pengenalan produk

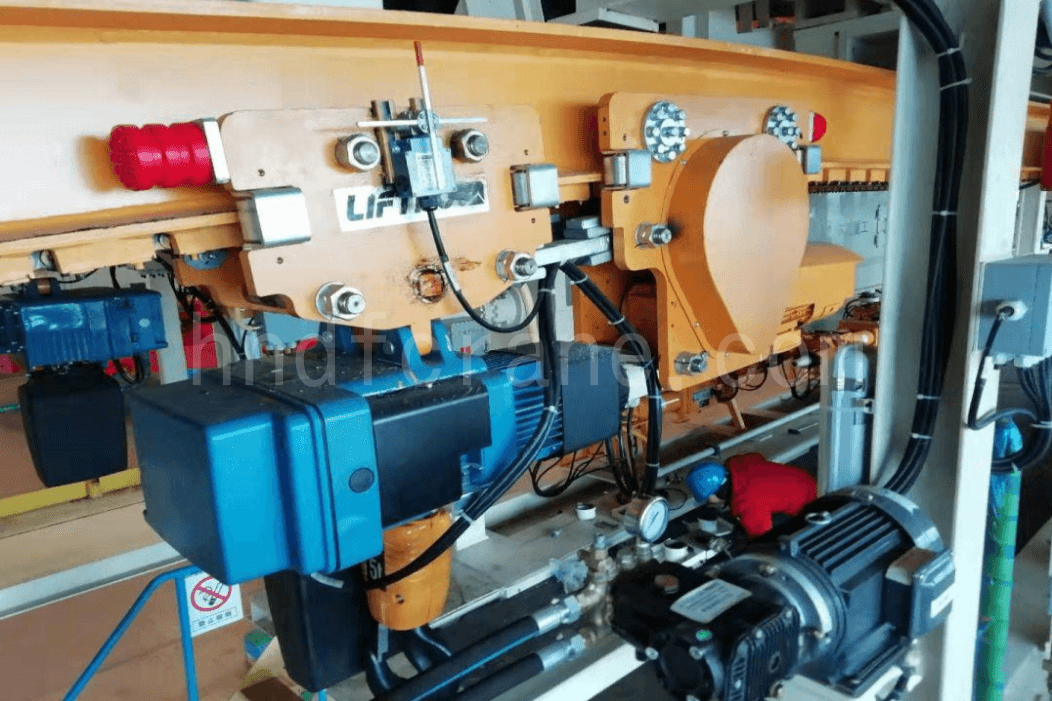

Sistem pengendalian segmen merupakan penyelesaian pengangkatan khusus untuk mesin terowong perisai. Ia membolehkan cengkaman, putaran dan pengangkutan segmen terowong dan komponen pembetung kotak, berfungsi sebagai jaminan utama untuk pembinaan terowong perisai yang selamat dan cekap.

Sistem ini boleh direka bentuk khas mengikut diameter kepala pemotong dan keadaan kerja khusus mesin perisai. Ia mampu mengendalikan segmen tunggal, berbilang segmen dan komponen pembetung kotak.

Kren segmen ini mempunyai struktur keseluruhan yang padat, gerakan mengangkat dan bergerak yang lancar dan stabil, serta ketepatan kedudukan yang tinggi. Ia dilengkapi dengan kawalan PLC, cengkaman hidraulik, pecutan dan nyahpecutan automatik, saling kunci keselamatan, kedudukan mekanikal, keupayaan bergerak cerun, perlindungan angin lampau dan fungsi brek keselamatan yang andal.

Ciri-ciri Utama Sistem Pengendalian Segmen

Sistem pengangkatan dan pengendalian segmen merupakan peralatan penting yang digunakan dalam pembinaan terowong perisai untuk mengangkut segmen terowong. Ciri-ciri utamanya merangkumi aspek berikut:

Kebolehsuaian kepada Keadaan Kerja yang Kompleks

- Mampu beroperasi dengan stabil dalam persekitaran pembinaan terowong yang kompleks.

- Rel perjalanan boleh menampung kecerunan 1°–10°, memenuhi keperluan cerun terowong membujur dan keratan melengkung.

- Mampu bekerjasama dengan mesin perisai dan peralatan lain di dalam ruang terkurung.

Keupayaan Mengangkat dan Mengendalikan Berkecekapan Tinggi

- Kapasiti angkat biasa adalah antara 2 tan hingga 10 tan, sesuai untuk mengendalikan segmen terowong dan komponen pembetung kotak pelbagai spesifikasi.

- Kelajuan angkat dan perjalanan boleh laras, mengimbangi kecekapan dan keselamatan operasi.

- Dalam sesetengah sistem, kelajuan pengangkatan boleh mencapai 0.4–4 m/min, manakala kelajuan perjalanan beban ringan boleh mencapai 0.2–40 m/min.

Kedudukan Tepat dan Kawalan Segerak

- Dilengkapi dengan pengekod, sensor dan peranti pemantauan lain untuk memastikan kawalan kedudukan cangkuk yang tepat.

