Mahsulot taqdimoti

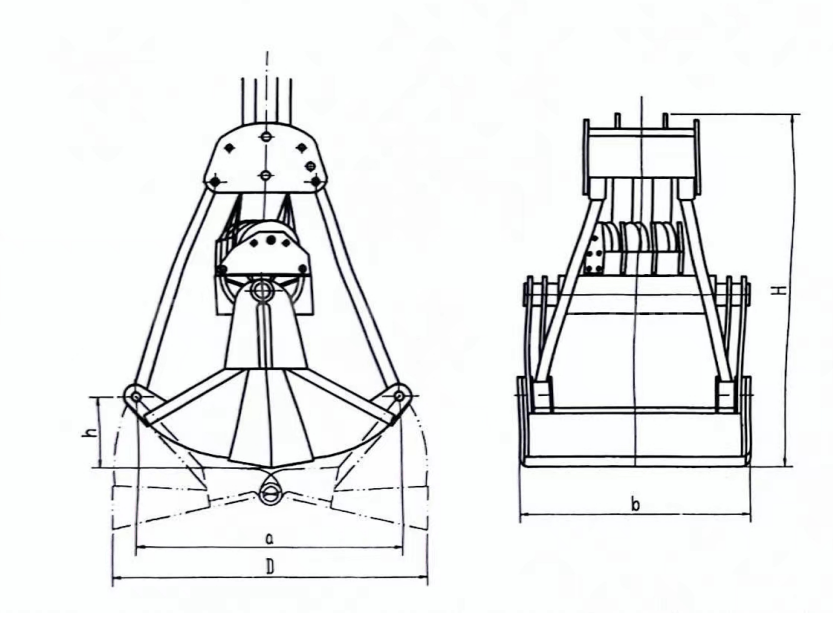

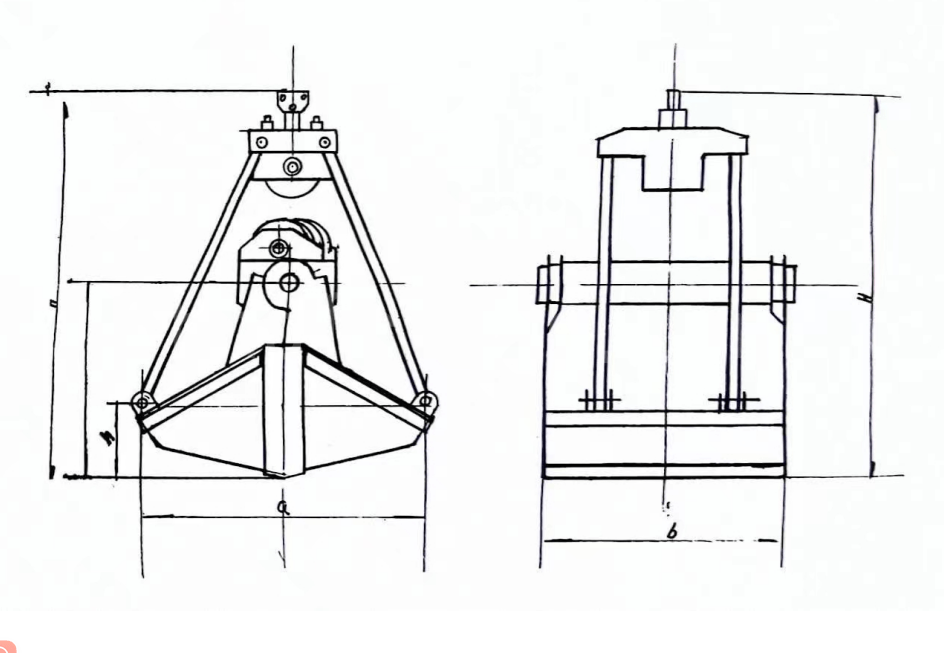

Monoray ko'targichli elektr monorayli chelak - bu 201 turi, 301 turi va DZ12 turi bilan ifodalangan stereotipli mahsulot.

