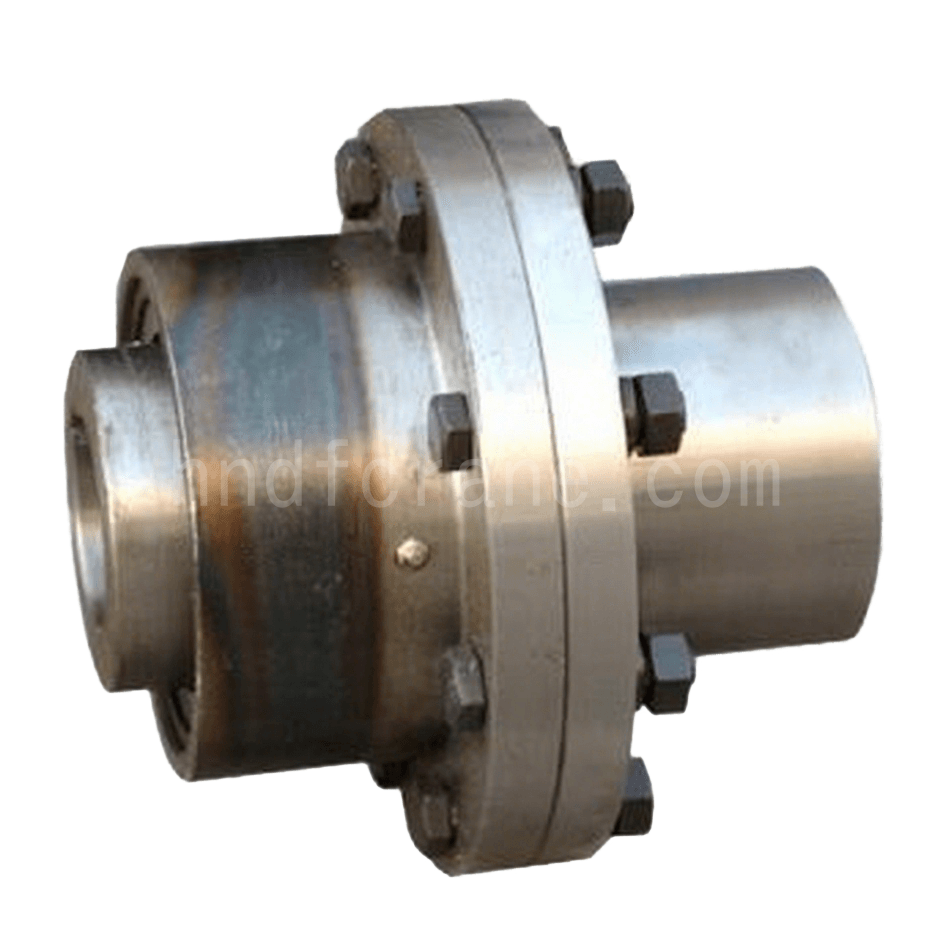

Full Gear Couplings

- Mga Katangian sa Estruktura: Ang clearance sa gilid ng ngipin ay mas malaki kaysa sa ordinaryong gear transmission, na nagbibigay-daan sa isang partikular na angular na displacement. Ang panloob at panlabas na mga ibabaw ng ngipin ay sumasailalim sa panaka-nakang axial relative sliding, na nagbibigay ng mahusay na pagpapadulas at pagganap ng sealing. Mayroon itong maliit na sukat ng radial at mataas na kapasidad na nagdadala ng pagkarga.

- Saklaw ng Aplikasyon: Angkop para sa paghahatid sa pagitan ng mababang bilis at mabigat na pagkarga.

- Ginagamit sa: Pagkonekta sa driving shaft at driven shaft sa mga mekanismo ng hoisting at travelling ng mga crane.

Half Gear Couplings

- Makinis na paghahatid, malakas na pagtutol sa pagkabigla at panginginig ng boses, at mataas na pagganap ng kaligtasan.

