Cranes za Juu kwa Chakula na Vinywaji Utangulizi

Kwa kuendeshwa na mambo kama vile ongezeko la watu, masuala ya usalama wa chakula na vinywaji, maendeleo ya teknolojia ya kibayoteki, na ukuaji wa miji, sekta ya kimataifa ya chakula na vinywaji inazidi kushamiri. Sababu hizi zimesababisha kuongezeka kwa mahitaji ya tasnia ya washirika wa kuaminika na wanaokubalika wa vifaa vya kushughulikia maji. Dafang Crane inaelewa kuwa usalama wa chakula ni kipaumbele cha juu. Tunatoa aina mbalimbali za vifaa vya kuinua vinavyotumika katika sekta ya chakula na vinywaji ili kutatua mahitaji yako ya uhandisi na kufikia viwango vya juu zaidi vya usafi. Tunaweza kutoa suluhu za kushughulikia nyenzo ili kuboresha ufanisi, tija, na usalama wa utengenezaji, usindikaji, ufungashaji na vifaa vya usambazaji. Crane inayotumiwa sana ni crane safi ya chumba. Kuinua crane kawaida ni 1t hadi 10t.

Cranes za Juu za Uainishaji wa Chakula na Vinywaji

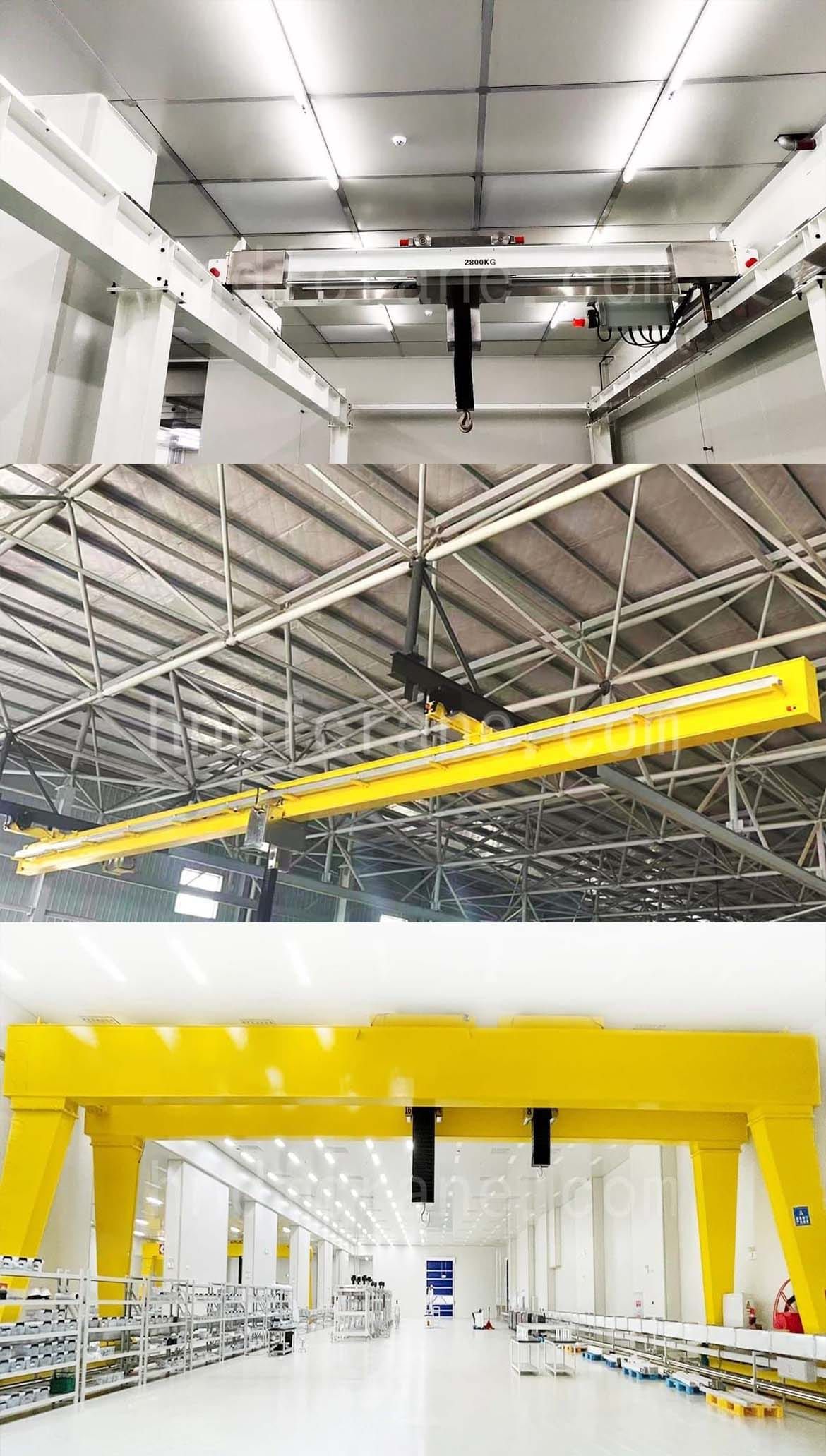

Cranes za Chumba cha Kusafisha

Korongo za chumba safi ni aina ya vifaa vya kunyanyua vilivyoundwa mahsusi kwa ajili ya kushughulikia nyenzo ndani ya vyumba vya usafi. Mazingira haya maalum ni safi sana, hayana vumbi, na yanadhibitiwa madhubuti ili kudumisha utasa. Katika tasnia kama vile chakula na vinywaji, ambapo usafi ni muhimu, Cranes za juu za Chakula na Vinywaji ni muhimu ili kuhakikisha shughuli zisizo na uchafuzi wakati wa kushughulikia, kupakia na kupakua nyenzo. Vifaa vya kawaida vya kunyanyua vinaweza kuleta uchafu kama vile vumbi na bakteria, kwa hivyo korongo zilizoundwa mahususi za chumba safi ni muhimu ili kukidhi masharti magumu ya usafi.

Maombi ya Cranes ya Cleanroom