Monoray ko'targichli elektr monorayli chelak, ko'tarish operatsiyasi va tutqichni ochish va yopish uchun elektr ko'targichning ish yig'ish printsipini qabul qiladi.

Elektr monoray krani uchun mo'ljallangan monoray ko'targichli elektr chelak.

Monoray ko'targichli elektr monoray chelak portlarda, qurilish maydonchalarida, ustaxonalarda, yong'in joylarida, omborlarda, shlakli hovuzlarda va shilimshiq hovuzlarda qo'llaniladi.

Elektr monorayli tutqichli chelakning texnik parametri

201

DZ12

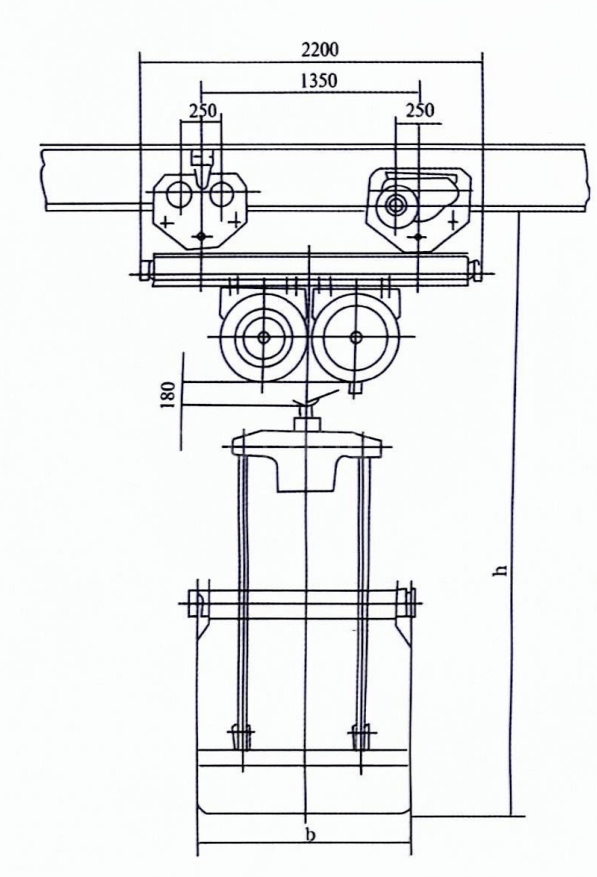

DZ12 qisqa yerdan boshqariladigan monoray kranining o'lchamlari

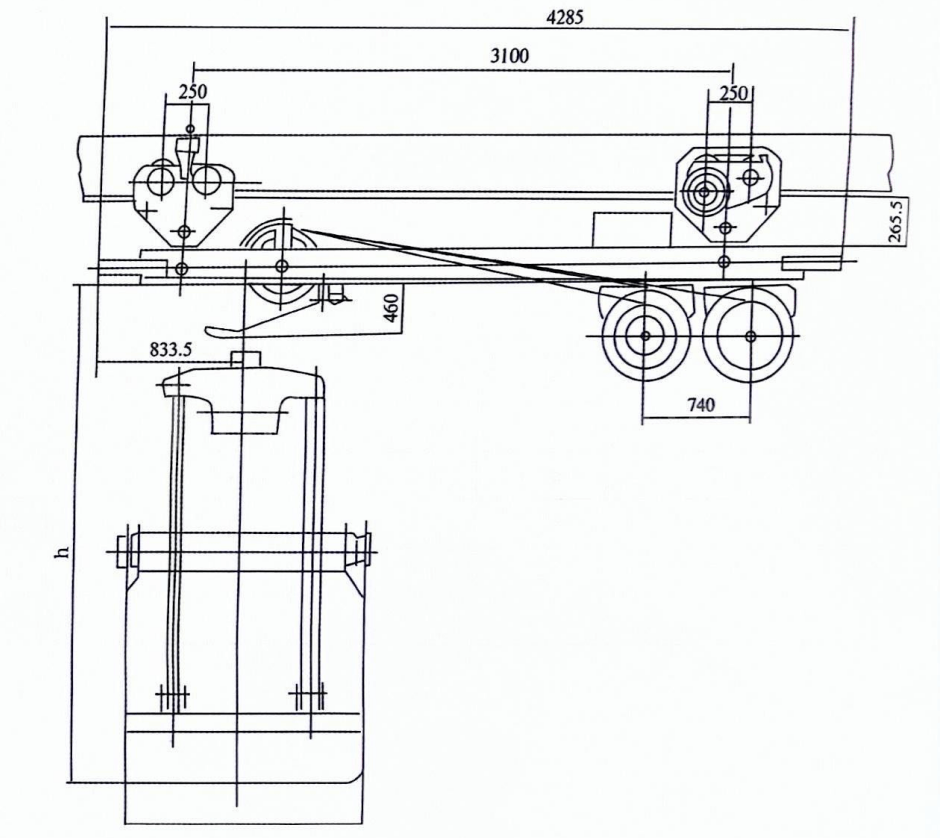

DZ1 tipidagi uzun trolleyli yerdan boshqariladigan monorelsli tutqichli kranning o'lchamlari

| Model | Tutib olish hajmi (m³) | Qabul qilish turi | Materiallar zichligi (t/m³) | Suratga olish materiali (t) | Kasnak tezligi | Chelik arqon diametri (mm) | Kranli tonnaj | Kasnak diametri (mm) | O'z vaznini olish (t) | H (mm) | Maksimal ochilish hajmi D (mm) | Ochilgan balandlik H (mm) | Paqir hajmi axbxh (mm) |

