Utangulizi wa Bidhaa

Kreni ya Stacker, ambayo pia inajulikana kama stacker, ni mojawapo ya mifumo muhimu zaidi ya kuinua na kushughulikia nyenzo katika mfumo wa kuhifadhi na kurejesha kiotomatiki (AS/RS). Pia ni kifaa muhimu kinachowakilisha sifa kuu za ghala la kiotomatiki.

Kulingana na muundo wa kimuundo na hali ya uendeshaji, kreni za stacker zimegawanywa katika aina mbili: kreni za stacker za pallet na kreni za stacker za juu (aina ya daraja), na kuziwezesha kukidhi mahitaji ya mizani tofauti ya ghala na mifumo ya uendeshaji.

Kazi kuu ya kreni ya stacker ni kusafiri na kurudi ndani ya njia za ghala au katika njia nyingi, kuhifadhi kwa usahihi bidhaa kutoka kwa njia ya kuingilia kwenye sehemu zilizotengwa za raki, au kupata bidhaa haraka kutoka kwa raki za kuhifadhi na kuzipeleka kwenye sehemu ya kuingilia kwenye njia, na hivyo kufikia uhifadhi, urejeshaji, na utunzaji wa nyenzo kiotomatiki kwa ufanisi.

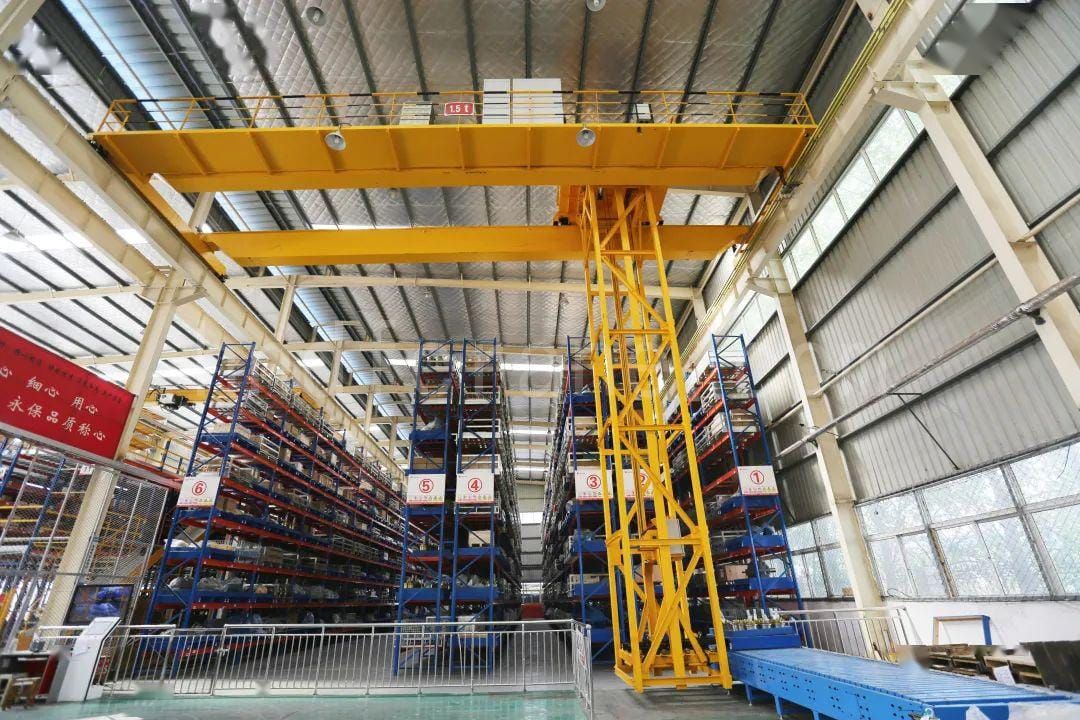

Crane ya Stacker ya Juu (aina ya daraja)

Vigezo

- Uwezo wa Kuinua: tani 3 – tani 16

- Muda: mita 10 – mita 40

- Kuinua Urefu: mita 6 – mita 12

- Kasi ya Kuinua: 1.5 m/dakika – 15 m/dakika

- Kasi ya Kusafiri: 30 m/dakika – 60 m/dakika

- Darasa la Wajibu: A5 – A6

Faida

- Utumiaji wa Nafasi ya Juu: Huongeza matumizi ya urefu wa ghala, kuwezesha hifadhi ya kiwango cha juu na mnene, na kuongeza kwa kiasi kikubwa uwezo wa kuhifadhi kwa kila eneo la kitengo.

