Mga Pangunahing Bahagi ng AGV Transfer Carts para sa Matibay at Mahusay na Pagganap

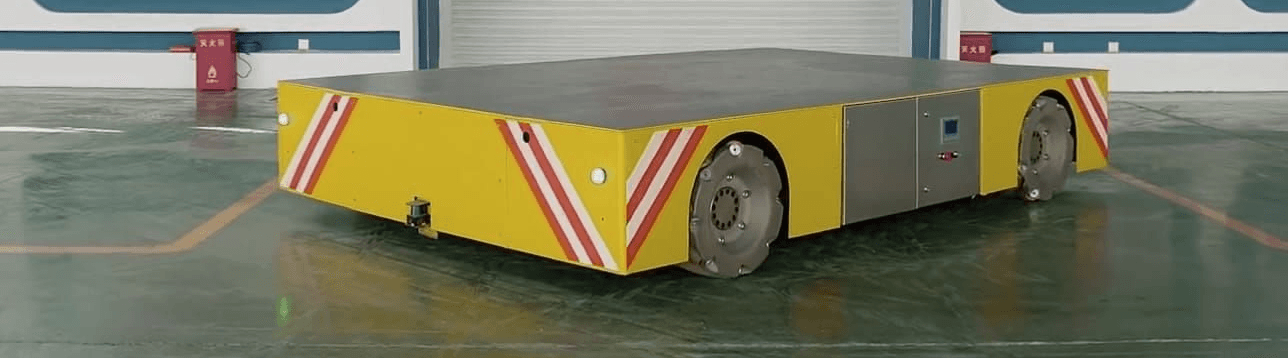

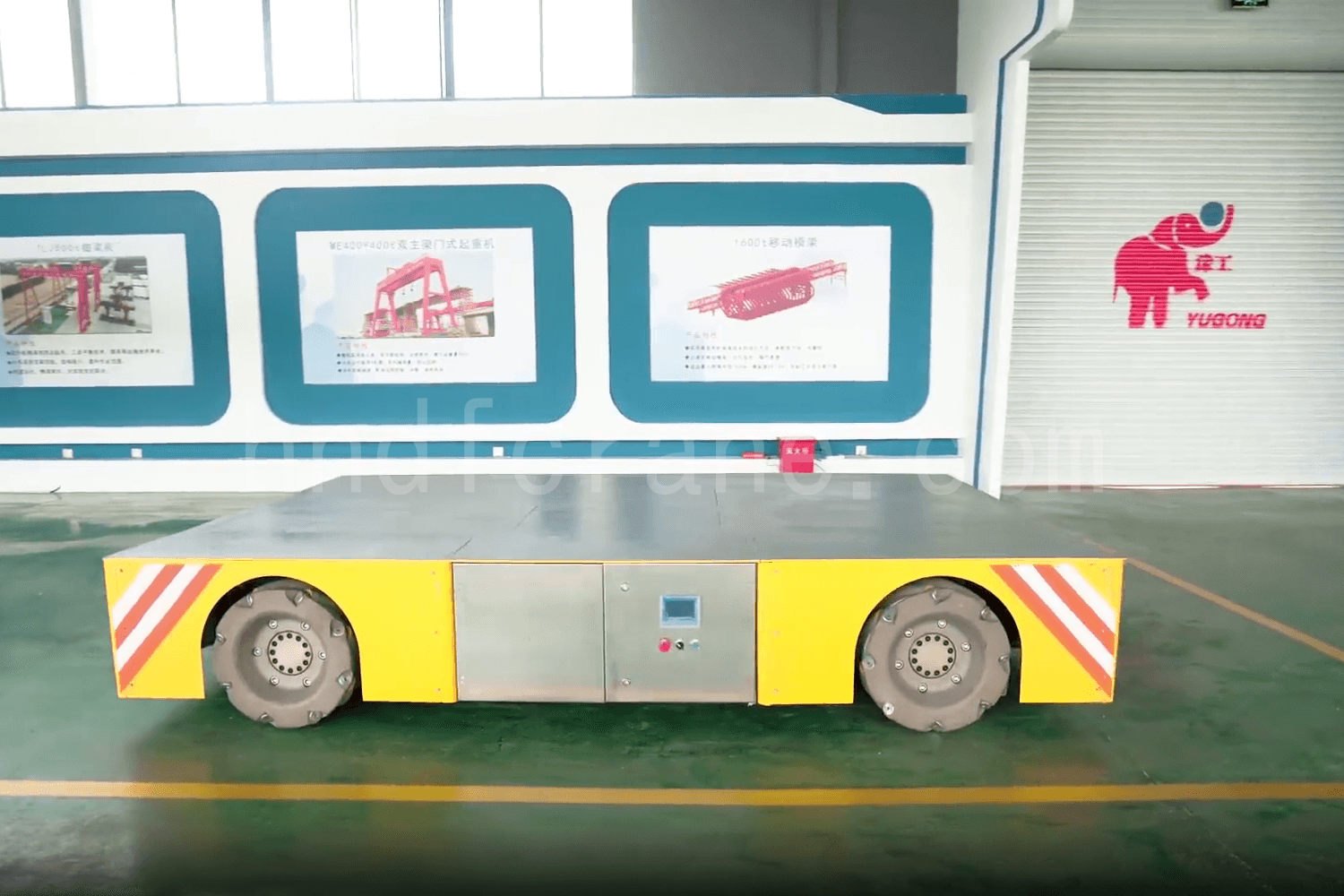

Frame

- Box-type na istraktura para sa mataas na lakas at mahabang buhay ng serbisyo.

Sistema ng Pagpipiloto

- Pinagsamang drive motor, drive reducer, steering motor, at steering reducer sa isang compact na disenyo.

- Pinapagana ang tumpak, naka-synchronize na paggalaw—perpekto para sa mabibigat na pagkarga at mataas na katumpakan na pagpoposisyon.

