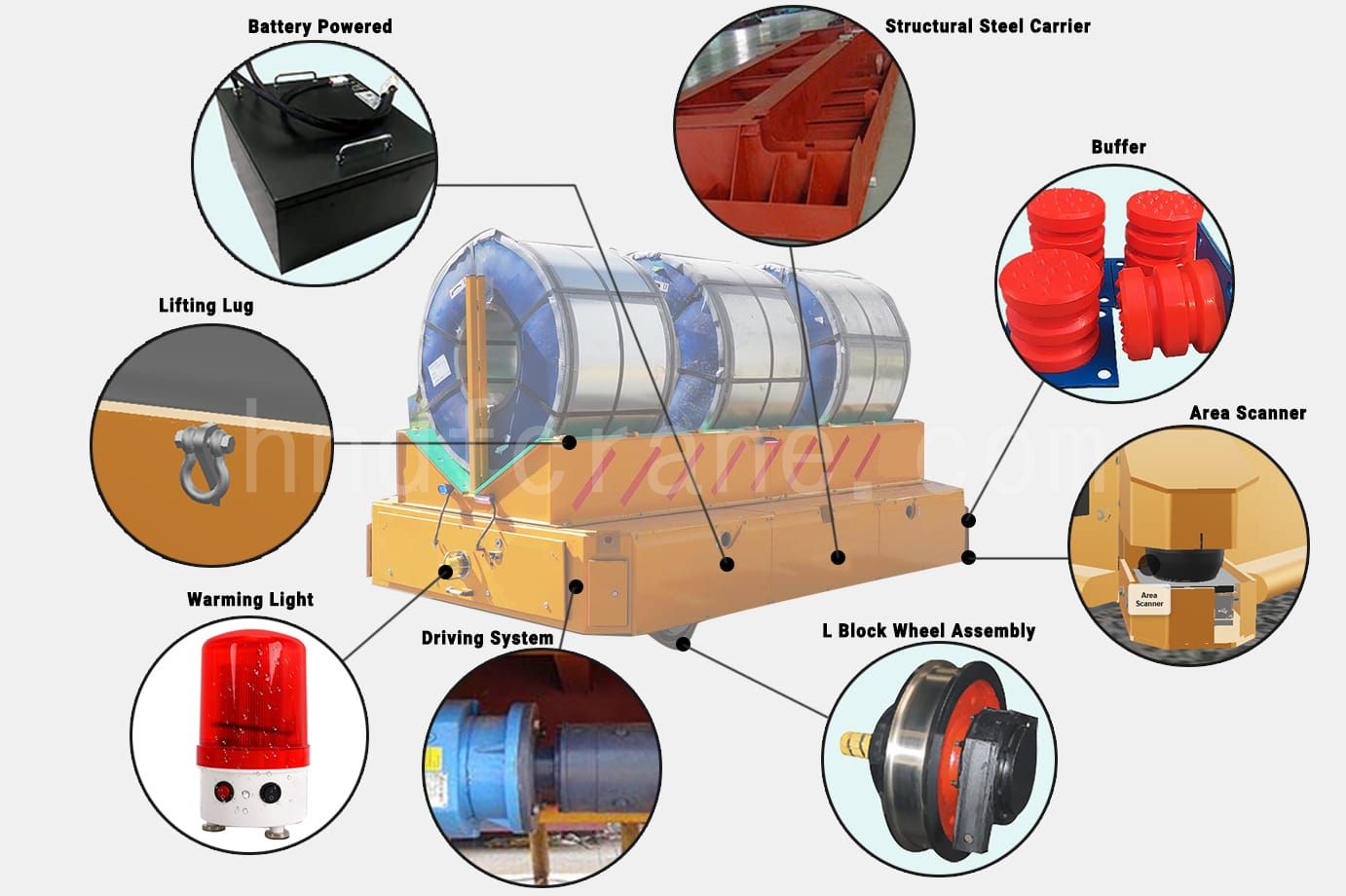

耐久性に優れた設計:すべてのコイル移送カートにはプレミアム部品が使用されています

1. 吊り上げラグ

- 持ち上げや位置決めが簡単: クレーンフックの取り付け用に設計されており、積み込み、積み下ろし、再配置を迅速かつ安全に行うことができます。

- 一体型で頑丈 デザイン: 強化構造のフレームに溶接されており、満載の吊り上げ時の安全性を確保します。

- 標準またはカスタム構成: 持ち上げラグは、取り扱い要件に応じてサイズと位置を変更できます。

2. Lブロックホイールアセンブリ

- 高強度鋳鋼: 鋳鋼55製で、耐荷重性と耐摩耗性に優れています。

- カスタムキャストオプション: お客様のご要望に応じて、鋳造タイプまたは鍛造タイプをご用意しております。

- 柔軟なホイールカラー設計: さまざまなレール条件に適合するシングルカラーまたはダブルカラーのホイール。

3. ポリウレタンバッファー

- 極端な温度(高温または低温)でも優れたパフォーマンスを発揮します。

- 耐腐食性があり、経年劣化しないので長期間ご使用いただけます。

- 負荷がかかっても安定しており、ゆっくりとリバウンドして衝撃を効果的に制御します。

4. 構造用鋼材キャリア

- 高強度ボックスガーダー設計: 二重の縦桁と補強梁を装備し、均一な荷重分散と変形の防止を確保します。

- 高品質スチール素材:Q235B: 耐久性があり溶接可能で、高負荷の産業用途に最適です。

- より美しい外観のための精密仕上げ: 表面を研磨し、ほこりを除去して耐腐食性と清潔な美観を実現。

5. 電池駆動

- オプションのバッテリータイプ: さまざまな使用ニーズに合わせて、鉛蓄電池とメンテナンスフリーのオプションが用意されています。

- 長持ちするパフォーマンス: 1回の充電で4~5時間のフル負荷連続動作をサポートします。

- スマート充電ソリューション: インテリジェント バッテリー チャージャーが付属。8 ~ 10 時間でフル充電できます。

6. ステアリングと 動作機構

- 効率的なDCモータードライブ: 安定した始動、高トルク、低電圧動作、省エネ - 高負荷作業に最適です。

- 硬化表面ギア減速機: 低ノイズで高い伝送効率を実現し、耐久性と静かな動作を実現します。

- メンテナンスと設置が簡単: 柔軟なシャフト回転、モジュール式アセンブリ、メンテナンスしやすいレイアウト。

