Průvodce nákupem mostových jeřábů v Thajsku pro rok 2025: Klíčové aspekty pro každého kupujícího

Obsah

Rychlý průmyslový růst Thajska v oblasti výroby, logistiky a infrastruktury vedl k stabilní poptávce po mostových jeřábech. Ačkoli země disponuje určitými místními výrobními kapacitami, ty jsou většinou omezeny na malé a střední jeřáby a zakázková řešení, která nejsou schopna uspokojit plnou poptávku trhu. V důsledku toho se rozsáhlé nebo vysoce výkonné projekty stále silně spoléhají na dovoz, aby zaplnily mezeru v nabídce. Tato závislost na dovážených jeřábech zdůrazňuje jak příležitosti, tak i výzvy na thajském trhu s mostovými jeřáby, které budou prozkoumány v následující části.

Klíčová odvětví pohánějící poptávku po mostových jeřábech v Thajsku

Mostové jeřáby pro zemědělský zpracovatelský průmysl v Thajsku

Thajsko je největším světovým vývozcem rýže a druhým největším producentem kaučuku. Zemědělské zpracovatelské parky jsou soustředěny v centrální nížině řeky Chao Phraya (např. Ayutthaya) a v hlavních oblastech produkce kaučuku na jihu, které vyžadují častou manipulaci s volně loženými/balenými zemědělskými materiály a zpracovatelským zařízením a kladou vysoké nároky na ochranu proti prachu a prevenci zbytků materiálu u jeřábů.

Mostový jeřáb používaný v zařízení na skladování plodin

V oblasti skladování surovin v závodech na zpracování rýže a sacharózy v Thajsku se k manipulaci s objemným obilím a částicemi sacharózy používají drapákové mostové jeřáby s jedním nosníkem. Každý rok se z produkčních oblastí do zpracovatelských závodů na centrálních pláních přepravuje velké množství rýže a sacharózové suroviny se nepřetržitě přepravují do cukrovarů. Prostorové uspořádání těchto skladovacích zařízení je obvykle kompaktní s rozpětím 8–12 metrů, což činí drapákové mostové jeřáby s jedním nosníkem obzvláště vhodné pro tato prostředí. Tato praktická aplikace zdůrazňuje význam thajských mostových jeřábů, které se dokáží přizpůsobit skladům s malým rozpětím a zajistit efektivní manipulaci s objemným materiálem.

Samotný systém uchopení je unikátní. Dvoulaločný zakřivený uchopovač je na vnitřní stěně vybaven gumovými podložkami odolnými proti opotřebení. Tato konstrukce řeší specifickou texturu thajské rýže a částic sacharózy, zabraňuje lámání zrn a přilnutí cukru a zároveň zajišťuje snadné čištění. Uchopovač je poháněn hydraulickým pohonem, který byl zvolen pro svou stabilitu a snadnou údržbu v horkém a vlhkém thajském klimatu. Vzhledem k silným dešťům během monzunového období je přidán speciální vodotěsný kryt, který chrání hydraulický systém před poškozením vlhkostí. Jeřáb pracuje uvnitř skladu s horními vodicími lištami z nerezové oceli, což zajišťuje odolnost proti korozi a přesné polohování. Přeprava surovin přímo z přepravních vozů do skladovacích sil systém snižuje ruční manipulaci, zvyšuje efektivitu a snižuje náklady na pracovní sílu. Thajské aplikace mostových jeřábů tak hrají zásadní roli v modernizaci zpracování rýže a cukru a jsou v souladu s trendem země směrem k automatizaci a snižování nákladů.

Mostové jeřáby v dílnách na zpracování pryže

Mostové jeřáby se široce používají ve válcovnách gumárenských závodů k přepravě těžkých gumových briket a vulkanizačního zařízení. Většina thajských gumárenských závodů je soustředěna v oblastech tropických deštných pralesů na jihu (například Songkhla) a pobřežních provinciích na východě (například Rayong). Roční srážky na jihu přesahují 2000 mm a vlhkost vzduchu často dosahuje 901 T/1T nebo více. Na východě představuje další environmentální problém solná mlha z Thajského zálivu. Protože gumárenské dílny musí být v provozu 24 hodin denně, aby se zabránilo tuhnutí, je nezbytný spolehlivý thajský systém mostových jeřábů, navržený pro nepřetržitý provoz s rozpětím 15–20 metrů.

Zvedací systém je pečlivě navržen s ohledem na specifické potřeby pryže. Uzavřený hák s protiskluzovými zuby je spárován s odnímatelným „závěsným rámem ze speciální pryže“. Při zvedání briket se rám mechanicky zajistí, aby se zabránilo chvění způsobenému pružností materiálu. Do základny rámu jsou přidány větrací otvory, což je obzvláště užitečné v thajském vysokoteplotním klimatu, kde se zabraňuje znehodnocení pryže. Tyto konstrukční úpravy ukazují, jak lze thajský mostový jeřáb přizpůsobit pro specifické materiály v daném odvětví a zároveň zajistit spolehlivost a bezpečnost v náročných výrobních linkách.