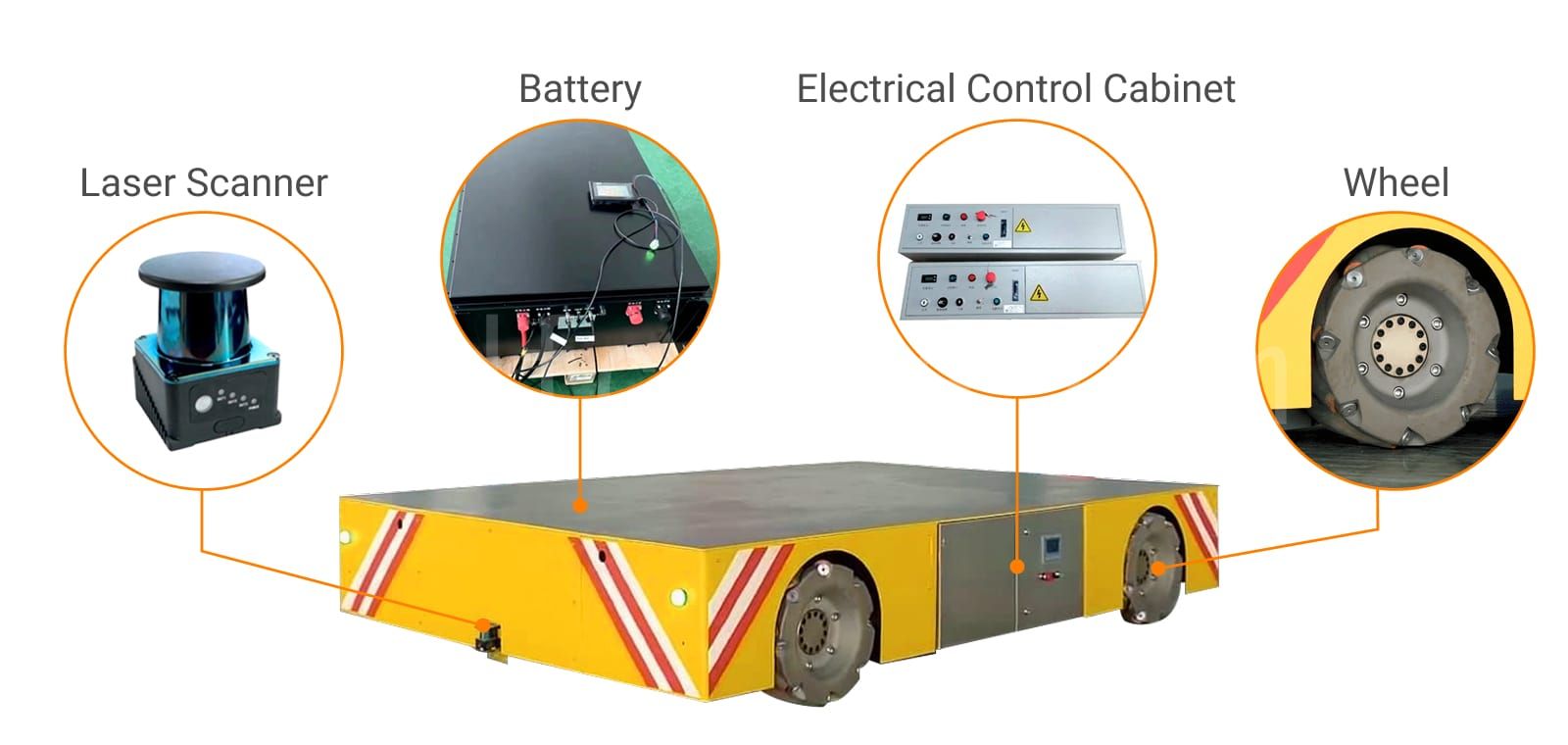

Mga Gulong ng Mecanum

- Mga gulong ng mecanum para sa omnidirectional na paggalaw: pasulong, lateral, dayagonal, pag-ikot, at mga kumbinasyon.

- Angkop para sa makitid na espasyo at masikip na operating aisles.

Baterya

- Opsyonal na lead-acid o lithium na baterya.

- Lead-acid: mababang gastos, mas mahabang oras ng pagsingil, mas maikling habang-buhay.

- Lithium: mataas na density ng enerhiya, mahabang buhay, mabilis na pagsingil, mas mataas na gastos.

HMI (Human-Machine Interface)

- Real-time na pagpapakita ng katayuan at mga parameter.

- Intuitive na operasyon para sa mas mahusay na pamamahala.

Kabinet ng Pagkontrol ng Elektrisidad

- Nilagyan ng touchscreen, mga ilaw ng status, at pangunahing switch ng kuryente.

