Cranes za Juu nchini Uturuki: Kuagiza kutoka Uchina na Matumizi Muhimu ya Kiwanda

Jedwali la Yaliyomo

Katika msururu wa usambazaji wa viwanda wa kimataifa, korongo za juu ni vifaa muhimu katika utengenezaji, vifaa, na tasnia zingine nzito. Mahitaji yao ya kuagiza yanaonyesha moja kwa moja afya ya kiviwanda ya kanda. Korongo za juu nchini Uturuki zinahitajika sana kutokana na ukuaji wa haraka wa kiviwanda na nafasi ya kimkakati ya taifa hilo kama kitovu cha biashara kinachounganisha Ulaya na Asia. Ukuaji huu unaunda fursa muhimu kwa wasambazaji wa kimataifa, haswa kutoka Uchina.

Kulingana na takwimu za 2023 kutoka kwa Hifadhidata ya Benki ya Dunia ya WITS (chini ya HS code 842619, inayojumuisha “Creni za Usafirishaji au daraja”), jumla ya thamani ya Uturuki ya kuagiza ya kreni za juu ilifikia dola elfu 99,036.69 mwaka huo, ikionyesha mahitaji makubwa ya vifaa hivyo katika sekta yake ya viwanda.

Kwa upande wa vyanzo vya kuagiza, soko la uagizaji la korongo la juu la Uturuki linatoa muundo wa "utawala-mbili, wa ziada":

- Uchina na Ireland kama wasambazaji wakuu: Uchina ilishika nafasi ya pili kwa thamani ya uagizaji ya dola 37,786.88,000, ikichukua takriban 38% ya jumla ya uagizaji wa Uturuki. Ireland ilichukua nafasi ya kwanza kwa tofauti ndogo (USD 37,985.72 elfu). Kwa pamoja, nchi hizo mbili zilichangia zaidi ya 76% ya jumla ya uagizaji wa Uturuki, na kuibuka kama vyanzo vya msingi vya korongo za juu za Uturuki.

- Nchi za Ulaya kama wauzaji muhimu: Ujerumani ilishika nafasi ya tatu kwa dola 10,036.84 elfu, ikifuatiwa kwa karibu na Shirikisho la Urusi kwa dola 9,534.87 elfu. Nchi zingine za Ulaya, kama vile Uholanzi, Poland, na Luxemburg, pia zilishikilia $ 10,036.84 elfu muhimu, ikifuatiwa kwa karibu na Shirikisho la Urusi katika hisa za soko za $ 9,534.87,000, ikionyesha utegemezi wa Uturuki kwa teknolojia ya Ulaya na minyororo ya usambazaji katika uagizaji wa vifaa.

Data hizi hazifichui tu ukubwa na muundo wa soko la uagizaji wa kreni za daraja la Kituruki lakini pia zinaangazia nafasi ya Uchina kama msambazaji mkuu, ikithibitisha uhusiano wa karibu kati ya mnyororo wa kimataifa wa ugavi na mahitaji ya maombi ya viwandani ya Uturuki. Mahitaji ya korongo za juu nchini Uturuki ni onyesho la moja kwa moja la ukuaji wa haraka wa viwanda nchini humo na jukumu lake la kimkakati kama kitovu. Baada ya korongo hizi za juu kuingia Uturuki, zinasaidia moja kwa moja mahitaji ya uendeshaji wa maeneo ya msingi kama vile vituo vya utengenezaji, vitovu vya usafirishaji, vifaa vya nishati, na tovuti za ujenzi kote nchini, zikitumika kama uti wa mgongo wa maendeleo ya viwanda.

Viwanda Muhimu vya Uturuki na Mahitaji ya Juu ya Crane

Maombi ya Juu ya Crane katika Sekta ya Utengenezaji ya Uturuki

Sekta ya utengenezaji wa Uturuki imeendelezwa vyema, ikitumika kama msingi muhimu wa utengenezaji barani Ulaya. Sekta muhimu kama vile sekta ya magari na mashine nzito zinakabiliwa na ukuaji mkubwa, huku makampuni ya kimataifa kama vile Ford na Fiat yakiwa na viwanda vilivyoanzisha. Nguvu hii ya viwanda inaunda mahitaji makubwa ya vifaa vya utunzaji wa nyenzo. Hasa, korongo za juu nchini Uturuki zina jukumu muhimu katika kuhakikisha usahihi na ufanisi unaohitajika katika michakato hii ya utengenezaji. Hitaji hili la korongo za daraja kusaidia katika uzalishaji ni hitaji la kawaida na linaakisiwa katika maeneo yaliyoendelea ya utengenezaji duniani kote.

Cranes za Juu Zinatumika katika Warsha ya Kusanyiko la Sehemu za Magari

Katika warsha ya kuunganisha sehemu za magari, korongo za juu nchini Uturuki hutumiwa kubeba vipengee vya kazi nzito kama vile injini na fremu za chassis. Sehemu hizo zimechukuliwa kwa usahihi na hoists za umeme au ndoano, na uhamisho wa mchakato unakamilika kwa kupigwa kwa mstari wa uzalishaji. Kwa mfano, kwenye mstari wa kusanyiko wa Hifadhi ya Viwanda ya Magari ya Istanbul, kreni ya daraja inaweza kutambua tafsiri ya mlalo na uwekaji wa sehemu moja ya tani 5-20, kuhakikisha usahihi na ufanisi katika mazingira yanayohitaji utengenezaji.

