Ознайомлення з продуктом

Metro Slag Handling Gantry Crane is a specialized lifting device used in metro construction projects. It is primarily designed for handling excavated slag produced by shield tunneling machines, as well as for lifting and installing tunnel lining segments.

Compared with a conventional gantry crane, the Metro Slag Handling Gantry Crane is equipped with an additional slag overturning system, which is the key functional difference. The main purpose of this system is to tip and discharge the slag bucket efficiently and safely.

The hoisting mechanism adopts a lifting beam as the lifting appliance. A freely rotating central hook is arranged at the middle of the lifting beam, enabling the crane to handle tunnel segments and other construction materials when required. A slag overturning mechanism is installed on the trolley, consisting of a driving device and an overturning hook.

Before lifting the slag bucket, the operator actuates the overturning mechanism, and the driving device moves the overturning hook backward to a designated position. The slag bucket is then hoisted to a position above the overturning hook. Subsequently, the operator drives the overturning hook forward beneath the bucket, and the bucket is lowered. The eccentric overturning shafts on both sides of the bucket rest on the overturning hook. As the bucket continues to descend, the eccentric structure, combined with the bucket’s own weight, initiates a controlled rotation, completing the tipping and slag discharging process.

Key Structure and Functional Features

- Dedicated Tipping System

Equipped with a hydraulic overturning mechanism, the system utilizes a combination of overturning hooks and eccentric shafts to achieve automatic tipping and discharge of the slag bucket. The entire dumping process is completed without manual intervention, ensuring high efficiency and enhanced operational safety. - Variable Span Capability

The main girder is designed with an adjustable span function, allowing quick adaptation to different tunnel cross-section dimensions across various construction sections, significantly improving equipment versatility and site adaptability. - Directional Slag Dumping Trolley

Selected models are fitted with a trolley capable of adjusting the dumping direction. This enables a single crane to serve multiple slag discharge points, reducing the number of machines required and lowering overall equipment investment. - High Stability and Safety

The crane adopts an 8-wheel, 4-drive long-travel system to ensure smooth and stable operation. Rail clamps are installed as standard to firmly grip the rails when the crane is not in operation, effectively preventing unintended movement caused by wind or external forces. - Structural Configuration

The crane mainly consists of a gantry structure, a trolley with an integrated hydraulic overturning mechanism, a long-travel traveling system, an operator’s cabin, and an electrical control system. The leg structure is typically designed in an A-frame or U-frame configuration to suit different construction environments.

Metro Slag Handling Gantry Crane-Smooth and Stable Operating Performance

The Metro Slag Handling Gantry Crane is specifically engineered for slag handling operations in metro and tunnel construction projects. It combines high load capacity with smooth and stable operation, ensuring reliable lifting, traveling, and slag dumping performance under continuous working conditions. This design effectively meets the dual requirements of safety and efficiency demanded by modern construction sites.

For detailed technical specifications, please refer to the PDF document below.

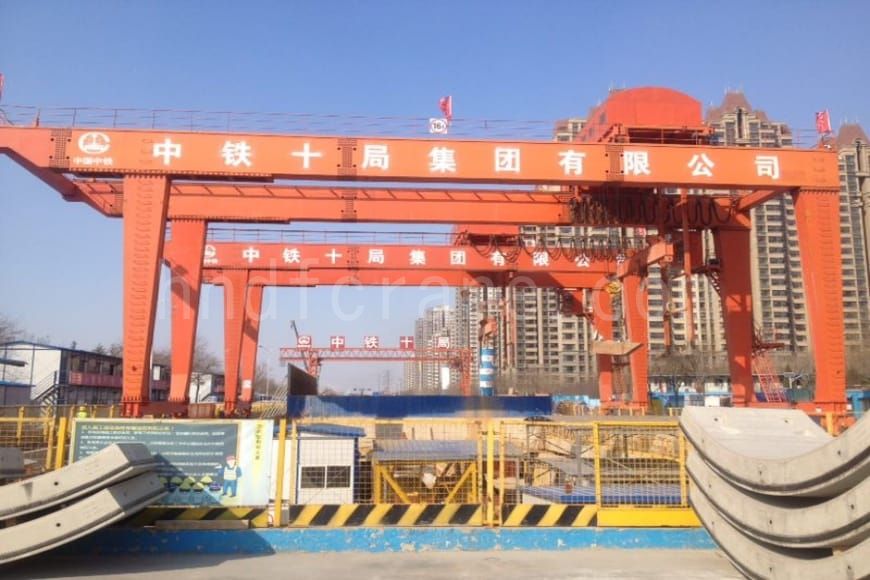

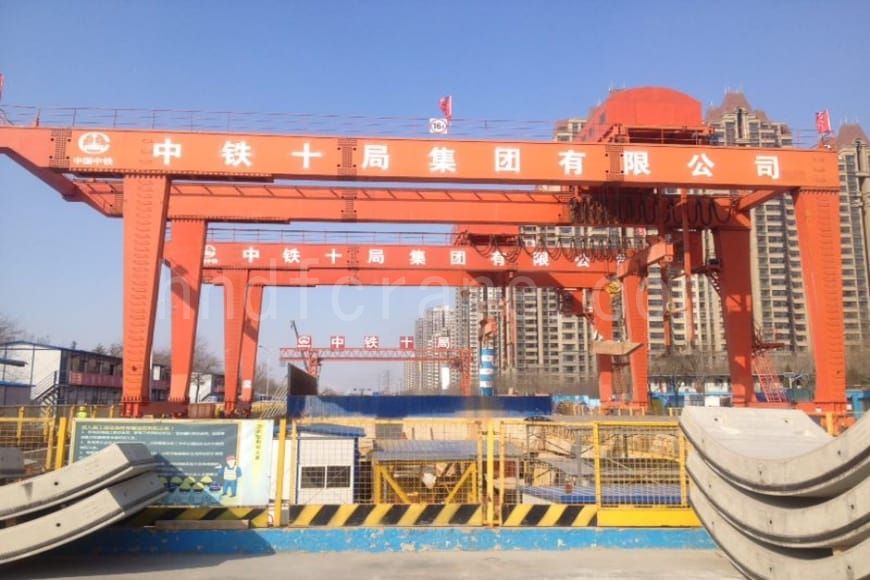

Metro Slag Handling Gantry Crane Cases

With proven performance across multiple metro construction projects, our Metro Slag Handling Gantry Crane demonstrates consistent reliability and operational stability while meeting high standards of safety and efficiency, ensuring dependable operation throughout long-term and continuous construction cycles.