| 201 | 0.75 | yorug'lik | ≤ 1 | 0.75 | 4 | PH 14 | 3 | PH250 | 1.217 | 2250 | 2240 | 2580 | 1620x1000x690 |

| 203 | 0.3 | yorug'lik | ≤ 1 | 0.3 | 4 | PH 14 | 2 | PH250 | 0.612 | 1860 | 1500 | 2040 | 1060x760x500 |

| 205 | 0.5 | yorug'lik | ≤ 1 | 0.5 | 4 | PH 14 | 2 | PH250 | 0.82 | 2400 | 2132 | 2650 | 1400x896x578 |

| 207 | 0.75 | yorug'lik | ≤ 1 | 0.75 | 4 | PH 14 | 3 | PH300 | 1.10 | 2460 | 2200 | 2780 | 1620x1000x690 |

| 301 | 1.5 | yorug'lik | ≤ 1 | 1.5 | 4 | PH 13 | 4 | PH345 | 1.565 | 3000 | 3000 | 3650 | 1940x1120x690 |

| 305 | 0.5 | o'rtada | ≤ 1,5 | 0.75 | 4 | PH350 | 5 | PH350 | 1.10 | 2460 | 2230 | 2780 | 1620x1120x690 |

| 307 | 0.75 | o'rtada | ≤ 1,5 | 1.125 | 4 | PH350 | 5 | PH350 | 1.32 | 2460 | 2230 | 2780 | 1620x1120x690 |

| 308 | 1 | yorug'lik | ≤ 1 | 1 | 4 | PH 14 | 5 | PH350 | 1.4 | 2320 | 2230 | 2780 | 1620x1120x690 |

| 309 | 1.5 | yorug'lik | ≤ 1 | 1.5 | 4 | PH 14 | 5 | PH350 | 1.565 | 2730 | 2740 | 3170 | 1780x1230x740 |

| 308A | 1 | o'rtada | ≤ 1,5 | 1.5 | 4 | PH 14 | 5 | PH350 | 1.3 | 2700 | 2700 | 3300 | 1620x1120x690 |