Kwa sababu ya eneo maalum la kijiografia la Uturuki, ambalo linaenea Eurasia, shughuli za tetemeko hufanyika mara kwa mara, ambayo inahitaji korongo za juu nchini Uturuki kuwa na utendaji wa juu wa mitetemo. Muundo wao wa miundo unahitaji kuwa imara zaidi. Chuma cha juu-nguvu hutumiwa kujenga sura ya daraja na muundo wa msaada. Sehemu kuu za uunganisho hutibiwa kwa teknolojia maalum ya kulehemu na vifaa vya kuimarisha ili kuhakikisha kwamba crane bado inaweza kudumisha uadilifu wake wa kimuundo katika dharura kama vile matetemeko ya ardhi na kuepuka ajali za kiusalama zinazosababishwa na sehemu zilizolegea. Mashine ya daraja inachukua ndoano na ndoano isiyo na kuteleza au kisambazaji kilichoboreshwa ili kurekebisha kazi kwa njia ya muundo wa hydraulic au mitambo ya kufunga ili kuhakikisha kuwa hakuna kutikisika wakati wa kushughulikia.

Sehemu za Uturuki huwa na joto na ukame wakati wa kiangazi, jambo ambalo huleta changamoto kwa mfumo wa umeme wa crane na mfumo wa kulainisha. Kwa hiyo, cranes za juu nchini Uturuki zinazotumiwa katika warsha ya mkusanyiko wa magari ya Kituruki zina vifaa vya kutosha vya kusambaza joto ili kuhakikisha uendeshaji thabiti wa vipengele vya umeme katika mazingira ya juu ya joto. Wakati huo huo, mafuta ya kulainisha ya juu ya joto hutumiwa kupunguza kuvaa kati ya vipengele vya mitambo na kupanua maisha ya huduma ya vifaa.

Double Girder Overhead Crane Inatumika katika Mitambo Nzito ya Utengenezaji wa Mashine

Viwanda vya kutengeneza mashine nzito, kama vile kiwanda cha mashine za ujenzi huko Ankara, hutegemea korongo za juu nchini Uturuki kushughulikia vitu vizito vyenye uzito wa zaidi ya tani 30, ikijumuisha zana kubwa za mashine na molds za kukanyaga. Muundo wa boriti mbili hutoa uwezo wa kubeba mzigo wenye nguvu zaidi, unaweza kufunika eneo la kazi kamili la warsha, na inafaa kwa mahitaji ya kusanyiko na kuagiza ya vifaa vya kiasi kikubwa.

Mazingira ya kipekee ya kijiografia ya Uturuki yana ukanda wa pwani mrefu na changamano wa kilomita 7,200, ambayo ina maana kwamba korongo zenye miale miwili zinazofanya kazi katika maeneo ya pwani lazima ziwe na uwezo wa kustahimili kutu. Uso wa sehemu za miundo ya chuma hutibiwa na mipako maalum ya safu nyingi za kuzuia kutu, kwa kutumia primer ya hali ya juu ya epoxy-tajiri ya zinki na topcoat ya akriliki ya polyurethane. Hii hustahimili mmomonyoko wa chumvi kutoka kwa upepo wa bahari na ukungu, huzuia kutu ya chuma na kupoteza nguvu za muundo, na kuhakikisha utendakazi thabiti wa muda mrefu wa vifaa katika mazingira yenye unyevu na kutu kando ya pwani.

Mandhari ya Uturuki ni tofauti, yenye nyanda nyingi na milima. Ankara iko katika Uwanda wa Anatolia wa kaskazini-kati, wenye mwinuko wa mita 895. Katika maeneo hayo ya juu, hewa nyembamba na shinikizo la chini la hewa huathiri uharibifu wa joto na mali ya insulation ya mfumo wa umeme wa crane. Kwa hivyo, korongo za juu nchini Uturuki zinazotumiwa katika maeneo haya zina vifaa vya umeme vya aina ya tambarare vilivyoboreshwa. Utendaji wao wa kusambaza joto umeundwa mahsusi ili kuhakikisha kuwa vipengee vya umeme vinaweza kusambaza joto kwa kawaida katika mazingira ya juu na ya shinikizo la chini, kuzuia kushindwa kutokana na joto. Wakati huo huo, kiwango cha insulation ya mfumo wa umeme kinaboreshwa, na hatua za ulinzi wa insulation zinaimarishwa ili kuhakikisha uendeshaji thabiti wa crane kwenye urefu wa juu, kukidhi mahitaji ya juu na ya juu ya kushughulikia kwa usahihi wa warsha za utengenezaji wa mashine nzito. Kuzingatia huku kwa muundo maalum ni alama mahususi ya korongo za hali ya juu nchini Uturuki zinazotumika katika sekta hii muhimu.

Maombi ya Juu ya Crane katika Sekta ya Chuma ya Uturuki

Uzalishaji wa chuma wa Uturuki unashika nafasi ya juu zaidi barani Ulaya na inajumuisha kampuni kubwa kama Erdemir Steel Group. Katika mchakato wa uzalishaji wa chuma, cranes maalum za daraja za metallurgiska zinahitajika kwa kuinua ladles na billets za joto la juu. Mahitaji ya korongo hizi maalum za juu nchini Uturuki ni muhimu kwa kudumisha tasnia ya chuma yenye pato la juu na bora. Wakati huo huo, ujenzi na uendeshaji wa viwanda vya nishati, kama vile miradi ya nishati ya joto na nishati ya upepo, pia inahusisha utunzaji wa vifaa na matukio mengine ambayo yanahitaji cranes za daraja. Kwa kiwango cha kimataifa, tasnia ya nishati na metallurgiska ni maeneo muhimu ya matumizi ya korongo za daraja, na umakini wa Uturuki katika sekta hizi unaifanya kuwa soko kuu la aina hii ya vifaa.