Korongo za chumba safi hutumika sana katika vyumba vya usafi katika tasnia mbali mbali, pamoja na halvledare, vifaa vya elektroniki, na dawa. Kulingana na viwango vya usafi, korongo za chumba safi kwa ujumla zimeainishwa katika viwango kama vile Daraja la 100, Daraja la 1,000, Daraja la 10,000 na Daraja la 100,000. Darasa la 100 linahitaji usafi wa hali ya juu zaidi, ilhali Darasa la 100,000 lina mahitaji ya chini ya usafi. Kumbuka: Usafi unarejelea kiwango cha mkusanyiko wa chembe (pamoja na vijidudu) katika hewa safi.

- Darasa la 1: Hutumika kimsingi katika tasnia ya elektroniki ndogo kwa utengenezaji wa saketi zilizojumuishwa.

- Daraja la 10: Hutumika sana katika tasnia ya semiconductor kwa michakato yenye kipimo data kisichozidi mikromita 2.

- Darasa la 100: Kiwango kinachotumiwa zaidi, kinachofaa kwa michakato ya utengenezaji wa aseptic katika tasnia ya dawa na shughuli za upasuaji.

- Daraja la 1,000: Hutumika hasa kwa ajili ya utengenezaji wa bidhaa za hali ya juu za macho, na pia kwa ajili ya kupima na kuunganisha gyroscope za ndege na fani ndogo za ubora wa juu.

- Darasa la 10,000: Inatumika kwa mkusanyiko wa vifaa vya hydraulic au nyumatiki, na wakati mwingine, kwa tasnia ya chakula na vinywaji.

- Daraja la 100,000: Hutumika katika sekta nyingi za viwanda, kama vile utengenezaji wa bidhaa za macho, utengenezaji wa vijenzi vidogo vya mifumo mikubwa ya kielektroniki, mifumo ya majimaji au nyumatiki, na uzalishaji wa chakula na vinywaji.

Kesi za Cranes za Safi

Safi korongo za jib za chumba kwa viwanda vya dawa

Semi gantry clean room crane kwa warsha ya biopharmaceutical

Safi pandisha

Safi nyuzi za chumba na kiinua cha umeme

Katika uwanja wa biomedicine, vipandikizi vya umeme vya bendi ya nyuzi pia vina jukumu muhimu katika kuhakikisha mzunguko salama na bora wa malighafi tasa na bidhaa zilizokamilishwa ndani ya mazingira ya vyumba safi. Sawa na korongo za juu kwa chakula na vinywaji, vipandikizi hivi vimeundwa ili kupunguza hatari za uchafuzi huku vikidumisha viwango vya juu vya usafi na ufanisi wa kufanya kazi.