Důležitým hlediskem je také odolnost vůči vlivům prostředí. V horkých a vlhkých jižních oblastech jsou protiskluzové zuby háku ošetřeny keramickými povlaky odolnými vůči teplotám v dílně nad 35 °C. Zámky z nerezové oceli 304 na závěsném rámu zabraňují korozi při konstantní vlhkosti. Ve východních pobřežních zpracovatelských oblastech je mostní konstrukce jeřábu opatřena fluorouhlíkovým antikorozním povlakem a elektrické komponenty jsou utěsněny podle standardů IP65, aby byly chráněny před solnou mlhou. Ovládací skříň odolná proti vlhkosti a prachu navíc chrání před zkraty způsobenými pryžovými úlomky a kondenzací. Tyto specializované vlastnosti ukazují, jak si thajský mostový jeřáb dokáže udržet dlouhodobý výkon v tropickém průmyslovém prostředí.

Mostové jeřáby pro automobilovou výrobu v Thajsku

Východní ekonomický koridor Thajska (provincie Rayong, provincie Chonburi) sdružuje továrny společností Toyota, Honda a dalších automobilek, které se zaměřují na montáž vozidel a výrobu dílů. Mostové jeřáby jsou nutné k přepravě těžkých součástí, jako jsou motory a rámy, s vysokou přesností a jeřáby musí běžet hladce (aby se zabránilo kolizi s přesnými díly).

Dvojitý nosníkový mostový jeřáb používaný v dílně pro montáž automobilů

Dvounosníkové mostové jeřáby se v thajském automobilovém průmyslu široce používají, zejména na montážních linkách pro karoserie automobilů a těžké formy. Díky své velké nosnosti a přesnému polohování jsou nezbytné pro manipulaci s kompletními rámy vozidel, lisovacími nástroji a dalšími objemnými součástmi, což zajišťuje efektivitu a bezpečnost výroby.

Vzhledem k tropickému klimatu a pobřežní geografii Thajska musí být thajské mostové jeřábové systémy specificky přizpůsobeny místním podmínkám. Vysoké teploty a vlhkost vyžadují korozivzdorné nátěry a spolehlivé ventilační systémy, zatímco slaný pobřežní vzduch vyžaduje ochranu námořní úrovně a utěsněné elektrické rozvody. V kombinaci s prachotěsným provedením dílen tyto vlastnosti zajišťují stabilní dlouhodobý výkon v náročném průmyslovém prostředí Thajska.

Jednonosníkový mostový jeřáb pro dílny na výrobu dílů

Jednonosníkové mostové jeřáby s kladkostroji hrají klíčovou roli v thajských dílnách na výrobu automobilových součástek – například v těch, které vyrábějí motory, převodovky a lisované díly – díky vysoké efektivitě a častým zdvihacím cyklům. Jejich zjednodušená a lehká konstrukce umožňuje rychlou instalaci a plynulý provoz, což z nich činí ideální thajské mostové jeřáby pro dílny, které vyžadují nepřetržitý tok materiálu a vysokou míru využití.

Thajská tropická a pobřežní geografie a trvale vysoká vlhkost vzduchu vytvářejí jedinečné výzvy pro provoz jeřábů a jejich dlouhodobou životnost. Aby bylo možné tyto požadavky splnit, mnoho thajských mostových jeřábových systémů je vybaveno elektrickými kryty s krytím IP (IP55 nebo vyšším), kladkostroji odolnými proti vlhkosti a ochrannými nátěry, jako jsou epoxidové zinkové základní nátěry, které chrání před korozí a poškozením způsobeným vlhkostí. Pro zajištění spolehlivosti v horkých a vlhkých podmínkách se používají také vylepšené ventilační systémy a utěsněné motory. Tato technická úprava posiluje odolnost thajského mostového jeřábu, což mu umožňuje udržovat stabilní výkon a minimalizovat prostoje v náročném automobilovém výrobním sektoru země.

Mostové jeřáby v Thajsku, elektronický a elektrotechnický průmysl

Thajsko je významným centrem výroby elektroniky a domácích spotřebičů v jihovýchodní Asii s klastry v provinciích, jako jsou Chonburi, Pathum Thani a Nakhon Ratchasima. Toto odvětví zahrnuje polovodiče, pevné disky, domácí spotřebiče a elektrická zařízení, což z elektroniky dělá jednu ze tří nejvýznamnějších exportních kategorií Thajska a klíčového přispěvatele k HDP. Velkoobjemové montážní linky v tomto odvětví vyžadují systémy manipulace s materiálem, které jsou efektivní, přesné a čisté, kde mostové jeřáby podporují přesun jemných součástí, těžkých strojů a velkých podsestav za přísných požadavků na kontrolu prachu, bezpečnost a minimální prostoje.

Mostový jeřáb pro čisté prostory používaný v přesných elektronických čistých závodech

Mostový jeřáb pro čisté prostory se v Thajsku široce používá v oblasti výroby polovodičů a přesné elektroniky, zejména v Rayongu a Chonburi ve Východním ekonomickém koridoru (EHS) - zde se shromažďují čisté továrny společností Tyco Electronics, Anson Semiconductor a dalších, které se používají hlavně pro manipulaci s destičkami, přepravu zařízení na balení čipů a přesnou montáž elektronických součástek a další scénáře. Díky zvláštní geografické poloze a klimatu Thajska.