- Sinusuportahan ang komunikasyon sa mga upper-level system para sa madaling pagsasama at remote na pamamahala.

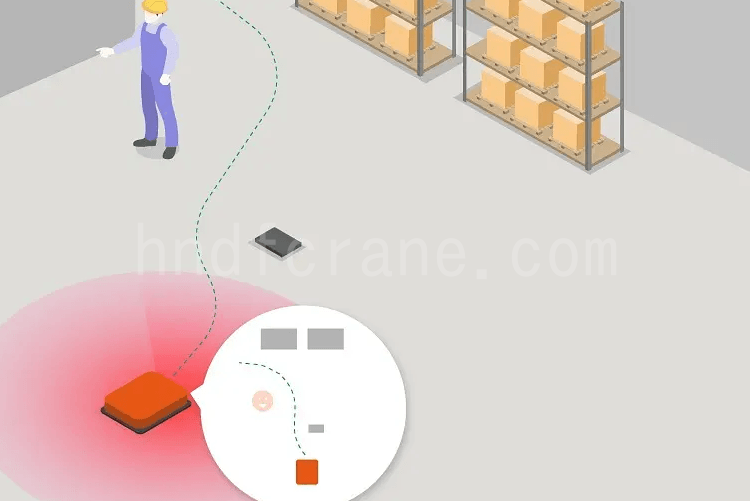

Laser Scanner

- Patuloy na sinusuri ang ruta para sa awtomatikong pag-iwas sa balakid.

- Awtomatikong humihinto para sa mga tao o bagay upang matiyak ang kaligtasan.

Malayong A/O Station

- Wireless command transmission.

- Pinapagana ang matalinong pagpapadala at pinapahusay ang kahusayan sa transportasyon.

Advanced at Maaasahang Control System

Ang control system ng AGV transfer cart ay binubuo ng tatlong pangunahing bahagi. Gumagana ang mga layer na ito sa koordinasyon upang paganahin ang autonomous navigation, pagsasagawa ng gawain, at malayuang pag-iiskedyul.

