Gru a ponte per l'industria automobilistica Introduzione

Nell'industria automobilistica, sono necessari personale e attrezzature ingenti per garantire l'efficienza della linea di produzione. Le gru vengono solitamente utilizzate nelle linee di assemblaggio, nelle officine di stampaggio e nei magazzini. L'industria automobilistica, in rapida evoluzione, richiede gru efficienti. Per soddisfare i severi requisiti di rapidità di funzionamento, avviamento fluido, posizionamento preciso e funzionamento continuo e affidabile, Dafang Crane si affida a tecnologie avanzate per fornire gru di varie dimensioni che aiutino le aziende a sollevare e trasportare carichi in fabbrica. Ad esempio, le nostre gru di processo vengono utilizzate per il trasporto e lo stoccaggio di coils di acciaio, che a loro volta vengono utilizzati per la produzione di componenti della carrozzeria. Le nostre gru a catena possono anche essere dotate di soluzioni ergonomiche per la postazione di lavoro.

Classificazione delle gru a ponte per l'industria automobilistica

Gru per la movimentazione di stampi

Nell'officina di stampaggio dell'industria automobilistica, ogni giorno vengono prodotti più di un milione di componenti di carrozzeria di varie forme e dimensioni per una vasta gamma di modelli. A causa di questa elevata differenza, il modulo stampo deve essere sostituito frequentemente, riducendo così il ciclo di produzione. Pertanto, le gru per la movimentazione degli stampi (gru a ponte a doppia trave) sono spesso utilizzate per le operazioni. I tre tipi più comuni sono: gru con pinza per stampi, gru per movimentazione stampi e gru per movimentazione coil.

1. Gru con pinza a matrice

Le gru con pinza per stampi sono progettate specificamente per applicazioni di movimentazione stampi nel settore automobilistico. A differenza dei tradizionali sistemi di sollevamento come catene o funi, queste gru utilizzano pinze per stampi specializzate per sollevare e posizionare gli stampi, consentendo uno stoccaggio rapido, compatto e multistrato degli stampi. Ciò è particolarmente vantaggioso per i cambi stampo ad alta frequenza, tipici delle linee di produzione automobilistica.

Ogni gru con pinza per stampi è dotata di un carrello con argano accoppiato, tecnologia di sensori intelligenti, funzioni di automazione avanzate e un sistema di posizionamento preciso. Queste caratteristiche garantiscono il trasporto sicuro, preciso ed efficiente degli stampi, soddisfacendo le complesse esigenze operative del settore automobilistico.

Vantaggio

- Puleggia con argano aperto accoppiato.

- La progettazione di tutti i componenti tiene conto dell'eccentricità del baricentro di 100 mm, correlata al peso massimo dello stampo. Sospensioni di carico stabili a 4 punti con bilanciere bilanciato.

- Posizionamento senza pendolo con precisione millimetrica.

- Sistema di misurazione laser o codice a barre ridondante.

- Controllo dello swing.

- Portastampo con dispositivo rotante integrato.

- Grazie al bilanciere di compensazione integrato, il tasso di utilizzo dei trefoli della fune è uniforme e testato. La fune per questa applicazione presenta un'elevata stabilità strutturale e un elevato carico di rottura.

- Il sensore sincrono adotta un design ridondante e viene valutato in un controllore logico programmabile (PLC) a prova di errore.

- Sostituzione più rapida dello stampo.

- Gestione più sicura degli stampi (prelievo, trasporto e deposito).

- Utilizzo efficiente e salvaspazio delle aree di stoccaggio disponibili.

- Le gru e le pinze per stampi possono essere personalizzate in base alle esigenze del cliente.

- Ottimizzando il metodo di infilaggio della fune e utilizzando un numero minimo di pulegge, è possibile massimizzare la durata utile della fune.

- La tecnologia dei sensori intelligenti è in grado di identificare il prelievo sicuro del carico e di rilevare l'area attorno alla pinza per evitare collisioni.