Thajsko má tropické monzunové klima. Přestože se v čistých prostorách udržuje konstantní teplota a vlhkost, vnější vysoká teplota (průměrná roční teplota 28–32 °C) může snadno zvýšit zatížení klimatizačního systému závodu. Motor mostového jeřábu pro čisté prostory v Thajsku potřebuje nízkoteplotní konstrukci, například vysoce účinné motory s frekvenčním měničem, aby se snížilo rušení odvodu tepla vlhkostí v čistých prostorách. Zároveň během období dešťů (květen–říjen) vlhkost často přesahuje 85%. I když je vnitřní vlhkost v čistých prostorách regulována na 45%–55%, musí být elektrická rozvaděč jeřábu vybavena krytím IP67 odolným proti vlhkosti, aby se zabránilo selhání obvodu vnější vlhkostí. Kromě toho musí být mazivo použité v lanovém kladkostroji pro čisté prostory odolné vůči teplu a vlhkosti, aby se zabránilo zhoršení a kontaminaci čistých prostor.

Kromě toho se některé továrny na polovodiče v Thajsku nacházejí v blízkosti Thajského zálivu, kde vzduch obsahuje stopové množství solné mlhy. Povrch hlavního nosníku thajského mostového jeřábu z hliníkové slitiny musí být potažen antistatickým čistým nátěrem, který nejen splňuje požadavky na prachotěsnost, ale také odolává korozi v solné mlze a prodlužuje životnost zařízení. To plně uspokojuje výrobní požadavky thajského průmyslu přesné výroby na „nulové znečištění a vysokou stabilitu“ a zároveň splňuje požadavky na čistotu a přizpůsobení se životnímu prostředí pro zdvihací zařízení uvedené v dokumentu Ministerstva průmyslu Thajska „Technické specifikace pro elektronická zařízení pro čisté prostory“ (TISI 2388-2022).

Stropní mostový jeřáb používaný v závodech na montáž elektroniky

Stropní mostový jeřáb se používá v závodech na montáž elektroniky (například v závodě na zpracování desek plošných spojů v provincii Rayong). Používá se hlavně pro manipulaci s lehkými malými součástkami, jako jsou desky plošných spojů, malé elektronické součástky a obaly hotových výrobků. Dokáže se flexibilně pohybovat mezi výrobními linkami v malých prostorách.

Vzhledem k jedinečné geografické poloze Thajska a tropickému klimatu vyžaduje tento typ jeřábu cílenou optimalizaci. Thajsko se po celý rok potýká s vysokými teplotami (průměrné denní teploty v dílně se pohybují od 28 do 35 °C, přičemž v některých oblastech v blízkosti zařízení dosahují až 40 °C), takže hnací motor thajského mostového jeřábu musí používat izolační materiály odolné vůči vysokým teplotám, aby se zabránilo přehřátí a poruše motoru. Zároveň během období dešťů (květen–říjen) venkovní vlhkost často přesahuje 90 °F (37 °C). I při použití ventilace dílny musí být spojovací části závěsné kolejnice vyrobeny z nerezové oceli 304, aby byla zajištěna odolnost a spolehlivý provoz v těchto extrémních podmínkách.

Kromě toho se některé továrny v Thajsku nacházejí podél řeky Chao Phraya, kde vzduch obsahuje mírné množství vodní páry a prachu. Kráčící kola thajského mostového jeřábu musí být vyrobena z polyuretanového materiálu odolného proti opotřebení a pod kolejnicí je instalována odnímatelná prachotěsná nádrž. Tato konstrukce nejen zajišťuje flexibilní provoz jeřábu v uzavřených prostorách, ale také splňuje požadavky na přizpůsobení se vlivům prostředí na dílenské vybavení stanovené thajským ministerstvem průmyslu.

4 nejlepší místní výrobci mostových jeřábů v Thajsku

Místní thajští výrobci hrají důležitou roli v uspokojování potřeb domácího průmyslu. Zatímco rozsáhlé nebo vysoce výkonné projekty se stále silně spoléhají na dovážené jeřáby, řada thajských společností si na místním trhu vybudovala silnou pozici díky řešením na míru, spolehlivým servisním systémům a rozsáhlým technickým zkušenostem. Pro firmy, které hledají výrobce mostových jeřábů v okolí, tyto místní společnosti nabízejí dostupnou a pohotovou podporu. Níže představujeme čtyři. tvýrobci mostových jeřábů v Thajsku a představí své klíčové kompetence a silné stránky produktů.

ALLA

✅ Plná certifikace pro veškeré manipulační zařízení

✅ Integrovaná řešení od skladu až po solární systémy

✅ Desítky let zkušeností se silnou poprodejní podporou

Společnost Alla Public Company Limited je důvěryhodnou thajskou společností již více než 30 let, která se specializuje na integrované systémy pro manipulaci s materiálem a zdvihací řešení. Díky komplexnímu portfoliu – včetně jeřábů, elektrických kladkostrojů, nakládací techniky, systémů pro správu skladů, solárních článků a automatizovaných parkovacích systémů – Alla dodává komplexní řešení přizpůsobená moderním průmyslovým a logistickým potřebám. Jako jedna ze zavedených společností zabývajících se mostovými jeřáby v regionu hraje důležitou roli v podpoře rychle rostoucí průmyslové základny Thajska.

