Funksjoner ved åpen vinsjtralle

- Enkel struktur

Den åpne vinsjtrallen består hovedsakelig av en trommel, ståltau, trinseblokk og drivenhet. Strukturen er relativt enkel, noe som gjør den enkel å produsere, installere og vedlikeholde. - Sterk løftekapasitet

Ved å vikle ståltauet på trommelen muliggjør løpekatten vertikal løfting og senking av last. Løftehastigheten og kapasiteten kan utformes i henhold til driftskrav, noe som gjør den egnet for håndtering av last i ulike vektområder. - Fleksibel drift

Vognen kan bevege seg horisontalt langs skinnen, og når den kombineres med løftemekanismen, muliggjør den tredimensjonal lastbevegelse innenfor et bestemt arbeidsområde for å møte ulike materialhåndteringsbehov. - Bred tilpasningsevne

Den kan brukes på ulike typer løfteutstyr, som for eksempel dobbeltbjelkekraner og dobbeltbjelkeportalkraner. Den tilpasser seg godt til ulike arbeidsmiljøer og støtter diverse løfteutstyr, inkludert kroker, gripekloer og elektromagnetiske løftere.

NoteYtelsen og bruksområdet til en åpen vinsjtralle bør bestemmes basert på spesifikke design- og driftsforhold. All drift må være strengt i samsvar med sikkerhetsforskriftene.

