Introduzione al settore

Pressione economica, invecchiamento della forza lavoro, rapida digitalizzazione e standard ambientali in continua evoluzione: le aziende del settore petrolifero e del gas di oggi si trovano ad affrontare sfide sempre più complesse, garantendo al contempo la sicurezza e l'affidabilità di operazioni rigorosamente regolamentate. Dafang Crane si impegna da diversi anni a fornire gru a ponte affidabili, sicure ed efficienti per l'industria petrolifera e del gas, aiutando i nostri clienti a raggiungere sia l'efficienza operativa che la conformità ambientale.

Dafang Crane offre un'ampia gamma di tecnologie, servizi e soluzioni per l'intero ecosistema petrolifero e del gas. Le nostre innovazioni in termini di tenuta, orientate al mercato e basate su affidabilità e sostenibilità, aiutano i clienti a migliorare l'efficienza operativa, prolungare la durata utile delle apparecchiature e supportare i principali sforzi di riduzione delle emissioni. In qualità di fornitore affidabile di gru a ponte per l'industria petrolifera e del gas, ci impegniamo a fornire soluzioni di sollevamento che soddisfino i rigorosi standard di prestazioni e sicurezza del settore.

Classificazione delle gru a ponte per l'industria petrolifera e del gas

Gru a ponte per coker con benna

Le gru a ponte con benna per cokeria sono gru appositamente progettate per resistere alla continua usura e alla pressione del funzionamento in qualsiasi condizione atmosferica della cokeria. Come parte delle gru a ponte per l'industria petrolifera e del gas, la gru per cokeria negli impianti petrolchimici rimuove il combustibile di coke fresco caldo dalla fossa di cokeria dal tamburo di cokeria per raffreddarlo. Dopo 24 ore, la gru trasporta il coke raffreddato e disidratato al frantoio, alla tramoggia o al nastro trasportatore. Questo lavoro è rapido e continuo e qualsiasi fermo macchina interrompe completamente la produzione. La gru opera in un ambiente ostile, ricco di umidità, fumi corrosivi e polveri abrasive.

Vantaggi

- Esistono due tipi di configurazioni di estensione della benna mordente: parallela al piano e verticale alla trave portante. Il sistema pick-and-place utilizza una gru a benna mordente a quattro funi con tamburo a doppio cerchio, nota per la sua struttura semplice e le prestazioni affidabili. Come parte delle gru a ponte per l'industria petrolifera e del gas, la gru a ponte per coker consente l'estensione e la retrazione a qualsiasi altezza relativa, garantendo una movimentazione efficiente e flessibile dei materiali in ambienti difficili.

- La benna mordente è adatta alla movimentazione di materiali sfusi nel loro stato naturale. In caso di utilizzo per operazioni subacquee o materiali speciali, è necessario specificare chiaramente i requisiti specifici nell'ordine. Per applicazioni esterne, è essenziale un'attrezzatura impermeabile. Il sistema di sollevamento può essere utilizzato sia all'interno che all'esterno e, in caso di utilizzo all'esterno, è necessario installare una copertura antipioggia. Come componenti di gru a ponte per l'industria petrolifera e del gas, questi sistemi di benne mordenti sono progettati per adattarsi ad ambienti di lavoro difficili, mantenendo al contempo affidabilità ed efficienza.

- Struttura ragionevole, forte capacità portante

- Bassa rumorosità, avviamento e arresto graduali

- Funzionamento sicuro e affidabile

- Cabina comoda e vista aperta

- Manutenzione a basso costo, lunga durata

- Tipo di scatola robusta, saldatura a mano con macchina

- Le ruote sono realizzate con fusione sotto vuoto e tempra a media frequenza

- Il controllo dell'oscillazione può ridurre l'oscillazione del carico e la collisione con tramogge e pareti della fossa, riducendo così i danni a benne, tramogge e fosse.

- Grazie alla frenata rigenerativa, l'energia erogata viene restituita alla rete elettrica della gru, con conseguente risparmio energetico.

- Utilizzare un motore di conversione di frequenza per un controllo preciso della velocità

- La sala di controllo ha funzioni pressurizzate e resistenti alle intemperie

- I filtri chimici nella cabina rimuovono costantemente gli inquinanti dall'atmosfera e proteggono i componenti di controllo sensibili e i dipendenti.

