Tie Rod Free Standing Jib Cranes with I-Beam Product Introduction

The tie rod free standing jib cranes with I-beam achieves a perfect synergy of maximum ROI and engineering efficiency through its ingenious triangular load-distribution design. Unlike free standing jib cranes and cantilevered models that require heavy-duty reinforcement to counteract bending moments, this model utilizes a tie-rod to share the load, allowing for a lighter I-beam and reduced torque on the pillar bearings, which significantly slashes material costs.

Furthermore, tie rod free standing jib cranes with I-beam are usually suitable for simple object hoisting and handling, and are used in some smaller places or workspaces. The tie rod free standing jib cranes with I-beam operation are relatively simple, and work tasks can be completed quickly through manual adjustment; operators can not only fine-tune the beam’s levelness via the tie-rod bolts but also enjoy smooth 270° manual rotation thanks to high-performance bearings and an integrated braking device. However, tie rod free standing jib cranes with I-beam should note that safe operation must be ensured when using cantilever cranes, and relevant safety specifications and operating requirements must be followed.

Tie Rod Free Standing Jib Cranes with I-Beam Features

- Smooth Rotational Movement: Rolling bearings integrated into the rotating assembly reduce rotational resistance, ensuring steady boom movement and precise load positioning.

- Multiple Trolley Configurations: Supports manual push, geared, or electric trolley options; all models are supplied complete with integrated power lines.

- Adjustable Leveling System: The tie-rod system allows for fine-tuning of the boom’s levelness via bolt adjustments, ensuring an accurate and consistent hoisting path.

- Structural Advantage for Long Spans: The tie-rod design effectively manages self-weight over extended reaches, maintaining structural stability for large working radii and long-span applications.

- Reliable Manoeuvrability & Safety: Optimized mechanical design enhances operational flexibility while meeting rigorous industrial safety and productivity standards.

- Reduced Maintenance Requirements: The intuitive and rugged design minimizes the number of complex moving parts, helping to lower routine maintenance frequency and operational costs.