Faida

1. Nyenzo ya chini ya vumbi

Teo au kamba iliyotengenezwa kwa nyenzo maalum ya nyuzi kwa pandisho la umeme la ukanda wa nyuzi ina kiwango cha chini cha uzalishaji wa vumbi kuliko kamba ya jadi ya waya au mnyororo. Nyenzo hii si rahisi tu kuzalisha vumbi yenyewe, lakini pia inaweza kupunguza kwa ufanisi chembe zinazozalishwa wakati wa kusugua na vitu vingine ndani ya chumba safi, na hivyo kudumisha usafi wa chumba safi.

2. Udhibiti sahihi wa kupunguza hatari ya uchafuzi wa mazingira

Kiingilio cha umeme kinachukua mfumo wa kiendeshi wa umeme, ambao hutambua kuinua laini, kushuka, na harakati za usawa za utunzaji wa nyenzo kwa kudhibiti kwa usahihi kasi na nguvu ya gari. Aina hii ya udhibiti sahihi sio tu inaboresha ufanisi wa uendeshaji lakini pia hupunguza hatari ya mgongano na uchafuzi wa mazingira unaoweza kusababishwa na uendeshaji usiofaa wa mwongozo, na huhakikishia zaidi mazingira safi ya chumba safi.

3.Rahisi kusafisha na kudumisha

Ubunifu wa pandisha la umeme la ukanda wa nyuzi huzingatia kikamilifu mahitaji ya matengenezo ya mazingira safi ya chumba. Uso wake ni laini na hauna ncha zisizokufa, na kuifanya iwe rahisi kutumia visafishaji na zana za kusafisha haraka na kamili. Wakati huo huo, muundo wake wa kompakt hufanya iwe rahisi kutenganisha na kuchukua nafasi ya sehemu, ambayo hupunguza ugumu na gharama ya matengenezo.

4. Upinzani wa kutu na kubadilika kwa nguvu

Kwa gesi za kemikali au vitu vya babuzi ambavyo vinaweza kuwepo katika vyumba safi, viunga vya umeme vya bendi ya nyuzi hutengenezwa kwa nyenzo zinazostahimili kutu ili kuhakikisha uendeshaji thabiti wa muda mrefu katika mazingira magumu na kupanua maisha ya huduma ya vifaa.

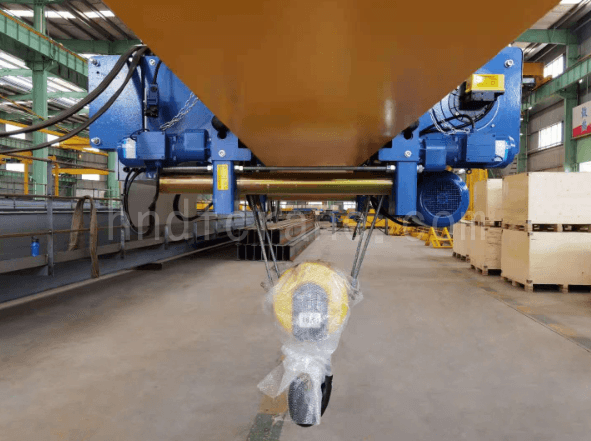

Safi pandisho la umeme la chumba

Wakati wa kusafirisha vitu vizito katika tasnia ya chakula, vinywaji na dawa, vifaa vya kunyanyua vilivyotumika visichafue chakula, vimiminika au dawa. Korongo za juu kwa ajili ya chakula na vinywaji lazima zifikie viwango vikali vya usafi ili kuhakikisha usalama katika kila hatua ya kushughulikia. Dafang Crane inaelewa changamoto hii na kuishughulikia kwa kutumia nyenzo za kiwango cha chakula ili kutoa masuluhisho ya kuinua yaliyo salama, yanayotegemeka na yasiyo na uchafuzi.

Faida

- Mafuta ya kiwango cha chakula

- Uwezo wa kubeba kilo 500-tani 2

- Urefu wa kawaida wa kuinua mita 3

- Breki iliyofeli-salama

- Mlolongo wa mzigo wa nikeli

- Kiwango cha ulinzi IP55

Muundo wa Pandisha

Chumba safi cha mnyororo wa pete usio na vumbi

Faida

1. Nyenzo za chuma cha pua

Chuma cha pua au vifaa maalum vya alloy hutumiwa kutengeneza minyororo na vipengele muhimu. Nyenzo hizi sio tu kuwa na upinzani bora wa kutu na upinzani wa kuvaa, lakini pia hupunguza kwa ufanisi umwagaji wa chembe na kuhakikisha kuwa mazingira ya chumba safi hayanajisi.