- L'eccellente accessibilità a tutti i componenti, la facile manutenzione e il monitoraggio remoto delle attività di assistenza possono garantire un piano di manutenzione informato.

Parametro tecnico

| Tipo | Attributo |

|---|---|

| Classificazione delle gruEN 13001 Classe U (cicli di carico) | U7 |

| Classificazione della gru EN 13001 Classe U (collettivo di carico) | Q5 |

| Classificazione del paranco (FEM/EN) | M7(FEM)A7(EN) |

| Tipo di carrello | 2 verricelli aperti accoppiati |

| Pinza per cicli di lavoro | 2 milioni |

| Capacità di carico sulla pinza portautensili | Fino a 66 t |

| Dimensioni della matrice in larghezza | 1.650-4.850 mm |

| Dimensioni dello stampo in altezza | 1.200-2.850 mm |

| Precisione di posizionamento | 1.600mm |

| Precisione di posizionamento dell'angolo di rotazione del carico | +/-10mm alla pinza |

| Durata | +/-0,2 gradi alla pinza |

| Altezza di sollevamento, max. | Fino a 40 m |

| Velocità di sollevamento con carico | 15 metri |

| Velocità di sollevamento con pinza vuota | 12 m/min |

| Velocità di viaggio Birdge | 18 m/min |

| Velocità di viaggio del carrello | Fino a 100 m/min |

| Velocità di alimentazione del carrello | Fino a 40 m/min |

| Controllo manuale | Radio/Pendente |

2. Gru per la movimentazione degli stampi

La gru di processo principale nel settore automobilistico viene utilizzata per trasportare gli stampi dal magazzino alla pressa per il carico e dalla pressa al magazzino. Le gru per la movimentazione degli stampi vengono utilizzate anche per ruotare gli stampi a scopo di manutenzione.

Le gru per la movimentazione di matrici sono solitamente gru a ponte a doppia trave, che possono essere dotate di varie configurazioni di carrelli, come due argani o due carrelli separati su carrelli pubblici, ganci di carico rotanti elettrici o travi di carico regolabili manualmente.

Vantaggio

- Funzioni speciali del carrello di sollevamento doppio o della soluzione con carrello indipendente per una guida più sicura del carico, angolo della fune fino a 10 gradi, protezione del carico: il sistema è costituito da una cella di carico e da un'unità di rilevamento del sovraccarico. Controllo di sovravelocità del paranco a velocità variabile.

- Funzione intelligente.

- Joystick radio e ciondolo per backup e manutenzione, può essere fornito un secondo freno di sollevamento.

- Regolatore di frequenza per il movimento principale.

- Freno di emergenza.

- La cabina elettrica è pressurizzata e dotata di aria condizionata.

- Il paranco garantisce in modo sincronizzato una movimentazione del carico rapida e precisa.

- La funzione di rotazione del carico consente un funzionamento sicuro.

- Le funzioni intelligenti semi-automatiche contribuiscono a migliorare la sicurezza e la produttività.

- Il monitoraggio remoto fornisce dati per la pianificazione della manutenzione e la valutazione delle condizioni e della sicurezza della gru.

