Mga Overhead Crane Application sa Mga Pangunahing Industriya at Gabay sa Pag-import ng South Africa mula sa China

Talaan ng mga Nilalaman

Ang pangangailangan para sa mga overhead crane sa South Africa ay patuloy na lumalaki, lalo na sa mga pangunahing industriya tulad ng pagmimina, bakal, at imprastraktura.

Nilalayon ng artikulong ito na bigyan ang mga mamimili ng malinaw na pangkalahatang-ideya ng overhead crane sa South Africa market, na nagpapaliwanag kung bakit nangingibabaw ang mga import sa supply chain, kung aling mga industriya ang humihimok ng demand, at kung paano makikinabang ang mga negosyo sa pakikipagtulungan sa mga mapagkakatiwalaang supplier na Tsino.

Mga Pangunahing Industriyang Nagtutulak ng Demand para sa mga Overhead Crane sa South Africa

Mga Aplikasyon sa Overhead Crane sa Sektor ng Pagmimina ng South Africa

Ang sektor ng pagmimina ng South Africa, na nag-aambag ng humigit-kumulang 7.5% ng pambansang GDP at nagkakahalaga ng higit sa 50% ng kabuuang pag-export ng paninda, ay nananatiling pangunahing haligi ng ekonomiya nito. Sa kabila ng kamakailang pagbaba ng mga benta ng mineral—lalo na para sa mga pangunahing bilihin tulad ng mga PGM, iron ore, ginto, at chrome—ang mabibigat na tungkulin ng industriya ay patuloy na nangangailangan ng mga overhead crane para sa mahusay na paghawak ng materyal at pagpapanatili ng kagamitan.

Kunin ang Overhead Crane Ginagamit sa Tailings Treatment System

Sa mga minahan sa South Africa, ang mga grab bridge machine ay karaniwang ginagamit sa mga sistema ng paggamot ng tailing, tulad ng transportasyon ng ore o pulbos. Ang mechanical grab ay may malakas na wear resistance at pinapalitan ang haydroliko na disenyo upang umangkop sa abrasive na kapaligiran na may mataas na nilalaman ng alikabok at mataas na pagsusuot ng mga particle ng ore. Ganap na awtomatikong kontrol + remote na operasyon upang makamit ang tumpak na pagpoposisyon (error ≤5 mm), na partikular na mahalaga sa mga lugar ng pagmimina kung saan ang alikabok ay malaki at ang manu-manong operasyon ay hindi maginhawa.

Ang polusyon ng alikabok sa mga lugar ng pagmimina sa South Africa ay malubha, at ang grab ay dapat na may mataas na wear resistance; kailangang selyadong ang control system, at mataas ang antas ng dustproof.

Sa pabagu-bagong supply ng kuryente at kakulangan ng stable na supply ng kuryente, ang mga automation system ay kadalasang kailangang nilagyan ng mga variable frequency drive (VFD), remote monitoring, at fault diagnosis system upang matiyak ang tuluy-tuloy na operasyon at pagpapanatili.

Underhung Overhead Cranes Uesd sa Diamond Mines

Ginagamit sa mga partikular na minahan sa southern Africa, tulad ng mga mina ng brilyante, ang I-beam ay nakadikit sa tuktok ng minahan sa pamamagitan ng rock expansion bolts, ang bridge machine ay dumadausdos sa ibaba, at ang istraktura ay nakabitin sa bubong.

Maaari nitong makabuluhang bawasan ang dami ng paghuhukay ng minahan at pagbutihin ang pagiging epektibo sa gastos. Ang isang karagdagang istraktura ng suporta ay kinakailangan, na napaka-angkop para sa makitid na kapaligiran ng minahan.

Ang top plate rock formation ay kailangang magdala ng timbang, at ang disenyo ng kagamitan ay kailangang isama sa rock mass stability at structural safety assessment. Ang halumigmig sa mga minahan sa ilalim ng lupa ay mataas, at ang kagamitan ay kailangang idinisenyo upang maging kalawang at hindi moisture; ang operating system ay dapat ding hindi tinatablan ng tubig at dust-proof.