Onboard Control System

Ang system na ito ay isinama sa AGV trolley body at may kasamang mga pangunahing bahagi tulad ng traction motor, motor driver, at PLC controller. Kabilang sa mga pangunahing pag-andar nito ang:

- Pagkontrol sa mga pangunahing gawi ng paggalaw ng AGV (pagsisimula, paghinto, pagpipiloto, regulasyon ng bilis, atbp.).

- Pinoproseso ang mga input ng sensor at pagsasagawa ng kaukulang mga aksyong lohika.

- Pagtanggap ng mga utos mula sa supervisory system at pagpapadala ng operational status.

Tinitiyak ng system na ito ang pangunahing kontrol, mga tugon sa kaligtasan, at pakikipag-ugnayan ng signal sa panahon ng operasyon. Ito ay nagsisilbing execution core ng buong control architecture.

Wireless na Sistema ng Komunikasyon

Binubuo ng maraming wireless access point (AP) na naka-deploy sa daanan ng pagpapatakbo, pinangangasiwaan ng system na ito ang pagpapadala ng signal sa pagitan ng AGV transfer cart at ng supervisory system.

- Nagtatatag ng isang matatag na link sa komunikasyon ng data.

- Pinapagana ang real-time na bidirectional na paghahatid ng mga control command, mga update sa status, at data ng gawain.

- Sinusuportahan ang sabay-sabay na operasyon ng maraming AGV transfer cart habang iniiwasan ang mga salungatan sa signal.

Ang sistema ng komunikasyon na ito ay nagsisilbing tulay ng impormasyon sa pagitan ng upper at lower layer, na tinitiyak ang tumpak at napapanahong pag-iiskedyul.

Supervisory Control System

Itinayo sa isang central PLC o industrial-grade host computer, pinamamahalaan ng system na ito ang koordinasyon ng gawain at pag-iiskedyul ng ruta para sa maraming AGV trolley. Kabilang sa mga pangunahing pag-andar ang:

- Pinoproseso ang mga signal ng pagpapatakbo at feedback sa status mula sa mga troli ng AGV.

- Pagpapadala ng mga gawain sa bawat AGV transfer cart batay sa mga tagubilin sa produksyon mula sa mas mataas na antas ng mga system (hal., MES, WMS).

- Pagsubaybay sa katayuan ng sasakyan sa real time upang maiwasan ang mga salungatan sa ruta at paganahin ang mga collaborative na operasyon.

Ang sistemang ito ay lubos na nababaluktot at matalino, na may kakayahang isama sa pangkalahatang imprastraktura ng automation ng enterprise. Ito ay nagsisilbing isang kritikal na hub para sa pagpapagana ng matalinong logistik sa mga pabrika.

Flexible Navigation System

Ang sistema ng nabigasyon ay isang pangunahing teknolohiya na nagsisiguro ng mahusay na operasyon ng mga AGV transfer cart. Nag-aalok kami ng iba't ibang mature at maaasahang paraan ng nabigasyon upang umangkop sa iba't ibang kapaligirang pang-industriya at mga kinakailangan ng user.

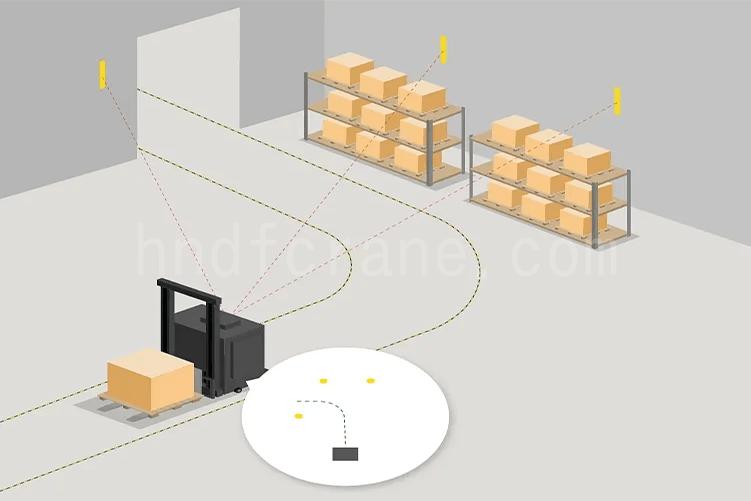

Natural na Pag-navigate

Ang pamamaraang ito ay gumagamit ng mga sensor ng laser upang i-scan ang nakapalibot na kapaligiran at bumuo ng isang mapa. Patuloy na ikinukumpara ng system ang real-time na posisyon ng AGV sa nakaimbak na mapa upang makamit ang tumpak na localization at navigation. Walang karagdagang imprastraktura sa lupa ang kinakailangan, na ginagawang simple ang pag-install at nagbibigay-daan para sa flexible na pagruruta.