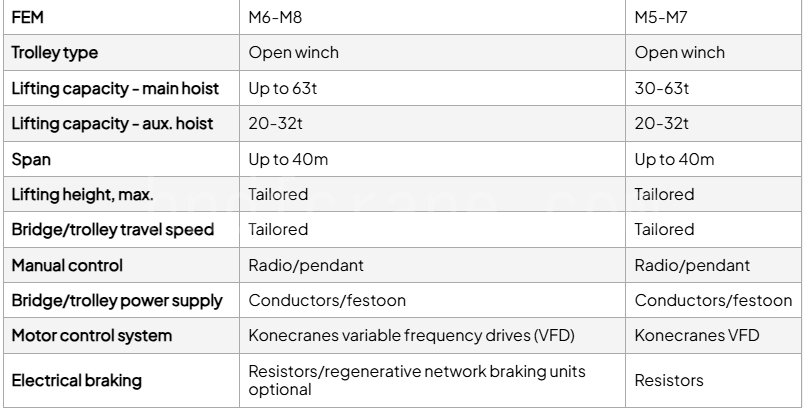

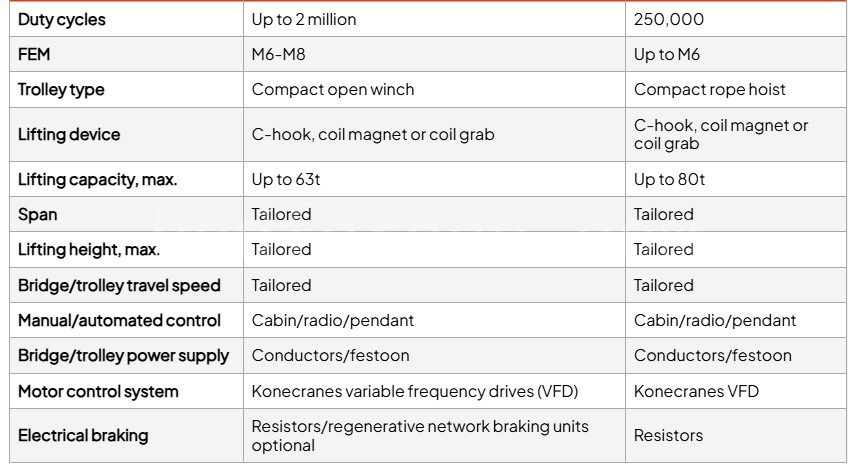

Parametro tecnico

3. Gru per la movimentazione di bobine

Le gru per la movimentazione di coil vengono utilizzate per trasportare le bobine di acciaio destinate allo svolgimento e al taglio dei pezzi grezzi. Una volta che l'acciaio è stato pretagliato alle dimensioni richieste, questi pezzi grezzi vengono stampati in una pressa per formare componenti della carrozzeria come cofani, portiere, bauli e tetti. Il processo di stampaggio prevede in genere da tre a cinque operazioni consecutive con forze che vanno da 1.000 a 25.000 kN per dare forma a ciascun componente.

Queste gru di movimentazione sono progettate per spostamenti rapidi e su lunghe distanze, riducendo i tempi di ciclo e soddisfacendo le esigenze di produzione ad alta velocità dell'industria automobilistica. Con gli accessori adeguati, garantiscono una movimentazione sicura ed efficiente delle bobine. La capacità di sollevamento standard è di 80 tonnellate e le gru possono essere completamente personalizzate per soddisfare le esigenze specifiche dei produttori del settore automobilistico.

Vantaggio

- Progettato per massimizzare il ciclo di lavoro orario

- Ottieni una movimentazione del carico precisa e veloce alla velocità di guida

- Utilizzo intensivo con carrelli

- La robusta struttura in acciaio tipo scatola aiuta a ridurre le vibrazioni

- Il controllo aggiuntivo dell'oscillazione e la fune anti-allentamento contribuiscono a migliorare la sicurezza e l'efficienza produttiva dell'area di lavoro

- Le funzioni semiautomatiche e completamente automatiche aiutano a ridurre il tempo di ciclo

- La frenata rigenerativa opzionale consente di risparmiare energia

- Dotato di carrello pesante speciale

- Fornire una varietà di intervalli di velocità

Parametro tecnico

Gru a bandiera a parete mobile

Nel settore automobilistico, le gru a bandiera autoportanti vengono utilizzate per sollevare e spostare componenti di veicoli, come motori, trasmissioni e componenti del telaio. Semplificano le operazioni di assemblaggio collegando rapidamente e facilmente i vari componenti del veicolo durante il processo di produzione e assemblaggio. Sono in grado di movimentare con precisione oggetti pesanti e garantire una gestione sicura ed efficace dei componenti automobilistici, riducendo così il rischio di danni e migliorando la qualità complessiva della produzione.