Mga Overhead Crane Application sa Steel Industry ng South Africa

Ang industriya ng pagpoproseso ng bakal at metal sa South Africa ay nananatiling pundasyon para sa imprastraktura, mga proyekto ng riles, at pagmamanupaktura. Sa mga operasyong ito, ang mga overhead crane ay kailangang-kailangan para sa paghawak ng mabibigat na steel plate, coils, at pipe. Mula sa pag-aangat ng mga hilaw na materyales sa mga gilingan ng bakal hanggang sa pagkarga ng mga natapos na produkto sa mga bakuran ng logistik, tinitiyak ng mga crane ang kahusayan, kaligtasan, at tumpak na kontrol. Ang malakas na pagsasama-sama ng mga overhead crane sa pang-araw-araw na produksyon ng bakal ay nagha-highlight kung bakit ang sektor ay patuloy na isa sa pinakamahalagang driver ng demand sa South Africa market.

Foundry Overhead Cranes Ginamit sa Smelting Steel Plant Workshop

Ang Foundry overhead cranes ay isang steel workshop sa South Africa. Ito ay malawakang ginagamit sa smelting workshop, tuluy-tuloy na casting workshop, at rolling workshop ng steel mill. Ito ay responsable para sa pag-angat ng mga sandok, tinunaw na bakal, slag, at mga metal na may mataas na temperatura. Higit pang mga istrukturang may apat na sinag at apat na riles ang ginagamit, na nilagyan ng dalawang hanay ng mga pangunahing at pantulong na mekanismo ng pag-aangat, at ang pangunahing kawit ay ginagamit upang iangat ang mga ladle o heavy-duty na steel billet. Ang mga auxiliary hook ay nakikipagtulungan sa mga operasyon, tulad ng paglalaglag ng tinunaw na bakal, pagpihit ng mga sandok, o pagtulong sa pagbubuhat. Karamihan sa mga spreader ay ladle spreader o electromagnetic spreader, na maaaring gumana nang matatag sa mataas na temperatura at alikabok na kapaligiran.

Sa kapaligiran ng steel mill ng South Africa, ang mga metalurgical bridge machine ay pangunahing nagsasagawa ng tatlong uri ng mga operasyon: transporting molten steel mula sa converter patungo sa refining o continuous casting station; pagsasagawa ng molten iron feeding at steel slag cleaning; at pag-angat ng malalaking bakal na billet, slab, o coils.

Ang power supply ng South African power grid ay hindi matatag, at ang mga metallurgical bridge machine ay karaniwang nilagyan ng frequency conversion drive (VFD) + PLC na awtomatikong kontrol upang matiyak ang matatag na pag-angat at maiwasan ang pagyanig kapag nag-aangat ng tinunaw na bakal.

Single Girder Overhead Cranes Ginagamit para sa Steel Material Handling Workshop

Ito ay karaniwang ginagamit sa mga pagawaan upang magdala ng mga natapos at intermediate na produkto tulad ng mga steel plate, coils, steel pipe, atbp. Ang mga single-beam bridge machine ay napakahalaga sa vertical loading at unloading at plate stacking. Maaari itong iakma sa isang malawak na espasyo sa pagtatrabaho at sumusuporta sa mas mataas na pagganap ng hoisting.

Ang South Africa ay angkop para sa mataas na kahalumigmigan at kaagnasan, at ang patong at anti-kalawang na paggamot ay dapat na mahusay.

Mga Aplikasyon sa Overhead Crane sa Industriya ng Infrastruktura ng South Africa

Sa South Africa, ang sektor ng konstruksiyon ay gumagawa ng katamtamang kontribusyon sa GDP, ngunit ang mga malalaking proyekto sa transportasyon, enerhiya, at mga tulay ay nagtutulak ng malakas na pangangailangan para sa mga overhead crane. Ang mga kamakailang pamumuhunan, gaya ng US$1.5 bilyon na pautang sa World Bank para i-upgrade ang imprastraktura, ang proyekto ng Mtentu Bridge (nakatakdang maging pinakamataas sa Africa), at mga bagong istasyon ng kuryente tulad ng Kusile at Medupi, lahat ay umaasa sa mga overhead crane para sa pagbubuhat ng mga istrukturang bakal, turbine, at mga prefabricated na seksyon. Itinatampok ng mga proyektong ito ang pag-asa ng industriya sa matibay na mga crane na inangkop sa mga lokal na hamon, tulad ng mataas na temperatura, kaagnasan sa baybayin, at hindi matatag na mga suplay ng kuryente.