- Kubadilika kwa Nguvu: Inaweza kubinafsishwa kulingana na aina za godoro, mapipa ya mizigo, uwezo wa kubeba mizigo, na vipimo vya njia, kuhakikisha utangamano na vipimo mbalimbali vya mizigo.

- Usahihi wa Nafasi ya Juu: Imewekwa na viendeshi vya servo, visimbaji, na teknolojia za kuweka leza ili kuhakikisha utunzaji sahihi wa mzigo bila hitilafu kubwa ya kuweka.

- Ufanisi Ulioboreshwa wa Kuingia na Kutoka: Usafiri wa mlalo, kuinua wima, na upanuzi wa uma vinaweza kufanya kazi kwa wakati mmoja, kupunguza muda wa mzunguko kwa kila operesheni na kuboresha upitishaji wa jumla.

Mifumo Mitatu Mikuu Inayohakikisha Uendeshaji Unaotegemeka na Salama

- Mfumo wa Kreni: Inajumuisha mfumo wa kuweka kreni, mfumo wa kudhibiti dhidi ya kuyumbayumba, kiolesura cha binadamu na mashine (HMI), udhibiti wa mbali wa kreni, usanidi wa mtandao usiotumia waya, seva za nyuma, na mfumo mkuu wa udhibiti wa kreni.

- Mfumo wa Usimamizi wa Ghala: Inajumuisha mifumo ya usimamizi wa WCS na WMS, vifaa vya kuchanganua msimbopau, programu ya usimamizi wa ghala, mifumo ya ufuatiliaji wa video, mifumo ya mtandao wa waya na usiotumia waya, na violesura vya MES kwa ajili ya ujumuishaji wa mifumo ya uzalishaji.

- Mfumo wa Usalama na Onyo la Eneo la Ghala: Hushughulikia usimamizi wa usalama wa maeneo ya uendeshaji wa kreni, njia za watembea kwa miguu, na njia za magari, pamoja na taa za viashiria vya usalama, vifaa vya kengele, na uzio wa kutenganisha usalama kwa ajili ya ulinzi kamili.

Kreni ya Kuweka Pallet

Vipengele vya Kreni ya Stacker ya Pallet

- Njia za Udhibiti wa Umeme: Chaguo ni pamoja na uendeshaji wa mwongozo, nusu otomatiki, otomatiki inayojitegemea, au unaodhibitiwa na kompyuta. Hali yoyote moja inaweza kuchaguliwa kulingana na mahitaji.

- Udhibiti wa Kasi ya Masafa Yanayobadilika: Kreni nyingi za stacker hutumia viendeshi vya VFD na anwani ya fotoelectric, kutoa udhibiti wa kasi laini na usahihi wa juu wa kusimama.

- Ugavi Salama wa Nishati: Imewekwa na kifaa salama cha kusambaza umeme kinachoteleza ili kuhakikisha usambazaji wa umeme unaotegemeka.

- Ulinzi wa Usalama: Vifaa vya ulinzi dhidi ya kamba inayoweza kuteleza kupita kiasi na kamba zinazoweza kuvunjika vinatekelezwa ili kuhakikisha uendeshaji salama.

- Kabati la Opereta: Ina kibanda cha mwendeshaji kinachoweza kusongeshwa chenye vipini na vifungo vilivyopangwa kwa njia ya ergonomic, na muundo mzuri wa viti.

- Fremu Ngumu, Nyepesi: Fremu ya stacker ni nyepesi lakini inatoa kupinda kwa juu na ugumu wa msokoto. Reli za mwongozo za kuinua ni sahihi na hazichakai, na hivyo kuruhusu uwekaji sahihi.

- Uma za darubini: Punguza mahitaji ya upana wa njia na uboreshe matumizi ya jumla ya nafasi ya ghala.