Na konkurenčním trhu s mostovými jeřáby v Thajsku je společnost Alla uznávána pro svou plnou certifikaci ve všech kategoriích jeřábů a zdvihacích zařízení a také pro své prokázané odborné znalosti v oblasti optimalizace skladů a logistiky. Ve srovnání s mnoha jinými výrobci mostových jeřábů se Alla odlišuje kombinací inženýrských schopností se spolehlivým poprodejním servisem. Díky své dlouholeté přítomnosti v oboru a pověsti spolehlivého dodavatele mostových jeřábů je preferovanou volbou pro výrobní závody, logistická centra a komerční developery, kteří vyžadují efektivní a vysoce kvalitní řešení pro zvedání a manipulaci.

CRANETHAI

✅ Plná certifikace pro lokalizovaná jeřábová řešení

✅ Strategická poloha v Bangkoku s efektivním pokrytím služeb

✅ Podpora na míru pro vysoce poptávková odvětví v Thajsku

Společnost ย่งฮง (ประเทศไทย) จำกัด je profesionální poskytovatel služeb v oblasti mostových jeřábů se sídlem v Thajsku a sídlem v okrese Phaya Thai v Bangkoku. Díky své vynikající poloze umožňuje rychlý přístup k hlavním průmyslovým oblastem, jako je Východní ekonomický koridor (EEC) a centrální zemědělské zpracovatelské zóny, což ji staví mezi důvěryhodného místního partnera mezi regionálními výrobci mostových jeřábů.

Společnost je držitelem plné certifikace pro kategorie jeřábů přizpůsobené thajskému trhu a splňující místní normy, jako je TISI. Díky své základně v Bangkoku úzce spolupracuje s místními dodavateli na poskytování efektivních instalačních a údržbářských služeb na místě. Její zařízení je navrženo s ohledem na specifické potřeby Thajska – jako je vysoká vlhkost, prašné prostředí při zpracování rýže, cukru a gumy a požadavky na zvedání těžkých břemen ve výrobě v EHS – a je konstruováno pro dlouhou životnost. Díky dvěma horkým linkám (0-2618-3000, 02-036-3000) pro rychlou reakci se stala preferovanou volbou pro podniky, které hledají lokalizovaná řešení pro mostové jeřáby v Thajsku.

Jeřáb AT

✅ 20 let zkušeností v jeřábnictví

✅ Továrna v Ladkrabangu s moderním CNC a testovacím zařízením

✅ Komplexní služby: návrh, výroba, instalace, školení a údržba

Společnost AT Crane byla založena zkušenými odborníky s téměř 20 lety zkušeností v jeřábnictví a poskytuje efektivní a spolehlivá řešení pro manipulaci s materiálem. Továrna, která se nachází v blízkosti průmyslové oblasti Ladkrabang, je vybavena pokročilým CNC plazmovým řezáním, systémy pro tváření s vychylováním nosníků, čtvercovými ocelovými pásovými pilami s úhlem 45° a zařízením pro zátěžové testování, které zajišťuje přesnost v celém výrobním procesu. Společnost je uznávaná jako spolehlivý výrobce jeřábů EOT a je certifikována dle norem ISO 9001:2015, ISO 14001:2015 a ISO 45001:2018. Její produktové portfolio zahrnuje mostové jeřáby, lanové kladkostroje, řetězové kladkostroje, dálkové ovladače a příslušenství k jeřábům a slouží odvětvím, jako je energetika, výroba, veřejné služby a infrastruktura.

Nabízí kompletní škálu služeb, včetně návrhu jeřábů, výroby, instalace, poprodejní podpory, školení jeřábníků s certifikací Ministerstva práce, zátěžových zkoušek a údržby. Díky zkušenostem s projekty po celém Thajsku – včetně Thajského úřadu pro elektřinu, Úřadu pro vodohospodářství a obchodních center – společnost dodává spolehlivá řešení šitá na míru pro místní průmyslové požadavky. Kombinací mezinárodních standardů s lokálními znalostmi se etablovala jako důvěryhodný výrobce jeřábů EOT a partner pro domácí i dovážená jeřábová řešení v Thajsku.

AJ Crane Service Company Limited

✅ Lokální odbornost se sídlem v Chonburi v Thajsku

✅ Integrované služby od návrhu přes instalaci, údržbu až po technickou podporu

✅ Nonstop servis, včetně poradenství, rekonstrukcí, demontáže a stěhování

AJ Crane Service je místní společnost se sídlem v Chonburi v Thajsku, která se specializuje na návrh, výrobu, instalaci a údržbu mostových jeřábů a průmyslových zdvihacích systémů. Jako zkušený thajský dodavatel mostových jeřábů se její hlavní činnost zaměřuje na instalaci, údržbu a inženýrskou integraci a poskytuje řešení na míru pro rozmanité potřeby průmyslového zvedání.

