পণ্য পরিচিতি

স্ট্যাকার ক্রেন, যা কেবল স্ট্যাকার নামেও পরিচিত, একটি স্বয়ংক্রিয় স্টোরেজ এবং পুনরুদ্ধার ব্যবস্থার (AS/RS) সবচেয়ে গুরুত্বপূর্ণ উত্তোলন এবং উপাদান পরিচালনা ব্যবস্থাগুলির মধ্যে একটি। এটি একটি ল্যান্ডমার্ক সরঞ্জাম যা একটি স্বয়ংক্রিয় গুদামের মূল বৈশিষ্ট্যগুলিকে প্রতিনিধিত্ব করে।

কাঠামোগত নকশা এবং অপারেটিং মোড অনুসারে, স্ট্যাকার ক্রেনগুলিকে প্রধানত দুটি প্রকারে শ্রেণীবদ্ধ করা হয়: প্যালেট স্ট্যাকার ক্রেন এবং ওভারহেড (ব্রিজ-টাইপ) স্ট্যাকার ক্রেন, যা তাদের বিভিন্ন গুদাম স্কেল এবং অপারেটিং প্যাটার্নের প্রয়োজনীয়তা পূরণ করতে সক্ষম করে।

একটি স্ট্যাকার ক্রেনের প্রাথমিক কাজ হল গুদামের আইলের মধ্যে বা একাধিক আইল জুড়ে এদিক-ওদিক ভ্রমণ করা, আইল প্রবেশপথ থেকে নির্ধারিত র্যাক অবস্থানে পণ্যগুলি সঠিকভাবে সংরক্ষণ করা, অথবা স্টোরেজ র্যাক থেকে দ্রুত পণ্যগুলি উদ্ধার করে আইল প্রবেশপথে পৌঁছে দেওয়া, যার ফলে দক্ষ স্টোরেজ, পুনরুদ্ধার এবং স্বয়ংক্রিয় উপাদান পরিচালনা অর্জন করা যায়।