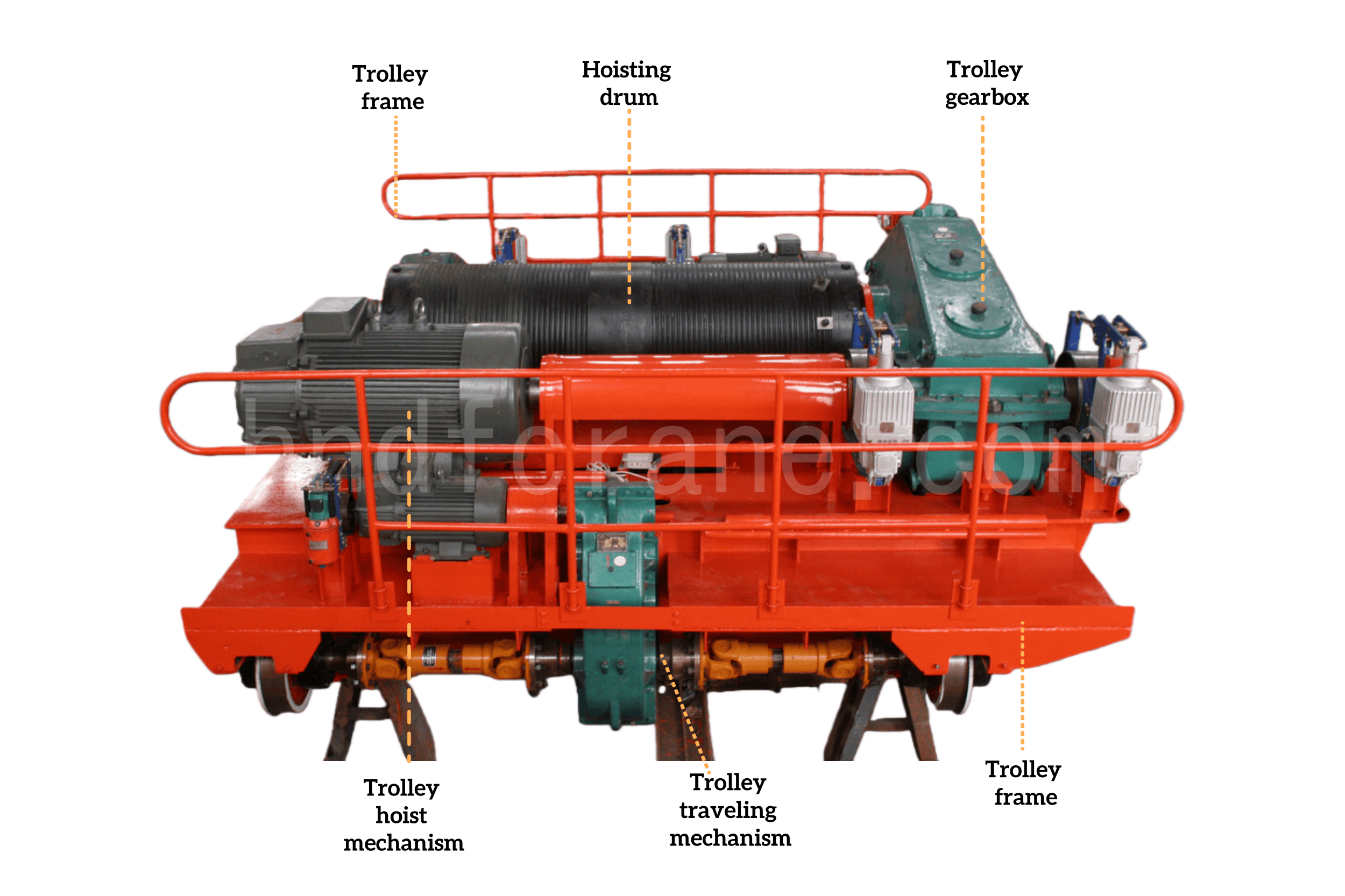

Komponent av åpen vinsjtralle

Egenskaper

- Tralleramme:

En sveiset konstruksjon med høy styrke, utmerket stivhet og motstand mot deformasjon. - Løftetrommel:

Brukes til vikling av ståltau; laget av slitesterke materialer og utstyrt med spiralformede tauspor for å forhindre tauforstyrrelser. - Girkasse for tralle:

Har høyfaste gir med høy gireffektivitet og lavt støynivå. - Tralleheisemekanisme:

Består av en heisemotor, girkasse, trommel, brems og andre komponenter. Den gir høyt dreiemoment med stabil, sikker og pålitelig løfteytelse. - Tralle-reisemekanisme:

Består av en drivmotor, giraksel, koblinger og hjul, som sikrer jevn kjøring og presis posisjonering.