Vantaggio

La gru a bandiera mobile tipo BXQ è adatta all'utilizzo in un'area di lavoro unilaterale all'interno dell'officina. Le sue rotaie di scorrimento sono montate sulle colonne dell'officina o su supporti installati separatamente, garantendo una superficie di lavoro libera da ostacoli: una configurazione ideale per le officine del settore automobilistico, dove l'efficienza degli spazi e la facilità di accesso al pavimento sono essenziali.

Le gru mobili a braccio BXQ sono comunemente installate in strutture dotate di sistemi di sollevamento a doppio livello. Operano al livello inferiore per movimentare e trasportare pezzi di piccolo tonnellaggio, operando trasversalmente alle gru per carichi pesanti del livello superiore senza alcuna interferenza. Questo le rende particolarmente adatte agli ambienti di produzione multilivello del settore automobilistico, dove è spesso richiesta la movimentazione simultanea di componenti di diverso tonnellaggio.

La gru è facile da installare e manutenere, offre flessibilità di funzionamento e garantisce prestazioni sicure e affidabili.

Le gru a braccio mobile a parete Dafang Crane consentono una movimentazione laterale prolungata dei materiali senza occupare spazio o interferire con le grandi gru a ponte. I bracci mobili a parete aumentano la produttività complessiva dell'impianto, gestendo rapidamente sollevamenti di piccole dimensioni. Le gru a braccio mobile a parete Dafang Crane sono soluzioni personalizzate ed economiche, progettate specificamente per soddisfare le vostre esigenze di produzione e le specifiche costruttive.

Parametro tecnico

| Modello | Capacità di sollevamento (t) | L(mm) | R1(mm) | R(mm) | Hmm) |

| BXS0.25 | 0.25 | 3200 | 250 | 3000 | 800 |

| BXS0.5 | 0.5 | ||||

| BXD1 | 1 | 3400 | 300 | 950 | |

| BXD2 | 2 | 3500 | 450 | 3000 | 1150 |

| BXD3 | 3 | 4500 | 500 | 4000 | 1350 |

| BXD5 | 5 | 4700 | 550 | 4000 | 1500 |

Gru a ponte sospese a trave singola per postazioni di lavoro

Nella linea di produzione di un'automobile, dalla movimentazione e assemblaggio dei componenti fino all'uscita del veicolo finale dalla linea, ogni fase si basa sul supporto di attrezzature di sollevamento. Le gru a ponte sospese KBK, in quanto tipologia di gru leggera, offrono vantaggi unici che migliorano significativamente l'efficienza produttiva. Le loro capacità di sollevamento e posizionamento ad alta precisione consentono di spostare i componenti in modo rapido e preciso nelle posizioni designate lungo la linea, riducendo gli errori manuali e migliorando il flusso di lavoro. Queste caratteristiche rendono le gru KBK una soluzione ideale per l'industria automobilistica, dove precisione ed efficienza sono fondamentali in ogni fase della produzione.

Vantaggio

- Adottare una struttura articolata per eliminare i vincoli, soprattutto quando si movimentano carichi all'estremità del ponte.

- Sono disponibili ponti lunghi fino a 14 metri.

- Controllo facile e preciso.

- I profili dei binari sono standardizzati in unità di un metro, il che consente di ottimizzare il peso del ponte gru e dell'intero sistema. Esistono due tipi di profili dei binari: profili in acciaio e profili in alluminio.

- Infrastruttura affidabile, senza necessità di supporti trasversali o saldature in loco dell'edificio. La gru può essere installata con successo ovunque sul pavimento in calcestruzzo, purché sia in grado di supportare la forza di ancoraggio richiesta.

