澳大利亚桥式起重机:行业需求不断增长,中国进口产品稳定

目录

在澳大利亚,受全国多个核心工业部门的推动,澳大利亚对桥式起重机(包括桥式起重机和电动高架移动式起重机 (EOT) 等主要类型)的需求一直稳步增长。从西澳大利亚州的铁矿山到昆士兰州的煤炭设施,再到新南威尔士州的制造业中心,这些行业都依赖澳大利亚的桥式起重机解决方案来支持重载搬运、设备维护和精简的生产流程,从而推动了市场需求的持续增长。从西澳大利亚州的采矿场到维多利亚州的汽车制造车间,从昆士兰州的液化天然气加工厂到新南威尔士州的重型机械维修厂,桥式起重机已成为简化重型起重、提高运营效率和确保工作场所安全的核心设备。无论是在矿山中移动大型采矿设备,在造船厂组装船体部件,还是在发电厂维护涡轮机组,此类设备在关键的工业流程中都发挥着不可替代的作用。

仔细观察澳大利亚的桥式起重机供应链,可以发现一个显著特点:进口产品占据了相当大的市场份额,补充了本地生产。据 联合国商品贸易统计数据库2023年,中国已成为澳大利亚最大的桥式起重机进口来源国,这一趋势在加拿大等其他全球市场也普遍存在。这种对进口的依赖受多种因素影响,包括国际制造商(尤其是中国制造商)提供的成本效益、生产规模和产品多样性,这些制造商能够灵活地适应采矿、制造和能源等不同行业的定制需求。与此同时,虽然澳大利亚拥有许多本土桥式起重机公司,但它们的业务通常侧重于专业服务和区域支持,而非大规模设备供应。

本文旨在为澳大利亚买家提供全面的指南,帮助他们在澳大利亚桥式起重机市场中脱颖而出。我们将深入探讨采矿、制造和能源等主要需求驱动行业的特点——可靠的桥式起重机对这些行业的运营效率至关重要——并阐释为何进口已成为这些供应链的基石。我们还将结合实际出口经验,分享实用见解,帮助企业成功将桥式起重机从中国进口到澳大利亚,确保符合当地标准(例如 AS 1418 安全法规)和运营需求。此外,我们还将重点介绍该领域值得信赖的合作伙伴,并对国产和进口产品进行均衡比较,帮助买家根据其具体的生产、预算和合规要求做出明智的决策。

澳大利亚主要行业及桥式起重机需求:推动市场增长的核心行业

澳大利亚采矿作业用的桥式起重机

矿业是澳大利亚经济的核心支柱,在2024财年贡献了21%的GDP增长,并创造了$594亿澳元的税收和特许权使用费收入,为基础设施和公共服务提供了重要支撑。作为全球领先的矿产供应国,澳大利亚2024年锂产量占全球36%,出口额达到$52亿澳元,拥有世界第二大铜储量,并在黄金、铀等矿产资源方面保持领先地位。在这些密集的采矿作业中,澳大利亚的桥式起重机发挥着不可替代的作用:澳大利亚桥式起重机类别中的大跨度双梁起重机在铁矿厂搬运数十吨的选矿设备,提高煤矿的煤炭运输效率,防爆型号确保高风险液化天然气设施中压力容器的安全处理。无论是新矿开发的基础设施和调试,还是现有运营的设备升级,原材料转运和重型设备维护等核心任务都依赖于澳大利亚的桥式起重机解决方案来维持生产的连续性。即使在周期性的行业波动中,这种需求依然保持稳定和刚性。

矿石加工厂使用的抓斗桥式起重机

抓斗桥式起重机广泛应用于澳大利亚的煤矿或铁矿项目中,用于装卸矿石、煤炭等散装物料。抓斗桥式起重机是澳大利亚桥式起重机的一个重要类别,具有高效、自动化的特点,常用于矿石预处理厂或尾矿处理区。

采用机械抓斗(如抓斗式、橙瓣式)从筒仓或堆料车间抓取大块散装物料,通过澳大利亚桥式起重机、行走及主钩操作控制精确卸料。抓斗的开闭采用机构或液压控制,适应大尺寸、低密度物料的连续作业需要。

由于澳大利亚矿区长期高温干燥带来的粉尘和干扰,澳大利亚这些桥式起重机的抓斗本体需要采用高耐磨钢材,并设置中央润滑系统以简化维护(减少人工上部结构维护)。在沿海矿山或高湿度环境下,桥机钢结构和抓斗还需要配备防腐涂层和密封电器,以应对盐雾侵蚀。

