大方起重机桥式起重机安装服务:确保项目安全、高效、优质交付

目录

我们提供专业的现场起重机安装服务。经验丰富的工程师将直接前往客户现场,完成从设备拆箱、结构组装、轨道校准到电气接线、调试验收等全过程,确保设备安全高效运行。如果您想自行安装,我们可以提供详细的技术资料,并在您遇到技术问题时提供远程视频指导或在线支持。无论是现场安装还是远程协助,我们始终致力于为客户提供高效、无忧的服务体验。

经验丰富的工程师提供桥式起重机安装服务

我们的高架起重机现场安装服务包括以下内容:

派遣安装工程师

一般情况下,根据桥式起重机安装的复杂程度和客户的具体需求,我们会指派一至三名工程师提供现场安装服务。

我们的安装工程师涵盖机械设计、机械制造、电气自动化等多个专业领域,均具有中高级专业技术职称,熟悉各类桥式起重机的安装调试流程,拥有丰富的国内外项目实践经验。

我们的工程团队已成功完成埃及、沙特、阿根廷、乌兹别克斯坦、阿尔及利亚等国家的桥式起重机安装项目,赢得了客户的广泛认可和赞誉。

桥式起重机安装

- 安装前准备:在吊装作业开始前,我们会进行全面的技术准备。这包括现场检查吊装区域、审查施工图纸、组织吊装团队熟悉安装程序,并对所有现场人员进行安全和技术交底。

- 主梁和端梁吊装及组装:根据现场情况制定合适的吊装方案。主梁和端梁按顺序吊装就位,然后进行焊接或螺栓连接。安装工程师现场监控螺栓扭矩和焊接质量,确保结构完整性。检查结构尺寸和标高是否符合设计规范。

- 小车组装及轨道安装:根据装配方案,小车部件分段或整体组装。小车轨道安装精准,并调整轨道间距和标高,确保运行平稳。现场检查车轮直径、轨距和运行状况,并相应地微调定位装置。

- 电气系统安装及接线:按照设计图纸进行电缆敷设、电气柜及控制箱安装。现场接线确保连接规范、正确,符合安全要求。全面检查电气设备的防护等级及接地措施。

一般来说,安装 单梁桥式起重机 大约需要15到20天。

实际安装工期可能因多种因素而异,例如起重机结构的复杂程度、待安装单元的数量、轨道长度以及我们是否负责轨道安装。此外,天气条件等外部因素也会影响安装进度。我们将根据具体情况制定切实可行且组织有序的安装计划,确保安装过程高效、安全、有序。

安装质量检查

桥式起重机安装完成后,我们将对所有关键部件进行全面检查,以确保设备符合安全、稳定、可靠的运行标准。检查内容包括以下几个方面:

- 起重机金属结构节点的装配质量

- 现场组装的滑轨安装质量

- 现场组装的小车和桥梁运行机构的安装质量

- 安全装置的安装和功能性能

桥式起重机测试

为了确保桥式起重机在投入运行前能够提供可靠的性能并符合安全标准,在成功安装后会进行一系列测试:

- 试运行:确认各操作机构的控制方向与实际运动方向一致。每台电机均单独测试,以确保正常运行,制动器、限位开关和安全装置准确可靠地工作。吊钩降至最低位置时,卷筒上必须至少留有两圈完整的钢丝绳。防撞装置、缓冲器及类似系统必须正常工作。

- 静载试验:该试验用于检查起重机的稳定性和承重能力。起重机将起重物提升至额定载荷的1.25倍,并使其悬挂在距离地面100至200毫米的高度,持续10分钟。卸载后,检查桥梁结构是否存在永久性变形。

- 动态负载测试:该测试评估所有机构和制动系统的性能。起重机的起重量为额定负载的1.1倍,测试后,所有部件均不得出现裂纹或损坏,并且所有连接必须牢固,起重机方可视为合格。