- Ralat penyegerakan boleh dikawal dalam lingkungan 2 mm, memastikan ketepatan semasa pengendalian dan pemasangan segmen.

- Menyokong pengangkatan dan perjalanan serentak berbilang pengangkat atau troli.

Perlindungan Keselamatan Komprehensif

- Dilengkapi dengan pelbagai peranti keselamatan, termasuk sistem brek, suis had dan peranti penimbal.

- Ciri-ciri termasuk perlindungan beban lampau dan fungsi pecutan beban ringan.

- Boleh disepadukan dengan pad sedutan vakum atau peranti pencengkam, dengan maklum balas status untuk mengelakkan gelinciran segmen.

Reka Bentuk Modular dan Boleh Diskala

- Mengguna pakai reka bentuk struktur modular, membolehkan konfigurasi fleksibel mengikut diameter perisai dan keperluan projek.

- Menyokong penyepaduan lancar dengan pengumpan segmen, erektor dan peralatan lain untuk membentuk sistem pengangkutan dan pemasangan segmen yang lengkap.

Kawalan Pintar dan Jauh

- Boleh mengintegrasikan kawalan PLC dan teknologi kawalan jauh tanpa wayar untuk operasi jarak jauh dan pemantauan status masa nyata.

- Menyokong perkaitan dengan sistem kawalan mesin perisai untuk mendayakan aliran kerja automatik dan mengurangkan campur tangan manual.

Parameter Sistem Pengendalian Segmen

| Prestasi Keseluruhan Kren Pengendalian Segmen Tunggal | ||

| Sistem Pengangkat | Kapasiti Pengangkat Penyebar | 20t (Penyebar: 4t; Muatan: 16t) |

| Kelajuan Mengangkat | 8 m/min | |

| Mengangkat Ketinggian | 6 m | |

| Sistem Perjalanan Troli | Kelajuan Perjalanan | 30 m/min (Kecerunan: ±5%) |

| Penyebar Berputar | Kelajuan Putaran | 1.15 r/min |

| Sudut Putaran | ±90° | |

| Pengangkat Dram | Kapasiti Mengangkat | 1600 kg |

| Kelajuan Mengangkat | 4.0/1.3 m/min | |

| Prestasi Keseluruhan Kren Pengendalian Segmen Berganda | ||

| Sistem Pengangkat | Kapasiti Pengangkat Penyebar | 40t (Penyebar: 8t; Muatan: 32t) |

| Kelajuan Mengangkat | 8 m/min | |

| Mengangkat Ketinggian | 10 m | |

| Mod Kawalan | Alat Kawalan Jauh + Berwayar | |

| Sistem Perjalanan Troli | Kelajuan Perjalanan | 50 m/min (Cerun: ±5%) |

| Sistem Terjemahan | Jarak Terjemahan | ±400 mm |

| Prestasi Keseluruhan Kren Pengendalian Kotak Culvert | ||

| Sistem Pengangkat | Kapasiti Pengangkat Penyebar | 25t |

| Kelajuan Mengangkat | 5 m/min | |

| Mengangkat Ketinggian | 10 m | |

| Mod Kawalan | Alat Kawalan Jauh + Berwayar | |

| Sistem Perjalanan Troli | Kelajuan Perjalanan | 50 m/min (Cerun: ±5%) |

| Sistem Terjemahan | Jarak Terjemahan | ±300 mm |

Sistem Pengendalian Segmen DAFANG – Rujukan Operasi

Sistem Pengendalian Segmen DAFANG ditunjukkan beroperasi dalam persekitaran projek TBM, melakukan cengkaman, putaran dan pengangkutan segmen terowong konkrit pratuang. Sistem ini direka bentuk untuk menyokong pengendalian segmen yang selamat, stabil dan cekap di bawah keadaan terowong perisai berterusan.

Keperluan Pelinciran dan Penyelenggaraan

Untuk memastikan operasi sistem yang stabil dalam jangka masa panjang, sistem pengendalian segmen memerlukan pelinciran dan penyelenggaraan piawai:

- Semburkan minyak gear 220 atau 320 yang sesuai secara berkala pada permukaan rantai gelang pengangkat elektrik (permukaan rantai hendaklah dibersihkan sebelum menyembur).

- Sapukan gris yang sesuai secara berkala pada permukaan rantai pacuan berjalan atau rak.

- Sapukan gris pada permukaan luar penyokong rasuk imbangan untuk memastikan pergerakan kepala pencengkam yang lancar dan andal.

Sistem pengendalian segmen ini menggabungkan pelbagai disiplin, termasuk teknologi kawalan mekanikal, elektrik, hidraulik dan automatik. Ia menampilkan kecekapan, ketepatan, keselamatan dan kebolehpercayaan yang tinggi, menjadikannya peralatan teras yang sangat diperlukan untuk penggalian terowong TBM (Mesin Pengorek Terowong). Melalui reka bentuk tersuai dan kawalan pintar, sistem ini dapat meningkatkan kecekapan pembinaan dengan berkesan, mengurangkan risiko operasi dan menyediakan sokongan padu untuk kemajuan projek TBM yang lancar.