双梁桥式起重机在矿井维护作业区的应用

在铁矿石加工厂或矿山维护作业区,双梁桥式起重机是澳大利亚必不可少的桥式起重机类型,用于吊运选矿设备、大型选矿模块,或维护机械设备。桥式起重机跨越车间,采用主钩和副钩互补,起升力大、载荷高,作业效率高。载重量可达数十吨,跨度大,有利于覆盖广阔的作业区域。

澳大利亚车间温度变化较大,有时高温可达40℃+粉尘环境,对电气系统、制动系统等可靠性提出了很高的要求。

该类设备大多为矿山工厂的关键设备,需要稳定运行;现代设计配备了变频调速、负荷保护、远程监控功能,以应对高负荷循环运行。

澳大利亚汽车冲压和装配桥式起重机

在澳大利亚制造业,尤其是在曾经盛极一时的汽车冲压车间(尽管当地整车制造已停止,但零部件和改装厂的需求仍然存在),起重效率和精度对于维持生产节奏至关重要。澳大利亚面临着高而严格的安全标准(例如AS/NZS 1418),车间空间通常较为狭窄,环境温差较大。随着高效生产和设备自动化成为主流,桥式起重机在模具、钢圈和加工设备搬运方面的需求持续稳定。

汽车冲压车间使用的模具搬运起重机

在汽车冲压车间,模具更换频繁,重量大且需要精确定位。澳大利亚工厂经常使用模具搬运起重机(Die Handling Cranes),这是一种澳大利亚特有的桥式起重机,用于在模具仓库和冲压机之间来回搬运模具,确保模具维护安全快速。

采用双主梁结构,提升刚性和承载能力;配备双葫芦或旋转吊具,可实现模具精准安装和旋转维护;采用更智能的控制系统,支持无线或地面按键操控,适应车间温差和空间限制。配合定位传感器和PLC,可快速切换模具,确保冲压效率和安全性——这正是该工业场景对澳大利亚桥式起重机的关键性能要求。

澳大利亚当地车间温度经常达到40℃,因此设备电气系统需要具备抗热失控和防尘功能,进一步优化了澳大利亚型号桥式起重机在恶劣运行环境下的耐用性。

型材加工区卷材搬运桥式起重机

在冲压和型材加工区域,钢卷需要从仓库运输到开卷机或送料设备。钢卷搬运桥式起重机是澳大利亚金属加工行业重要的桥式起重机类型,专为重型钢卷设计,可实现快速安全的运输和卸载。

桥式起重机配备专用夹具或磁性吊具固定钢卷,移动将钢卷运送至物料线;桥式起重机常采用大跨度框架结构,配备无线夹具控制系统,满足高频次物料移动和灵活车间布局的需求。

澳洲南部海岸地区,仓库湿度较高,因此澳洲桥式起重机的固定装置及桥架结构均需具备防锈、防腐蚀的设计;同时,车间电源不稳定,要求设备配备变频软启动功能,以增强运行稳定性并延长设备使用寿命。

澳大利亚发电站桥式起重机

澳大利亚的发电基础设施——包括斯坦威尔(1,445 兆瓦)和科根溪(750 兆瓦)等大型燃煤电厂,以及天然气和水力发电站——对国家能源供应至关重要。在这些高风险环境中,澳大利亚的桥式起重机不可或缺。从水力发电站的涡轮机安装到燃煤电厂锅炉房的重型设备维护,澳大利亚的桥式起重机确保了安全、高效和可靠的运行——在发电厂的发电站和涡轮机房严格的安全标准、高压区域和狭窄的空间限制下,这一点尤为重要。

发电机房双梁桥式起重机

该起重机用于发电站的发电机房,用于搬运发电所需的定子、转子等重型旋转机械。采用双梁结构,可实现最大负载能力和稳定性。

主钩和副钩可精确安装和拆卸定子/转子组件。其特点是行程平稳,并借助精细速度控制系统进行定位。通常集成防摇和对准辅助装置,以便安全地搬运精密、高价值的部件。

对于部署在澳大利亚发电设施中的桥式起重机而言,它们必须能够承受发电机房独特的环境挑战,包括内部温度和湿度的波动。除了环境适应能力之外,高安全标准也不容置疑:为了降低高压高温区域的风险,必须配备防爆控制装置(对于汽轮机房附近区域至关重要)。此外,澳大利亚用于该领域的桥式起重机经过专门设计,可在周期性重载下实现长使用寿命,同时还采用了便捷的维护设计,以满足发电厂严格的运营和维护要求。