Mga kalamangan:

- Walang kailangan ng auxiliary hardware, na nagreresulta sa mababang gastos sa pag-deploy.

- Lubhang nababaluktot ang mga ruta, madaling ibagay sa mga dynamic at kumplikadong kapaligiran.

- Angkop para sa malalaking operasyon, madalas na pagbabago ng mga gawain, at pakikipagtulungan sa maraming AGV transfer cart.

Mga Limitasyon:

- Nangangailangan ng mga advanced na algorithm at tumpak na pagbuo ng mapa.

- Mas tumatagal ang paunang pag-debug at pag-setup.

Magnetic Navigation

Ang mga magnetic strip ay inilalagay sa sahig, at ang AGV transfer cart ay sumusunod sa landas sa pamamagitan ng pag-detect ng mga magnetic signal upang matukoy ang mga ruta at mga posisyon ng istasyon.

Mga kalamangan:

- Matatag na nabigasyon na may tumpak na pagpoposisyon.

- Mababang gastos para sa mga pagbabago sa ruta, perpekto para sa mga operasyon ng fixed-path.

Mga Limitasyon:

- Ang mga magnetic strip ay madaling masira o masira at nangangailangan ng regular na pagpapanatili.

- Ang AGV transfer cart ay limitado sa magnetic path, walang intelligent na pagsasaayos ng path at flexible na pag-iwas sa balakid.

Laser Navigation

Gumagamit ang AGV transfer cart ng mga laser scanner upang makita ang mga paunang naka-install na reflector, na nagpapagana ng tumpak na lokalisasyon at nabigasyon.

Mga kalamangan:

- Mataas na katumpakan, na may mga error na kinokontrol sa loob ng hanay ng milimetro.

- Mababang maintenance at flexible na pagruruta.

Mga Limitasyon:

- Sensitibo sa mga kondisyon ng pag-iilaw at pagmuni-muni sa lupa.

- Mas mataas na pamumuhunan sa paunang kagamitan.

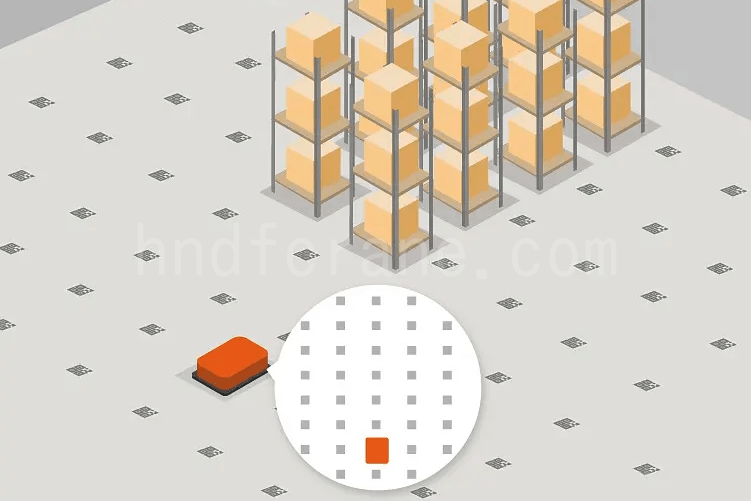

QR Code Navigation

Tinutukoy ng AGV transfer cart ang mga pre-set na QR code label sa sahig para sa tumpak na pagpoposisyon at kontrol sa landas.

Mga kalamangan:

- Madaling pag-install na may mataas na katumpakan ng pagpoposisyon.

- Mabilis na mapalitan ang mga ruta, na sumusuporta sa mga nababagong linya ng produksyon.

Mga Limitasyon:

- Ang mga QR code ay madaling ma-contaminate o masira at nangangailangan ng regular na inspeksyon at pagpapalit.