CasoS

Binario in lega di alluminio sulla linea di montaggio dell'automobile in uso

Attrezzature di spinta come guide in alluminio e bracci a T per linee di assemblaggio di automobili

Officina di assemblaggio di ricambi auto New Energy

Gru monorotaia

L'industria automobilistica si affida a una movimentazione dei materiali precisa ed efficiente per supportare le linee di produzione e i processi di assemblaggio. Le nostre gru monorotaia e gru a sbalzo sono ideali per le case automobilistiche, per aumentare la produttività e garantire la movimentazione sicura dei componenti.

Vantaggio

- Migliorare l'efficienza del lavoro

- Freno sicuro e affidabile

- Lunga durata

- La manutenzione è conveniente

- Usa una cassaforte

- Peso leggero

- Le gru monorotaia sono più efficaci nelle applicazioni di produzione in cui i materiali vengono spostati ripetutamente da un punto all'altro. Il paranco e il carrello della monorotaia corrono su un'unica trave fissa, normalmente include trave ad H o trave a I.

- Esempi includono operazioni di assemblaggio, trasporto di materiali alle postazioni di lavoro e linee di sabbiatura, verniciatura o rivestimento dei componenti. Le monorotaie fungono anche da alternativa per la movimentazione dei materiali in luoghi in cui non è possibile installare una gru a ponte.

CasoS

Gru monorotaia per l'assemblaggio di automobili

Gru monorotaia per l'assemblaggio di automobili

Gru monorotaia per l'assemblaggio di automobili

Sistemi di sollevamento per postazioni di lavoro

Qualsiasi tipo di gru per postazioni di lavoro è principalmente dedicata al supporto della linea di assemblaggio e alla movimentazione dei componenti. Pertanto, le gru per postazioni di lavoro sono un complemento ideale per gli impianti di produzione automobilistica. Nello specifico, le gru per postazioni di lavoro possono essere installate sulla linea di assemblaggio di un impianto di produzione automobilistica per aiutare gli operatori a spostare i componenti all'interno dell'impianto. Similmente alle gru a sbalzo, le gru per postazioni di lavoro possono essere utilizzate per ridurre la pressione sui dipendenti, aumentando al contempo la produttività complessiva dell'impianto. Rispetto alla produzione manuale di automobili di decenni fa, attrezzature come le gru per postazioni di lavoro possono ora essere utilizzate per produrre automobili più velocemente. Un altro utilizzo delle gru per postazioni di lavoro è quello di supportare le attività di manutenzione in fabbrica. Poiché la gru può sollevare e riposizionare il componente, gli operatori possono entrare in contatto con il componente per eventuali riparazioni necessarie senza dover esercitare alcuna pressione fisica.

Vantaggio

- Elevata affidabilità e stabilità. Il sistema di gru leggera è composto da componenti modulari standard, che garantiscono una produzione in serie e di alta qualità. Può essere personalizzato in base alle esigenze del cliente.

- Elevata adattabilità. I sistemi di gru leggere possono essere progettati e installati in modo flessibile in base alle esigenze di ogni stazione dello stabilimento. Possono essere assemblati a piacimento, da un punto fisso a linee di trasporto automatizzate multi-punto e multi-battuta ad alta precisione.

- Installazione pratica ed efficienza economica. Il sistema di gru leggero è facile da installare e da mettere a punto. I componenti standard dei moduli possono essere utilizzati solo tramite collegamento a bulloni, il che consente di risparmiare spazio in fabbrica e migliorare i vantaggi aziendali.

- Peso leggero, maneggevolezza e facile movimento manuale.

- Costo dell'impianto ridotto, bassa potenza, basso consumo energetico e vantaggi complessivi elevati.