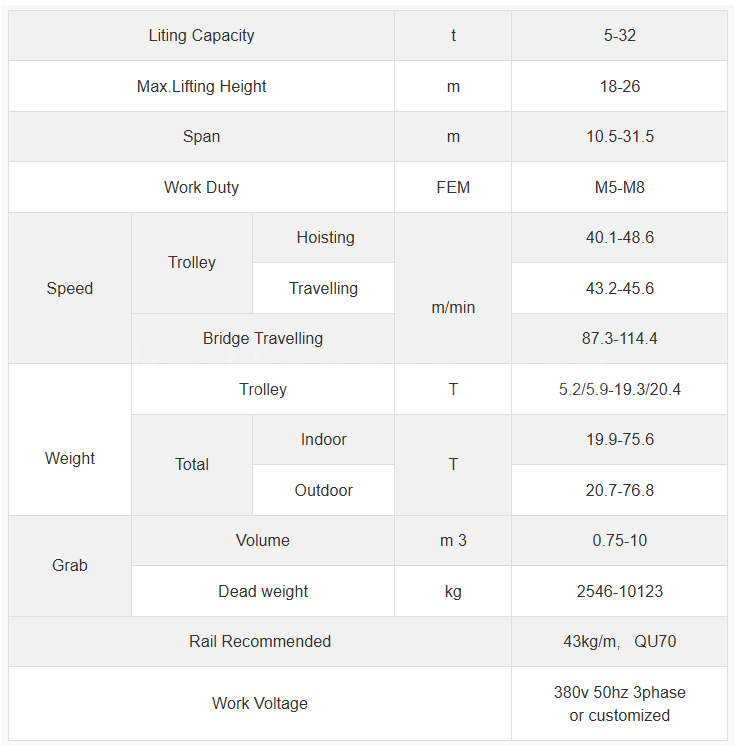

Parametri tecnici delle gru a ponte Coker con benna

Servizio gru Dafang

- Forniamo il miglior servizio di assistenza 24 ore su 24, 7 giorni su 7 per qualsiasi marca di gru a ponte per coker con pinza, inclusa la gestione delle chiamate per guasti importanti, la manutenzione preventiva, l'installazione e la messa in servizio.

- La nostra caratteristica è quella di fornire un servizio di altissima qualità e soddisfare i clienti.

- Disponiamo di esperti responsabili del funzionamento e della manutenzione di tali gru di processo, che svolgono un ruolo fondamentale nella raffineria DCU.

- Siamo esperti in analisi delle unità e capacità di manutenzione.

- Forniamo supporto correttivo per il posizionamento dei binari e delle ruote.

- Forniamo servizi di ispezione annuale e manutenzione preventiva a prezzi ragionevoli e competitivi.

Gru intelligente per serbatoi di coke

Vantaggi della gru intelligente per serbatoi di coke

- Regolazione della velocità tramite conversione di frequenza, elevata efficienza e risparmio energetico: come parte delle nostre gru a ponte per l'industria petrolifera e del gas, l'intero sistema della gru adotta un sistema di regolazione della velocità tramite conversione di frequenza, che garantisce elevata precisione di posizionamento, maggiore efficienza, notevoli risparmi energetici e un'affidabilità eccezionale.

- L'interazione uomo-computer è completamente automatizzata, senza intervento umano, e l'efficienza lavorativa è migliorata grazie alla videosorveglianza a distanza e alla tecnologia di interazione uomo-computer.

- Per garantire il funzionamento regolare della gru del serbatoio del coke vengono utilizzati un sistema integrato, un sistema anti-vibrazione preciso, un controllo elettrico centralizzato e un sistema anti-vibrazione assistito meccanicamente.

- Ricerca e sviluppo personalizzati, prestazioni superiori per soddisfare le esigenze dell'industria della cokeria, progettazione e ricerca personalizzate per garantire che le attrezzature della gru abbiano prestazioni eccellenti in tutti gli aspetti di funzionamento e utilizzo e soddisfino le esigenze del processo produttivo.

Cassa intelligente per gru per serbatoi di cokeS

Gru intelligente per serbatoi di coke

Gru intelligente per serbatoi di coke

Gru intelligente per serbatoi di coke

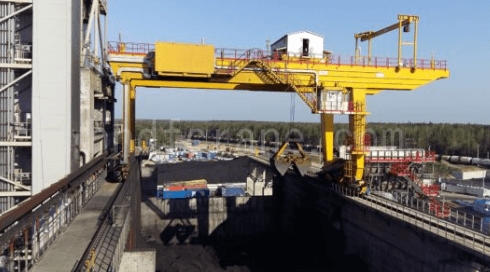

Gru a portale per coker

La gru a portale per cokeria può operare in un ampio intervallo di temperatura, da -50 °C a +38 °C. Il materiale movimentato, il coke di petrolio verde, è sia abrasivo che corrosivo. Come parte dei nostri carriponte per l'industria petrolifera e del gas, tutte le macchine sono specificamente progettate e protette per resistere alle difficili condizioni ambientali dell'impianto.

Vantaggi delle gru a portale per coking

- Controllo continuo

- Ingranaggio temprato Classe di protezione IP55

- Heavy duty motor, 60%ED rating

- Freno a disco elettromagnetico, antipolvere

- Nessuna perdita d'olio, freno autoregolante

- Cavo metallico zincato per impieghi gravosi

- Progettazione affidabile e performante

- Dimensioni più piccole, carico della ruota più leggero

Caso di gru a portale per cokerS

Le gru a portale singolo vengono utilizzate nel progetto di ammodernamento dei residui petroliferi della raffineria turca

Gru a portale singolo per coking utilizzate nelle raffinerie spagnole

Gru a portale singolo per coker per raffinerie russe