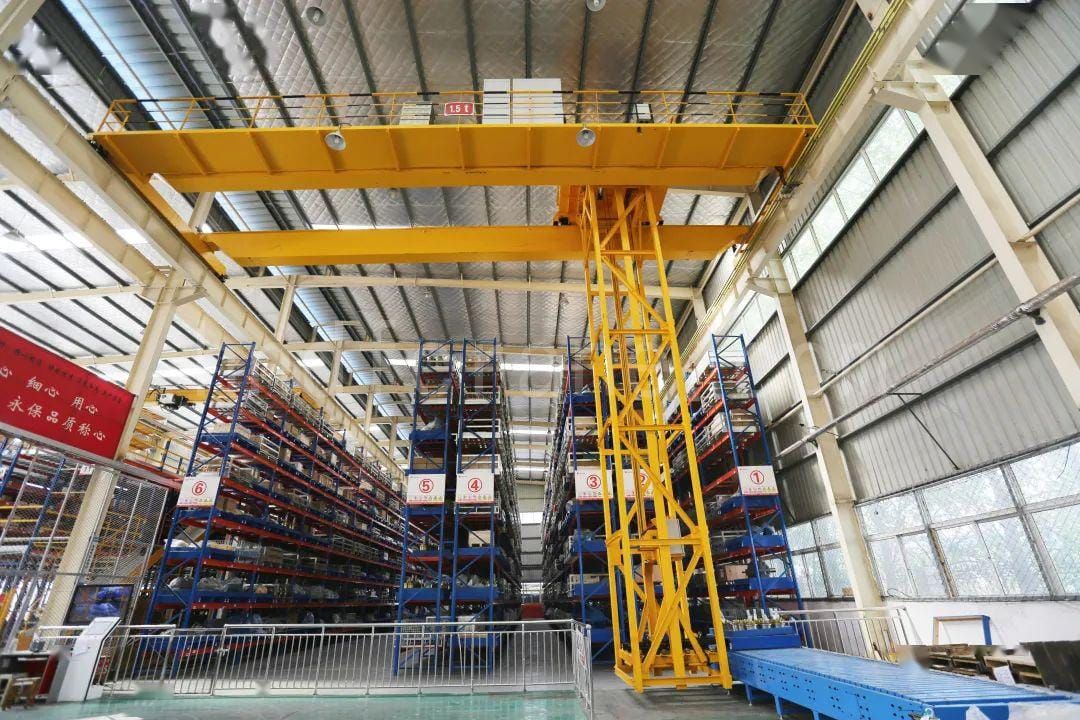

ওভারহেড (ব্রিজ-টাইপ) স্ট্যাকার ক্রেন

পরামিতি

- উত্তোলন ক্ষমতা: ৩ টন – ১৬ টন

- স্প্যান: ১০ মিটার – ৪০ মিটার

- উচ্চতা উত্তোলন: ৬ মিটার – ১২ মিটার

- উত্তোলনের গতি: ১.৫ মি/মিনিট – ১৫ মি/মিনিট

- ভ্রমণের গতি: ৩০ মি/মিনিট – ৬০ মি/মিনিট

- ডিউটি ক্লাস: A5 – A6

সুবিধাদি

- উচ্চ স্থান ব্যবহার: গুদামের উচ্চতার ব্যবহার সর্বাধিক করে তোলে, উচ্চ-স্তরের এবং ঘন সঞ্চয়স্থান সক্ষম করে, প্রতি ইউনিট এলাকায় সংরক্ষণ ক্ষমতা উল্লেখযোগ্যভাবে বৃদ্ধি করে।

- শক্তিশালী অভিযোজনযোগ্যতা: প্যালেটের ধরণ, বিন, লোড ক্ষমতা এবং আইলের মাত্রা অনুসারে কাস্টমাইজযোগ্য, বিভিন্ন কার্গো স্পেসিফিকেশনের সাথে সামঞ্জস্য নিশ্চিত করে।

- উচ্চ অবস্থান নির্ভুলতা: সার্ভো ড্রাইভ, এনকোডার এবং লেজার পজিশনিং প্রযুক্তি দিয়ে সজ্জিত, যাতে ন্যূনতম পজিশনিং ত্রুটি সহ সুনির্দিষ্ট লোড হ্যান্ডলিং নিশ্চিত করা যায়।

- উন্নত ইনবাউন্ড এবং আউটবাউন্ড দক্ষতা: অনুভূমিক ভ্রমণ, উল্লম্ব উত্তোলন এবং কাঁটাচামচ সম্প্রসারণ একই সাথে কাজ করতে পারে, প্রতি অপারেশনে চক্রের সময় হ্রাস করে এবং সামগ্রিক থ্রুপুট উন্নত করে।

নির্ভরযোগ্য এবং নিরাপদ পরিচালনা নিশ্চিত করার জন্য তিনটি প্রধান সিস্টেম

- ক্রেন সিস্টেম: ক্রেন পজিশনিং সিস্টেম, অ্যান্টি-সোয়াই কন্ট্রোল সিস্টেম, হিউম্যান-মেশিন ইন্টারফেস (HMI), ক্রেন রিমোট কন্ট্রোল, ওয়্যারলেস নেটওয়ার্ক কনফিগারেশন, ব্যাকএন্ড সার্ভার এবং ক্রেনের প্রধান নিয়ন্ত্রণ ব্যবস্থা অন্তর্ভুক্ত।

- গুদাম ব্যবস্থাপনা ব্যবস্থা: WCS এবং WMS ম্যানেজমেন্ট সিস্টেম, বারকোড স্ক্যানিং ডিভাইস, গুদাম ব্যবস্থাপনা সফটওয়্যার, ভিডিও নজরদারি সিস্টেম, তারযুক্ত এবং বেতার নেটওয়ার্ক সিস্টেম এবং উৎপাদন সিস্টেম ইন্টিগ্রেশনের জন্য MES ইন্টারফেস অন্তর্ভুক্ত।

- গুদাম এলাকার নিরাপত্তা ও সতর্কতা ব্যবস্থা: ক্রেন অপারেটিং জোন, পথচারীদের হাঁটার পথ এবং যানবাহনের পথের নিরাপত্তা ব্যবস্থাপনা, পাশাপাশি নিরাপত্তা নির্দেশক আলো, অ্যালার্ম ডিভাইস এবং ব্যাপক সুরক্ষার জন্য নিরাপত্তা বিচ্ছিন্নতা বেড়া অন্তর্ভুক্ত করে।