Cranes za Juu za Foundry Zinatumika katika Warsha za Utengenezaji wa Chuma

Katika karakana ya utengenezaji wa chuma ya kinu cha chuma, korongo za juu nchini Uturuki hutumiwa kuinua ngazi za chuma na bati za chuma zenye joto la juu. Katika eneo la kiwanda cha chuma cha Iskenderun, korongo kama hizo zinahitaji kustahimili halijoto iliyoko zaidi ya 1000℃, zikiwa na ngao za kuhami joto na kamba za waya zinazostahimili joto la juu ili kuhakikisha usalama wa mchakato wa uhamishaji wa chuma kilichoyeyushwa.

Uturuki iko katika eneo la mitetemo ya Bahari ya Mediterania-Himalaya na ina shughuli za mara kwa mara za mitetemo, ambayo inahitaji kwamba mitambo ya daraja la mihimili miwili inayofanya kazi hapa lazima iwe na utendaji bora wa mitetemo. Sura ya daraja na muundo wa usaidizi wa korongo hizi za juu nchini Uturuki zimetengenezwa kwa chuma maalum cha kuzuia mitetemo, na teknolojia za hali ya juu za kulehemu na uimarishaji hutumiwa kuhakikisha kuwa muundo huo ni thabiti wakati wa tetemeko la ardhi. Hii inazuia ajali kubwa, kama vile ladi za chuma kupinduka kwa sababu ya kutikisika. Uunganisho huo unafanywa kwa kitambaa maalum cha chuma, na muundo wa usawa wa ndoano mbili hupitishwa ili kuzuia kutega na kumwagika kwa chuma kilichoyeyuka, na ina kifaa cha ulinzi wa overload ili kuzuia ajali.

Aidha, hali ya hewa katika baadhi ya maeneo ya Uturuki inaweza kubadilika, na tofauti kubwa ya joto kati ya mchana na usiku. Wakati joto linapungua usiku, muundo wa chuma wa crane ya juu unakabiliwa na mabadiliko ya dhiki kutokana na upanuzi wa joto na contraction, ambayo huathiri usahihi na utulivu wa vifaa. Korongo za juu nchini Uturuki hutumia muundo wa fidia ya mafuta. Kupitia viungo maalum vya upanuzi na viunganishi vya elastic, mkazo wa joto hupunguzwa kwa ufanisi ili kuhakikisha kuwa mashine ya daraja bado inaweza kufanya kazi kwa usahihi katika mazingira yenye mabadiliko makubwa ya joto.

Vyombo vya Juu vya Juu vya Uthibitisho wa Mlipuko Hutumika katika Ghala za Mitambo ya Nguvu ya Joto ya Makaa ya Mawe.

Korongo za juu zisizoweza kulipuka nchini Uturuki hutumika kusafirisha vifaa vinavyoweza kuwaka na vilipuzi kama vile matangi ya makaa ya mawe na gesi katika maeneo ya kutibu mafuta ya maghala yanayotumia makaa ya mawe au vituo vya kuzalisha umeme kwa gesi katika mitambo ya nishati ya joto. Korongo hizi maalum ni muhimu kwa kuhakikisha usalama katika mazingira hatarishi.

Adana iko kwenye pwani ya Mediterania na ina hali ya hewa ya Mediterania yenye majira ya joto ya muda mrefu, ya joto na kavu na baridi kali na ya mvua. Hali hii ya hali ya hewa inatoa changamoto maalum kwa mifumo ya umeme na mitambo ya crane ya juu ya boriti mbili. Ili kushughulikia hili, korongo za juu nchini Uturuki zinazofanya kazi katika eneo hili zina vifaa vya uingizaji hewa bora na mifumo ya kusambaza joto. Hii inahakikisha kwamba hali ya joto katika baraza la mawaziri la kudhibiti umeme hudumishwa ndani ya safu inayofaa katika msimu wa joto, kuzuia kushindwa kwa sehemu ya umeme kwa sababu ya joto kupita kiasi na kuhakikisha uthabiti na usalama wa crane wakati wa kushughulikia vifaa vinavyoweza kuwaka na kulipuka. Wakati huo huo, sehemu za mitambo za korongo hizi za juu nchini Uturuki hupitia mchakato maalum wa matibabu ya kuzuia kutu ili kukabiliana na hatari ya kutu kutokana na mazingira yenye unyevunyevu wa msimu wa baridi, na kupanua maisha ya huduma ya vifaa.

Kwa mtazamo wa kijiografia, Uturuki, ambako Adana iko, iko katika eneo linalokumbwa na tetemeko la ardhi. Ili kuhakikisha kwamba mashine ya daraja la boriti yenye mihimili miwili bado inaweza kufanya kazi kwa usalama kukitokea majanga ya kijiolojia kama vile matetemeko ya ardhi na kuepuka ajali mbaya kama vile uvujaji wa mafuta unaosababishwa na hitilafu za vifaa, korongo za juu nchini Uturuki zinahitaji kujumuisha dhana ya upinzani wa tetemeko katika mchakato wa kubuni na utengenezaji. Muundo wao wa daraja umeboreshwa na umeundwa, kwa kutumia chuma cha juu-nguvu na cha juu ili kuimarisha utulivu wa muundo wa jumla; viunganishi maalum vya seismic hutumiwa katika sehemu muhimu za uunganisho, ambazo zinaweza kunyonya na kutawanya kwa ufanisi nishati inayotokana na tetemeko la ardhi, na kupunguza sana uharibifu wa vifaa vilivyosababishwa na tetemeko la ardhi. Haja ya muundo thabiti na unaostahimili tetemeko la ardhi ni jambo muhimu kwa korongo zote za juu nchini Uturuki. ili kuhakikisha usalama na mwendelezo wa uendeshaji.

