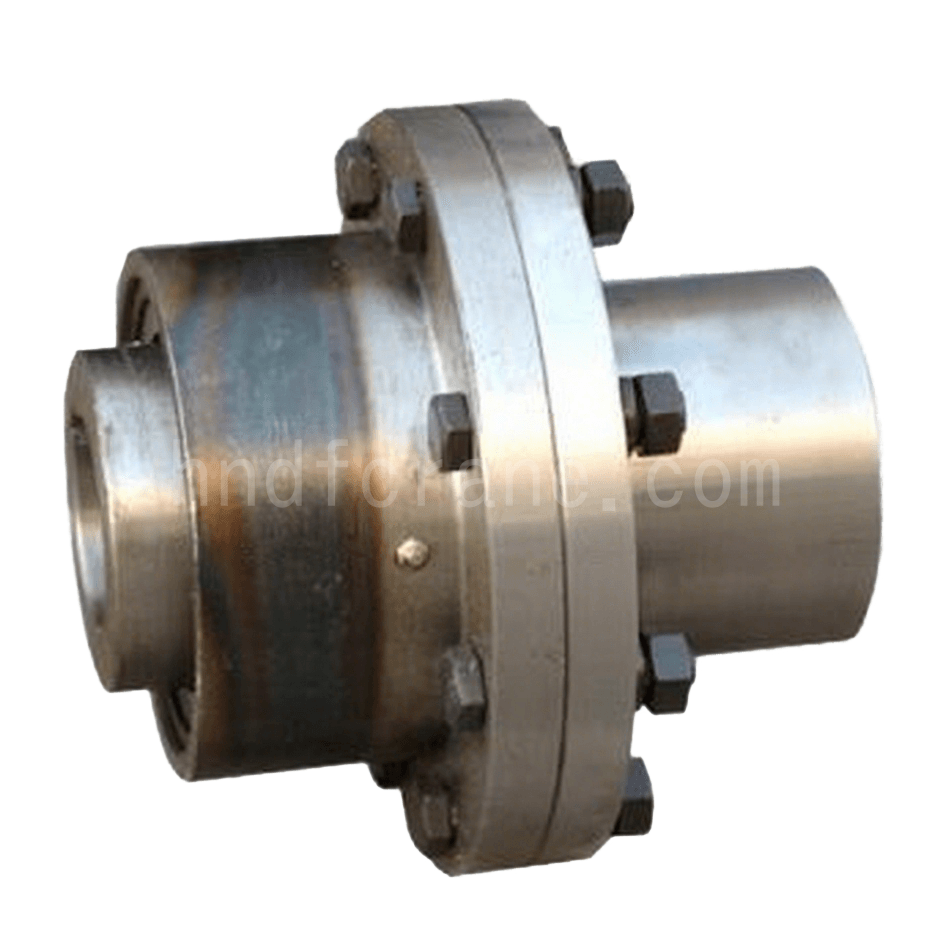

Tam Dişli Kaplinleri

- Yapısal Özellikler: Diş tarafı boşluğu, sıradan dişli şanzımanlarından daha büyüktür ve belirli bir açısal yer değiştirmeye izin verir. İç ve dış diş yüzeyleri periyodik olarak eksenel bağıl kaymaya maruz kalarak iyi bir yağlama ve sızdırmazlık performansı sağlar. Küçük radyal boyutlara ve yüksek yük taşıma kapasitesine sahiptir.

- Uygulama Alanı: Düşük hız ile ağır yük arasındaki iletimde kullanıma uygundur.

- Kullanım Alanı: Vinçlerin kaldırma ve yürütme mekanizmalarında tahrik mili ile tahrik edilen mili birbirine bağlamak için kullanılır.

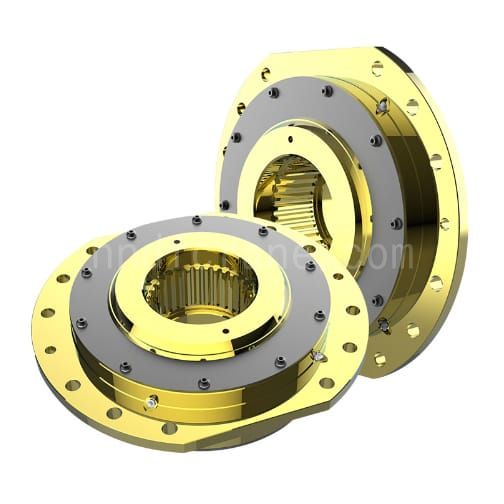

Yarım Dişli Kaplinler

- Pürüzsüz şanzıman, darbe ve titreşime karşı güçlü direnç ve yüksek güvenlik performansı.

- Düşük hız ve ağır yük bağlantısına uygun, küçük radyal kompanzasyon.

- Vinçlerin kaldırma ve yürütme mekanizmalarında tahrik mili ile tahrik edilen mili birbirine bağlamak için kullanılır.

Fren Tekerlek Kaplinleri

- Pürüzsüz şanzıman, darbe ve titreşime karşı güçlü direnç ve yüksek güvenlik performansı.

- Sık çalıştırma ve düşük hızlı, ağır yük bağlantıları için uygun, küçük radyal kompanzasyon.

- Vinçlerin kaldırma ve yürütme mekanizmalarında tahrik mili ile tahrik edilen mili birbirine bağlamak için kullanılır.

Elastomerik Kaplinler

- Basit yapı, küçük radyal boyut, yağlama gerektirmez, kolay bakım ve iyi şok emilimi ve tamponlama performansı.

- Sık çalıştırma, orta-düşük hız, orta-küçük güç ve yüksek güvenilirlik gerektiren durumlar için uygundur; ağır yükler veya sıkı eksenel alan kısıtlamaları olan uygulamalar için uygun değildir.

- Vinçlerin kaldırma ve yürütme mekanizmalarında tahrik mili ile tahrik edilen mili birbirine bağlamak için kullanılır.

Üniversal Kaplinler

- Çapraz şaft üniversal kaplin, temel bir üniversal şanzıman bileşenidir. Başlıca özelliği, aynı eksende hizalanmamış iki tahrik milini birbirine bağlayarak tork ve hareketi güvenilir bir şekilde iletme yeteneğidir.

- Bu tip kaplinler yüksek yük kapasitesi, uzun hizmet ömrü, düzgün çalışma, gürültü yapmama, büyük eksenel kompanzasyon ve basit bakım imkânı sunar.

- Kaplin, tahrik mili ve tahrik edilen mil ile birbirine bağlı iki yarıdan oluşur.

Tambur Bağlantıları

- Çap aralığı: Φ120mm ila Φ2500mm.

- Büyük radyal yükleri taşıyabilir ve önemli tork iletebilir.

- Yüksek güvenilirlik ve emniyet performansı.

- Uzun ömürlü, aşınmaya dayanıklı.

- Geleneksel kaplinlere göre daha yüksek güvenilirlik ve emniyetle, daha büyük radyal yükleri taşıyabilir ve daha yüksek tork iletebilir.

- Tüm parçalarda düşük aşınma, sağlam yapı, güvenlik arızası endişesi yok.

- Küresel yüzeyler arasında bulunan özel anahtar, büyük açısal yer değiştirme ile esnek dönüşe olanak vererek montaj ve ayar kolaylığı sağlar.

- Redüktör mili ile tamburun birbirine bağlanmasında kullanılır.