को पूरा करता है।

फिलीपींस जैसे विदेशी बाजारों में, DAFANG को एक विश्वसनीय ओवरहेड क्रेन आपूर्तिकर्ता के रूप में मान्यता प्राप्त है, जो तेजी से डिलीवरी समय, पूर्ण क्षमता वाली कार्यशालाएं और विश्वसनीय वेल्डिंग और परीक्षण मानकों की पेशकश करता है।

कुआंगशान क्रेन

✅ क्षेत्र-केंद्रित समाधान (इस्पात, ऊर्जा, बंदरगाह)

✅ 20 वर्षों से अधिक की विशेषज्ञता

✅ मजबूत निर्यात ट्रैक रिकॉर्ड

केएस क्रेन एक अग्रणी चीनी ईओटी क्रेन निर्माता है, जो इस्पात, बिजली और रसद क्षेत्रों में अपनी मज़बूत उपस्थिति के लिए जानी जाती है। 2002 में स्थापित, इस कंपनी ने उद्योग-विशिष्ट क्रेन डिज़ाइन और सख्त गुणवत्ता मानकों के लिए एक प्रतिष्ठा अर्जित की है।

इसके ओवरहेड क्रेन को अंतर्राष्ट्रीय प्रमाणनों को पूरा करने या उससे बेहतर करने के लिए डिज़ाइन किया गया है, और कंपनी उन्नत वेल्डिंग और स्वचालन प्रणालियों के साथ आधुनिक उत्पादन सुविधाएं संचालित करती है।

फिलीपींस जैसे बाजारों के लिए, केएस क्रेन भारी-भरकम, उच्च-तापमान और उच्च-धूल वाले वातावरण में मजबूत प्रदर्शन के साथ अनुकूलित लिफ्टिंग समाधान प्रदान करता है।

न्यूक्लिऑन

✅ AI स्मार्ट नियंत्रण (स्विंग कोण <2%)

✅ सटीक उठाने और नौका हैंडलिंग अनुप्रयोगों में मजबूत

न्यूक्लिऑन क्रेन एक चीनी ओवरहेड क्रेन निर्माता है जो उन्नत नियंत्रण प्रणालियों और मॉड्यूलर डिज़ाइन के साथ उच्च-प्रदर्शन लिफ्टिंग समाधानों में विशेषज्ञता रखता है—जिसमें शीर्ष-स्तरीय फ़िलीपींस ओवरहेड क्रेन भी शामिल हैं। यूरोपीय शैली की क्रेन तकनीक में एक प्रवर्तक के रूप में मान्यता प्राप्त, न्यूक्लिऑन उत्पाद विशेष रूप से इस्पात प्रसंस्करण, जहाज निर्माण और सटीक विनिर्माण जैसे उद्योगों के लिए उपयुक्त हैं, और फ़िलीपींस ओवरहेड क्रेन अपनी विश्वसनीयता के लिए विशिष्ट हैं।

इसके ओवरहेड क्रेन, जिनमें विश्वसनीय फिलीपींस ओवरहेड क्रेन भी शामिल हैं, को फिलीपींस के बाजार में उनकी ऊर्जा दक्षता, स्मार्ट एंटी-स्वे एल्गोरिदम और स्वच्छ या उच्च परिशुद्धता वाले वातावरण के लिए अनुकूलनशीलता के लिए पसंद किया जाता है।

इसके डबल-गर्डर ओवरहेड क्रेन—फिलीपींस के ओवरहेड क्रेनों में प्रमुख—फिलीपींस के भारी औद्योगिक बाज़ार में लोकप्रिय हैं, जो एआई-आधारित एंटी-स्वे तकनीक प्रदान करते हैं जो लोड स्विंग को 95% तक कम कर देती है। मॉड्यूलर संरचनाएँ इन फिलीपींस ओवरहेड क्रेनों को विभिन्न कार्य वातावरणों में लचीले विन्यास की अनुमति देती हैं।

विनालिफ्ट

✅ कस्टम-निर्मित क्रेन प्रणालियों में मजबूत

✅ बंदरगाहों, इस्पात संयंत्रों और भारी उद्योगों में सक्रिय

✅ पूर्ण परियोजना जीवनचक्र सेवाओं के साथ विश्वसनीय क्षेत्रीय भागीदार

VINALIFT वियतनाम में कस्टमाइज़्ड ओवरहेड क्रेन और गैर-मानक स्टील संरचनाओं के अग्रणी निर्माताओं में से एक है। 2006 में स्थापित, यह कंपनी क्षेत्रीय स्तर पर अपनी मज़बूत उपस्थिति के साथ उत्पादों की एक विस्तृत श्रृंखला प्रदान करती है।

