天井クレーンレールの紹介

クレーンレールは鉄道業界において重要な位置を占めており、その特殊な設計により、高い横方向荷重に耐え、クレーンの安定性と安全性を確保しています。Dafang Craneは、幅広い産業用途のニーズに応える高品質なクレーンレールソリューションの提供に注力しています。当社のレール製品は、以下の点を念頭に設計・製造されています。

- 幅広ベース設計:高い横方向荷重下でもトラックの安定性を確保し、トラックの変形や損傷を防止します。

- 厚いウェブ: トラックの運搬能力が向上し、特に大型クレーンの使用に適しています。

- 特殊プロファイル: 当社は、中国規格 GB クレーンレール、ドイツ規格 DIN クレーンレール、英国規格 BS クレーンレール、欧州規格 EN クレーンレール、日本規格 JIS クレーンレール、オーストラリア規格 AS クレーンレール、およびさまざまな地域や業界のニーズを満たすために特定のプロジェクト向けにカスタマイズされた特殊トラックなど、さまざまな大型クレーンレール プロファイルを提供しています。

- カスタマイズされたサービス: お客様の特定のニーズに応じて、各プロジェクトに最適なクレーンレールのパフォーマンスを確保するためのカスタマイズされたソリューションを提供します。

大方クレーンは、お客様の業務効率の向上とプロジェクトの安全性確保に貢献するため、最も信頼性の高いクレーンレール製品の提供に尽力しています。高品質な製品を提供するだけでなく、専門的な技術サポートとコンサルティングサービスも提供し、あらゆるプロジェクトが円滑に遂行されるよう尽力しています。大方クレーンを選ぶことは、高品質と卓越したサービスを選ぶことを意味します。