Overhead Crane Ginagamit para sa Boiler Auxiliary Vehicles

Sa mga coal-fired power station, gaya ng Kusile Power Station (isa sa pinakamalaking coal-fired power station sa South Africa, na may kabuuang naka-install na kapasidad na 4,800 MW.) Gumamit ng mga bridge machine (5-10 tons) para iangat ang mga boiler pipe, support parts at medium-sized na steel structure na bahagi sa boiler auxiliary workshop at pipeline manufacturing area.

Ang spreader ay karaniwang isang electric hoist hook o isang espesyal na kabit, na ginagamit upang tumpak na ilipat ang siko at suportahan ang bakal mula sa lugar ng pagpoproseso patungo sa assembly point.

Dahil sa malaking halaga ng alikabok sa pagawaan, ang makina ng tulay ay kailangang nilagyan ng takip ng alikabok; ang temperatura sa lugar ng power station ay mataas, at ang motor ay madalas na gumagamit ng H-class na pagkakabukod na may mas mataas na antas ng paglaban sa init; kitang-kita ang pagbabagu-bago ng boltahe ng power grid, at ang frequency conversion drive (VFD) ay karaniwang naka-configure upang matiyak ang isang matatag na proseso ng pag-angat at maiwasan ang pag-alog ng load.

Overhead Crane Ginagamit para sa Bridge Prefabricated Platform Area

Sa lugar ng produksyon ng mga prefabricated bridge panel at steel cage ng South African bridges, tulad ng Mtentu Bridge, ang single-beam bridge machine ay ginagamit upang iangat ang mga medium-sized na bahagi (tulad ng mga template, steel frame, atbp.) sa panahon ng transportasyon. Sa pamamagitan ng bridge machine sa fixed track, ang mga prefabricated na bahagi ay mabilis na inilipat mula sa processing area patungo sa loading area o sa pre-assembled area, na epektibong nagpapahusay sa kahusayan ng on-site material flow.

Seryosong apektado ng coastal salt spray, ang katawan ay kailangang magkaroon ng malakas na anti-corrosion coating at moisture-proof na disenyo. Ang konstruksiyon ay matatagpuan sa isang malayong bulubunduking lugar, at ang kagamitan ay kailangang magkaroon ng moisture-resistant at waterproof na mga electrical interface upang matiyak ang tuluy-tuloy na operasyon.

Dafang: Pag-import ng Chinese Overhead Cranes sa South Africa – Praktikal na Gabay

Ipinapakita ng data ng customs (2022–2025) na ang South Africa ay nag-import ng mahigit USD 11.6 milyong halaga ng mga overhead crane mula sa 24 na bansa sa nakalipas na tatlong taon. Nangunguna ang China na may humigit-kumulang na USD 3.55 milyon, nangunguna sa Turkey (USD 1.9 milyon), India (USD 1.45 milyon), at Finland (USD 1.39 milyon). Matatag nitong itinatatag ang China bilang pinakamahalagang kasosyo sa ibang bansa ng South Africa para sa mga pag-import ng crane.