燃煤电厂单梁桥式起重机

这些起重机安装在锅炉房或部件装配区,用于吊运重型管道、锅炉外壳和维护平台。

采用坚固的单梁结构,并配备高容量绞车或提升机。配备耐热吊钩或吊架,用于搬运高温锅炉部件。通常配备远程控制功能,以便在远离高温表面或蒸汽的情况下安全操作。

澳大利亚电力设施的桥式起重机采用澳大利亚环保设计——配备隔热电气元件,并针对锅炉区域进行冷却设计。这些起重机的构造符合澳大利亚高风险、高温区域的安全规范,旨在实现高正常运行时间,并配备冗余安全功能,以最大程度地减少关键维护期间的停机时间。

从中国进口桥式起重机到澳大利亚:大方起重机值得信赖的解决方案

随着澳大利亚采矿、制造和电力行业对桥式起重机的需求持续增长,越来越多的买家开始向国际供应商寻求先进、可靠且经济高效的起重解决方案。虽然澳大利亚确实有一些本地桥式起重机制造商,例如 艾尔贝克 和 JDN单臂起重机其产品组合通常侧重于5至100吨的中型车间起重机和定制服务。对于大型项目,本地供应商通常采用定制模式,许多零部件从国际采购,这可能导致更长的交货时间。

相比之下,中国桥式起重机制造商, 大方起重 和 狂山 我们提供从1吨到500吨及以上的全面产品系列,并拥有大规模生产设施和常见型号的部分库存,这使得他们能够保持30至60天的稳定交货时间。此外,中国供应商凭借远程监控、变频驱动、耐腐蚀涂层和智能控制系统等解决方案,提供了强大的技术适应性,确保在澳大利亚高温、粉尘和沿海盐雾等严苛条件下可靠运行。

贸易政策进一步提升了成本效益:根据澳大利亚边境执法局 (ABF) 的规定,HS 编码 8426 下的桥式起重机适用 5% 的基准关税。然而,根据《中澳自由贸易协定》(ChAFTA),符合条件的产品可享受 0% 的关税税率,仅需缴纳 10% 的商品及服务税 (GST)。这显著增强了中国进口产品的竞争优势。

基于这些优势,下文将结合大方起重机作为经验丰富的桥式起重机供应商的出口经验,概述从中国进口桥式起重机至澳大利亚的流程。本章节涵盖关键步骤,包括所需文件(例如中澳自贸协定原产地证书和ISPM 15包装合规性)、最佳运输方式(针对双梁起重机等重型机械量身定制)以及简化的清关程序。本实用指南旨在帮助澳大利亚企业与可靠的桥式起重机供应商合作,更高效地完成进口,最大限度地减少延误并确保符合当地运营需求。

✅ 熟悉澳大利亚的进口和合规标准

✅ 先进的内部制造系统

✅ 适用于重型和精密项目的灵活解决方案

大方起重机是全球十大起重机制造商之一,拥有强大的生产能力和严格的质量管理框架。公司持有涵盖多种起重机产品的多项国际认证,并运营智能生产线,旨在确保精度、效率和始终如一的质量。其解决方案广泛应用于采矿、制造、物流和基础设施领域。

作为服务澳大利亚市场的顶级桥式起重机制造商之一,大方起重机专注于应对当地特有的挑战——包括强烈的阳光照射、干旱多尘的内陆矿区、港口区域的沿海盐雾环境,以及矿业和能源项目严格的安全法规。为了有效应对这些挑战,大方起重机在其设计中融入了定制解决方案:用于抵御强烈日晒的抗紫外线涂层、用于内陆作业的防尘提升机、适用于沿海环境的防腐结构以及节能变频驱动器。这些改进确保了其起重机在澳大利亚多样化的气候条件下都能提供可靠的性能,这也进一步证明了其在满足当地行业需求的顶级桥式起重机制造商中脱颖而出。