Produktová řada společnosti zahrnuje elektrické mostové jeřáby, portálové jeřáby, otočné jeřáby, příslušenství k jeřábům, elektrické výrobky a související zařízení, které slouží odvětvím, jako je offshore, ropa a plyn, stavebnictví a další průmyslová odvětví. Díky silným odborným znalostem a nepřetržitým servisním možnostem se společnost AJ Crane Service pozicionuje jako spolehlivý partner pro mostové jeřáby v Thajsku a nabízí poradenství, výrobu, renovace, demontáž, přemístění a plnou poprodejní podporu pro zajištění dlouhodobé provozní efektivity.

Klíčoví světoví dodavatelé mostových jeřábů působící v Thajsku

Vzhledem k tomu, že poptávka po mostových jeřábech v různých odvětvích v Thajsku neustále roste, je nalezení správného dodavatele klíčové. Ať už se jedná o místní nákupy nebo dovoz, kupující hledají spolehlivé výrobce, kteří jim zajistí rychlou podporu, konkurenceschopné ceny a vysoce kvalitní služby.

Podle Údaje OSN o ComtradeThajsko v roce 2023 dovezlo mostové jeřáby (HS 842619) v hodnotě přibližně 21,42 milionu USD, přičemž přibližně 731 kusů TP1T pocházelo z Číny. To nejen potvrzuje závislost Thajska na dovážených jeřábech, ale také odráží rostoucí poptávku po velkých zdvihacích zařízeních v odvětvích, jako je zemědělské zpracování, výroba automobilů a přístavní logistika. Čínské společnosti se postupně staly dominantními hráči v thajském dodavatelském řetězci jeřábů, což připravilo půdu pro následující profily výrobců.

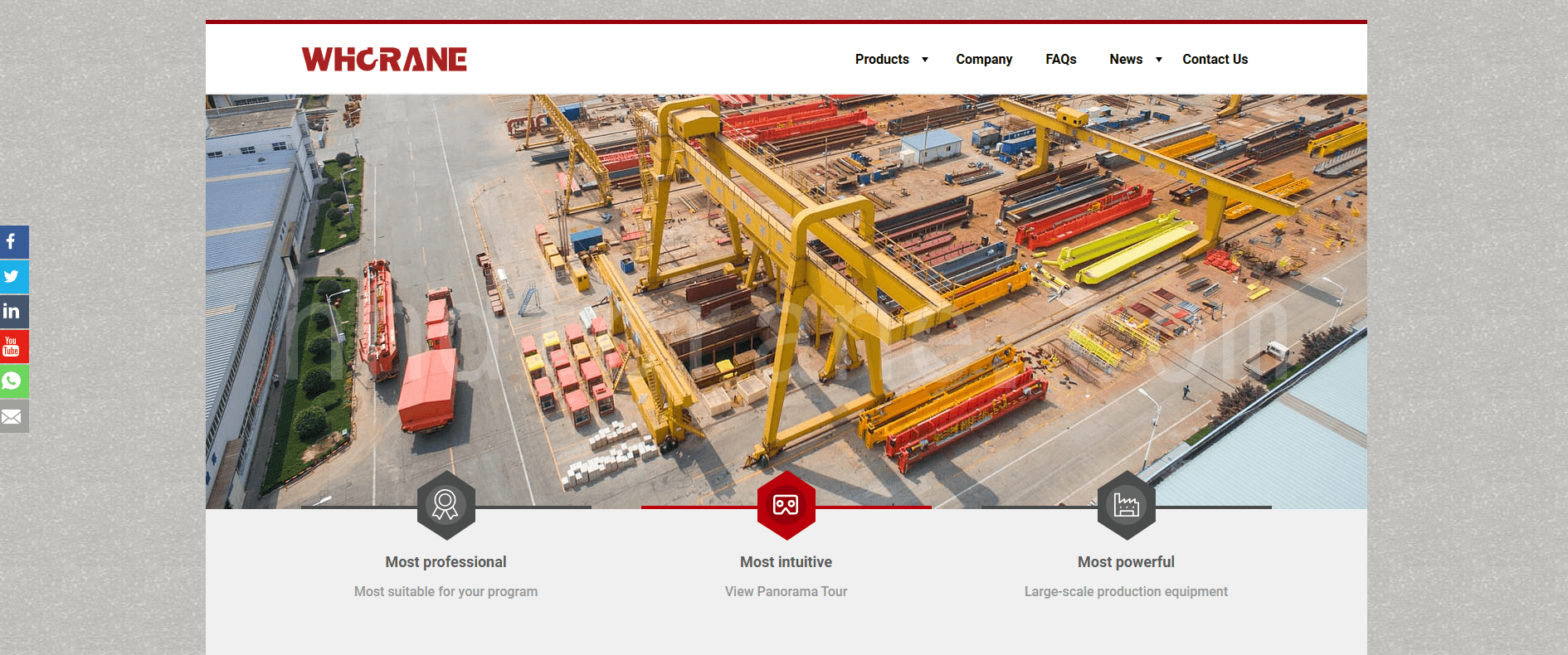

WHCRANE

✅ Certifikace ISO a CE | Určeno pro tropické a pobřežní podmínky

✅ Prokazatelné zkušenosti v Thajsku a jihovýchodní Asii

✅ Kompletní sortiment s možností rychlého dodání

WHCRANE je jedním z největších čínských výrobců mostových jeřábů s více než 35 lety zkušeností a globální působností. Společnost WHCRANE, uznávaná mezi 10 nejlepšími výrobci mostových jeřábů EOT na světě, je známá svými odolnými konstrukcemi, inteligentními řídicími systémy a širokým rozsahem nosností (až 800 tun). Na thajském trhu poskytuje WHCRANE spolehlivá řešení pro mostové jeřáby v Thajsku a slouží různým odvětvím od ocelářství a logistiky až po elektroniku a automobilový průmysl.