2.Mfumo wa lubrication usio na mafuta

Tumia vilainishi visivyo na mafuta au visivyo na tete kupunguza utepetevu na mabaki ya grisi za kulainisha na kuepuka uchafuzi wa hewa safi ya chumba. Wakati huo huo, boresha muundo wa lubrication, kupanua mzunguko wa lubrication, na kupunguza mzunguko wa matengenezo.

3.Imefungwa vizuri

Kuimarisha muhuri wa gourd, kuzuia vumbi vya nje kuingia kwenye utaratibu wa ndani, na pia kuzuia kuvuja kwa chembe zinazosababishwa na kuvaa kwa vipengele vya ndani. Kupitia muundo mzuri wa kuziba, inahakikishwa kuwa hoist haitoi uchafuzi wa ziada wakati wa operesheni.

4.Udhibiti wa kupambana na static

Kwa mahitaji fulani maalum, kama vile katika uwanja wa utengenezaji wa semicondukta, udhibiti wa kielektroniki wa pandisho la mnyororo wa pete pia unahitaji kuzingatiwa. Kwa kuongeza mipako ya conductive au kifaa cha kutuliza, mkusanyiko wa umeme wa tuli huondolewa kwa ufanisi na kutokwa kwa umeme huzuiwa kusababisha uharibifu wa vipengele nyeti.

Waya kamba vumbi bure pandisha umeme

Viingilio vya waya visivyo na vumbi, kama jina linavyopendekeza, ni aina ya vifaa vya kunyanyua vilivyoundwa mahsusi kwa ajili ya mazingira ya chumba safi. Zina vifaa vya hali ya juu na miundo ya miundo inayolenga kupunguza au hata kuondoa chembe za vumbi zinazozalishwa wakati wa operesheni, na hivyo kuhifadhi usafi na utasa wa mazingira. Aina hii ya pandisha haijaboreshwa kimitambo tu ili kupunguza msuguano na uchakavu kati ya sehemu zinazosogea lakini pia huangazia kamba za waya zilizotibiwa maalum—kama vile vilainishi maalum au matumizi ya nyenzo zisizo na vumbi zaidi—ili kupunguza zaidi uzalishaji wa chembe.

Katika tasnia kama vile biomedicine-na vile vile katika matumizi yanayohusisha korongo za juu kwa chakula na vinywaji-usafirishaji salama wa malighafi na bidhaa ndani ya mazingira tasa ni muhimu. Kwa kuanzisha viinua visivyo na vumbi vya waya, biashara haziwezi tu kuboresha ubora wa bidhaa lakini pia kupunguza kwa kiasi kikubwa kiwango cha urekebishaji na gharama za uzalishaji zinazohusiana na uchafuzi. Hii inafanya mifumo kama hiyo kuwa suluhisho bora sio tu kwa sekta ya dawa lakini pia kwa kampuni zinazotafuta viwango vya juu katika korongo za juu kwa chakula na vinywaji, na hatimaye kufikia faida za kiuchumi na kijamii.

Faida

1. Muundo wa vumbi wa chini kabisa

Kupitia teknolojia sahihi ya utengenezaji na uteuzi wa nyenzo, pandisha lisilo na vumbi la kamba ya waya haitoi vumbi wakati wa operesheni, na kudumisha kiwango cha usafi cha chumba safi.

2.Ufanisi na imara

Kamba za ubora wa juu na mifumo ya maambukizi ya usahihi hutumiwa ili kuhakikisha uendeshaji wa kuinua laini na sahihi, na uendeshaji salama unaweza kufanywa hata karibu na vyombo vya usahihi au bidhaa za thamani ya juu.

3.Rahisi kutunza

Muundo huo unazingatia urahisi wa matengenezo, kuwezesha kusafisha na matengenezo ya kila siku, na kupunguza gharama za chini na matengenezo.

4.Udhibiti wa akili

Baadhi ya miundo ya hali ya juu pia huunganisha mifumo mahiri ya udhibiti, ambayo inaweza kutambua utendaji kazi kama vile udhibiti wa mbali, ufuatiliaji wa upakiaji, na hitilafu ya onyo la mapema ili kuboresha ufanisi wa uzalishaji na usalama.