天井クレーンレールの分類

クレーンレールの化学組成

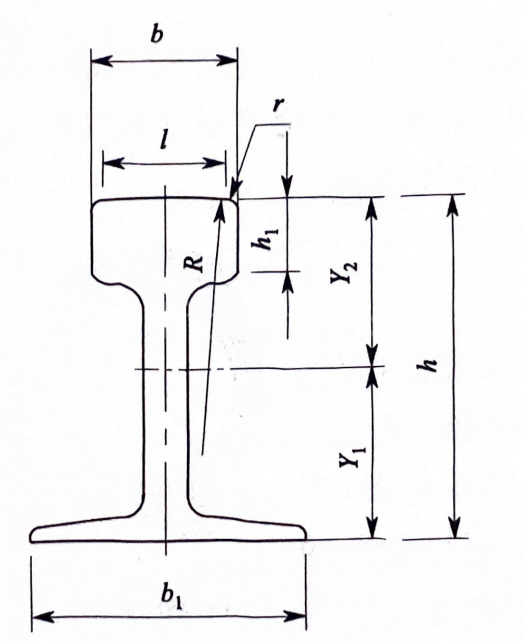

| タイプ | 化学組成/% | ||||

| C | シ | マン | P | S | |

| U71Mn | 0.65~0.77 | 0.15~0.35 | 1.10~1.50 | ≤0.40 | ≤0.40 |

クレーンレールの分類

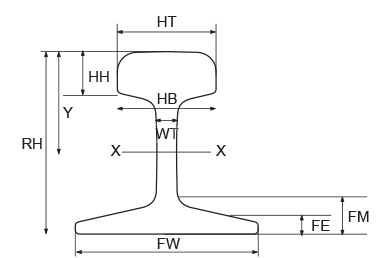

クレーンレール部

厚いウェブのレール

薄いウェブのレール

ドイツ規格DINクレーンレール

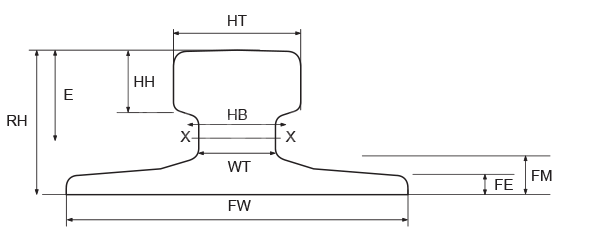

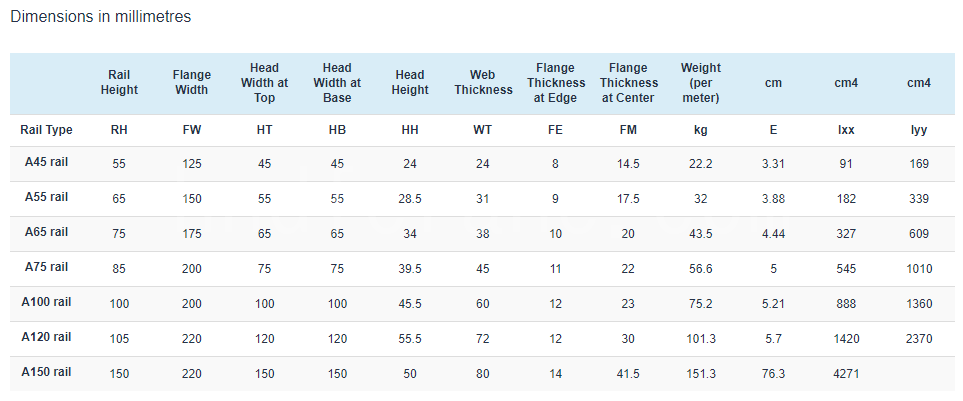

短くて低いレールのクラスはヨーロッパで開発され、DIN 536規格で規定されています。一般的に「DIN」レールと呼ばれるこれらのレールは世界中で使用されており、その使用量は世界で最も広く使用されているクレーンレールです。

DINレールは、A45(22.1 kg/m)からA150(150.3 kg/m)までの幅広いサイズを取り揃えており、ほとんどのクレーンレールシステムの要件を満たすことができます。他の多くのレールの名称とは異なり、DINレールの名称はヘッドの幅を表しており、重量を表しているわけではありません(例えば、A45はヘッド幅が45mmです)。

各DINレールプロファイルは、低重心、比較的幅広で堅牢なヘッド、そして非常に幅広のウェブとベースを特徴としています。連続した支持を提供する梁や基礎に設置するように設計されており、低い高さは頭上クリアランスが重要な設置において大きなメリットとなります。幅広さと角ばった形状は非常に安定しており、クレーン用途に最適です。

DIN 536規格では、引張強度が690MPaを超える鋼と880MPaを超える鋼の2種類の鋼種が定義されています。時を経て、各製鉄所ではこれらの鋼種を表すために異なる専門用語を使用するようになりました。Wirth RailのDINレールサプライヤーであるArcelorMittalは、70kgと90kgという名称を使用しています。(ちなみに、880MPa = 880 N/mm² ˜ ( 90kg × 重力定数 9.81m/s² )/mm² です。)

欧州にはさらに2つのグレードがありますが、DIN 536規格には記載されていません。この鋼はクロムとバナジウムを合金化することで、1080MPaを超える引張強度を実現しています。アルセロール・ミッタルは、これらの鋼を資料の中で110 CrVおよびR340と呼んでいます。

欧州大型クレーンレールの標準長さは、9、10、12、15、18メートル(≈30、33、39、49、59フィート)です。その他の長さも特注でご提供可能です。レールは形状が太いため、穴あけ加工が困難です。端部は標準で直角仕上げですが、マイターカットも承っております。

すべてのクレーンレールは、厳格な冶金品質基準に従って製造・試験されています。レールの耐荷重性を向上させながら、使用中の摩耗率を低減する複数のグレードをご用意しています。クレーンレールの等級分けは、その産地によって異なります。北米ではブリネル硬さが等級分けの目的で使用され、欧州規格では引張強度が重視されます。これら2つのシステムには、おおよその相関関係があります。