Katika hali ya vitendo ya utumizi, korongo za juu za mihimili miwili zisizoweza kulipuka nchini Uturuki zinaweza kufanya kazi kwa usalama katika maghala ya mitambo ya kuzalisha umeme ya makaa ya mawe yaliyojaa vumbi au maeneo ya kutibu mafuta yanayoweza kuwaka ya vituo vya nguvu vinavyotumia gesi. Wanatumia ndoano iliyofungwa au kifaa cha kunyakua cha aina ya kunyakua kwa nyenzo nyingi kama makaa ya mawe. Muundo huu kwa kiasi kikubwa hupunguza uvujaji wa nyenzo na uzalishaji wa cheche za msuguano, kupunguza hatari za usalama katika mazingira ya kuwaka na ya kulipuka kutoka kwenye mizizi. Kwa mfano, wakati wa kushughulikia tank ya gesi, ndoano iliyofungwa inaweza kurekebisha tank kwa usalama ili kuzuia uvujaji wa gesi kutokana na migongano au kutetemeka wakati wa kuinua. Kwa kunyakua makaa ya mawe, muundo maalum wa kuziba na vifaa vya msuguano wa chini hupunguza uwezekano wa cheche kutoka kwa msuguano, kuhakikisha usalama wa shughuli za utunzaji wa mafuta na kukidhi mahitaji magumu ya tasnia ya nishati katika mkoa wa Adana.

Maombi ya Juu ya Crane katika Sekta ya Usafirishaji na Hifadhi ya Bandari ya Uturuki

Uturuki ina eneo bora zaidi la kijiografia, ikiwa na bandari kuu za kimataifa kama vile Bandari ya Istanbul na Bandari ya Izmit, na mbuga nyingi za maghala na vifaa. Sehemu hizi muhimu za miundombinu, pamoja na vifaa vya kubeba na kuhifadhi mizigo bandarini, vyote vinahitaji vifaa bora vya kunyanyua. Korongo za juu nchini Uturuki ni muhimu kwa kukidhi mahitaji haya, zikicheza jukumu muhimu katika usafirishaji wa bidhaa kupitia bandari kuu za nchi na vituo vya usafirishaji. Mahitaji haya ya korongo za kutegemewa na zenye uwezo wa juu ni kipengele cha kawaida katika uendeshaji wa vifaa na bandari duniani kote, na nafasi ya kimkakati ya Uturuki inaifanya kuwa soko muhimu sana.

Single Girder Overhead Crane Inatumika katika Maghala ya Ndani

Kama jiji kubwa zaidi nchini Uturuki, Istanbul inazunguka Eurasia na kulinda njia ya Bahari ya Mediterania kupitia Bahari ya Marmara hadi Bahari Nyeusi. Eneo lake la biashara huria lina vifaa vingi na mahitaji ya juu ya mauzo ya mizigo. Ghala la ndani katika Ukanda Huria wa Biashara wa Istanbul, kreni moja ya juu hutumika kubebea vyombo na bidhaa za pallet (tani 1-10). Muundo wa boriti moja ni nyepesi na unafaa kwa maghala madogo na ya kati. Inashirikiana na viinua vya umeme ili kufikia kuinua haraka na tafsiri ya bidhaa, na inaboresha ufanisi wa mauzo ya hifadhi.

Kwa kuwa Istanbul ina hali ya hewa ya bara, ni baridi wakati wa baridi na joto wakati wa kiangazi. Katika majira ya baridi, hali ya joto inaweza kushuka chini ya 0 ℃, na muundo wa chuma wa vifaa huathirika na joto la chini na inakuwa brittle, kupunguza mali ya mitambo. Kwa hiyo, cranes za juu za boriti moja nchini Uturuki zinapaswa kutumia chuma na upinzani bora wa baridi ili kuhakikisha kuwa muundo bado ni imara katika mazingira ya joto la chini. Wakati huo huo, kwa vifaa muhimu vya upitishaji wa mitambo, kama vile sanduku za gia na fani za magurudumu za viinua vya umeme, grisi zilizo na utendaji mzuri wa joto la chini hutumiwa kuzuia kufungia kwa vifaa kwa sababu ya kutofaulu kwa lubrication, na kuhakikisha kuwa crane inaweza kukimbia vizuri wakati wa baridi. Katika majira ya joto, joto la juu linaweza kufikia zaidi ya 40 ℃, na mfumo wa umeme unakabiliwa na mtihani mkali. Ili kufikia lengo hili, korongo za juu za boriti moja nchini Uturuki zina vifaa vya kupoeza vyema, kama vile kusakinisha kipeperushi cha kupoeza chenye nguvu nyingi kwenye kabati la kudhibiti umeme ili kuhakikisha kuwa vijenzi vya umeme vinaweza kufanya kazi kwa kawaida katika mazingira ya halijoto ya juu bila joto kupita kiasi, kujikwaa na matatizo mengine, ili kudumisha mwendelezo wa shughuli za kuhifadhi na kushughulikia.

Kunyakua Juu Inatumika katika Eneo la Kuhifadhi Nafaka

Katika eneo la kuhifadhi nafaka la Bandari ya Izmit na ghala nyingi za bandari mbalimbali, korongo za kunyakua zina jukumu la kunyakua nyenzo nyingi kama vile nafaka na madini kwa makundi. Wanaweza kukusanya tani 5-15 za nafaka kwa wakati mmoja kwa kutumia vinyakuzi vilivyo wazi na vilivyofungwa na kuhamisha moja kwa moja kwenye magari au maghala ya kuhifadhi. Kama kitovu muhimu cha baharini nchini Uturuki, bandari ya Izmit ina mahitaji ya kipekee ya korongo kwa sababu ya eneo lake maalum la kijiografia na hali ya hewa.