Na thajském trhu vyniká společnost WEIHUA svými přizpůsobitelnými konstrukcemi přizpůsobenými tropickým podmínkám, vylepšenou antikorozní ochranou pro pobřežní prostředí a efektivními dodacími lhůtami. Díky těmto výhodám je WEIHUA konkurenceschopným dodavatelem mostových jeřábů v Thajsku důvěryhodnou volbou pro automobilové klastry v Chonburi a Rayongu, elektronická centra v Pathum Thani a také pro ocelárny a logistické zóny v celém Východním ekonomickém koridoru (EEC).

EMH

✅ Projektování a montáž kladkostrojů a jeřábů

✅ Certifikace technika se zárukou

✅ Opravy a bezpečnostní certifikační služby

EMH Thailand je thajská pobočka společnosti EMH, Inc., výrobce se sídlem v USA, založeného v roce 1988, který navrhuje, vyrábí a servisuje komplexní sortiment zařízení pro manipulaci s materiálem – od elektrických kladkostrojů až po mostové a portálové jeřáby. EMH využívá americké technické standardy a osvědčené globální postupy a poskytuje thajským společnostem řešení pro mostové jeřáby, která jsou navržena tak, aby splňovala přísné požadavky na výkon a bezpečnost a zároveň podporovala rychle rostoucí průmyslová odvětví země.

Díky místním pobočkám nabízí společnost EMH Thailand kompletní projekční, výrobní, instalační a údržbářské služby, které splňují thajské normy průmyslové bezpečnosti. Její thajské mostové jeřábové systémy, podpořené zárukou a profesionální inženýrskou certifikací, poskytují spolehlivý zdvihací výkon pro výrobní závody, logistická centra a rozsáhlé infrastrukturní projekty po celé zemi.

JEŘÁB DAFANG

✅ Plná certifikace pro všechny kategorie jeřábů

✅ Velkoformátové dílny s automatizovanou výrobou

✅ Konkurenceschopné ceny vysokokapacitních jeřábů

DAFANG CRANE je přední čínský výrobce mostových jeřábů s jedním z nejkomplexnějších licenčních systémů v oboru. Díky rozsáhlým výrobním dílnám a pokročilým robotickým svařovacím linkám udržuje DAFANG přísnou kontrolu kvality v každé fázi výroby.

Na thajském trhu si společnost DAFANG vybudovala silnou reputaci v oblasti dodávek cenově dostupných a spolehlivých řešení pro mostové jeřáby v Thajsku, zejména pro těžké aplikace. Díky své schopnosti dodávat velké série s konzistentní kvalitou je preferovanou volbou pro ocelárny, logistická centra a developery infrastruktury v celém Východním ekonomickém koridoru (EEC). Pro společnosti, které hledají vysokokapacitní zdvihací zařízení, zajišťují odborné znalosti společnosti DAFANG spolehlivý výkon mostových jeřábů v Thajsku, podpořený osvědčenou konstrukční silou a velkovýrobní kapacitou.

KSCRANE

✅ Návrhy zaměřené na odvětví oceli, energetiky a přístavů

✅ Více než 20 let zkušeností v těžkém průmyslu

✅ Osvědčená spolehlivost na exportních trzích

V Thajsku je společnost KS CRANE uznávána jako spolehlivý poskytovatel mostových jeřábů přizpůsobených požadavkům těžkého průmyslu – ať už se jedná o manipulaci s roztaveným kovem v ocelárnách, podporu projektů v oblasti biomasy a energie nebo práci v pobřežních přístavech v rámci Východního ekonomického koridoru (EEC). Díky mezinárodním certifikacím a pokročilým automatizovaným výrobním linkám dodává KS CRANE odolné jeřáby specifické pro daný projekt, které zajišťují dlouhodobý výkon. Její odborné znalosti umožňují klientům nasadit v Thajsku systémy mostových jeřábů, které odolávají vysoké vlhkosti, silným dešťům a korozi pobřeží, což z ní činí důvěryhodného partnera pro průmyslový růst.

NUKLÓN

✅ AI kontrola proti kývání (úhel natočení <2%)

✅ Přesné zvedání pro jachty, elektroniku a ocelářské aplikace

Společnost NUCLEON CRANE se specializuje na vysoce výkonné mostové jeřáby s pokročilými řídicími systémy a modulárními konstrukcemi evropského typu. Značka, uznávaná jako inovátor v oblasti technologií přesného zvedání, je obzvláště vhodná pro odvětví, která vyžadují stabilitu a přesnost, jako je zpracování oceli, stavba lodí a výroba s vysokou hodnotou.