প্যালেট স্ট্যাকার ক্রেন

প্যালেট স্ট্যাকার ক্রেনের বৈশিষ্ট্য

- বৈদ্যুতিক নিয়ন্ত্রণ মোড: বিকল্পগুলির মধ্যে রয়েছে ম্যানুয়াল, আধা-স্বয়ংক্রিয়, স্বতন্ত্র স্বয়ংক্রিয়, অথবা কম্পিউটার-নিয়ন্ত্রিত অপারেশন। প্রয়োজনীয়তার উপর ভিত্তি করে যেকোনো একটি মোড নির্বাচন করা যেতে পারে।

- পরিবর্তনশীল-ফ্রিকোয়েন্সি গতি নিয়ন্ত্রণ: বেশিরভাগ স্ট্যাকার ক্রেন VFD ড্রাইভ এবং ফটোইলেকট্রিক অ্যাড্রেসিং ব্যবহার করে, যা মসৃণ গতি নিয়ন্ত্রণ এবং উচ্চ স্টপিং নির্ভুলতা প্রদান করে।

- নিরাপদ বিদ্যুৎ সরবরাহ: নির্ভরযোগ্য বিদ্যুৎ সরবরাহ নিশ্চিত করার জন্য একটি নিরাপদ স্লাইডিং-কন্টাক্ট পাওয়ার ট্রান্সমিশন ডিভাইস দিয়ে সজ্জিত।

- নিরাপত্তা সুরক্ষা: নিরাপদ অপারেশন নিশ্চিত করার জন্য ওভারলোড স্ল্যাক-রোপ এবং রোপ-ব্রেক সুরক্ষা ডিভাইসগুলি প্রয়োগ করা হয়েছে।

- অপারেটর কেবিন: এর বৈশিষ্ট্য হল একটি চলমান অপারেটর কেবিন যার হাতল এবং বোতামগুলি এরগনোমিকভাবে সাজানো এবং আরামদায়ক আসন নকশা।

- হালকা, অনমনীয় ফ্রেম: স্ট্যাকার ফ্রেমটি হালকা হলেও উচ্চ নমন এবং টর্সনাল কঠোরতা প্রদান করে। উত্তোলন গাইড রেলগুলি সুনির্দিষ্ট এবং পরিধান-প্রতিরোধী, যা সঠিক অবস্থান নির্ধারণের অনুমতি দেয়।

- টেলিস্কোপিক ফর্ক: আইলের প্রস্থের প্রয়োজনীয়তা হ্রাস করুন এবং সামগ্রিক গুদাম স্থানের ব্যবহার উন্নত করুন।

প্যালেট স্ট্যাকার ক্রেনের প্রকারভেদ

| আইটেম | একক-মাস্ট প্যালেট স্ট্যাকার ক্রেন | ডাবল-মাস্ট প্যালেট স্ট্যাকার ক্রেন |

| কাঠামোগত নকশা | একটি মাস্তুল, একটি উপরের রশ্মি এবং একটি নীচের রশ্মি দিয়ে গঠিত; তুলনামূলকভাবে সহজ গঠন | দুটি মাস্তুল, একটি উপরের মরীচি, একটি নীচের মরীচি এবং একটি ভারবাহী গাড়ি দিয়ে গঠিত, যা একটি বন্ধ আয়তাকার ফ্রেম তৈরি করে। |

| ফ্রেমের দৃঢ়তা এবং শক্তি | তুলনামূলকভাবে কম কঠোরতা; অদ্ভুত লোডের প্রতি সীমিত প্রতিরোধ ক্ষমতা | উচ্চ শক্তি এবং সামগ্রিক অনমনীয়তা; বিকৃতির বিরুদ্ধে শক্তিশালী প্রতিরোধ ক্ষমতা |

| অপারেটিং স্থিতিশীলতা | মাঝারি স্থিতিশীলতা; অপারেটিং অবস্থার উপর উচ্চতর প্রয়োজনীয়তা | কম কম্পন সহ মসৃণ অপারেশন; ঘন ঘন শুরু-থামা এবং ব্রেকিংয়ের জন্য উপযুক্ত |