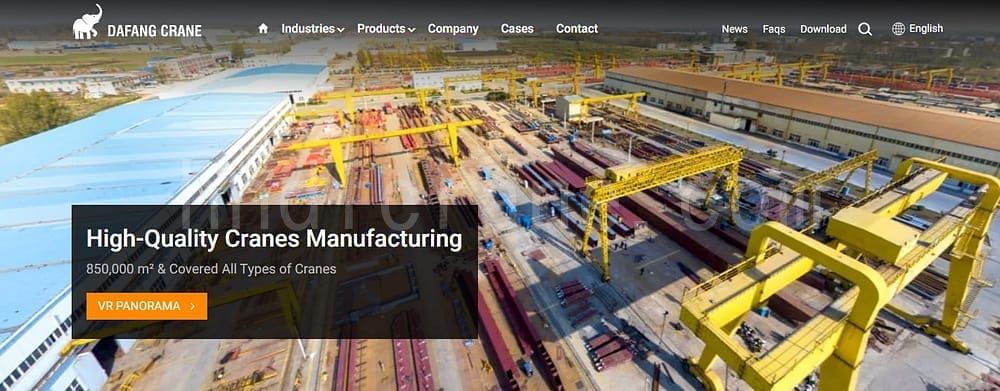

Bilang isa sa nangungunang tatlong tagagawa ng overhead crane sa China, Dafang Crane humahawak ng nangungunang posisyon sa pandaigdigang industriya ng lifting. Kinikilala hindi lamang bilang isang maaasahang tagagawa ng bridge crane kundi bilang isang pinagkakatiwalaang supplier ng overhead crane, pinagsasama ng kumpanya ang malakihang kapasidad sa pagmamanupaktura sa isang malawak na portfolio ng produkto, advanced na teknolohiya, at mahusay na itinatag na kadalubhasaan sa pag-export. Para sa mga mamimili na naghahanap ng overhead crane para sa pagbebenta sa South Africa, ang proseso ay mas kumplikado kaysa sa simpleng pag-order—nangangailangan ito ng mga hakbang sa pag-navigate gaya ng teknikal na pagpili, pagsunod sa mga pamantayan sa kaligtasan at elektrikal sa South Africa, transoceanic shipping, at customs clearance. Ang mga hamon na ito ay maaaring makabuluhang maantala ang mga proyekto at mapataas ang mga gastos, lalo na sa mga sektor ng pagmimina, bakal, at konstruksiyon. Tinutugunan ng Dafang Crane ang mga isyung ito sa pamamagitan ng napatunayang one-stop export service nito, na sumasaklaw sa pagpaplano ng proyekto, customized na disenyo, produksyon, pagpapadala, clearance, at after-sales maintenance, na tinitiyak na ang mga customer sa South Africa ay makakatanggap ng mahusay at maaasahang mga solusyon sa crane.

✅ Pamilyar sa mga kinakailangan sa pag-import at customs clearance ng South Africa

✅ Perpektong sariling sistema ng produksyon

✅Mga mapagkumpitensyang presyo para sa malakihan at customized na mga proyekto

Ang Dafang Crane ay isa sa nangungunang 10 overhead crane manufacturer, na nagraranggo sa nangungunang 10 EOT crane manufacturer sa mundo, na may malakas na kapasidad sa pagmamanupaktura at isang mahigpit na sistema ng pamamahala ng kalidad. Bilang isang pandaigdigang kinikilalang EOT crane manufacturer at isang pinagkakatiwalaang pangalan sa mga nangungunang overhead crane na kumpanya, ang Dafang ay may hawak na internasyonal na mga sertipikasyon na sumasaklaw sa maraming uri ng crane at nagpapatakbo ng matalinong mga linya ng produksyon. Nakatuon sa kalidad at kahusayan, ang kumpanya ay nagbibigay ng cost-effective na mga solusyon sa pag-aangat para sa mga industriya ng pagmimina, metalurhiya, logistik, at imprastraktura sa buong mundo.

Dahil sa mga espesyal na pangangailangan ng South Africa market, tulad ng mataas na temperatura, coastal salt spray corrosion, dust environment, at power grid fluctuations, ang Dafang Crane ay gumagamit ng corrosion-resistant na disenyo, dust-proof at heat-resistant na mga motor, at frequency conversion drive control system upang matiyak na ang kagamitan ay maaari pa ring gumana nang matatag sa malupit na kapaligiran. Pinahahalagahan lalo na ng mga customer sa South Africa ang mapagbigay na kakayahan sa pag-customize, maaasahang paghahatid, at matalik na serbisyo pagkatapos ng benta, na ginagawa itong perpektong kasosyo para sa mga minahan, daungan, at malalaking proyektong pang-imprastraktura.

Ang Dafang Crane ay may ilang mga internasyonal na sertipikasyon upang matiyak na ang mga produkto nito ay nakakatugon sa pandaigdigang kalidad, kaligtasan, at mga pamantayan sa pagsunod. Sa pamamagitan ng matalinong kontrol at modular na disenyo, ang Dafang Crane ay maaaring magbigay ng mga pinasadyang solusyon ayon sa mga espesyal na pangangailangan ng South African port transportasyon at mga pang-industriyang aplikasyon upang matugunan ang mga pangangailangan ng aplikasyon ng mga bridge machine sa ilalim ng iba't ibang mga kondisyon sa pagtatrabaho.