Aina za Kreni ya Stacker ya Pallet

| Kipengee | Kreni ya Kuweka Pallet ya mlingoti mmoja | Kreni ya Kuweka Pallet ya Mlingoti Mbili |

| Ubunifu wa Muundo | Imeundwa na mlingoti mmoja, boriti ya juu, na boriti ya chini; muundo rahisi kiasi | Imeundwa na milingoti miwili, boriti ya juu, boriti ya chini, na behewa la kubebea mizigo, na kutengeneza fremu ya mstatili iliyofungwa |

| Uthabiti na Nguvu ya Fremu | Ugumu wa chini kiasi; upinzani mdogo kwa mizigo isiyo ya kawaida | Nguvu ya juu na ugumu wa jumla; upinzani mkubwa kwa mabadiliko |

| Uthabiti wa Uendeshaji | Utulivu wa wastani; mahitaji ya juu zaidi katika hali ya uendeshaji | Uendeshaji laini na mtetemo mdogo; inafaa kwa kuanza-kusimama na kusimama mara kwa mara |

| Utendaji wa Kuanza/Kusimamisha na Kuweka Breki | Utendaji wa kusimama na kuanzia kwa kuanzia na kusimama kwa breki unaodhibitiwa na muundo | Huwezesha kusimama kwa kasi na kusimama kwa breki kwa kiwango kikubwa cha usalama |

| Uwezo wa Kupakia Ufaao | Inafaa kwa mizigo midogo hadi ya kati; haipendekezwi kwa matumizi ya mizigo mizito | Inafaa kwa uwezo mkubwa wa kubeba mizigo |

| Ustahiki wa Kuinua Urefu | Inafaa kwa urefu wa chini hadi wa kati wa kuinua | Inafaa kwa maghala marefu ya kiotomatiki |

| Kasi ya Kusafiri ya Mlalo | Haifai kwa usafiri wa kasi ya juu mlalo | Uwezo wa kukidhi mahitaji ya kasi ya juu ya mlalo |

| Uzito wa Jumla | Uzito wa jumla mwepesi | Uzito zaidi kwa ujumla |

| Gharama ya Utengenezaji | Matumizi ya chini ya nyenzo na gharama ya utengenezaji | Matumizi ya juu ya nyenzo na gharama kubwa zaidi ya utengenezaji |

| Matumizi ya Kawaida | Maghala madogo hadi ya ukubwa wa kati yanayojiendesha yenyewe, yenye mzigo mdogo au ya gharama nafuu ya AS/RS | Ghala zenye sehemu kubwa, hifadhi nzito, mifumo ya hifadhi otomatiki ya kasi ya juu |

Mapendekezo ya Uteuzi wa Kreni ya Stacker

Zipe Kipaumbele Koreni za Stacker za Juu (Aina ya Daraja) Wakati:

- Kuna njia nyingi zenye viwango vya matumizi visivyo sawa

- Ni muhimu kupunguza idadi ya mashine na kuboresha unyumbufu wa ratiba kwa ujumla

- AS/RS ina urefu wa wastani wa kuinua na uwezo mdogo hadi wa kati wa kubeba mizigo

Toa Kipaumbele kwa Kreni za Pallet Stacker Wakati:

- Njia moja inahitaji upitishaji wa hali ya juu na utendaji madhubuti wa wakati wa mzunguko

- Urefu wa juu wa kuinua na uwezo mkubwa wa kubeba mizigo unahitajika

- Miradi inasisitiza uthabiti wa mfumo na teknolojia iliyothibitishwa na kukomaa

Kama vifaa vya msingi vya mfumo wa kuhifadhi na kurejesha kiotomatiki (AS/RS), kreni ya stacker ya ghala ina jukumu muhimu katika kuboresha matumizi ya nafasi, ufanisi wa uendeshaji, na usimamizi wa jumla wa ghala. Kulingana na mpangilio wa ghala, sifa za mizigo, na mahitaji ya uendeshaji, tunatoa suluhisho maalum za kreni ya stacker ili kuwasaidia wateja kujenga mifumo salama, bora, na endelevu ya ghala.