VINALIFT निर्माण, जहाज निर्माण, कोयला खनन और बिजली उत्पादन में अपने अनुकूलित समाधानों और मज़बूत परियोजना निष्पादन रिकॉर्ड के लिए जाना जाता है। फिलीपींस और आसपास के क्षेत्रों के ग्राहकों के लिए, यह निकटता, तेज़ प्रतिक्रिया समय और पूर्ण-सेवा सहायता प्रदान करता है—जिसमें डिज़ाइन परामर्श, परिवहन, स्थापना और ऑपरेटर प्रशिक्षण शामिल है।

किनहुआंगदाओ तियानये टोलियन हेवी इंडस्ट्री एंड टेक्नोलॉजी कंपनी लिमिटेड

✅ खंड उठाने और पुल निर्माण क्रेन में विशेषज्ञता

✅ उच्च-भार, कस्टम-निर्मित ओवरहेड क्रेन सिस्टम

✅ परिवहन और सुरंग निर्माण मेगा परियोजनाओं में सिद्ध प्रदर्शन

तियानये टोलियान, एक चीनी निर्माता, भारी-भरकम ओवरहेड क्रेन और पुल निर्माण लिफ्टिंग प्रणालियों में एक मान्यता प्राप्त अग्रणी कंपनी है, जो पूरे एशिया में बड़े पैमाने पर बुनियादी ढांचे और औद्योगिक क्षेत्रों को सेवा प्रदान करती है - जिसमें फिलीपींस ओवरहेड क्रेन के प्रदाता भी शामिल हैं।

अपने कस्टम-इंजीनियर्ड क्रेन समाधानों के लिए प्रसिद्ध, टोलियन मेट्रो, एक्सप्रेसवे और सुरंग परियोजनाओं के लिए विशेष डबल-गर्डर ब्रिज क्रेन, सेगमेंट हैंडलिंग क्रेन और लॉन्चिंग गैन्ट्रीज़ का निर्माण करता है। फिलीपींस जैसे बाजारों में, टोलियन उच्च-भार, लंबी अवधि और जटिल निर्माण वातावरणों, विशेष रूप से पुल और रेलवे प्रतिष्ठानों के लिए, उच्च-प्रदर्शन वाले फिलीपींस ओवरहेड क्रेन डिज़ाइन करने की अपनी क्षमता के लिए जाना जाता है।

हुआडा

✅ पुल से संबंधित ओवरहेड क्रेन में विशेषज्ञ

✅ बहुभाषी टीमों के साथ वैश्विक परियोजना समर्थन

✅ एमआरटी, एलआरटी, राजमार्ग और केबल-स्टेड पुल निर्माण के लिए विश्वसनीय

चीनी ओवरहेड क्रेन निर्माता, हुआडा, पुल निर्माण उपकरण और ओवरहेड क्रेन में विशेषज्ञता रखती है, और इसका मुख्य ध्यान एमआरटी, राजमार्गों और पुलों जैसी परिवहन अवसंरचना परियोजनाओं पर है। 2008 से, कंपनी ने कस्टम क्रेन सिस्टम—जिसमें लॉन्चिंग गैन्ट्री, बीम लिफ्टर और हेवी-ड्यूटी ओवरहेड क्रेन शामिल हैं—को जटिल निर्माण वातावरण में बड़े-स्पैन सेगमेंट हैंडलिंग के लिए अनुकूलित किया है।

विदेशी ग्राहकों के लिए - जिनमें फिलीपींस में विश्वसनीय फिलीपींस ओवरहेड क्रेन की मांग करने वाले ग्राहक भी शामिल हैं - HUADA ऑन-साइट असेंबली सहायता और अंग्रेजी बोलने वाले इंजीनियरों की पेशकश करता है, जिससे जटिल सिविल परियोजनाओं पर इन फिलीपींस ओवरहेड क्रेन की तेजी से तैनाती और कमीशनिंग सुनिश्चित होती है।

जीएच क्रेन और घटक

✅ क्रेन नवाचार में 60 से अधिक वर्षों का अनुभव

✅ स्मार्ट नियंत्रण + सुरक्षा निगरानी

✅ कठोर औद्योगिक वातावरण में सिद्ध विश्वसनीयता

जीएच क्रेन्स एक स्पेनिश क्रेन निर्माता है जिसके पास 60 से ज़्यादा वर्षों का अनुभव है और जो उच्च-गुणवत्ता वाले ओवरहेड क्रेन बनाने में विशेषज्ञता रखता है। इसकी क्रेनें टिकाऊ स्टील संरचनाओं, सहज नियंत्रण और उन्नत सुरक्षा सुविधाओं के लिए जानी जाती हैं, जिनका व्यापक रूप से बंदरगाहों, खनन, पवन ऊर्जा और विनिर्माण में उपयोग किया जाता है।