协调事宜

为确保起重机安装顺利进行,请客户根据图纸提前完成基础工作,确保轨道布置等关键结构符合技术要求。

我司现场安装服务费为每位工程师每天1200元人民币,工程师往返机票、签证、住宿、餐费由客户承担。

请提前协调现场情况,安排必要的资源,包括起重设备、电源、工具、人员保障等,以保证安装过程高效、有序进行。

客户自行安装桥式起重机

对于具备独立安装能力的客户,我们可根据要求提供技术文件,包括安装手册、电气原理图、桥式起重机图纸以及所需安装工具清单。此外,我们还提供远程视频指导或在线支持,以解决安装过程中遇到的任何技术问题。

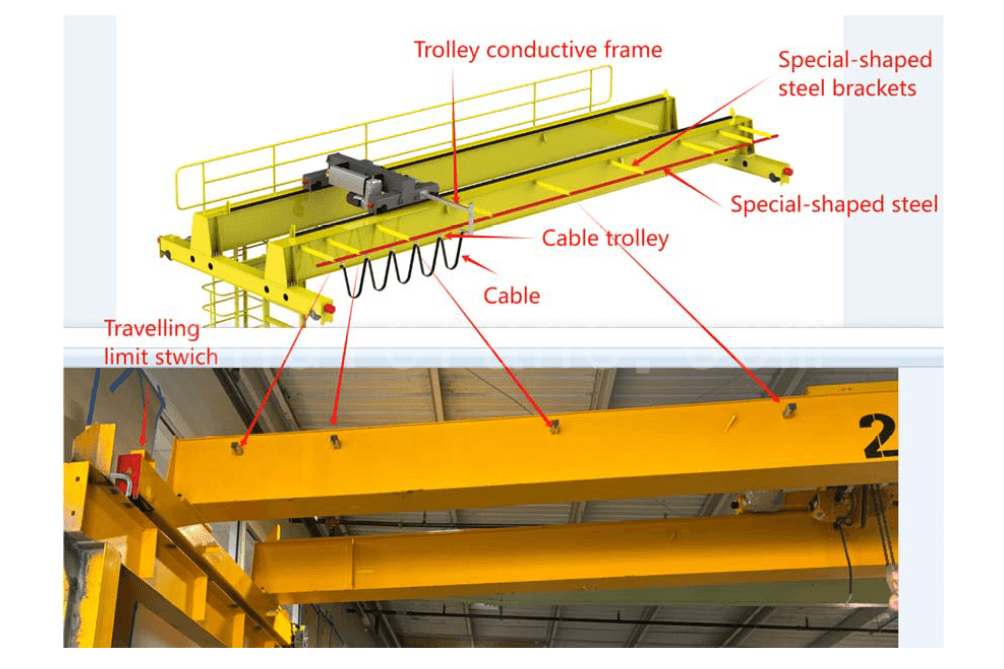

- 安装手册:本手册详细介绍了桥式起重机安装的各个步骤,包括安装前的准备工作及注意事项、主梁与端梁的连接、端梁组装后的找正调整、电控箱、限位开关、电缆拖令系统的安装位置及方法,以及起重机跑道末端缓冲器的安装要求等。内容详尽,清晰实用,为安装人员提供指导,有效减少安装失误。

- 接线:本手册提供起重机、起升机或小车的电气控制箱图以及详细的接线说明。手册还讲解了行程限位开关、过载限制器和平衡重限制器等安全装置的接线方法,确保安装过程安全规范。

- 桥式起重机总装图:桥式起重机总装图展现了起重机的结构布置图和关键尺寸参数,包括设备外形图、吊钩中心与起重机轨道中心的最大允许距离、起重机总宽度、轮距、最大轮重等。该图有助于用户理解整体安装逻辑,指导安装人员准确识别主梁、端梁、走道、电缆小车等部件的位置,从而提前规划现场工作空间和安装顺序。

- 所需安装工具清单:工具清单指定了完整起重机安装所需的标准工具和特殊工具,包括扳手、千斤顶、手动链式葫芦、拉绳、 叉车、移动式起重机等等。此清单可帮助客户在安装前做好充分准备,避免因现场工具缺失而导致停工或返工。