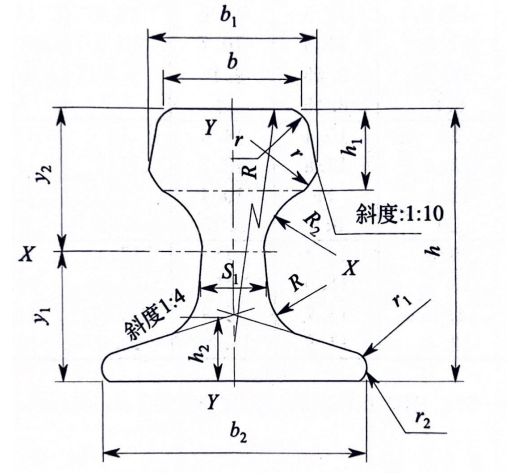

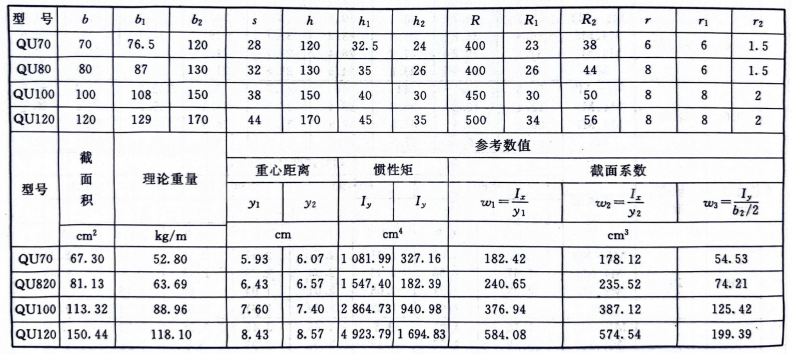

技術パラメータ

欧州規格ENクレーンレール

クレーンレールは6メートルから12メートルまで、様々な長さをご用意しております。ご要望に応じて、その他の長さも承ります。

当社では、クレーンホイールの用途やシステムの予想寿命に合わせて、お客様のご要望に応じてさまざまな品質と仕様の鋼を生産しています。

残念ながら、クレーンレールの最も一般的なセクションは現在圧延中であるため、すべてのセクションがすぐに入手できるわけではありません。ご希望のセクションが入手できず、圧延予定日も未定の場合、Dafang Craneはお客様と協力して、類似の特性を持つ代替セクションをご提案いたします。

技術パラメータ

中国規格GBクレーンレール

クレーンレールは特殊な鋼製レールです。クレーンレールは、クレーンレールにも適用できるという点で、通常の鋼製レールとは異なります。クレーンの種類や用途に応じて、クレーンレールは、通常のレールレール、特殊クレーンレール(鋼製クレーンレール)、または角形・長方形断面レールに分類されます。

地上クレーンは主に一般的なクレーン軌道を採用しています。橋梁クレーンでは特殊なクレーン軌道が使用されることが多く、他にも様々な軌道を選択できます。トロリーにも同様の軌道があり、クレーンの橋梁または水平アームに固定されます。鉄骨梁のフランジを台車の軌道として使用することもできます。クレーン軌道の基礎は、コンクリート、鉄筋コンクリート、スラグライニング、金属梁などです。

- 軌道線の直線度、軌間、2本のレールの高低差などはクレーンの動作性能に大きな影響を与えるため、仕様で要求される精度に従って設置する必要があります。

- 基礎に沿って滑らないように、トラックはしっかりと固定する必要があります。

- 使用中にトラックが変形したり、レールの頭部が摩耗したりすることがあるため、調整や交換を容易にするために、トラックボルトやその他のトラックファスナーを使用して、トラックと基礎を可能な限り分解する必要があります。