Andre typer åpen vinsjtralle

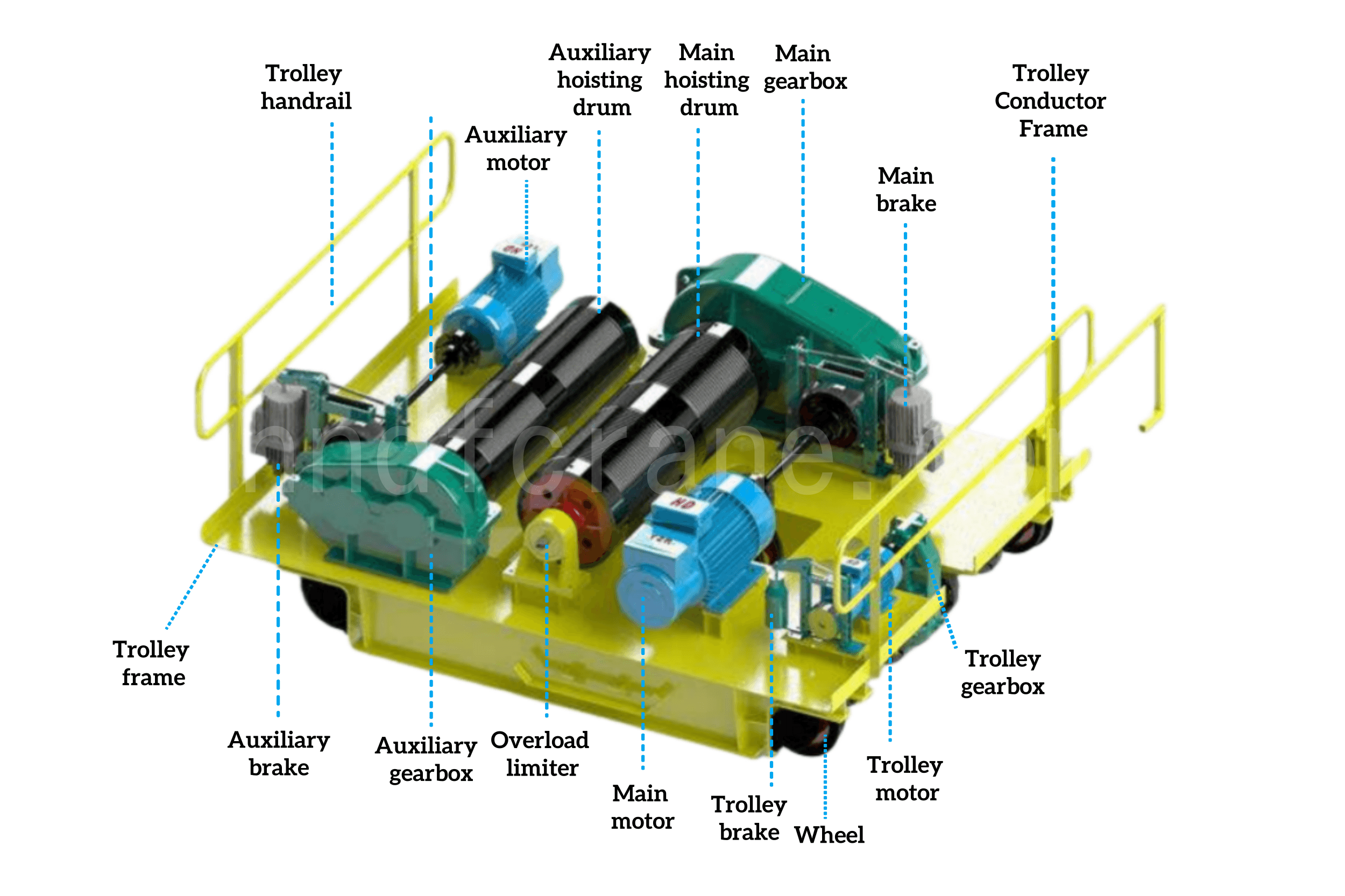

Hoved-/hjelpeheisemekanisme Type Åpen vinsjtralle

- Konfigurasjon med dobbel vinsj

Utstyrt med to uavhengige systemer – hovedløfteanordning og hjelpeløfteanordning – designet for å håndtere tunge og lette oppgaver separat, og støtter både primære og hjelpeløfteoperasjoner. - Høy driftsfleksibilitet

Hovedkroken håndterer løfting med stor kapasitet, mens hjelpekroken opererer med høyere hastigheter for lette laster, høyfrekvente oppgaver og høypresisjonsbevegelser. Den muliggjør komplekse operasjoner som lastvending, finjusteringer og monteringsposisjonering. - Betydelig effektivitetsforbedring

Lette operasjoner kan utføres utelukkende med hjelpekroken, noe som forbedrer arbeidseffektiviteten betraktelig og reduserer energiforbruket og tidskostnadene.

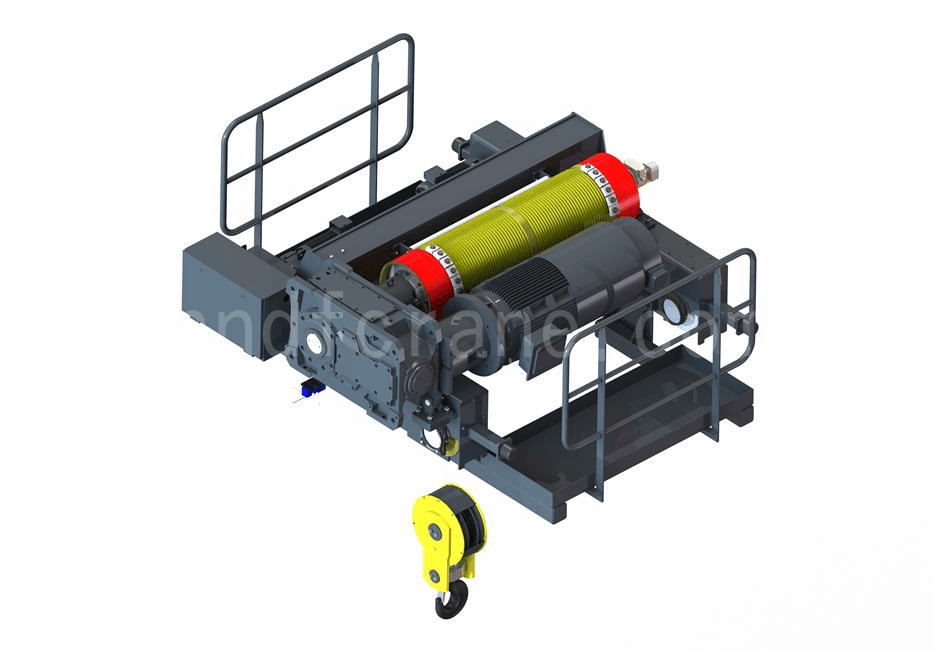

Europeisk type åpen vinsjtralle

- Kapasitet: 5–500 tonn | Løftehøyde: opptil 160 m

- Kompakt og lett design reduserer byggehøyden og de totale byggekostnadene

- Fleksibelt, høyeffektivt drivsystem med lav intern belastning

- Kompatibel med flere løfteutstyr

- Intelligente funksjoner: krypehastighet/mikrohastighet, elektronisk anti-sving, selvdiagnostikk, HMI-grensesnitt

Åpen vinsjtralleapplikasjon for traverskraner og portalkraner

Den åpne vinsjtrallen er designet for allsidig integrering og kan sømløst kobles til traverskraner og portalkraner. Den kompakte strukturen, stabile driften og sterke tilpasningsevnen gjør den til en ideell heiseenhet for ulike industrielle løftesystemer.