Piattaforme aeree a forbice

Un sollevatore a forbice è un veicolo motorizzato con una piattaforma stabile, chiusa e dotata di binari, che può essere estesa verticalmente. Il suo nome deriva dalla struttura di supporto metallica a incrocio sotto la piattaforma: una volta sollevato, il meccanismo ricorda un paio di forbici con "lame" intersecate in corrispondenza delle giunture. I sollevatori a forbice sono ampiamente utilizzati nelle attività di produzione e manutenzione, incluso il settore automobilistico, dove è richiesto un sollevamento sicuro e preciso per operazioni di assemblaggio, ispezione o sollevamento in altezza.

Vantaggio

- La piattaforma elevatrice idraulica fissa è un tipo di attrezzatura per il sollevamento di carichi con un'ottima stabilità di sollevamento e un ampio campo di applicazione. Viene utilizzata principalmente per il trasporto di merci tra i diversi livelli di altezza della linea di produzione.

- I materiali sono disponibili online e offline.

- Regolare l'altezza del pezzo in lavorazione durante l'assemblaggio dello stesso.

- Mangiatoia ad alta quota.

- Sollevamento di parti durante il montaggio di grandi apparecchiature.

- Carico e scarico di grandi macchine utensili.

- I siti di stoccaggio e carico sono dotati di carrelli elevatori e altri veicoli per la movimentazione, per un rapido carico e scarico delle merci.

- La piattaforma di sollevamento idraulica fissa può essere configurata con altri dispositivi aggiuntivi in base alle esigenze di utilizzo, in qualsiasi numero o combinazione per ottenere risultati di utilizzo migliori.