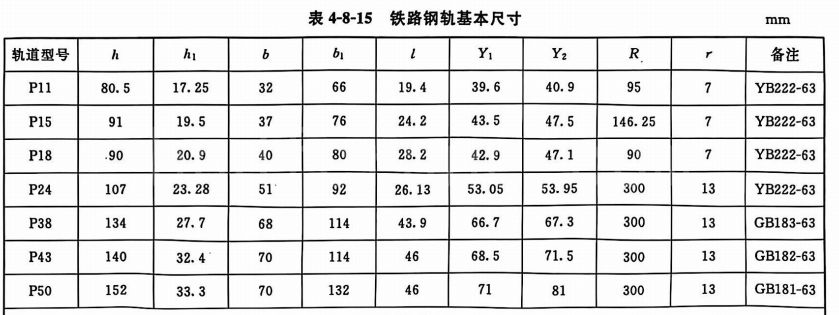

技術パラメータ

クレーンレール部

薄ウェブP型レール

英国規格BSクレーンレール

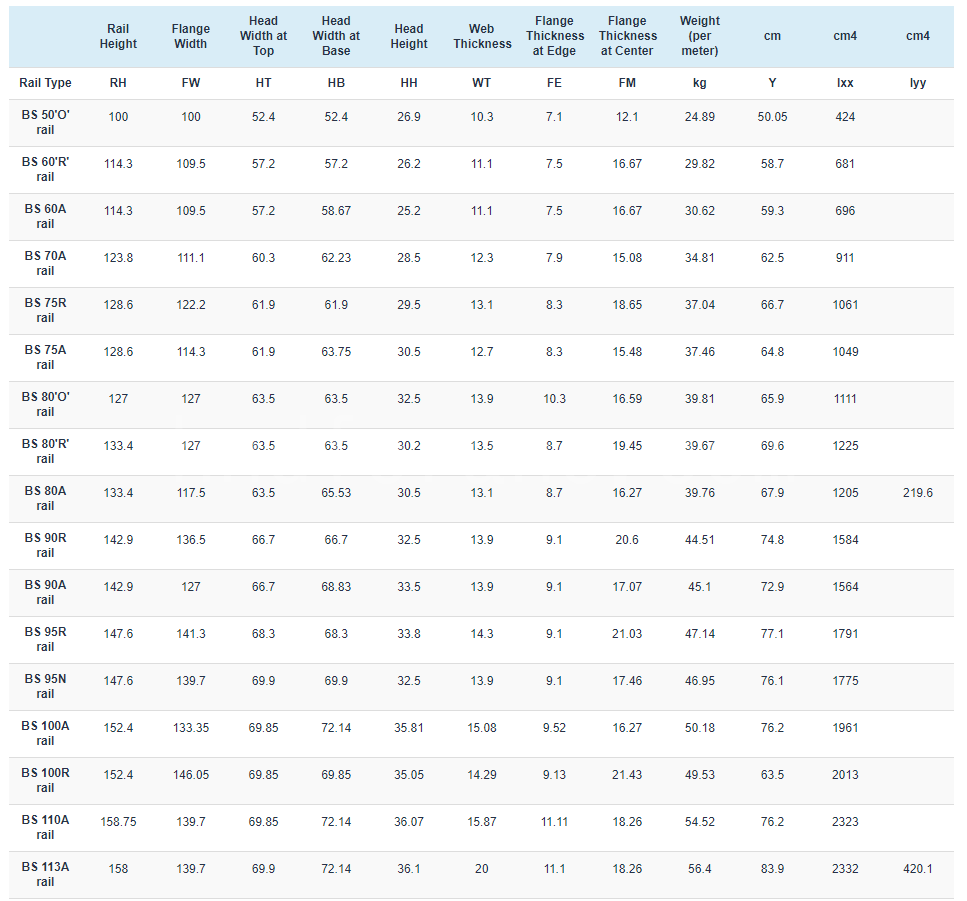

技術パラメータ

日本規格 JIS クレーンレール

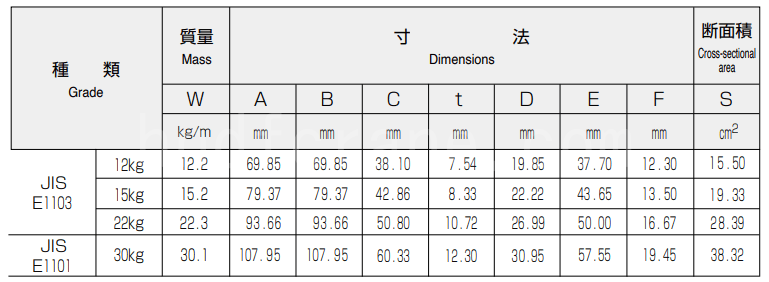

技術パラメータ

私たちは以下を提供できます

- サイズの範囲が広いです。

- 在庫状況。

- 完全に時間通りに配達されます。

- 処理: 穴あけ、切断、超精密試験。

- プロジェクト管理: 例: フロー配信とストレージ オプション。

- フィッシュプレート、クレーン クリップ、パッドなどの固定システムを提供します。

- 当社は、鉄道のみ、または鉄道パッケージ全体を供給しているあらゆる市場のあらゆる企業と協力してきました。