| স্টার্ট/স্টপ এবং ব্রেকিং পারফর্মেন্স | কাঠামোর উপর নির্ভর করে স্টার্ট-স্টপ এবং ব্রেকিং কর্মক্ষমতা সীমিত | দ্রুত শুরু-থামা এবং ব্রেকিংয়ের সুবিধা প্রদান করে, যার ফলে নিরাপত্তার ক্ষেত্রেও অনেক উন্নতি হয়। |

| লোড ক্যাপাসিটি উপযুক্ততা | ছোট থেকে মাঝারি লোডের জন্য উপযুক্ত; ভারী-শুল্ক অ্যাপ্লিকেশনের জন্য সুপারিশ করা হয় না। | বড় লোড ক্ষমতার জন্য উপযুক্ত |

| উচ্চতা উত্তোলনের উপযুক্ততা | কম থেকে মাঝারি উচ্চতার উত্তোলনের জন্য উপযুক্ত | উচ্চ-বৃদ্ধি স্বয়ংক্রিয় গুদামের জন্য উপযুক্ত |

| অনুভূমিক ভ্রমণের গতি | উচ্চ-গতির অনুভূমিক ভ্রমণের জন্য উপযুক্ত নয় | উচ্চতর অনুভূমিক গতির প্রয়োজনীয়তা পূরণ করতে সক্ষম |

| মোট ওজন | সামগ্রিক ওজন হালকা | সামগ্রিক ওজন বেশি |

| উৎপাদন খরচ | কম উপাদান খরচ এবং উৎপাদন খরচ | উচ্চ উপাদান খরচ এবং তুলনামূলকভাবে উচ্চ উৎপাদন খরচ |

| সাধারণ অ্যাপ্লিকেশন | ছোট থেকে মাঝারি আকারের স্বয়ংক্রিয় গুদাম, হালকা-লোড বা সাশ্রয়ী AS/RS | হাই-বে গুদাম, ভারী-শুল্ক স্টোরেজ, উচ্চ-গতির স্বয়ংক্রিয় স্টোরেজ সিস্টেম |

স্ট্যাকার ক্রেন নির্বাচনের সুপারিশ

ওভারহেড (ব্রিজ-টাইপ) স্ট্যাকার ক্রেনগুলিকে অগ্রাধিকার দিন যখন:

- অসম ব্যবহারের হার সহ একাধিক আইল রয়েছে

- মেশিনের সংখ্যা কমানো এবং সামগ্রিক সময়সূচীর নমনীয়তা উন্নত করা প্রয়োজন।

- AS/RS-এ মাঝারি উচ্চতার উত্তোলন এবং ছোট থেকে মাঝারি ভার বহন ক্ষমতা রয়েছে

প্যালেট স্ট্যাকার ক্রেনগুলিকে অগ্রাধিকার দিন যখন:

- একটি একক আইলের জন্য উচ্চ থ্রুপুট এবং কঠোর চক্র-সময় কর্মক্ষমতা প্রয়োজন।

- উচ্চ উত্তোলন উচ্চতা এবং বৃহৎ ভার ধারণক্ষমতা প্রয়োজন

- প্রকল্পগুলি সিস্টেমের স্থিতিশীলতা এবং প্রমাণিত, পরিপক্ক প্রযুক্তির উপর জোর দেয়

একটি স্বয়ংক্রিয় স্টোরেজ এবং পুনরুদ্ধার ব্যবস্থার (AS/RS) মূল সরঞ্জাম হিসেবে, গুদাম স্ট্যাকার ক্রেন স্থান ব্যবহার, পরিচালনা দক্ষতা এবং সামগ্রিক গুদাম ব্যবস্থাপনা উন্নত করতে গুরুত্বপূর্ণ ভূমিকা পালন করে। গুদাম বিন্যাস, পণ্যসম্ভার বৈশিষ্ট্য এবং অপারেটিং প্রয়োজনীয়তার উপর ভিত্তি করে, আমরা গ্রাহকদের নিরাপদ, দক্ষ এবং টেকসই বুদ্ধিমান গুদাম ব্যবস্থা তৈরিতে সহায়তা করার জন্য কাস্টমাইজড স্ট্যাকার ক্রেন সমাধান প্রদান করি।