Crane Hydraulic Grabs

Unyakuzi huu wa majimaji, ulioundwa kwa ajili ya kunyakua kimchi na kachumbari, umetengenezwa kwa chuma cha pua cha ubora wa juu cha 304 ili kuhakikisha kwamba kiwango cha juu cha viwango vya usafi na uimara vinadumishwa wakati wa usindikaji wa chakula. 304 chuma cha pua sio tu hutoa upinzani bora wa kutu na inaweza kuhimili kwa ufanisi mmomonyoko unaosababishwa na asidi na chumvi, lakini pia hutoa nguvu kali ya mitambo ili kuhakikisha utulivu wa muda mrefu na uaminifu wa kunyakua. Hii huifanya ilingane sana na korongo za juu kwa chakula na vinywaji, ambazo zinahitaji viambatisho sawa vya usafi na thabiti kwa mazingira ya chumba safi.

Kunyakua kwa majimaji kuna mfumo wa hali ya juu wa kituo cha kusukumia majimaji, ukitoa usaidizi wa nguvu na thabiti ili kukamilisha kazi za kunyakua haraka na kwa usahihi. Mfumo huu wa ufanisi sio tu huongeza tija lakini pia hupunguza matumizi ya nishati na gharama za uendeshaji. Kama ilivyo kwa korongo za juu za chakula na vinywaji, udhibiti wa akili wa kunyakua huruhusu urekebishaji sahihi wa kasi na nguvu ya kushika, kuhakikisha utunzaji wa viungo kwa upole ili kudumisha ubora na umbo asili wa kimchi na kachumbari.

Muundo wa muundo wa wavu wa kunyakua huiwezesha kushikilia viungo kwa usalama huku ikiruhusu unyevu kupita kiasi kupita kwenye mianya, ambayo husaidia kuzuia kujaa kupita kiasi na kusaidia uchakataji na ufungashaji wa mkondo wa chini. Kipengele hiki cha kudhibiti unyevu kinapatana vyema na kanuni za muundo nyuma ya korongo za juu kwa chakula na vinywaji, ambazo zimeundwa kushughulikia viungo na bidhaa kwa njia safi, bora na ya usafi. Zaidi ya hayo, muundo wa mesh ni rahisi kusafisha na kudumisha, kuhakikisha zaidi usafi wa uendeshaji.

Kwa kuongezea, kunyakua kwa majimaji kuna muundo wa kompakt na usanikishaji rahisi, unaofaa kwa mimea ya usindikaji wa chakula na warsha za ukubwa tofauti. Muundo wake wa msimu hurahisisha matengenezo na uingizwaji wa sehemu, na kupanua maisha ya vifaa. Kama vile korongo za juu kwa ajili ya chakula na vinywaji, unyakuzi huu hufanya kazi kwa uhakika katika mazingira ya unyevu wa juu na uendeshaji wa masafa ya juu, kutoa usaidizi thabiti wa kiufundi kwa sekta ya usindikaji wa chakula.

Kwa kifupi, pamoja na vifaa vyake vya hali ya juu, mfumo wa hali ya juu wa majimaji, na muundo wa akili wa muundo, unyakuzi huu wa 304 wa chuma cha pua umekuwa kifaa cha lazima katika utengenezaji wa kimchi na kachumbari—kinachokamilisha kikamilifu korongo za juu kwa chakula na vinywaji ili kuongeza ufanisi wa uzalishaji, kuhakikisha ubora wa bidhaa, na kukidhi mahitaji ya soko yanayokua.

Kuinua Mzito katika Vyakula na Vinywaji

Kuinua Nzito hutumika kushughulikia vifaa vya kazi kama vile roli, katoni, mizigo, mapipa, fremu, n.k. Inaweza kuchukua nafasi ya vibano tofauti kuinua bidhaa tofauti za chakula.

Faida

1.Mzigo: ≤150KG

- Kishikio cha ndani au mkono wa nje wa mkono

- Sura ya kawaida ya mlango imeundwa kwa alumini, SS304/316 ni ya hiari

- Kukidhi mahitaji ya matumizi safi ya chumba

- Cheti cha CE EN13155:2003

- Kiwango cha GB3836-2010 cha China kinachostahimili mlipuko

- Imeundwa kulingana na kiwango cha Ujerumani UVV18

2.Kusaidia ubinafsishaji usio wa kawaida

- Uzito mwepesi, unaohamishika, rahisi kufanya kazi

- Rahisi kusonga pande zote ikiwa imejaa kikamilifu

3.Weka mfumo wa breki wa kanyagio na breki ya kuegesha, mzunguko wa kawaida wa makabati au usukani wa uelekeo

- Kazi ya kuinua yenye utendaji wa kasi ya kutofautiana huacha kwa usahihi

- Sura ya mlango wa kuinua moja hutoa uwanja wazi wa maono ili kuhakikisha uendeshaji salama