Uturuki imezungukwa na bahari kwa pande tatu, na bandari ya Izmit imeathiriwa kwa kiasi kikubwa na hali ya hewa ya baharini. Unyevu wa hewa ni wa juu mwaka mzima, na mara nyingi kuna ukungu wa baharini wenye chumvi. Hii inahitaji muundo wa chuma wa crane ya kunyakua kuwa na upinzani bora wa kutu. Kwa hiyo, wakati cranes za kunyakua zinazotumiwa katika bandari ya Izmit zinatengenezwa, sehemu za chuma zinafanywa kwa chuma maalum cha kuzuia kutu, na uso unatibiwa na tabaka nyingi za matibabu ya anticorrosive. Kwanza, tumia safu ya primer yenye utajiri wa zinki kutumia ulinzi wa cathodic ya zinki ili kuzuia kutu ya chuma; kisha funika na safu ya juu ya utendaji wa epoxy topcoat ili kutenganisha kwa ufanisi mmomonyoko wa mvuke wa maji na chumvi, na kuhakikisha kwamba crane inafanya kazi kwa utulivu kwa muda mrefu katika mazingira ya bandari yenye unyevu wa juu na ukungu wa bahari, na kupanua maisha ya huduma ya vifaa.

Kukabiliana na hali hii, crane ya kunyakua, kama korongo zingine nyingi za juu nchini Uturuki zinazofanya kazi katika bandari za pwani, ina mfumo wa ufuatiliaji wa unyevu na joto ili kuhisi mabadiliko ya mazingira kwa wakati halisi. Mara tu sifa za hali ya hewa ya upepo unaowaka zikifuatiliwa, mfumo hurekebisha kiotomati mkakati wa kukamata wa kunyakua, hupunguza kwa kiasi nguvu ya kukamata, na huepuka uharibifu wa nyenzo dhaifu. Wakati huo huo, uso wa muundo wa chuma wa cranes hizi za juu nchini Uturuki umewekwa na mipako maalum ya kinga. Mipako sio tu ina mali nzuri ya kupambana na ultraviolet, lakini inaweza kuhimili jua kwa muda mrefu na kudumisha utulivu katika hali ya juu ya joto na kavu, kuzuia deformation au kutu kutokana na upanuzi wa joto, kupungua kwa baridi, na mmomonyoko wa ultraviolet, na kuhakikisha uendeshaji thabiti wa vifaa.

Katika shughuli halisi, crane ya kunyakua inaendeshwa kwa njia ya maji ili kufungua na kufunga ncha ya makucha ya kunyakua, ambayo inaweza kurekebisha kwa usahihi nguvu ya kukamata kulingana na msongamano tofauti wa nafaka, ore na nyenzo zingine ili kuzuia kutawanyika kwa nyenzo. Kwa kuongeza, crane pia ina seli za mizigo za usahihi wa juu, ambazo zinaweza kufuatilia uzito wa vifaa vilivyokamatwa kwa wakati halisi, kudhibiti kwa usahihi kiasi cha upakiaji, kuzuia usafirishaji wa mizigo kupita kiasi, kuboresha ufanisi na usalama wa utunzaji wa mizigo mingi kwenye bandari, na kukidhi kikamilifu mahitaji ya vifaa vya ufanisi katika mazingira magumu ya Bandari ya Izmit.

Mwongozo wa Kuagiza Cranes za Juu za Dafang kutoka Uchina hadi Uturuki

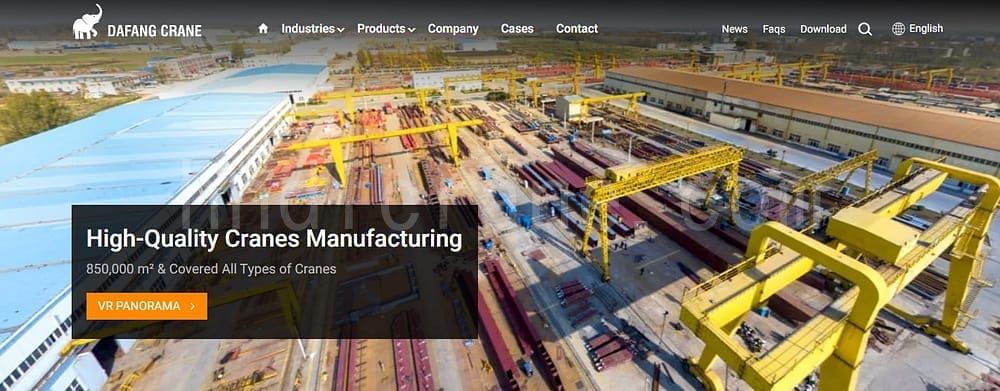

Uturuki ni kivutio kingine kinachokua kwa kasi cha uagizaji wa kreni za juu, zinazoendeshwa hasa na ghala na vifaa, uzalishaji wa chuma, na utengenezaji wa magari. Kama mwanachama wa G20 na sehemu ya Umoja wa Forodha wa Umoja wa Ulaya, Uturuki inadumisha ushirikiano thabiti wa kibiashara na Ulaya huku ikipanua msingi wake wa viwanda vya ndani. Ingawa nchi ina watengenezaji wa korongo wa ndani, suluhu zilizoagizwa kutoka nje husalia kuwa muhimu, hasa kwa miundo ya uwezo wa juu, ya hali ya juu ya kiteknolojia au miundo maalum. Hii inaifanya China kuwa mshirika mkuu kwa wanunuzi wa Kituruki wanaotafuta vifaa vya kutegemewa vilivyo na nyakati za ushindani wa kuongoza na utaalamu wa mauzo ya nje uliothibitishwa. Kama mmoja wa watengenezaji wakuu watatu wa juu wa crane wa China, Crane ya Dafang, kama mmoja wa viongozi watengenezaji wa crane za juu, huongeza uwezo wa uzalishaji wa kiwango kikubwa, teknolojia ya hali ya juu, na uzoefu mkubwa wa mradi wa ng'ambo ili kutoa masuluhisho yaliyolengwa. Kuanzia mashauriano ya kiufundi na urekebishaji wa muundo hadi usafirishaji na utiifu wa viwango vinavyohusiana na EU, Da

✅ Kufahamu mahitaji ya Uturuki ya uingizaji na kibali cha forodha

✅ Mfumo kamili wa uzalishaji wa ndani

✅ Suluhisho za kuaminika kwa miradi mikubwa na iliyobinafsishwa

Dafang Crane imeorodheshwa kati ya watengenezaji 10 bora wa korongo duniani kote, ikiwa na uwezo mkubwa wa utengenezaji na mfumo madhubuti wa usimamizi wa ubora. Kampuni ina uthibitisho wa kimataifa unaofunika aina mbalimbali za korongo na ina vifaa vya utayarishaji wa akili. Dafang imejitolea kutoa vifaa vya kudumu, vyema na vilivyotengenezwa maalum kwa ajili ya sekta ya madini, madini, vifaa na miundombinu.

Kwa kuzingatia mahitaji maalum ya soko la Uturuki, kama vile halijoto ya juu, ulikaji wa dawa ya chumvi kwenye pwani, mazingira yenye vumbi, na mabadiliko ya gridi ya umeme, Dafang Crane inachukua miundo inayostahimili kutu, injini zinazostahimili vumbi na joto, na mifumo ya udhibiti wa ubadilishaji wa frequency ili kuhakikisha utendakazi thabiti hata katika hali ngumu. Wateja wa Uturuki wanathamini sana ubinafsishaji wa kina, uwasilishaji unaotegemewa, na huduma makini baada ya mauzo, na kuifanya Dafang kuwa mojawapo ya watengenezaji bora wa korongo za daraja kwa migodi, bandari, na miradi mikubwa ya miundombinu.

Kwa vyeti vingi vya kimataifa vinavyohakikisha utiifu wa viwango vya ubora na usalama wa kimataifa, Dafang Crane hutoa udhibiti wa akili na miundo ya kawaida. Tunatoa masuluhisho yaliyoundwa mahususi kwa usafiri wa bandari ya Uturuki na matumizi ya viwandani, yanayokidhi mahitaji mbalimbali ya korongo za daraja chini ya hali tofauti za kazi.

Mchakato wa Uagizaji wa Cranes wa Uturuki wa Juu

Uturuki iko kimkakati katika njia panda za Asia Magharibi na Kusini-mashariki mwa Ulaya, ikicheza jukumu muhimu katika biashara ya kimataifa. Kama mshiriki mkuu katika Mpango kabambe wa China wa Ukanda na Barabara, Uturuki imeendeleza uhusiano thabiti wa kiuchumi na China, mshirika wake mkubwa wa uagizaji bidhaa, huku Ujerumani ikisalia kuwa kivutio chake kikuu cha mauzo ya nje. Uhusiano huu thabiti wa kibiashara unaleta mahitaji makubwa ya suluhu za kutegemewa za usafirishaji wa korongo kutoka China hadi Uturuki.

- Maliza Ainisho za Kiufundi na Nukuu

- Saini Mkataba na Toa PO

- Uzalishaji (siku 30-60)

- Usafirishaji wa Bahari (FCL / LCL / Breakbulk)

- Tamko la Forodha na Uidhinishaji wa Bidhaa Nje (Uchina)

- Usafirishaji wa Bahari hadi Uturuki (Kawaida siku 3-36)

- Uondoaji wa Forodha nchini Uturuki + Uwasilishaji

Nyaraka Zinazohitajika

- Ankara ya Biashara

- Orodha ya Ufungashaji

- Mswada wa Kupakia (B/L)

- Cheti cha Asili

- Barua ya Mkopo au masharti mengine ya malipo

- Cheti cha Bima

- Leseni ya Kuagiza

- Hati za kiufundi / cheti cha CE

| Aina ya usafiri | Bidhaa zinazotumika | Muda uliokadiriwa (Uchina → Uturuki) | Sifa kuu |

|---|---|---|---|

| FCL (Mzigo Kamili wa Kontena) | Seti kamili ya korongo za daraja (boriti kuu, boriti ya mwisho, kiinua cha umeme, n.k.) | Siku 15-30 | Usafiri uliofungwa, salama na thabiti, unaofaa kwa vifaa kamili vya wingi, vya gharama nafuu. |

| LCL(Chini ya Upakiaji wa Kontena) | Vifaa vya kundi ndogo au sehemu moja. | 18-35 siku | Gharama ni ya chini, na inahitaji kuunganishwa na bidhaa nyingine, ambayo inaweza kuongeza muda wa upakiaji, upakuaji na kibali cha forodha. |

| Mizigo ya anga | Sehemu kubwa au vifaa vya uzito wa kati (kilo 300-500). | 3-10 siku | Kasi ya haraka, gharama ya juu, inayofaa kwa utoaji wa dharura. |

| POL (bandari ya upakiaji) | POD (bandari ya kutokwa) | Muda wa usafiri (siku) |

|---|---|---|

| Shanghai | Istanbul | 27 |

| Shanghai | Mersin | 34 |

| Shanghai | Izmir | 30 |

| Shenzhen | Istanbul | 22 |

| Shenzhen | Mersin | 30 |

| Shenzhen | Izmir | 24 |

| Qingdao | Istanbul | 35 |

| Qingdao | Mersin | 37 |

| Qingdao | Izmir | 36 |

Ushuru wa Kuagiza na Ushuru kwa Cranes za Juu nchini Uturuki

Ushuru wa Forodha:

- Kiwango cha Msingi: 0% - 10%.

- Viwango vya Juu: Inaweza kutumika kwa korongo zilizo na usanidi maalum (zito-uzito, urefu mkubwa) au maudhui ya juu ya chuma.

Kodi ya Ongezeko la Thamani (VAT):

- Kiwango: 18% ya jumla ya gharama ya kutua (CIF + ushuru).

- Athari: Sehemu kuu ya gharama za kuagiza.

Ada za Bandari na Uchakataji:

- Bandari Zinazohusika: Istanbul, Izmir, na Mersin (vitovu muhimu vya uagizaji wa vifaa vya viwandani nchini Türkiye).

- Ada: Utunzaji wa vituo, uhifadhi na ada za usimamizi (kulingana na ukubwa wa usafirishaji/utata wa uendeshaji, kulingana na orodha za bei zilizochapishwa na mamlaka ya bandari).

Udalali wa Forodha:

- Huduma: Madalali walio na leseni hushughulikia usajili wa forodha, maombi ya vibali, na uratibu wa ukaguzi (kwa kufuata mahitaji ya forodha ya Türkiye).

- Gharama: Inatozwa kulingana na saizi ya usafirishaji + ugumu wa kufuata (kwa mfano, korongo zilizo na usanidi wa hali ya juu wa kiufundi).

Hatari na Ada za Ziada:

- Ada za ziada: Gharama za ziada za msongamano wakati wa msongamano wa bandari; ada za kupunguza kwa ucheleweshaji wa kibali cha forodha (kulingana na sera za msongamano wa bandari/demurrage).

- Bima: Malipo ya juu zaidi kwa korongo za ukubwa wa juu (zinazosafirishwa kupitia vyombo vya rack wazi - juu au gorofa); hatari za uharibifu wakati wa usafirishaji kutokana na tofauti za hali ya hewa (unyevu wa pwani dhidi ya ukame wa bara), kulingana na mazoea ya tasnia ya bima ya shehena ya baharini.

Miradi ya Dafang Crane Overhead Crane nchini Uturuki

Tukizingatia muhtasari wa awali wa mchakato wa uagizaji na suluhu za usafirishaji wa korongo za juu kutoka Uchina hadi Uturuki, sasa tutageukia tafiti za ulimwengu halisi za mojawapo ya kampuni kuu za korongo, miradi ya Dafang Crane katika soko la Uturuki. Mifano hii inaangazia jinsi Dafang Crane, kama mtengenezaji maarufu wa eot crane, anavyobadilisha korongo zake kulingana na hali ya tasnia ya ndani - kama vile utengenezaji wa magari, utengenezaji wa chuma na usafirishaji wa bandari - huku ikihakikisha utendakazi unaotegemewa, ufaafu wa gharama, na utiifu wa viwango vya uendeshaji wa Türkiye, ikijumuisha ustahimilivu wa hali ya hewa kwa unyevu wa pwani na joto la ndani, pamoja na kanuni za usalama na kuzingatia desturi.

Crane ya Juu ya Girder Imesafirishwa hadi Uturuki

- Maombi: Inatumika katika warsha za uwanja wa meli kwa kuinua na kusakinisha vipengee vizito vilivyotengenezwa wakati wa ujenzi wa meli.

- Uwezo wa kuinua: Tani 2 × 32 (koreni nne za mhimili-mbili), tani 16 (kreni tatu zenye mhimili mara mbili + kreni moja ya juu ya mhimili-mbili)

- Kuinua urefu: Haijabainishwa, iliyoundwa ili kukidhi mahitaji ya mkusanyiko wa meli

- Muda: 17 m (kwa korongo 2 × 32 t), 30 m (kwa korongo tatu 16 t), 13.5 m (kwa kreni 16 t moja)

- Voltage ya kufanya kazi: 400V / 50Hz / 3-awamu

- Vipengele maalum: Ina vifaa vya kuinua kamba za waya, uendeshaji wa sehemu mbili, kasi ya kuinua iliyoimarishwa, na iliyoundwa kwa ajili ya kushughulikia kwa usahihi vipengele vya meli kubwa na nzito.

Crane ya Juu ya Umeme Inasafirishwa hadi Uturuki

- Maombi: Inatumika katika mitambo ya chuma na viwanda vya metallurgiska nchini Uturuki kwa kushughulikia bili, chuma chakavu na utupaji wa metali nzito.

- Uwezo wa kuinua: 35/5 tani

- Kuinua urefu:16/18 m

- Muda: 33.5 m

- Voltage ya kufanya kazi: 400V / 50Hz / 3-awamu

- Vipengele maalum: Ina kifaa chenye utendaji wa juu wa kuinua sumakuumeme, kufyonza kwa nguvu na uthabiti; mfumo wa juu wa udhibiti wa PLC unaounga mkono uendeshaji wa kijijini na automatisering; iliyoundwa kwa ajili ya halijoto ya juu, mazingira ya viwanda yenye mzigo mzito.

Ahadi ya Huduma ya Dafang Crane nchini Uturuki

Sisi sio tu wasafirishaji wa korongo—sisi ni mshirika wako wa kutegemewa katika kila hatua ya mzunguko wako wa maisha wa crane turkey. Kama muuzaji anayeaminika wa korongo katika eneo hili, Dafang Crane hutoa usaidizi wa kitaalamu kutoka kwa usanifu wa mradi na usakinishaji hadi matengenezo na uboreshaji wa muda mrefu. Ahadi yetu inaenea zaidi ya mauzo ya awali, kuhakikisha wateja wetu wanapokea huduma ya kitaalamu inayohitajika ili kuongeza utendakazi na maisha marefu ya vifaa vyao.

• Matengenezo

Kwa kuzingatia hali tofauti ya hali ya hewa ya Uturuki—kutoka hewa iliyojaa chumvi ya pwani hadi mazingira ya chuma yenye vumbi na ujenzi wa meli—tunatoa miongozo ya urekebishaji iliyoundwa maalum inayohusu ulinzi wa kuzuia kutu, uthabiti wa umeme chini ya mabadiliko ya gridi ya taifa, na ukaguzi wa mara kwa mara wa usalama ili kuhakikisha utendakazi wa kuaminika wa crane.

• Ugavi wa Vipuri

Ili kupunguza muda wa matumizi, tunatayarisha vipuri kulingana na miundo ya kreni zinazotolewa Uturuki. Kwa njia za vifaa kupitia bandari kuu kama vile Istanbul, Izmir, na Mersin, vipengele muhimu vinaweza kuwasilishwa kwa ufanisi kwa tovuti za wateja.

• Msaada wa Mafunzo

Ili kusaidia mahitaji ya wafanyikazi wa ndani, Dafang Crane hutoa miongozo ya lugha ya Kiingereza na Kituruki pamoja na vikao vya mafunzo vya tovuti au mtandaoni, kuhakikisha utendakazi salama na bora wa kreni katika tasnia kama vile chuma, madini, ujenzi wa meli na ujenzi.

• Msaada wa Kiufundi

Timu yetu ya wataalamu inatoa usaidizi wa haraka wa video za mbali na hufanya kazi na washirika wa huduma wa Kituruki wa ndani ili kutoa utatuzi wa matatizo kwenye tovuti, kupunguza ucheleweshaji na kuhakikisha uzalishaji unaoendelea.

Watengenezaji 10 bora wa Crane wa Juu nchini Uturuki

Kwa wanunuzi wanaochunguza korongo kwenye soko la Uturuki, watengenezaji kadhaa wa ndani wanaweza kutumika kama marejeleo muhimu:

- WIMACCRANE

- Asan Cranes

- CESAN Crane & Vipengele

- ARNIKON

- DINAMIKVINC

- OZFATIHLER CANE

- Mifumo ya Crane ya CMAK

- KM Kümsan Crane Systems Ind.

- Sekta ya Crane ya BVS Bülbüloğlu

- Vincser Ltd. Şti.

Makampuni haya yanasambazwa zaidi katika Istanbul, Ankara na Izmir, kutoa aina mbalimbali za uwezo wa kuinua kwa ajili ya utengenezaji wa magari, uzalishaji wa chuma, vifaa vya bandari na viwanda vingine, na majibu zaidi ya huduma kwa wakati.

- Manufaa ya watengenezaji wa ndani: usaidizi unaofaa baada ya mauzo, unaofahamu kanuni za kiufundi za Uturuki na viwango vya usalama, na uwasilishaji wa haraka wa vifaa vya kawaida.

- Faida za mauzo ya nje ya China: teknolojia ya juu ya utengenezaji, aina kamili ya bidhaa, na muundo wa seismic, upinzani wa joto la juu, anticorrosion ya pwani, na sifa nyinginezo zilizochukuliwa kwa hali ya hewa ya kijiografia ya Uturuki; mfumo wa udhibiti wa akili na usanidi wa kuokoa nishati unalingana zaidi na viwango vipya vya kimataifa. Ikitegemea uzoefu uliokomaa wa usafirishaji na usaidizi kamili wa mchakato wa uwasilishaji na kibali cha forodha, inaweza kutoa masuluhisho ya hali ya juu yaliyogeuzwa kukufaa na uhakikisho wa kuaminika wa uwasilishaji.

Wanunuzi wengine wanapendelea huduma za papo hapo kwenye tovuti, mara nyingi hutafuta watengenezaji wa korongo wa juu karibu nami, huku wengine wakichagua kununua moja kwa moja kutoka Uchina kutoka kwa baadhi ya watengenezaji wa juu wa korongo ili kupata ubinafsishaji wa hali ya juu (kama vile mahitaji maalum ya Kiwanda cha Mitambo Mizito cha Ankara na ushughulikiaji wa shehena nyingi za bandari ya Izmit). Kuelewa aina hizi mbili za chaguo kunaweza kusaidia makampuni ya Uturuki kuboresha maamuzi ya ununuzi na kupunguza hatari za uendeshaji. Iwapo unahitaji crane ya daraja la gharama nafuu iliyorekebishwa kwa hali ya kazi ya Kituruki, unaweza kuwasiliana na Dafang Crane kwa nukuu za hivi punde na mpango uliobinafsishwa.

Tuma Uchunguzi Wako

- Barua pepe: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegramu: +86 191 3738 6654

- Simu: +86-373-581 8299

- Faksi: +86-373-215 7000

- Ongeza: Wilaya ya Viwanda ya Changnao, Jiji la Xinxiang, Mkoa wa Henan, Uchina

WeChat

WeChat