- Hindi angkop para sa mga kapaligiran kung saan ang sahig ay maaaring madalas na nakaharang.

Malawak na Application ng AGV Transfer Carts

Ang mga transfer cart ng AGV ay malawakang ginagamit sa iba't ibang industriya gaya ng warehousing at logistics, manufacturing, healthcare at mga sektor ng kemikal, mga port at terminal, gayundin sa mga mapanganib at espesyal na kapaligiran. Epektibo nilang natutugunan ang mga pangangailangan ng matalinong paghawak at awtomatikong transportasyon sa magkakaibang mga sitwasyon.

Aplikasyon sa mga Ospital

Sa mga modernong matalinong ospital, ang mga transfer cart ng AGV ay nagsasagawa ng malawak na hanay ng mga gawain sa transportasyon kabilang ang paghahatid ng mga pagkain ng pasyente, paglalaba, basurang medikal, mga sterilized na item, at mga gamot.

Mga Pangunahing Pag-andar:

- Paglipat ng materyal sa pagitan ng mga ward, parmasya, at iba pang mga departamento ng ospital.

- Cross-floor at cross-building na transportasyon nang walang manu-manong interbensyon.

- Awtomatikong pagpaplano ng landas at nababaluktot na pag-iwas sa mga hadlang, na nagbibigay-daan sa tumpak na pag-navigate kahit sa mga kumplikadong kapaligiran tulad ng mga parmasya o mga bulwagan ng masikip na outpatient.

Mga kalamangan:

- Pinahuhusay ang kahusayan sa transportasyon na may bilis na hanggang 1.5 m/s.

- Binabawasan ang direktang pakikipag-ugnayan ng tao sa mga nakakahawa o kontaminadong bagay, na binabawasan ang panganib ng cross-infection.

- Sinusuportahan ang 24/7 na tuluy-tuloy na operasyon na may mga kakayahan sa awtomatikong pag-charge, pagpapabuti ng pangkalahatang pagiging maaasahan.

- Binabawasan ang mga gastos sa paggawa at ino-optimize ang internal logistics system ng ospital.

Mga Aplikasyon sa Mga Port at Terminal

Sa mga port environment, ang mga AGV transfer cart ay pangunahing ginagamit para sa automated horizontal transport ng mga container, connecting quay crane, container yards, at mga kasunod na transfer channel upang mapahusay ang kahusayan sa paghawak ng port.

Mga Pangunahing Pag-andar:

- Automated container transport sa pagitan ng quay crane at storage yards.

- Pag-reposition at paglipat ng lalagyan sa maikling distansya.

- Transportasyon sa pagitan ng mga storage yard at rail o truck loading zones.

Mga kalamangan:

- Walang driver na operasyon na may mataas na kahusayan, na angkop para sa mataas na intensity, sa buong orasan na mga operasyon sa port.

- Multi-vehicle coordination sa pamamagitan ng sentralisadong pag-iiskedyul para maiwasan ang mga salungatan sa trapiko.

- Binabawasan ang mga carbon emissions at sinusuportahan ang pagbuo ng matalino at berdeng mga port.

Mga Application sa Warehousing at Logistics

Ang mga AGV transfer cart ay nagsisilbing pangunahing kagamitan para sa automated na paghawak ng materyal sa mga kapaligiran ng warehouse, na nagbibigay-daan sa mga ganap na hindi pinapatakbong operasyon mula sa papasok hanggang sa papalabas na mga proseso.

Mga Pangunahing Pag-andar:

- Pinapalitan ang mga manual na forklift para sa pagtanggap, pag-uuri, muling pagdadagdag, at pagpapadala.

- Hinahawakan ang mga pallet, bin, at iba pang medium hanggang malalaking bagay.

- Kumokonekta sa mga linya ng conveyor, racking system, at elevator para sa mga awtomatikong paglilipat sa pagitan ng mga lugar.

- Walang putol na isinasama sa mga WMS system upang paganahin ang mga naka-synchronize na operasyon ng warehouse.

Mga kalamangan:

- Pinapahusay ang kahusayan sa pagpapatakbo at pinapahusay ang katumpakan ng pagpili, paghawak, at paglo-load.

- Binabawasan ang labor intensity at pinapalakas ang antas ng automation ng warehouse.