- skrubu iliyofungwa ya kuinua-hakuna sehemu ya kubana

- Muundo wa msimu

- Jirekebishe kwa anuwai ya vifaa vya kazi kupitia uingizwaji wa haraka wa vifaa

- Lori nyepesi ni rahisi kufanya kazi na ina udhibiti wa mbali

- Uingizwaji rahisi wa athari ya mwisho, matumizi ya gharama nafuu ya lifti

- Haraka ondoa athari ya mwisho

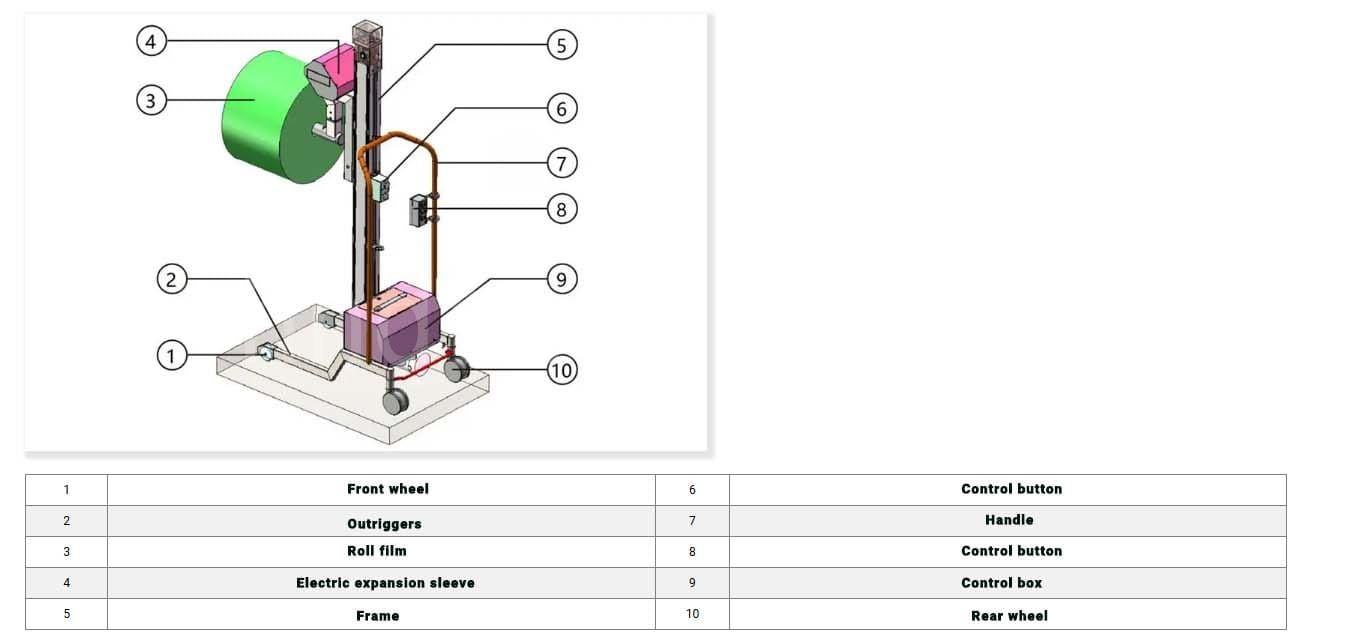

Muundo

Kazi ya udhibiti wa kati

- Kufuli ya mwelekeo

- Si upande wowote

- Breki kamili

- Vitengo vyote ni vya kawaida

Pakiti ya betri inayoweza kubadilishwa

- Rahisi kuchukua nafasi

- Kazi inayoendelea kwa zaidi ya masaa 8

Futa paneli ya uendeshaji

- Swichi ya dharura

- Kiashiria cha rangi

- Badili

- Ncha ya kudhibiti inayoweza kutenganishwa

Kuzuia kuanguka kwa ukanda wa kiti

- Uboreshaji wa usalama

- Kushuka kwa kudhibitiwa

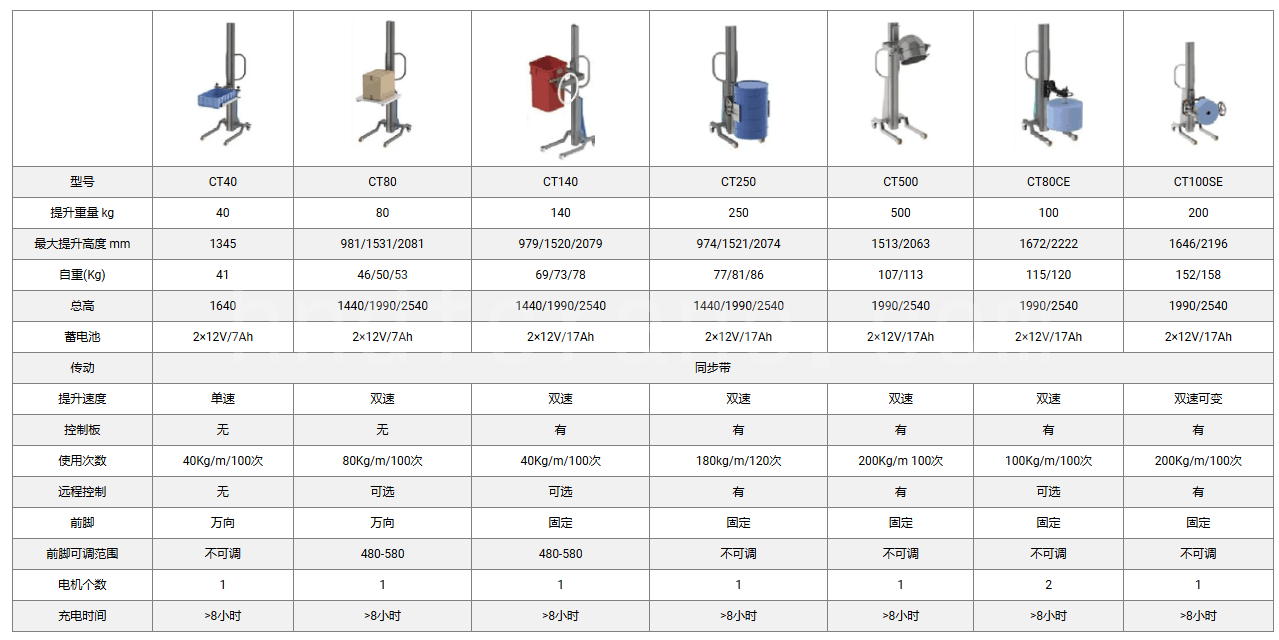

Kigezo cha Kiufundi

Kesi

Inatumika kwa kushughulikia unga katika mikate ya jikoni

Kusonga mapipa na reels katika uzalishaji wa maziwa

Kutumika kwa ajili ya utunzaji wa vifaa vya roll katika warsha safi

Vyumba vya Utupu vya Chuma cha pua

Faida