Proseso ng Pag-import ng mga Overhead Cranes ng South Africa

Matatagpuan ang South Africa sa katimugang dulo ng kontinente ng Africa at nasa hangganan ng Namibia, Botswana, Zimbabwe at Mozambique. Parehong ang China at South Africa ay maimpluwensyang umuunlad na mga bansa at mahalagang miyembro ng mga bansang BRICS. Mula noong 2007, ang kalakalan, patakaran, at ugnayang pampulitika sa pagitan ng dalawang bansa ay lalong naging malapit. Ang Tsina ay naging pinakamalaking bilateral na kasosyo sa kalakalan ng South Africa, na nagha-highlight ng malakas na pangangailangan para sa maaasahang transportasyon mula sa China hanggang South Africa.

- Tapusin ang Mga Teknikal na Detalye at Sipi

- Pumirma ng Kontrata at Isyu ng PO

- Produksyon (30–60 araw)

- Pagpapadala sa Dagat (FCL / LCL / Breakbulk)

- Customs Declaration at Export Clearance (China)

- Sea Freight papuntang South Africa (Karaniwang 20–35 araw)

- Customs Clearance sa South Africa + Paghahatid

Mga Kinakailangang Dokumento

- Komersyal na Invoice

- Listahan ng Pag-iimpake

- Bill of Lading (B/L)

- Certificate of Origin (CO) (Ang tumpak na pag-uuri ng HS ay nagsisiguro ng wastong pagbabayad ng buwis at maayos na customs clearance upang maiwasan ang mga parusa.)

- Letter of credit o iba pang mga tuntunin sa pagbabayad (depende sa kontrata sa pagitan ng mga kasangkot na partido)

- Air waybill (para sa air freight) o sea waybill (para sa sea freight)

| Paraan ng Pagpapadala | Angkop na Cargo | Tinatayang Oras ng Pagbiyahe (China → South Africa) | Mga Pangunahing Tampok |

|---|---|---|---|

| FCL (Buong Container Load) | Kumpletong mga overhead crane (pangunahing girder, end beam, hoists, atbp.) | 22–30 araw | Karamihan sa cost-effective, selyadong at independiyenteng transportasyon, ligtas at matatag, perpekto para sa maramihang kagamitan |

| LCL (Mas mababa sa Container Load) | Maliit na batch ng kagamitan o indibidwal na bahagi | 25–35 araw | Ang mas mababang halaga, nangangailangan ng pagbabahagi ng mga lalagyan sa iba pang kargamento, ay maaaring may kasamang karagdagang paghawak at oras ng customs clearance |

| Panghimpapawid na Kargamento | Apurahang kritikal na bahagi o medium-sized na bahagi | 5–7 araw | Pinakamabilis na opsyon, mas mataas na gastos, na angkop para sa agarang paghahatid |

| POL (Port of Loading) | POD (Port of Discharge) | Tinatayang Oras ng Pagbiyahe (Mga Araw) |

|---|---|---|

| Shanghai | Durban | 24 |

| Shanghai | Cape Town | 27 |

| Shenzhen | Durban | 22 |

| Shenzhen | Cape Town | 25 |

| Qingdao | Durban | 26 |

| Qingdao | Cape Town | 30 |

Mga Tungkulin sa Pag-import at Buwis para sa mga Overhead Crane sa South Africa

Tungkulin sa Customs. Ang mga overhead crane ay karaniwang inuri sa ilalim ng HS Code 84261100. Ang base duty rate ay karaniwang 0%–10%, ngunit ang ilang mga configuration o steel-intensive na modelo ay maaaring mahulog sa mas matataas na bracket. Ang mga anti-dumping o safeguard duty ay maaari ding ilapat sa mga partikular na import.

Value-Added Tax (VAT). Ang isang flat 15% VAT ay sinisingil sa kabuuang halaga ng landed (CIF + duty). Ito ang pinakamalaking bahagi ng buwis para sa karamihan ng mga pag-import ng crane.

Mga Bayarin sa Pagproseso ng Pag-import at Mga Bayad sa Port. Ang mga daungan sa Timog Aprika gaya ng Durban at Cape Town ay nagpapataw ng mga bayarin sa paghawak, pag-iimbak, at pangangasiwa ng terminal, na maaaring makadagdag nang malaki sa gastos sa landed.