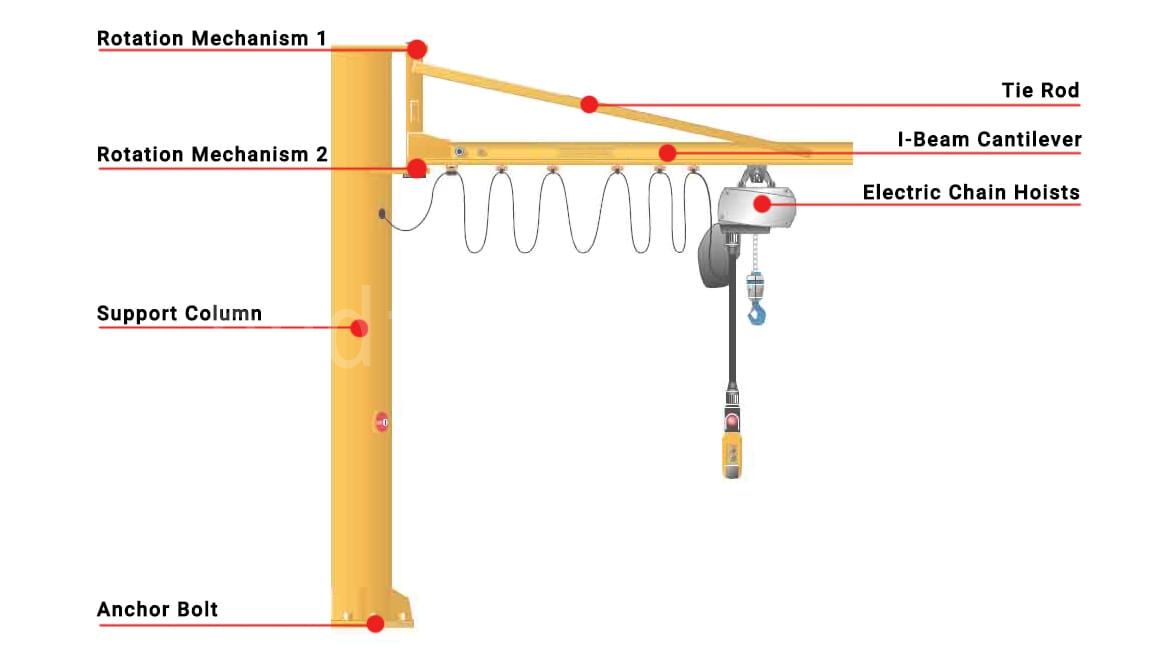

Tie Rod Free Standing Jib Cranes with I-Beam Structural Composition

Mekanisme Rotasi

The tie rod free standing jib cranes with I-beam rotation mechanism features two support points on the pillar: the beam root (lower) and the tie-rod head (upper). Both points integrate high-performance rolling bearings within sealed housings to ensure dust protection and grease containment. With minimal friction, the operator only needs to manually pull the load or tagline gently to swing the entire triangular assembly smoothly around the pillar. Due to the pillar’s position, the rotation range is typically limited to 270°.

Tie Rod

The tie-rod structure leverages the inherent stability of a triangular configuration and the principles of tensile and compressive stress distribution. By absorbing the majority of the tensile stress generated by the load, the tie-rod allows the I-beam to remain lightweight, eliminating the need for excessively thick steel to withstand bending moments. This engineering approach not only ensures sensitive tilting adjustment and trolley stability but also proves highly effective over long spans (e.g., 6–8 meters) by minimizing oscillation and end-deflection at the tip of the boom.

I-Beam Cantilever

The I-beam structure provides a higher load capacity, supporting larger tonnages (up to 2,000kg) and longer boom lengths (up to 8m). Its lower flange is perfectly suited for installing electric travel trolleys, whereas enclosed C-tracks are typically restricted to manual push and offer a smaller load capacity. Furthermore, because the track is completely exposed, cleaning and inspection are extremely convenient, greatly simplifying the maintenance process.

Kerek Rantai Listrik

Equipped with a running electric hoist to achieve lifting in the left, right and up and down directions. Manual trolley-type electric hoists are also more common. The hoists are electric for lifting, and the trolley moves left and right manually. The electric hoist can lift heavy objects and move vertically along the main beam.It is equipped with safety devices, such as lifting limit switches, end limit switches, etc.

Support Column

The columns are made of seamless round tubing. At one end it has a perforated base plate for anchoring to the base using chemical anchors or anchor rods, and at the other end two plates, a head plate and an intermediate plate, for supporting the boom.

Anchor Bolt

Standard modular components that can be freely combined and connected according to operational conditions and on-site requirements.

Tie Rod Free Standing Jib Cranes with I-Beam Applications

General Manufacturing & Industrial Workshops

This pillar jib cranes with I-beam is typically used in indoor workshops, production areas, and assembly stations for localized lifting, rotating, and precise positioning of materials. The crane is floor-mounted with a vertical column, and the I-beam jib is reinforced by a tie rod structure, allowing a wide working radius without relying on the building roof or overhead support. During operation, the electric hoist travels along the jib beam while the jib arm rotates around the column, enabling efficient movement of loads from storage areas to machining, assembly, or maintenance positions. It is commonly applied in machinery manufacturing, equipment maintenance, parts assembly, and general fabrication workshops where frequent short-distance lifting is required.

Metal Parts Machining & Assembly Industry

The tie rod free standing jib cranes with I-beam are mainly used in machining workshops and equipment maintenance stations for lifting and precise positioning of small to medium-sized metal parts, mechanical components, tooling fixtures, and molds within a fixed working area. The crane is mounted on an independent column, allowing it to serve individual or adjacent workstations. During operation, the electric hoist travels smoothly along the I-beam jib, while the jib arm rotates around the column to enable short-distance material handling between machine tools, workbenches, and surrounding equipment. The tie rod free standing jib cranes with I-beam are commonly applied in machine loading and unloading, parts assembly, maintenance operations, mold changeover, and tooling adjustment, effectively reducing manual handling effort while improving operational safety and on-site efficiency.

Automated Production Lines and Assembly Workshops

Tie rod free standing jib cranes with I-beam are typically used in automated production lines and assembly workshops, where precise and frequent lifting of components or tooling is required. The jib crane features a compact design and is installed alongside production equipment, providing localized lifting coverage without interfering with the production layout. During operation, the electric hoist moves smoothly along the I-beam jib, while the jib arm rotates around the column to support tasks such as equipment installation, component replacement, tooling adjustment, and assisted assembly, making it well-suited for space-limited environments with high positioning accuracy requirements.