7. エリアスキャナ

- アクティブ障害物検知: 周囲を継続的にスキャンし、カートの進路上にある人や物体を検出します。

- 自動緊急停止: 障害物を検知すると停止し、運転の安全性を高めます。

- カスタマイズ可能な検出ゾーン: スキャン範囲と警告ゾーンは、作業環境のニーズに応じて調整できます。

8. 警告灯

- 視覚的な安全警告: 作動中に自動的に点滅し、近くの人員に警告を発し、事故のリスクを軽減します。

- リアルタイムステータスインジケーター: 電源オン、移動、または障害の状態を示し、より安全な操作とメンテナンスをサポートします。

- 耐久性と耐候性: 産業グレードのコンポーネントで構築されており、過酷な工場環境に適しています。

あらゆる移動に対応する4種類のコイル搬送カート

バッテリー駆動のコイル搬送カート

- 操作性が高く、旋回や柔軟なルーティングをサポートします。

- 軽負荷から中負荷の用途に適しています。

- 実行時間が限られているため、定期的なバッテリーのメンテナンスが必要です。

ケーブル電源コイル移送カート

- 作業時間に制限がなく、ワークショップでの使用に最適です。

- 積載容量をカスタマイズでき、重量物の輸送に最適です。

- 絶縁レールが不要になり、レールのセットアップが簡単になります。

レールガイド式コイル搬送カート

- 重い荷物や長距離輸送に最適です。

- 絶縁トラックの設置が必要です。

- 高負荷環境でも安定して効率的です。

無軌道コイル搬送カート

- 工場全体にわたって完全にトラックフリーで柔軟な動きを実現します。

- ステアリングホイール2個+駆動輪2個を装備。

- レールのレイアウトやルートの長さに制限はありません。

あらゆるコイル移動作業に対応するコイル搬送カート

鉄鋼業界向けコイル搬送カート

あらゆる作業場で効率的かつ安全なコイル処理を実現

- 複数のワークショップアプリケーションに適しています

製鋼、冷間圧延、コーティング、完成品保管に最適で、あらゆる生産段階でコイルの動きに対応できるように構築されています。 - 安全で安定したコイル輸送

V 字型のサポートと交換可能な耐摩耗パッドを装備し、移動中に転がりを防止し、コイル表面を保護します。 - 安全機能を備えた簡単な操作

オペレーターはカートの横を歩き、手持ちパネルで操作します。緊急停止ボタンと警告灯により、産業環境における安全な使用が保証されます。 - トラックまたはトラックレスのオプションが利用可能