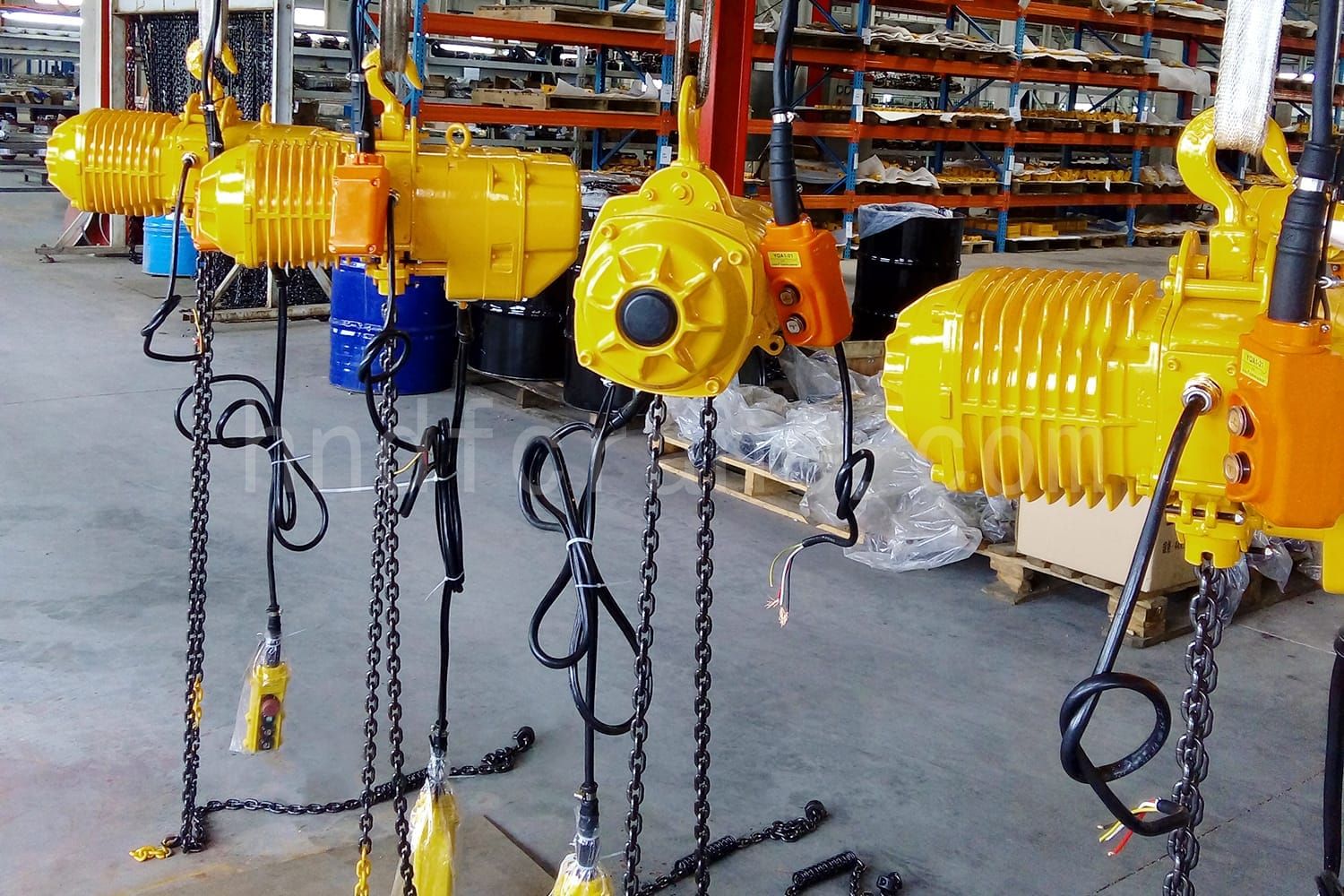

Paranchi elettrici a catena

Nel processo di produzione dei veicoli a nuova energia sono coinvolti molti processi complessi e delicati, tra i quali l'assemblaggio dei componenti dell'automobile riveste la massima priorità. In questo anello chiave, il paranco elettrico a catena svolge un ruolo indispensabile e importante.

Il paranco elettrico a catena ha un'eccellente capacità di carico.

I componenti dei veicoli a nuova energia, in particolare alcuni componenti chiave di grandi dimensioni, come pacchi batteria, motori, ecc., tendono ad essere più pesanti. Grazie alla sua struttura robusta e al potente sistema di alimentazione, il paranco elettrico a catena può trasportare facilmente questi componenti pesanti, garantendone il sollevamento costante e lo spostamento preciso nella posizione designata durante il processo di assemblaggio, fornendo una solida base per il successivo lavoro di assemblaggio preciso.

Il funzionamento del paranco elettrico a catena è estremamente comodo.

In una linea di produzione automobilistica molto impegnata, il tempo è sinonimo di efficienza e ogni fase deve essere semplificata e ottimizzata il più possibile. Grazie ai pulsanti di controllo intuitivi di un paranco elettrico a catena, gli operatori possono eseguire facilmente il sollevamento, la movimentazione orizzontale e il posizionamento dei componenti con una semplice pressione. Questo controllo preciso è particolarmente vantaggioso per l'assemblaggio di componenti che richiedono un'elevata accuratezza. Non solo riduce la complessità della movimentazione manuale, ma migliora anche significativamente l'efficienza e la qualità dell'assemblaggio. Tali apparecchiature svolgono un ruolo fondamentale nell'industria automobilistica, dove precisione e produttività sono fondamentali per mantenere flussi di lavoro produttivi frenetici.

Il paranco elettrico a catena offre un elevato grado di sicurezza.

In un ambiente come un'officina di produzione automobilistica, dove il personale è denso e le attrezzature sono altamente concentrate, la sicurezza è sempre la massima priorità. I paranchi elettrici a catena sono dotati di una serie completa di funzioni di protezione di sicurezza, come sistemi di protezione da sovraccarico che interrompono automaticamente il funzionamento quando il carico supera la portata nominale, prevenendo danni alle apparecchiature e incidenti di sicurezza. Inoltre, i finecorsa garantiscono che il paranco funzioni rigorosamente entro l'intervallo di corsa designato, evitando collisioni involontarie con oggetti o macchinari circostanti. Questi meccanismi di sicurezza integrati consentono agli operatori di utilizzare il paranco in tutta sicurezza, concentrandosi sull'attività di assemblaggio senza preoccuparsi costantemente di potenziali rischi. Nel settore automobilistico, dove precisione e sicurezza devono andare di pari passo, tale protezione è essenziale per mantenere sia la produttività che il benessere sul posto di lavoro.