फिलीपींस सहित दक्षिण पूर्व एशिया में, GH क्रेन्स को इसकी यूरोपीय इंजीनियरिंग, दीर्घकालिक विश्वसनीयता और स्मार्ट नियंत्रण प्रणालियों के लिए महत्व दिया जाता है, जो परिचालन दक्षता को बढ़ाती हैं और डाउनटाइम को न्यूनतम करती हैं।

ज़ोके क्रेन

✅ क्रेन निर्माण में 15+ वर्षों का अनुभव

✅ डिजाइन, स्थापना और बिक्री के बाद के लिए प्रमाणित

2005 में स्थापित, चीनी ओवरहेड क्रेन निर्माता, ज़ोके क्रेन, निर्यात बाज़ारों पर विशेष ध्यान देने वाली एक पेशेवर ईओटी क्रेन निर्माता कंपनी है। 15 वर्षों से अधिक के अनुभव और ISO9001, ISO14001, और OHSAS18001 प्रमाणपत्रों के साथ, ज़ोके कुशल उत्पादन, सख्त गुणवत्ता नियंत्रण और कस्टम इंजीनियरिंग को मिलाकर बिजली, निर्माण, इस्पात और पेट्रोकेमिकल जैसे उद्योगों की सेवा करती है।

कम समय सीमा और लचीले परियोजना समर्थन के लिए प्रसिद्ध, ZOKE फिलीपींस में ग्राहकों को परामर्श से लेकर स्थापना और प्रशिक्षण तक संपूर्ण क्रेन समाधान प्रदान करता है।

फिलीपींस को ओवरहेड क्रेन निर्यात करने के लिए दाफांग क्रेन का संपूर्ण समाधान

समृद्ध निर्यात अनुभव वाले एक क्रेन निर्माता के रूप में, दफांग क्रेन, फिलीपींस के ओवरहेड क्रेन चाहने वाले फिलीपींस के ग्राहकों को कुशल और नियंत्रणीय अंतर्राष्ट्रीय रसद सहायता प्रदान करता है। हम आपके फिलीपींस के ओवरहेड क्रेन के लिए सर्वोत्तम परिवहन मार्ग की योजना बनाएंगे ताकि समय पर डिलीवरी, पारदर्शी लागत और सुरक्षित माल ढुलाई सुनिश्चित हो सके।

चरण-दर-चरण आयात प्रक्रिया ओवरहेड क्रेन फिलीपींस

- तकनीकी विवरण और कोटेशन को अंतिम रूप दें

- अनुबंध पर हस्ताक्षर करें और पीओ जारी करें

- उत्पादन(30-60 दिन)

- समुद्री शिपमेंट (FCL या LCL)

- सीमा शुल्क घोषणा और निर्यात निकासी (चीन)

- फिलीपींस के लिए समुद्री माल ढुलाई (आमतौर पर 15-31 दिन)

- फिलीपींस में सीमा शुल्क निकासी + डिलीवरी

- ऑन-साइट स्थापना और कमीशनिंग (वैकल्पिक)

आवश्यक दस्तावेज

- वाणिज्यिक चालान

- पैकिंग सूची

- बिल ऑफ लैडिंग (बी/एल)

- उत्पत्ति प्रमाणपत्र (CO)

| शिपिंग का तरीका | इसके लिए अनुशंसित | पारगमन समय | प्रमुख विशेषताऐं |

|---|---|---|---|

| 🚢 एफसीएल (पूर्ण कंटेनर लोड) | संपूर्ण क्रेन सेट (मुख्य गर्डर, अंतिम बीम, होइस्ट) | 15–31 दिन | सर्वोत्तम मूल्य, सीलबंद कंटेनर, स्थिर और सुरक्षित |

| 📦 एलसीएल (कंटेनर लोड से कम) | छोटे बैच या एकल उत्तोलक इकाइयाँ | 9–24 दिन | कम लागत, लेकिन इसमें समेकन और अनपैकिंग शामिल है |

| ✈️ हवाई माल ढुलाई | तत्काल स्पेयर पार्ट्स और छोटी वस्तुएं | 3–7 दिन | सबसे तेज़ लेकिन सबसे महंगा |

| मूल बंदरगाह | गंतव्य बंदरगाह | अनुमानित समय |

|---|---|---|

| शंघाई | मनीला | 15 दिन |

| वुहु | मनीला | 24 दिन |

| गुआंगज़ौ | मनीला | 15 दिन |

| ज़ियामेन | मनीला | 31 दिन |

| Lianyungang | दवाओ | 31 दिन |

| क़िंगदाओ | सेबू | 31 दिन |

ओवरहेड क्रेन फिलीपींस के लिए आयात शुल्क और कर

- सीमा शुल्क. आमतौर पर इसकी सीमा होती है 1% से 7%, उत्पाद वर्गीकरण और व्यापार समझौतों (जैसे, चीन-आसियान मुक्त व्यापार क्षेत्र) पर निर्भर करता है।