現場のレイアウトに合わせて、レールガイド式または操舵式無軌道式モデルをお選びいただけます。狭い通路や複雑な通路でも柔軟なナビゲーションを実現します。 - 耐久性の高い容量とモジュール構造

高強度鋼製で、メンテナンスが容易なモジュール設計を採用しています。製鉄所の厳しいニーズに応えるため、最大1500トンの積載量に対応できるよう設計されています。

製紙・印刷業界向けコイル搬送カート

効率的な包装と印刷のための大型紙ロールの信頼性の高い取り扱い

- 製紙工場の包装ライン向けカスタムソリューション

生産ラインまたは仕上げライン内で大きなロールの包装紙を効率的に配置および輸送できるように設計されています。 - 複数のロールサイズをサポート

長さ 30 インチから 100 インチ以上、重量最大 6,500 ポンドの紙ロールを処理できるようにカスタマイズされており、多様な生産ニーズに対応します。 - 柔軟なスリングハンドリング

ロール径、重量に応じて様々なスリングタイプに対応し、安全で安定した作業を実現します。 - 耐久性があり、手動で操作しやすい設計

人間工学に基づいた手動操縦用ハンドルと、コンクリートの床での屋内使用に長期間耐えられるエポキシコーティングされた表面を備えています。

Dafang Craneのコイル搬送カートを活用したグローバルプロジェクト

コイル搬送カートをポーランドに輸出

国: ポーランド

タイプ: バッテリー駆動のコイル搬送カート

電源: バッテリー駆動

適用業界: 鉄骨構造物製作工場。

アドバンテージ:

- 動力のない鉄道車両+トラクターを置き換え、自動輸送を可能にします。

- レーザー障害物回避センサーとポリウレタン バッファーを装備し、二重の安全保護を実現します。

- 油圧式リフトシステムは、5~500トンのカスタマイズ可能な荷重で、マルチプロセスの積み込み/積み下ろしに適応します。

- 生産効率が向上し、顧客からも高い評価を得ています。

コイル搬送カートをハンガリーへ輸出

国: ハンガリー

タイプ: 25トンバッテリー駆動コイル搬送カート

電源: バッテリー駆動

適用業界: 鉄鋼サービスセンター。

アドバンテージ:

- バッテリー駆動で柔軟性と効率性に優れ、人件費と調達コストを削減します。

- パンデミック中のサプライチェーンの課題を克服し、プロジェクトの遂行を確実にしました。

- 輸送の安全性と生産効率が大幅に向上し、顧客から高い評価を得ています。

コイル搬送カートをチェコ共和国に輸出

国: チェコ共和国

タイプ: 30トンバッテリー駆動コイル搬送カート

電源: バッテリー駆動

適用業界: 板金製造工場。

アドバンテージ:

- 完全に電動化されたリモートコントロール車両がトラックの使用に取って代わり、手作業による取り扱いのリスクが軽減されます。

- モジュラー V テーブルには、フラットシートの輸送用に取り外し可能なコイルと、二重の目的を持つカートが保持されます。

- スマートファクトリー対応で、自動化システムに簡単に接続できます。

- 耐久性に優れた設計により、厳しい環境、狭いスペース、不均一な床にも対応し、ワークフローを向上させます。

適切なコイル移送カートを選択するにはどうすればよいでしょうか?

最も適切なコイル転送を見つけるには、次の重要な情報を提供するだけです。

- 移送する必要があるコイルの具体的な仕様は何ですか(直径、幅など)?

- 必要な積載量はトン単位で何トンですか?

- 移送カートは線路上または地上を走行する必要がありますか?

- 作業台の寸法(長さ × 幅 × 高さ)に関する要件は何ですか?

- 片道の走行距離はどのくらいですか?

- 一日に何時間働きますか?

コイル搬送トロリーの不適合で生産が停滞しないよう、ご要件をご記入の上、当社のシニアエンジニアまでお気軽にお問い合わせください。1対1のコイル搬送ソリューションをご提供いたします。正確なコスト見積もりと、お客様に合わせたお見積りを無料でご提供いたします。機種選定から現場での導入まで、コイル搬送システムのアップグレードをあらゆる段階でサポートいたします。