V Thajsku je společnost NUCLEON považována za důvěryhodného dodavatele mostových jeřábů pro pobřežní loděnice a montážní linky jachet, kde její systémy proti kymácení založené na umělé inteligenci minimalizují kývání zátěže až o 951 ton, což zajišťuje bezpečnou manipulaci s velkými částmi trupu a citlivými lodními komponenty. Její modulární dvounosníkové jeřáby se také používají v klastrech elektroniky a přesného strojírenství a poskytují přizpůsobivé konfigurace a spolehlivou automatizaci. Se zaměřením na čisté, efektivní a inteligentní zvedání posiluje společnost NUCLEON svou přítomnost na thajském trhu mostových jeřábů tím, že uspokojuje rostoucí poptávku země po pokročilých průmyslových řešeních.

ZOKE CRANE

✅ Více než 15 let zkušeností ve výrobě jeřábů

✅ Certifikováno pro návrh, instalaci a poprodejní servis

✅ Flexibilní dodání a přizpůsobení projektu

Společnost ZOKE CRANE, založená v roce 2005, je čínský výrobce mostových jeřábů se silnými zkušenostmi na exportních trzích. Společnost ZOKE, držitelka certifikací ISO9001, ISO14001 a OHSAS18001, integruje efektivní výrobu, přísnou kontrolu kvality a zakázkové inženýrství, aby poskytovala spolehlivá řešení pro zvedání.

V Thajsku je společnost ZOKE uznávána za dodávky všestranných thajských mostových jeřábových řešení, která podporují rozmanité projektové požadavky – od stavenišť a rozvoje infrastruktury až po elektrárny a ocelárny. Díky krátkým dodacím lhůtám a na míru šité inženýrské technice zajišťuje ZOKE, že jeřáby jsou přizpůsobeny tropickým průmyslovým podmínkám. Poskytováním kompletních služeb, které zahrnují konzultace, výrobu, instalaci a školení obsluhy, se společnost stala preferovaným partnerem pro firmy, které hledají efektivní a adaptabilní thajské mostové jeřábové systémy v různých odvětvích.

Z Číny do Thajska: Důvěryhodná řešení pro zvedání mostovými jeřáby od společnosti Dafang Crane

Po prozkoumání předních výrobců mostových jeřábů v Číně i Thajsku je dalším kritickým krokem pro kupující pochopení procesu dovozu. Výběr správného dodavatele je pouze částí cesty – úspěšná realizace projektu závisí také na jasné znalosti způsobů dopravy, celních postupů a dodržování thajských dovozních předpisů. V této části nastíníme základní kroky dovozu mostových jeřábů z Číny do Thajska a pomůžeme firmám přejít od výběru dodavatele k bezproblémovému dodání a instalaci.

Proces dovozu mostových jeřábů z Thajska

- Stanovení technických parametrů a cenové nabídky

- Podepsat smlouvu a vystavit proforma fakturu

- Podle smlouvy bude zahájena výroba a zhotovení mostního stroje a výrobní cyklus bude obecně trvat 30 až 60 dní.

- Dopravní podmínky (FCL, LCL nebo hromadné)

- Celní deklarace a propuštění vývozu z Číny

- Doprava do Thajska (obvykle 10–31 dní)

- Thajské dovozní celní prohlášení a celní odbavení

- Platba cla a daně z přidané hodnoty

- Uvolnění nákladu a doručení do cíle

Způsoby dopravy mostových jeřábů z Číny do Thajska

| Způsob dopravy | Vhodný náklad | Odhadovaná doba přepravy (Čína → Thajsko) | Klíčové vlastnosti |

| FCL (plná kontejnerová nakládka) | Autodíly, elektronika, zboží vysoké hodnoty a velkoobjemové zboží. | 6–17 dní | Vhodné pro velkoobjemovou a těžkou přepravu; vyvážená cena a doba přepravy. |

| LCL (Méně než kontejnerová zásilka) | Malé až středně velké zboží, náhradní díly, malé zásilky. | 12–17 dní | Platba za použitý prostor; nižší náklady; pevné plavební řády a doručování až ke dveřím. |

| Letecká přeprava | Naléhavé náhradní díly, zboží podléhající rychlé zkáze nebo křehké zboží. | 1–4 dny | Nejrychlejší rychlost; vhodné pro časově citlivý náklad. |

Doby přepravy námořní přepravy mezi Čínou a Thajskem

| POL (Přístav nakládky) | POD (Přístav vykládky) | Odhadovaná doba přepravy (dny) |

| Šanghaj | Bangkok | 14 (LCL) |

| Kanton | Bangkok | 12 (FCL), 13 (LCL) |

| Wuhu | Bangkok | 21 (LCL) |

| Šen-čen | Bangkok | 20 (FCL) |

| Ningbo | Bangkok | 31 (FCL), 15 (LCL) |

| Čchung-čching | Bangkok | 27 (FCL), 17 (LCL) |

| Huangpu | Bangkok | 14 (celoplošný přepravní prostředek a zkrácený přepravní prostředek) |

| Ťiang-men | Bangkok | 14 (LCL) |

| Dalian | Laem Chabang | 17 (FCL) |

| Shekou | Bangkok | 6 (FCL) |

| Shekou | Laem Chabang | 12 (FCL) |

Dovozní cla a daně pro thajské mostové jeřáby

Dohoda o volném obchodu mezi Čínou a Thajskem: V rámci zóny volného obchodu mezi Čínou a ASEAN (CAFTA) může zboží dovážené z Číny, které splňuje pravidla původu, požívat celní slevy 0%.