Mga Gastos sa Customs Brokerage at Pagsunod. Ang mga importer ay madalas na umaasa sa mga lokal na lisensyadong customs broker para mag-navigate sa pagpaparehistro ng DA185, ITAC permit (kung naaangkop), at SARS inspeksyon. Nag-iiba ang mga bayarin ayon sa laki at pagiging kumplikado ng kargamento.

Mga Karagdagang Panganib at Surcharge. Ang mga pag-import ay maaaring maharap sa mga surcharge ng congestion, mga bayarin sa demurrage (kung naantala ang clearance), at mga premium ng insurance, lalo na para sa malalaking bahagi ng crane na dinadala sa pamamagitan ng open-top o flat-rack na mga lalagyan.

Dafang Crane Overhead Crane Projects sa South Africa

Batay sa nakaraang pangkalahatang-ideya ng proseso ng pag-import at mga solusyon sa pagpapadala para sa mga overhead crane mula China hanggang South Africa, babalik na tayo sa real-world case study ng mga proyekto ng Dafang Crane sa South African market. Itinatampok ng mga halimbawang ito kung paano umaangkop ang Dafang Cranes sa mga kondisyon ng lokal na industriya—gaya ng pagmimina, produksyon ng bakal, at imprastraktura—habang tinitiyak ang maaasahang pagganap, kahusayan sa gastos, at pagsunod sa mga pamantayan sa pagpapatakbo ng South Africa.

5 Ton LX Overhead Crane na Ini-export sa South Africa

- Aplikasyon: Ginamit sa isang bodega ng sakahan.

- Kayang buhatin: 5 tonelada (isang uri ng LX) + 10 tonelada (isang uri ng LX)

- Pag-angat ng taas: 6 m at 9 m

- Span: 13.1 m (0.75 + 0.75 m) at 13 m (1 + 1 m)

- Gumaganang boltahe: 400V / 50Hz / 3-phase

10 Ton HD Overhead Crane na Na-export sa South Africa

- Aplikasyon: Low-headroom workshop sa South Africa (bodega ng sakahan / panloob na pasilidad na may limitadong taas)

- Kayang buhatin: 10 tonelada (isang HD type overhead crane, walang main beam)

- Pag-angat ng taas: 8 metro

- Span: 15 metro

- Gumaganang boltahe: 400V / 50Hz / 3-phase

- Uri ng hoist: NR European-type na wire rope hoist na may mababang disenyo ng headroom.

25 Ton QDX Overhead Crane na Ini-export sa South Africa

- Application: Mga operasyon sa pagmamanupaktura at logistik ng mabibigat na kagamitan sa South Africa Kapasidad ng pag-angat: 25 tonelada (isang uri ng QDX na double girder overhead crane + istraktura ng bakal)

- Taas ng pag-aangat: 11 metroSpan: 15 metro

- Gumaganang boltahe: 380V / 50Hz / 3-phase

- Control mode: Intelligent electrical control system na may remote monitoring at fault diagnostics.

Dafang Crane Service Assurance para sa South Africa

Hindi lang kami isang crane exporter—kami ang iyong maaasahang kasosyo sa bawat yugto ng lifecycle ng iyong overhead crane sa South Africa. Bilang isang pinagkakatiwalaang tagapagbigay ng crane sa rehiyon, naghahatid ang Dafang Crane ng propesyonal na suporta mula sa disenyo at pag-install ng proyekto hanggang sa pangmatagalang pagpapanatili at pag-upgrade.

- Pagpapanatili

Isinasaalang-alang ang mainit na klima ng South Africa, baybayin ng hangin na puno ng asin, at maalikabok na mga kapaligiran sa pagmimina, nagbibigay kami ng mga iniangkop na alituntunin sa pagpapanatili na sumasaklaw sa proteksyon laban sa kaagnasan, katatagan ng kuryente sa ilalim ng mga pagbabago sa boltahe, at regular na mga inspeksyon sa kaligtasan upang mapanatiling maaasahang gumagana ang mga crane sa malupit na mga kondisyon. - Supply ng Spare Parts

