Pembinaan Infrastruktur Keretapi

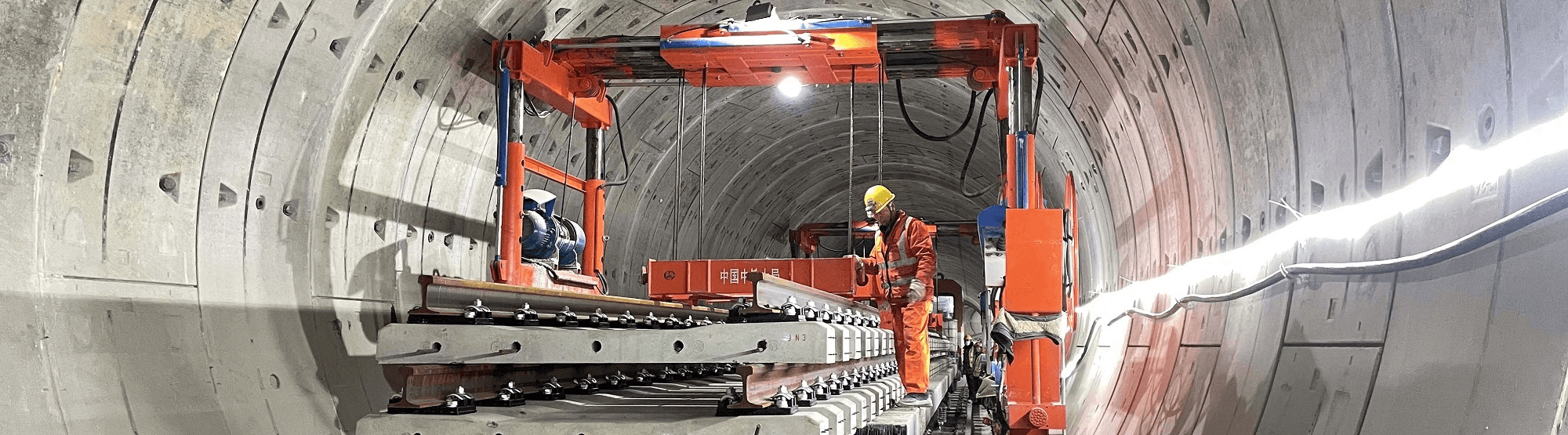

Kereta Api Bawah Tanah Meletak Kren Gantry

Kren gantri meletakkan landasan bawah tanah menggunakan pengangkat elektrik jenis CD1/MD1, yang menampilkan struktur ringkas, prestasi stabil dan ketahanan yang kukuh, untuk operasi pengangkatan yang diselaraskan. Mekanisme perjalanan kren menggunakan peranti pemacu menegak untuk pemacu berasingan, dan kawalan boleh direalisasikan melalui kawalan pautan tunggal atau berbilang. Kren gantri menggunakan struktur jenis kotak padat, dengan rentang dan ketinggian berubah-ubah untuk menyesuaikan diri dengan ruang terowong. Semasa operasi, berbilang kren berfungsi bersama dalam pengangkatan segerak.

- Mudah dipasang dan dikendalikan, dengan kos penyelenggaraan yang rendah.

- Kelajuan larian boleh laras dan kecekapan pengendalian yang tinggi.

- Struktur padat, sesuai untuk operasi dalam ruang terkurung.

- Fleksibiliti yang kuat, sesuai untuk pelbagai jenis terowong bawah tanah.

- Dilengkapi dengan fungsi pelarasan span dan ketinggian automatik.

- Boleh diangkut dan dipindahkan secara keseluruhan.

- Kren gantri jenis ini direka khas untuk projek peletakan landasan bawah tanah. Ia digunakan terutamanya untuk mengangkat panel trek, acuan, dan pemasangan rebar dalam pembinaan landasan bawah tanah; tapak kerja biasanya dalam ruang terkurung seperti bahagian bawah tanah.

- Berdasarkan beban dan kekerapan penggunaan, kren direka bentuk dengan kelas pekerja A3 atau lebih tinggi.

- Mengikut keperluan pembinaan kereta bawah tanah, kren gantri meletakkan landasan dikehendaki mempunyai fungsi pelarasan span dan ketinggian automatik; ia memenuhi syarat kerja semua jenis projek kejuruteraan landasan terowong bawah tanah di China. Kren boleh melalui platform, pintu skrin, bahagian lengkung kecil, dan laluan silang, dan boleh diangkut dan dipindahkan dalam terowong tanpa dibongkar.

- Kelembapan relatif: 55%–85%; kepekatan gas mudah terbakar tidak melebihi 10% daripada had letupan yang lebih rendah. Suhu persekitaran: -25℃~+40℃.

Pengeluaran dan Penyelenggaraan Rolling Stock

Kren Overhed Girder Tunggal

ini kren atas galang tunggal digunakan terutamanya untuk pembuatan, pemeriksaan, penyelenggaraan dan servis kereta api berkelajuan tinggi, kereta bawah tanah dan trem.

- Kren penuh mengguna pakai reka bentuk Eropah, menampilkan berat diri yang ringan, tekanan roda rendah dan dimensi kelegaan padat;

- Mudah dikendalikan, berjalan lancar, dan bunyi yang rendah;

- Ketepatan kedudukan tinggi, selamat dan boleh dipercayai;

- Pengendalian beban yang tepat dan boleh dipercayai.

Kren Overhed Double Girder

ini kren atas galang dua digunakan untuk mengangkat kenderaan transit rel seperti kereta api, kereta api berkelajuan tinggi, kereta bawah tanah dan gerabak barang, menjalankan tugas pemeriksaan dan penyelenggaraan di depoh perkhidmatan.

- Kawalan frekuensi berubah sepenuhnya untuk pengangkatan lancar dan perjalanan dengan impak yang minimum;

- Dilengkapi dengan teknologi anti hayunan untuk mengurangkan hayunan beban dengan berkesan;

- Komponen struktur dimesin secara keseluruhan untuk memastikan ketepatan pemasangan;

- Penampilan menarik, reka bentuk ringan dan bunyi yang rendah.

Kren Gantry Double Girder

Kren gantri double girder ini bertanggungjawab untuk pengeluaran dan operasi mengangkat dalam projek kereta api.

- Reka bentuk yang ringan

- Tekanan roda rendah

- Tanpa penyelenggaraan

- Operasi lancar

- Bunyi rendah

- Penjimatan tenaga dan mesra alam

Pengendalian Kontena untuk Kereta Api

Kren Gantry Kontena Dipasang Rel RMG

The kren gantri kontena yang dipasang di rel disokong pada trek oleh beberapa set roda keluli dan dikuasakan oleh elektrik sesalur. Ia terdiri daripada mekanisme perjalanan kren, pemasangan troli, rangka gantri, sistem kuasa dan penyebar khusus kontena.

Dafang Crane pakar dalam menyediakan:

- Kren gantri kontena yang dipasang di rel pusingan atas (putar troli).

- Kren gantri kontena yang dipasang di rel putaran bawah (pemutar penyebar).

- Kren gantri kontena yang dipasang pada rel dan bukan julur

- Kren gantri kontena yang dipasang di rel yang direka khusus untuk aplikasi kereta api

Produk kami serasi dengan pelbagai jenis dan model penyebar kontena tujuan umum atau khusus, memastikan pengendalian bekas standard atau khas yang cekap di bawah keadaan kerja yang berbeza.