Daň ze zboží a služeb (DPH)

Rovná sazba daně: Dovážené zboží podléhá dani z přidané hodnoty (DPH) 7%. Tato sazba daně je v současné době standardní sazbou daně pro většinu zboží v Thajsku.

Daňový základ: Základem pro výběr DPH je cena CIF (náklady, pojištění, přeprava) plus zaplacené clo.

Ostatní výdaje

- Poplatek za celní odbavení: Dovozní celní deklarace obvykle generuje dodatečné poplatky za celní odbavení, jejichž konkrétní výše se liší v závislosti na celní agentuře.

- Poplatky za přístavy a terminály: včetně poplatků za přístavní infrastrukturu, manipulaci s nákladem, skladování a prostoje atd. Konkrétní poplatky vybírá každý přístav a dopravce a neexistuje jednotný standard.

- Antidumpingová opatření: Je třeba poznamenat, že Thajsko může zavést antidumpingová opatření na určité zboží se specifickými daňovými čísly, která by měla být před dovozem potvrzena.

Důležitá poznámka: Hlavní náklady na dovoz jeřábů z Číny do Thajska obvykle představují daň z přidané hodnoty 7% a různé provozní poplatky. Díky dohodám o volném obchodu lze cla (dovozní daně) obvykle snížit na nulu, pokud je předložen platný certifikát původu.

Projekty mostových jeřábů Dafang Crane v Thajsku

3T jednonosníkové mostové jeřáby vyvážené do Thajska

- Aplikace: Kovovýroba - manipulace s dlouhými profily a těžkými součástkami.

- Kapacita: 3t

- Rozpětí: 23,2 m

- Výška zdvihu: Nespecifikováno (obvykle 6–9 m pro aplikace s jedním nosníkem)

- Provozní napětí: 380 V/50 Hz, 3 fáze (přizpůsobeno thajskému průmyslovému standardu)

10T dvounosníkový mostový jeřáb vyvážený do Thajska

- Aplikace: Zvedání dlouhého a těžkého zboží v dílně

- Rozpětí: 18,9 m

- Výška zdvihu: 8,45 m a 10,55 m

- Rychlost zvedání: 3,5 m/min, 7 m/min, 8 m/min

- Rychlost jízdy vozíku: 20 m/min

- Rychlost pojezdu jeřábu: 20 m/min

- Režim ovládání: Přívěsek + dálkové ovládání

- Pracovní stupeň: A3

- Napájení: 380 V, 50 Hz, 3 fáze

5t jednonosníkové mostové jeřáby vyvážené do Thajska

- Aplikace: Manipulace se stroji a materiály v omezené výšce budovy

- Produkt: Jednonosníkový mostový jeřáb

- Kapacita: 5 t × 2 sady

- Rozpětí: 18,9 m

- Výška zdvihu: 9,1 m a 7,2 m

- Režim ovládání: Nespecifikováno (pravděpodobně závěsný ovladač + volitelný dálkový ovladač)

- Pracovní stupeň: A3

- Napájení: 380 V, 50 Hz, 3 fáze

Záruka servisu jeřábů Dafang pro Thajsko

Nejsme jen vývozci jeřábů – jsme vaším spolehlivým partnerem v každé fázi životního cyklu vašeho mostového jeřábu v Thajsku. Jako důvěryhodný dodavatel jeřábů v regionu poskytuje společnost Dafang Crane podporu klientům od plánování projektu a instalace až po dlouhodobý provoz, údržbu a modernizace.

- Údržba

Vzhledem k tropickému monzunovému klimatu Thajska – vysoké vlhkosti, častým dešťům a prašným podmínkám v průmyslových zónách – nabízíme individuální plány údržby zahrnující antikorozní nátěry, ochranu elektrických systémů před výkyvy napájení a plánované bezpečnostní kontroly, abychom zajistili stabilní výkon jeřábu.

- Dodávka náhradních dílů

Vzhledem k roli Thajska jako logistického centra v jihovýchodní Asii jsou náhradní díly skladovány a dodávány efektivně přes klíčové přístavy, jako jsou Laem Chabang a Bangkok, což zajišťuje rychlou výměnu a minimální prostoje pro továrny v automobilovém, elektronickém a gumárenském průmyslu.

- Podpora školení

Aby společnost Dafang Crane uspokojila potřeby místních operátorů, poskytuje dvojjazyčné (thajsky/anglicky) manuály a praktická školení – ať už na místě nebo virtuálně – zaměřená na bezpečný a efektivní provoz jeřábů v různých odvětvích od automobilového průmyslu až po logistiku.

- Technická podpora

Náš tým odborníků poskytuje rychlé vzdálené poradenství a spolupracuje s thajskými servisními partnery na řešení problémů na místě, čímž pomáhá zákazníkům vyhnout se zpožděním a udržovat konzistentní výrobní výkon.

Pošlete svůj dotaz

- E-mailem: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Přidat: Changnao Industrial District, Xinxiang City, provincie Henan, Čína

WeChat

WeChat