- Maliit na radial compensation, na angkop para sa low-speed at heavy-load na koneksyon.

- Ginagamit para sa pagkonekta sa driving shaft at driven shaft sa hoisting at travelling mechanism ng mga crane.

Braking-wheel Couplings

- Makinis na paghahatid, malakas na pagtutol sa pagkabigla at panginginig ng boses, at mataas na pagganap ng kaligtasan.

- Maliit na radial compensation, na angkop para sa madalas na pagsisimula at mababang bilis, mabigat na mga koneksyon.

- Ginagamit para sa pagkonekta sa driving shaft at driven shaft sa hoisting at travelling mechanism ng mga crane.

Elastomeric Couplings

- Simpleng istraktura, maliit na radial size, walang lubrication na kailangan, madaling maintenance, at magandang shock absorption at buffering performance.

- Naaangkop sa mga sitwasyong may madalas na pagsisimula, katamtaman hanggang mababang bilis, katamtaman hanggang maliit na kapangyarihan, at mataas na mga kinakailangan sa pagiging maaasahan; hindi angkop para sa mabibigat na pagkarga o mga aplikasyon na may mahigpit na axial space constraints.

- Ginagamit para sa pagkonekta sa driving shaft at driven shaft sa hoisting at travelling mechanism ng mga crane.

Mga Universal Coupling

- Ang cross shaft universal coupling ay isang pangunahing universal transmission component. Ang pangunahing tampok nito ay ang kakayahang ikonekta ang dalawang drive shaft na hindi nakahanay sa parehong axis, habang mapagkakatiwalaan ang pagpapadala ng metalikang kuwintas at paggalaw.

- Ang ganitong uri ng coupling ay nag-aalok ng mataas na kapasidad ng pagkarga, mahabang buhay ng serbisyo, maayos na operasyon, walang ingay, malaking kompensasyon ng axial, at simpleng pagpapanatili.

- Ang pagkabit ay binubuo ng dalawang halves, na ayon sa pagkakabanggit ay konektado sa driving shaft at sa driven shaft.

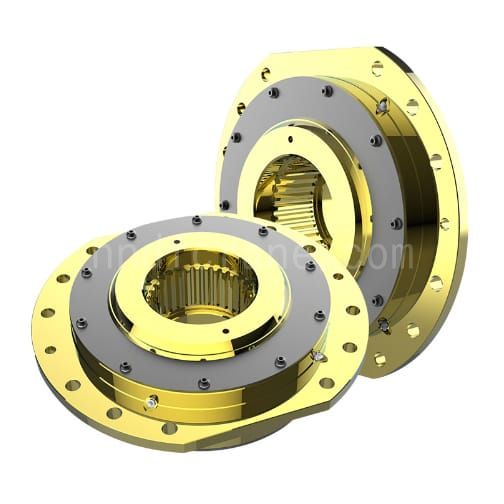

Drum Couplings

- Hanay ng diameter: Φ120mm hanggang Φ2500mm.

- May kakayahang makatiis ng malalaking radial load at magpadala ng malaking torque.

- Mataas na pagiging maaasahan at pagganap ng kaligtasan.

- Wear-resistant na may mahabang buhay ng serbisyo.

- Maaaring magdala ng mas malaking radial load at magpadala ng mas mataas na torque, na may reliability at kaligtasan na nakahihigit sa tradisyonal na mga coupling.

- Mababang pagsusuot sa lahat ng bahagi, matatag na konstruksyon, walang mga alalahanin sa pagkabigo sa kaligtasan.

- Ang espesyal na susi na nakapaloob sa pagitan ng mga spherical na ibabaw ay nagbibigay-daan sa nababaluktot na pag-ikot na may malaking angular na displacement, na nagpapadali sa pag-install at pagsasaayos.

- Ginagamit para sa pagkonekta sa reducer shaft at sa drum.