| DZ12-1 | 0.5 | yorug'lik | ≤ 1 | 0.5 | 4 | PH 14 | 5 | PH350 | 1.2 | 2250 | 2350 | 2350 | 1620x1120x690 |

| DZ12-2 | 0.75 | yorug'lik | ≤ 1 | 0.75 | 4 | PH 14 | 5 | PH350 | 1.2 | 2350 | 2500 | 2900 | 1620x1120x690 |

| DZ12-3 | 1 | yorug'lik | ≤ 1 | 1 | 4 | PH 14 | 5 | PH350 | 1.45 | 2650 | 2760 | 3080 | 1880x1120x515 |

| DZ12-4 | 1.5 | yorug'lik | ≤ 1 | 1.5 | 4 | PH 16 | 5 | PH350 | 1.63 | 2700 | 2760 | 3300 | 2080x1300x515 |

Qanday qilib to'g'ri tutqichni tanlash kerak

- Maqsadingizni aniqlang:

Variantlarni ko'rib chiqishdan oldin, iltimos, maxsus talablaringizni aniqlang. O'zingizdan so'rang:

- Siz qanday materiallar bilan shug'ullanmoqchisiz? (log'lar, metallolom, tosh va boshqalar)

- Tutqich qanday vazifalarni bajaradi? (Yuklash, saralash, demontaj qilish va h.k.)

- U qanday turdagi qurilmaga ulanadi? (Gantry kran, ko'prikli kran)

- Siz ushlagan materialning solishtirma og'irligi qanday? Tutqichning kublari soni?

Tutqich bilan jihozlangan kraningizning tonnaji qancha?

Qo'lga olinadigan materialning xususiyatlariga ko'ra, tortish odatda to'rtta asosiy turga bo'linadi: engil, o'rta, og'ir va o'ta og'ir.

| Qabul qilinadigan material turi | Materialni tortib oling | Imkoniyatlar og'irligi (t/m³) |

| Nur | Koks, shlak, don, kartoshka, o'rta sifatli antrasit ohak, tsement, tuproq, shag'al, gil, singan g'isht va boshqalar. | 0.5~1.2 |

| O'rta | Torf, antrasit koʻmirning yirik boʻlaklari, siqilgan koʻmir, gil, ohaktosh, shagʻal, tuz, shagʻal, gʻisht, boksit, temir oksidi parchalari, tsement, qum va suvdagi gʻisht va boshqalar. | 1.2~2.0 |

| Og'ir | Ohaktosh, ogʻir gil, mayda va oʻrta rudalar, qattiq jinslar, novdasimon temir oksidi, temir rudasi, qoʻrgʻoshin konsentrati kukuni va boshqalar. | 2.0~2.6 |

| Ortiqcha vazn | Yirik rudalar, yirik marganets rudasi, choʻkindi aglomeratsiyalangan qoʻrgʻoshin rudasi kukuni va boshqalar. | 2.6~3.3 |

- Aksessuarning mosligi: Tutqichning mavjud uskunaga mos kelishiga ishonch hosil qiling.

- Byudjet masalalari: Tutqichning narxi har xil. Tutqichning funksiyasi va chidamliligiga qarab byudjetingizni muvozanatlang.

- Fikr va takliflar: Internetda tadqiqot o'tkazing, foydalanuvchi sharhlarini o'qing va sanoat hamkasblaridan takliflarni izlang.

- Sotib olishdan oldin kran ishlab chiqaruvchisiga tashrif buyurib, joyida tekshirish va sinovdan o'tkazing: grabni iloji boricha real sharoitlarda sinab ko'ring.Uning ishlashi, foydalanish qulayligi va umumiy funksionalligini baholang.

Yodda tutingki, to'g'ri tutqichni tanlash funksionallik, xavfsizlik va xarajat o'rtasidagi muvozanatni talab qiladi.Ushbu omillarni hisobga olgan holda, siz unumdorlikni oshirish va muammosiz ishlashni ta'minlaydigan mukammal tutqichni topasiz.