Ushughulikiaji wa mifuko ya vifungashio ni mojawapo ya matumizi ya kawaida ya korongo za kufyonza mirija. Korongo hizi hutumika sana kuinua na kusafirisha mifuko ya sukari, mifuko ya chumvi, na mifuko ya unga wa maziwa katika tasnia ya chakula na dawa, pamoja na mifuko ya vifungashio mbalimbali katika sekta ya kemikali. Kama sehemu ya korongo za juu za chakula na vinywaji, korongo za kuvuta mirija hutoa suluhisho safi, bora na salama kwa kushughulikia bidhaa nyingi zilizopakiwa bila kuchafuliwa.

- Mzigo: ≤300 kg

- Kasi ya kuinua: 0-1 m / s

- Hushughulikia: kawaida/mkono mmoja/mkondo/umerefushwa

- Vipengee vya kazi: Aina mbalimbali za kazi zinazofaa kwa mizigo mbalimbali

- Kubadilika: Mzunguko wa digrii 360

- Pembe ya swing: digrii 240

- Saidia ubinafsishaji usio wa kawaida

- Cheti cha CE EN13155:2003

- Kiwango cha Kichina kisichoweza kulipuka GB3836-2010

- Imeundwa kulingana na kiwango cha Ujerumani UVV18

- Ergonomic

Kigezo cha Kiufundi

| Nambari ya mfano | VEL 100 | VEL120 | VEL140 | VEL160 | VEL180 | VEL200 | VEL230 | VEL250 | VEL300 |

| Nguvu ya kunyonya (kg) | 30 | 50 | 60 | 70 | 90 | 120 | 140 | 200 | 300 |

| Urefu wa trachea (mm) | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| Kipenyo cha trachea (mm) | 100 | 120 | 140 | 160 | 180 | 200 | 230 | 250 | 300 |

| Ongeza kasi (m/s) | takriban 1m/s | ||||||||

| Kuinua urefu (mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1700 | 1700 | 1500 | 1500 |