Upang mabawasan ang downtime, tinitiyak namin ang napapanahong paghahatid ng mga kritikal na bahagi. Ang mga ekstrang bahagi ay inihanda batay sa mga modelo ng crane na ibinibigay sa South Africa, na may mga logistics channel sa pamamagitan ng mga pangunahing daungan tulad ng Durban at Cape Town para sa mas mabilis na pag-access. - Suporta sa Pagsasanay

Upang matugunan ang mga pangangailangan ng lokal na manggagawa, ang Dafang Crane ay nagbibigay ng mga manwal sa wikang Ingles at mga on-site/virtual na sesyon ng pagsasanay, na tinitiyak ang ligtas at mahusay na operasyon ng crane sa mga industriya tulad ng pagmimina, bakal, at konstruksiyon. - Teknikal na Suporta

Nag-aalok ang aming ekspertong koponan ng agarang tulong sa malayuang video at nakikipagtulungan sa mga lokal na kasosyo sa serbisyo ng South Africa upang magbigay ng on-site na pag-troubleshoot, na binabawasan ang mga pagkaantala na dulot ng downtime ng kagamitan.

Nangungunang 10 Overhead Crane Manufacturers sa South Africa

Para sa mga mamimili na nag-e-explore sa South African bridge crane market, maraming lokal na tagagawa ang maaaring magsilbing mga kapaki-pakinabang na sanggunian. Sinisimulan ng maraming negosyo ang kanilang paghahanap gamit ang mga query tulad ng "mga tagagawa ng overhead crane na malapit sa akin", naghahanap ng mga kalapit na supplier na makakapagbigay ng mas mabilis na serbisyo pagkatapos ng benta at matiyak ang pagsunod sa mga lokal na regulasyon. Ang sumusunod na sampung kumpanya sa South Africa ay kumakatawan sa mga pangunahing lokal na manlalaro na dapat isaalang-alang:

- Morris

- Pro Crane

- RGM Cranes

- Stahl Cranes and Hoists (PTY) LTD

- JGS Lifting

- Condra Cranes &Hoists

- UpworX

- MGA WORLDHOIST

- SA CRANES AND HOISTS (PTY) LTD

- Charco Cranes

Ang mga overhead crane company na ito sa South Africa, pangunahing nakabase sa Johannesburg, Durban, at Cape Town, ay nag-aalok ng hanay ng lifting capacities para sa industriya ng pagmimina, bakal, at konstruksiyon, habang nagbibigay ng mas mabilis at mas lokal na serbisyo.

- Mga kalamangan ng mga lokal na tagagawa: maginhawang serbisyo pagkatapos ng benta, pamilyar sa mga regulasyon at pamantayan ng South Africa, at makapaghatid ng mga nakasanayang kagamitan nang mas mabilis.

- Ang mga bentahe sa pag-export ng China: advanced na teknolohiya, kumpletong mga uri ng produkto (na sumasaklaw mula sa 1 toneladang electric hoist hanggang 500 toneladang heavy bridge crane), at sa mga tuntunin ng intelligent control, anti-corrosion at weather resistance, mababang disenyo ng headroom, atbp., ay higit na naaayon sa mga pinakabagong internasyonal na pamantayan. Sa mature na karanasan sa pag-export at full-process na logistics at customs clearance na suporta, na ginawa sa China ay makakapagbigay sa mga customer ng South Africa ng mas mataas na antas ng mga customized na solusyon at maaasahang mga garantiya sa paghahatid.

Mas gusto ng ilang mamimili ang mga lokal na tagagawa para sa agarang pagtugon sa serbisyo, habang ang iba ay direktang nag-import mula sa China upang makinabang mula sa pagtitipid sa gastos at mas mataas na pag-customize. Ang pag-unawa sa parehong lokal at internasyonal na mga opsyon ay tumutulong sa mga negosyo sa South Africa na gumawa ng mas mahusay na mga desisyon sa pagkuha at mabawasan ang mga panganib sa pagpapatakbo.

Kung naghahanap ka ng mga overhead crane na matipid sa gastos na iniayon sa mga kondisyon sa pagtatrabaho sa South Africa, makipag-ugnayan sa Dafang Crane para sa pinakabagong quotation at customized na mga solusyon.

Ipadala ang Iyong Pagtatanong

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Idagdag: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat