Mahsulot Mexanik ikkita arqonli qisqichli tutqichlarning kiritilishi

Mexanik ikkita arqonli qisqichli tutqichlar ikki tomonlama yuk ko'tarish moslamasi tuzilishiga ega bo'lgan barcha turdagi kranlar uchun mos keladi va asosan portlar, docklar, qurilish yo'llari va ko'priklar va boshqa sohalarda qo'llaniladi.

Moddiy xususiyatlarga ko'ra, u engil, o'rta, og'ir va o'ta og'ir bilan jihozlanishi mumkin. Har qanday bo'shashgan to'planishlarni ushlash uchun javob beradi.

Keyin turli kranlar. Ikkita dvigatel g‘altaklari (ya’ni elektr ko‘targichlar) bilan jihozlangan har bir g‘altak to‘plami sim arqonga olib boradi, ulardan biri tutqich balansi romida tayanch bo‘lib xizmat qiladi, ikkinchi sim arqon esa yuqori va pastki to‘sinlar shkivlaridan o‘tib, shkiv blokini hosil qiladi, bu esa ochilishda rol o‘ynaydi.

Mexanik ikkita arqonli qisqichbaqasimon tutqichlar turli xil og'ir sharoitlarda sariq qum, ko'mir, ruda kukuni va quyma o'g'it kabi quyma yuklarni yuklash va tushirish uchun samarali vositadir.

Mexanik ikkita arqonli qisqichbaqasimon tutqichlar oddiy tuzilishga ega, yangi ochish va yopish mexanizmiga ega, oson ishlaydi va turli holatlarda ochilish va yopish harakatlarini aniq bajarishi mumkin.

Mexanik ikkita arqonli qisqichbaqasimon tutqichlar uch o'lchovli virtual dizaynni qabul qiladi va ANSYS dasturi quvvatni tahlil qilish va tekshirish uchun ishlatiladi. Og'irlikni taqsimlash yanada oqilona va xizmat muddati uzoqroq.

Mexanik ikkita arqonli qisqichli tutqichlarning yuqori rulman nurlari kranning ko'taruvchi arqoniga to'g'ridan-to'g'ri ulanishi mumkin bo'lgan quloqchalar bilan jihozlangan.

Texnik parametrlar mexanik ikkita arqonli qisqichli tutqichlardan

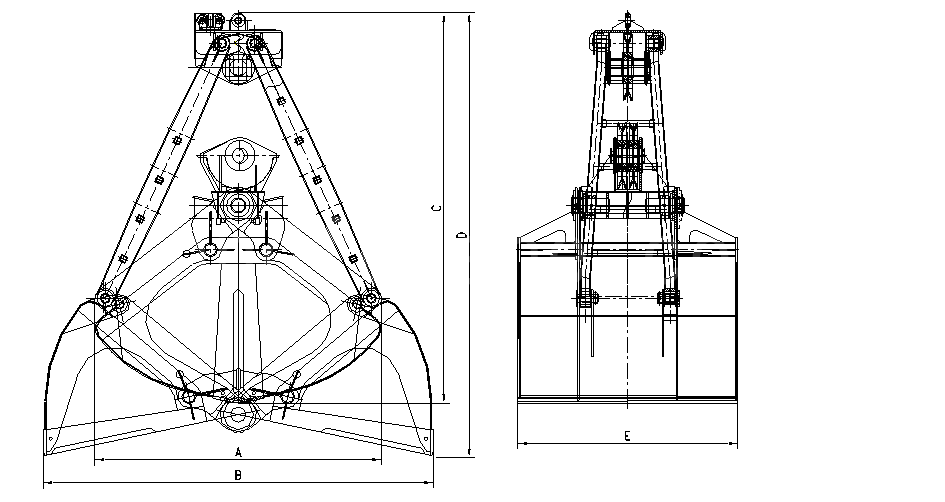

| Turi va hajmi | Ovoz balandligi(m3) | O'lik vazn (t) | Olchamlari (mm) | Shiva Dia.(mm) | Balandlikdan foydalaning(m) | Chelik arqon Dia.(mm) | SWL(t) | ||||

| A | B | C | D | E | |||||||

| BS3[1.2]1.3A | 1.2(300) | 1.4(4) | 1900 | 2537 | 2488 | 2841 | 1200 | ø400 | 9 | ø17.5 | 3 |

| BS3[1.6]1.4A | 1.6(300) | 1.4(4) | 2100 | 2631 | 2559 | 3040 | 1300 | ø400 | 9.5 | ø17.5 | 3 |

| BS5[1.5]2A | 1.5(350) | 2(3) | 2000 | 2659 | 2667 | 3075 | 1260 | ø445 | 8.5 | ø19.5 | 5 |

| 2(4) | 9.8 | ||||||||||

| BS5[2]2A | 2(350) | 2(4) | 2100 | 2778 | 2818 | 3248 | 1400 | ø445 | 10 | ø19.5 | 5 |

| BS5[2.5]2A | 2.5(350) | 2(3) | 2100 | 2787 | 2715 | 3091 | 1600 | ø445 | 8.5 | ø19.5 | 5 |

| BS5[3]2A | 3(400) | 2(3) | 2300 | 3130 | 2938 | 3362 | 1650 | ø445 | 9 | ø19.5 | 5 |

| BS8[2.6]3.2A | 2.6(300) | 2.6(4) | 2300 | 3038 | 3257 | 3736 | 1800 | ø560 | 11 | ø26 | 8 |

| BS8[3]3,3A | 3(300) | 3.3(4) | 2380 | 3118 | 3287 | 3786 | 1900 | ø560 | 11.5 | ø26 | 8 |

| BS8[3,8]3,5A | 3.8(300) | 3.5(4) | 2550 | 3536 | 3286 | 3733 | 2000 | ø560 | 12 | ø26 | 8 |

| BS8[4,5]3,8A | 4.5(300) | 3.8(3) | 2500 | 3505 | 3503 | 3975 | 2300 | ø560 | 12 | ø26 | 8 |

| BS10[3]4A | 3(300) | 4(4) | 2380 | 3118 | 3287 | 3786 | 1900 | ø560 | 11.5 | ø28 | 10 |

| BS10[5]4A | 5(350) | 4(4) | 2615 | 3605 | 3503 | 3975 | 2400 | ø560 | 12 | ø28 | 10 |

| BS10[6]4A | 6(400) | 4(4) | 2800 | 3814 | 3758 | 4290 | 2150 | ø560 | 12.5 | ø28 | 10 |

| BS16[3.6]6A | 3.6(300) | 6(5) | 2500 | 3313 | 3810 | 4206 | 2100 | ø720 | 13.5 | ø32 | 16 |

| BS16[4]6A | 4(350) | 6(5) | 2500 | 3313 | 3810 | 4206 | 2200 | ø720 | 13.5 | ø32 | 16 |

| BS16[6]6A | 6(350) | 6(4) | 2900 | 3800 | 4249 | 4612 | 2400 | ø720 | 13.5 | ø32 | 16 |

| BS16[10]6A | 10(400) | 6 (3) | 3200 | 4000 | 3938 | 4673 | 2500 | ø650 | 12 | ø28 | 16 |

Qanday qilib to'g'ri tutqichni tanlash kerak

- Maqsadingizni aniqlang:

Variantlarni ko'rib chiqishdan oldin, iltimos, maxsus talablaringizni aniqlang. O'zingizdan so'rang:

- Siz qanday materiallar bilan shug'ullanmoqchisiz? (log'lar, metallolom, tosh va boshqalar)

- Tutqich qanday vazifalarni bajaradi? (Yuklash, saralash, demontaj qilish va h.k.)

- U qanday turdagi qurilmaga ulanadi? (Gantry kran, ko'prikli kran)

- Siz ushlagan materialning solishtirma og'irligi qanday? Tutqichning kublari soni?

Tutqich bilan jihozlangan kraningizning tonnaji qancha?

Qo'lga olinadigan materialning xususiyatlariga ko'ra, tortish odatda to'rtta asosiy turga bo'linadi: engil, o'rta, og'ir va o'ta og'ir.

| Qabul qilinadigan material turi | Materialni tortib oling | Imkoniyatlar og'irligi (t/m³) |

| Nur | Koks, shlak, don, kartoshka, o'rta sifatli antrasit ohak, tsement, tuproq, shag'al, gil, singan g'isht va boshqalar. | 0.5~1.2 |

| O'rta | Torf, antrasit koʻmirning yirik boʻlaklari, siqilgan koʻmir, gil, ohaktosh, shagʻal, tuz, shagʻal, gʻisht, boksit, temir oksidi parchalari, tsement, qum va suvdagi gʻisht va boshqalar. | 1.2~2.0 |

| Og'ir | Ohaktosh, ogʻir gil, mayda va oʻrta rudalar, qattiq jinslar, novdasimon temir oksidi, temir rudasi, qoʻrgʻoshin konsentrati kukuni va boshqalar. | 2.0~2.6 |

| Ortiqcha vazn | Yirik rudalar, yirik marganets rudasi, choʻkindi aglomeratsiyalangan qoʻrgʻoshin rudasi kukuni va boshqalar. | 2.6~3.3 |

- Aksessuarning mosligi: Tutqichning mavjud uskunaga mos kelishiga ishonch hosil qiling.

- Byudjet masalalari: Tutqichning narxi har xil. Tutqichning funksiyasi va chidamliligiga qarab byudjetingizni muvozanatlang.

- Fikr va takliflar: Internetda tadqiqot o'tkazing, foydalanuvchi sharhlarini o'qing va sanoat hamkasblaridan takliflarni izlang.

- Sotib olishdan oldin kran ishlab chiqaruvchisiga tashrif buyurib, joyida tekshirish va sinovdan o'tkazing: grabni iloji boricha real sharoitlarda sinab ko'ring.Uning ishlashi, foydalanish qulayligi va umumiy funksionalligini baholang.

Yodda tutingki, to'g'ri tutqichni tanlash funksionallik, xavfsizlik va narx o'rtasidagi muvozanatni talab qiladi. Bu faktlarni hisobga olgan holda