- मूल्य वर्धित कर (वैट)। फ्लैट 12% वैट यह अधिकांश आयातित वस्तुओं पर लागू होता है, जिसकी गणना लैंडिंग लागत के आधार पर की जाती है।

- अतिरिक्त आयात कर. कुछ वस्तुओं पर उनके वर्गीकरण के आधार पर अतिरिक्त आयात कर लग सकता है।

- क्रेन के लिए सामान्य HS कोड. 842611 - ओवरहेड ट्रैवलिंग क्रेन; 842619 - अन्य प्रकार के उठाने वाले उपकरण।

दाफांग क्रेन ओवरहेड क्रेन फिलीपींस को निर्यात मामले

आपको यह समझने में मदद करने के लिए कि वास्तविक दुनिया की परिस्थितियों में हमारे क्रेन कैसे प्रदर्शन करते हैं, यहां उन चुनिंदा परियोजनाओं की सूची दी गई है जिन्हें हमने फिलीपींस में पूरा किया है।

20 टन यूरोपीय प्रकार के ओवरहेड क्रेन फिलीपींस को निर्यात किए गए

- अनुप्रयोग: कारखानों में भारी सामग्री/उत्पादों को उठाना और परिवहन करना

- ग्राहक: एक फिलीपीन विनिर्माण संयंत्र

- विस्तार: 20 मीटर

- उठाने की ऊँचाई: 12 मीटर

- कार्य वर्ग: A5

- नियंत्रण मोड: निलंबित नियंत्रण + रिमोट कंट्रोल

16 टन सिंगल गर्डर ओवरहेड क्रेन फिलीपींस को निर्यात किया गया

- अनुप्रयोग: पंप प्रतिस्थापन और रखरखाव के लिए उठाना

- ग्राहक: एक फिलीपीन औद्योगिक सुविधा (पंप रूम)

- विस्तार: 13 मीटर

- उठाने की ऊँचाई: 15 मीटर

- कार्य वर्ग: A3

फिलीपींस में दाफांग क्रेन सेवा प्रतिबद्धता

हम सिर्फ़ क्रेन की आपूर्ति ही नहीं करते—हम पूरे जीवनचक्र में आपका साथ देते हैं। फ़िलीपींस में एक विश्वसनीय ओवरहेड क्रेन आपूर्तिकर्ता के रूप में, दाफांग विश्वसनीय और पेशेवर बिक्री के बाद सेवा प्रदान करता हैपरियोजना नियोजन से लेकर स्थापना और दीर्घकालिक रखरखाव तक।

- रखरखाव। हम स्नेहन, विद्युत जाँच और सुरक्षा निरीक्षणों को कवर करने वाली विस्तृत रखरखाव मार्गदर्शिकाएँ प्रदान करते हैं - यह सुनिश्चित करते हुए कि आपकी क्रेन सर्वोत्तम स्थिति में रहे।

- ओवरहेड क्रेन के अतिरिक्त पुर्जे। हम तेज़ डिलीवरी के लिए, संभावित डाउनटाइम को कम करने के लिए, प्रमुख वेयर पार्ट्स का स्टॉक तैयार रखते हैं।

- प्रशिक्षण। क्रेन का सुरक्षित और सही उपयोग सुनिश्चित करने के लिए, हम द्विभाषी मैनुअल और आभासी प्रशिक्षण सहायता प्रदान करते हैं।

- तकनीकी सहायता। हमारी सहायता टीम समस्याओं का तुरंत निवारण और समाधान करने के लिए दूरस्थ वीडियो या स्थानीय भागीदारों के माध्यम से त्वरित प्रतिक्रिया प्रदान करती है।

अपनी जांच भेजें

- ईमेल: sales@hndfcrane.com

- व्हाट्सएप: +86 191 3738 6654

- टेलीग्राम: +86 191 3738 6654

- टेलीफ़ोन: +86-373-581 8299

- फैक्स: +86-373-215 7000

- जोड़ें: चांगनाओ औद्योगिक जिला, झिंजियांग शहर, हेनान प्रांत, चीन

WeChat

WeChat