| Pumpu ya utupu | 2.2Kw | 2.2Kw | 2.2Kw | 3-5.5Kw | 3-5.5Kw | 3-5.5Kw | 3-5.5Kw | 3-5.5Kw | 3-5.5Kw |

| Nambari ya mfano | VEL 120-2.5 kiwango | mzigo | Kunyonya kwa usawa hadi mnene wa kazi 50kg; Workpiece ya kupumua 30-40kg |

| Vipimo | 1610*1360*1020mm | Kujithamini (kg) | 520kg |

| Ugavi wa nguvu | 380VAC ±15% | Ingizo la nguvu | 50hz ±1hz |

| Mbinu ya kudhibiti | Zana ya utangazaji ya udhibiti wa uendeshaji kwa mikono | Safu ya uhamishaji wa sehemu ya kazi | Kibali kutoka chini 100-1600mm |

| Vifaa vya utupu | Kipulizia utupu | Nguzo ya safu wima | Urefu wa mkono 2500mm; Urefu wa safuwima 2900mm |

Muundo

Mkutano wa kikombe cha kunyonya

- Rahisi kuchukua nafasi

- Mchanganyiko wa Rotary

- Nchi ya kawaida na mpini unaonyumbulika ni wa hiari

- Kulinda uso wa workpiece

Kikomo cha mkono wa ond

- Kupunguza au kupanua

- Fikia uhamishaji wima

Utupu wa trachea

- Unganisha kipulizia kwenye kikombe cha kufyonza utupu

- Uunganisho wa bomba

- Shinikizo la juu na upinzani wa kutu

- Kutoa usalama

Sanduku la kudhibiti nguvu

- Kudhibiti pampu ya utupu

- Onyesha utupu

- Kengele ya shinikizo

Kesi

Koreni ya kufyonza ili kubeba bidhaa zinazofanana na mifuko

Kuinua na kushughulikia mifuko ya chumvi

Inatumika kwa usindikaji katika viwanda vya kusindika nyama

Cranes za Stacker za Pallets

Crane ya pallet stacker imeundwa ili kuboresha ufanisi wa uhifadhi na kuongeza ufanisi wa gharama katika maghala endelevu ya godoro. Suluhisho hili la kazi nyingi, la kuokoa nishati ni bora kwa shughuli zilizoinuliwa za ghala, kusaidia biashara kuongeza nafasi huku ikipunguza matumizi ya nishati. Imethibitishwa katika miradi zaidi ya 600 ya wateja, crane ya stacker hutoa utendakazi wa kutegemewa katika sekta mbalimbali, ikiwa ni pamoja na programu zinazohusisha korongo za juu kwa chakula na vinywaji, ambapo uhifadhi safi, sahihi na wa msongamano mkubwa ni muhimu.

Faida

- Inaweza kufanya kazi vizuri katika halijoto ya chini kama -30°C au juu kama +50°C katika maghala ya chakula yaliyogandishwa.

- Kulingana na msongamano wa uhifadhi na mahitaji ya upitishaji wa ghala, inaweza kushughulikia mzigo mmoja, mbili au zaidi katika mipangilio ya kina kirefu, ya kina, tatu-kirefu na ya kina.

- Katika majengo ya juu na maeneo yenye nafasi ndogo ya ardhi, cranes zinaweza kufanya kazi kwa urefu wa hadi mita 50.

- Pia wana uwezo wa kubeba mizigo mikubwa na isiyo ya kawaida kutoka kwa mwili hadi kwenye meli.

- Crane ya pallet ya multifunctional inaweza kusafirisha kila kitu kinachohitajika kwenye ghala iliyoinuliwa.

- Kutokana na ubunifu wa muundo wa mlingoti na uzito nyepesi wa kreni, matumizi ya nishati hupunguzwa kwa 20% ikilinganishwa na korongo za jadi.

- Chomeka na ucheze, korongo zote za godoro hukusanywa na kujaribiwa kabla ya usafirishaji, ambayo inahakikisha muda mfupi zaidi wa usakinishaji na uagizaji kwenye tovuti.

- Ikilinganishwa na korongo za kitamaduni, uzani mwepesi wa korongo humaanisha kuchakaa kidogo, huku uzalishaji wa hali ya juu unapunguza gharama za matengenezo na huduma.

Kesi

Shughuli za otomatiki za kuingia na kutoka kwa ghala

Usafirishaji wa bidhaa katika ghala

Usafirishaji wa bidhaa katika ghala