大方起重机桥式起重机安装服务案例

30/5T双梁桥式起重机安装

我们为客户提供了一台30/5吨双梁桥式起重机,跨度25米。根据客户要求,我们派出经验丰富的工程师前往现场参与安装。他们与当地工人紧密合作,完成了从机械装配、电气接线到全面调试的整个过程,确保设备能够在客户车间顺利投入运行。

现场安装流程

项目前期,我司工程师根据交付的图纸和现场情况,指导并协助完成主梁、端梁、驾驶室、小车等机械部件的组装。所有连接和安装作业均按照标准进行,确保结构强度和运行平稳性。

结构安装完成后,工程师与现场电工配合进行电气布线连接,包括主电源、控制柜、限位开关、信号线等,确保布线正确、布局合理。

电气调试和程序集成

该项目最关键的阶段之一是起重机的电气调试。在完成现场接线后,我们的工程师根据客户的要求对起重机控制系统进行了程序调整,使其能够与车间现有搬运设备的运行逻辑相融合。

调试过程中,我们与相关供应商协作,解决了出现的技术问题,并按照客户要求,成功将搬运设备的控制程序集成到起重机系统中,确保了整套设备的协调运行和控制响应。

项目完成

经过多轮调试和试运行,该桥式起重机各项功能运行正常稳定,完全满足了客户的搬运需求。项目竣工后,客户对我司的现场服务给予了充分的肯定,尤其对我司在安装过程中的专业配合和调试过程中的技术能力表示赞赏。

2吨双梁桥式起重机安装指导

我们向客户交付了一台2吨、跨度10.5米的双梁桥式起重机。根据客户的安排,我们的工程师没有亲临现场,而是远程协助安装。从准备阶段开始,我们就与客户保持密切沟通,并提供了详尽的中英文安装指导材料。材料包含图片和文字说明,方便客户理解和操作。在整个安装过程中,我们提供全天候远程技术支持,及时响应客户提出的每一个问题,并积极配合,确保安装顺利完成。

项目准备

发货前,我们与客户沟通了安装需求,了解到客户希望自行组织现场安装。因此,我们在发货时准备了安装手册、电气原理图、总布置图以及所需工具清单,以协助客户按照图纸和文档完成安装。

安装期间的远程支持

在整个安装过程中,我们的工程师始终与客户保持在线沟通,及时解答客户提出的技术问题。例如,客户遇到不熟悉的连接部件、线路标签、设备编号等问题时,会发照片或留言给我们,我们的工程师会结合图纸或书面说明进行解答。

我们承诺在工作日和关键安装阶段提供全天候响应,确保客户咨询得到及时解答。尽管存在时差,我们的团队仍安排轮班,以保持不间断的沟通和及时的支持。

项目成果

设备安装顺利,客户反馈整个安装流程清晰易懂,指导材料实用,远程沟通顺畅。虽然我们未能亲临现场,但通过准备全面的技术文档并提供持续的远程支持,我们帮助客户顺利完成安装。

选择大方起重机,安装可靠

大方起重机以其全面且以客户为中心的桥式起重机安装服务体系赢得了广泛认可。我们经验丰富的工程师提供专业的现场安装服务,确保设备安装安全、精准、及时。对于选择自行安装的客户,我们提供详尽的技术文档和远程指导,协助顺利完成组装和调试。我们的工程团队遵循严格的行业标准,灵活适应各种现场条件,帮助客户减少停机时间并避免安装错误。无论是常规安装任务还是复杂的系统集成,大方都能提供高效可靠的安装成果。

发送您的询问

- 邮箱: sales@hndfcrane.com

- 微信: +86 191 3738 6654

- 电报: +86 191 3738 6654

- 电话:+86-373-581 8299

- 传真:+86-373-215 7000

- 地址:中国河南省新乡市长脑工业区

微信

微信