Anche il paranco elettrico a catena ha una buona adattabilità.

La disposizione e l'ambiente dell'officina di produzione di veicoli a nuova energia possono variare a causa delle diverse esigenze produttive e il paranco elettrico a catena può adattarsi in modo flessibile a tali cambiamenti. Che si tratti di sollevare componenti in spazi ristretti o di operare in aree di lavoro di diverse altezze, può adattare i propri parametri e metodi operativi per soddisfare al meglio i requisiti di produzione e garantire il corretto assemblaggio dei componenti automobilistici.

Nell'attuale vigoroso sviluppo dei veicoli a nuova energia, il paranco elettrico a catena, con la sua eccellente capacità di carico, la comoda modalità di funzionamento, l'elevato grado di sicurezza e la buona adattabilità e molti altri vantaggi, svolge un ruolo fondamentale nell'assemblaggio dei componenti nel processo di produzione dei veicoli a nuova energia, garantendo in modo efficace il progresso efficiente e regolare della produzione dei veicoli a nuova energia e gettando solide basi per l'ampia applicazione dei veicoli a nuova energia sul mercato.

Carrelli elevatori/Carrelli elevatori

I carrelli elevatori vengono utilizzati principalmente nella produzione automobilistica, per spostare parti o componenti durante l'assemblaggio e persino per caricare e scaricare camion. Lavorano sia all'interno che all'esterno.

La movimentazione dei materiali nel settore automobilistico deve essere in grado di gestire grandi piastre metalliche e stampi per telai. Questi articoli pesano solitamente dalle 6 alle 8 tonnellate e vengono immagazzinati in un ambiente interno. Per questo motivo, i carrelli elevatori elettrici sono la scelta perfetta.

Nel settore automobilistico esistono requisiti molto specifici. Le persone preferiscono utilizzare carrelli elevatori elettrici perché questa applicazione viene svolta quasi interamente in ambienti chiusi. I carrelli elevatori elettrici contribuiscono a ridurre il rumore nell'ambiente di lavoro ed eliminare le emissioni nocive. Questo non solo contribuisce a creare un ambiente di lavoro più pulito, ma migliora anche il comfort dell'operatore.

Veicolo a guida automatica

Essendo uno dei primi settori ad adottare gli AGV e a collaborare con i fornitori di AGV, l'industria automobilistica è coinvolta nei quattro principali processi di produzione di veicoli (stampaggio, saldatura, verniciatura e assemblaggio). In diversi collegamenti di processo, i robot AGV svolgono ruoli diversi per contribuire all'automazione e all'intelligenza della gestione logistica.

- Il processo produttivo dell'industria automobilistica è fisso e presenta un elevato grado di standardizzazione, il che lo rende adatto all'applicazione degli AGV.

- L'industria automobilistica utilizza gli AGV da oltre 10 anni e sono diventati l'equipaggiamento standard nel settore automobilistico.

- Il ciclo produttivo complessivo dell'industria automobilistica è lungo e la domanda di AGV è elevata.

- L'industria automobilistica è caratterizzata da un elevato grado di automazione e da una forte applicabilità dei veicoli a guida automatica (AGV).

- Può migliorare il grado di automazione e flessibilità della fabbrica del cliente e ridurre notevolmente i costi di manodopera.

Casi

Officina di assemblaggio di automobili Geely Xiangtan

Officina di assemblaggio di automobili Hanteng Jiangxi

Officina di assemblaggio Toyota Tianjin