Avfallshåndtering

I avfallshåndteringsbransjen er traverskraner vanligvis utstyrt med en åpen vinsjtralle for drift. Denne konfigurasjonen gir høy løftekapasitet, stabil ytelse, høy driftsfrekvens og sterk tilpasningsevne til tøffe miljøer, noe som gjør den ideell for gripeskuffer, avfallshåndtering, tippeoperasjoner og kontinuerlige sykliske driftsforhold.

Metallproduksjon

I metallproduksjonsindustrien er traverskraner ofte paret med en åpen vinsjtralle for materialhåndtering. Denne industrien har tøffe forhold, inkludert høye temperaturer, mye støv og kontinuerlig tung drift.

Den åpne vinsjtrallen tilbyr høy lastekapasitet og pålitelig varmebestandighet. Strukturen og kontrollsystemet kan tilpasses for å møte prosesskravene. Den sikrer sikker og stabil transport av øser, ingotformer, metallplater og tungt utstyr.

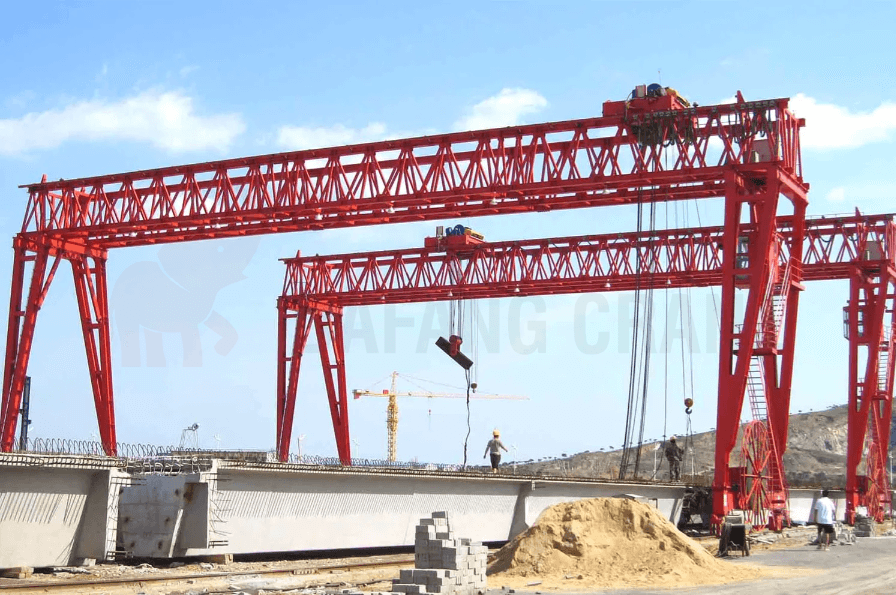

Prefabrikerte bjelkeanlegg og brobygging

I prefabrikerte bjelkeanlegg og brokonstruksjon er portalkraner ofte paret med en åpen vinsjtralle for løfting og transport av tunge komponenter. Denne industrien håndterer ofte store, tunge prefabrikerte bjelker, broforskaling og stålkonstruksjonselementer med strenge krav til løftepunkter. Den åpne vinsjtrallen gir sterk løftekapasitet og stabil drift. Kontrollsystemet støtter presis posisjonering. Det kan forbedre løfteeffektiviteten og sikkerheten betydelig.

DAFANG CRANE Globale prosjekter og tjenester

For å hjelpe kundene med å oppnå tryggere, smidigere og mer effektive løfteoperasjoner, tilbyr DAFANG CRANE skreddersydde løsninger som integrerer vår åpne vinsjtralle med traverskraner, portalkraner og halvportalkraner. Følgende prosjekteksempler viser hvordan vår tekniske støtte, pålitelige produksjon og tilpassede konfigurasjoner gir dokumenterte resultater i reelle industrielle applikasjoner.

Med DAFANGs profesjonelle tekniske støtte, rettidige kommunikasjon og pålitelige ettersalgsservice sørger vi for at alle installasjoner i utlandet opererer trygt, effektivt og konsekvent. Teamet vårt er fortsatt klare til å tilby teknisk assistanse, reservedelsforsyning og langsiktig vedlikeholdsstøtte for å holde utstyret ditt i topp stand.