澳大利亚客户尤其看重大方起重机的定制工程能力、可靠的项目交付和技术适应性,使该公司成为采矿厂、汽车生产线以及铁路和港口扩建等重大基础设施项目值得信赖的合作伙伴。

大方起重机还持有国际认可的认证,确保符合全球和澳大利亚的安全标准。凭借其模块化设计和智能控制系统,大方起重机制造商为重型采矿作业、精密制造车间和大型物流应用提供量身定制的解决方案,确保桥式起重机在澳大利亚严苛的条件下也能可靠运行。

澳大利亚桥式起重机进口流程

中国是澳大利亚最大的出口市场和主要进口来源地。2015年签署的具有里程碑意义的中澳自由贸易协定深化了两国贸易关系,为两国企业带来了重大机遇。尽管全球贸易形势起伏不定,但中澳双边贸易额仍保持强劲增长,凸显了对可靠高效的物流解决方案的迫切需求。

- 确定技术规格和报价

- 签订合同并发出采购订单

- 生产(30-60天)

- 海运(整箱/拼箱/散货)

- 报关及出口清关(中国)

- 海运至澳大利亚(通常 12-32 天)

- 澳大利亚清关+派送

所需文件

- 商业发票

- 包装清单

- 提单(B/L)

- 原产地证书(CO)(准确的 HS 分类可确保正确纳税和顺利清关,避免处罚。)

- 信用证或其他付款条件(取决于相关方之间的合同)

- 空运单(用于空运)或海运单(用于海运)

| 运送方式 | 适用货物 | 预计运输时间 (中国 → 澳大利亚) | 主要特点 |

|---|---|---|---|

| 整箱(FCL) | 完整的桥式起重机(主梁、端梁、提升机等) | 18至30天 | 散装设备最具性价比,密封独立运输,安全稳定 |

| LCL(拼箱) | 小批量设备或单个零件 | 22~35天 | 成本较低,与其他货物共用集装箱;可能涉及额外处理和更长的清关时间 |

| 空运 | 紧急关键零件或中型部件 | 5~8天 | 最快的选择,成本较高;非常适合紧急交货或备件 |

| 装货港 (POL) | 卸货港 (POD) | 预计运输时间(天) |

| 上海 | 悉尼/墨尔本 | 23–28(整箱/拼箱) |

| 上海 | 布里斯班/弗里曼特尔 | 27–31(整箱/拼箱) |

| 宁波 | 悉尼/墨尔本 | 22–25(LCL) |

| 青岛 | 悉尼/布里斯班 | 21–29(整箱/拼箱) |

| 广州 | 悉尼/墨尔本 | 24–35(整箱/拼箱) |

| 深圳/蛇口 | 悉尼/布里斯班 | 19–25(拼箱/整箱) |

| 天津/厦门/武汉 | 悉尼 | 31–36(整箱/拼箱) |

澳大利亚桥式起重机的进口关税和税费

关税

- 基本税率:桥式起重机(HS 代码 8426.11.00 和 8426.19.00)需缴纳 5% 基本关税。

- 中澳自贸协定优惠:符合原产地规定并提供有效文件的中国进口产品有资格享受0%关税(自2019年起,大多数机械设备均免征关税)。

商品及服务税(GST)

适用统一的 10% GST,根据应税进口价值计算,其中包括:海关价值、关税、国际运费+保险费和特定费用。

进口加工费(IPC)

费用根据货物价值和运输方式而有所不同(针对电子申报):

- 海运:价值 A$1,000-A$10,000 的货物需支付 A$99 费用;价值超过 A$10,000 的货物需支付 A$201 费用。

- 空运:价值 A$1,000-A$10,000 的货物需支付 A$88 费用;价值超过 A$10,000 的货物需支付 A$184 费用。

- 纸质申报需缴纳更高的费用。

生物安全和检疫成本

- 木质包装必须符合ISPM 15标准(热处理+标记)。

- 二手机械可能需要清洁和检疫检查;不遵守规定可能会导致额外的处理和仓储费用。

港口和码头费用

- 包括墨尔本、悉尼和布里斯班等港口收取的码头搬运费、基础设施费以及仓储费/滞期费。具体金额因港口和承运商而异。

反倾销措施(如适用)

- 仅适用于特定关税细目。进口前请查看反倾销委员会的现行措施。

对于大多数从中国进口到澳大利亚的起重机,主要成本通常包括10% GST + IPC + 港口费用。通常情况下,只要提供正确的原产地声明,即可免征关税。

大方起重机澳大利亚桥式起重机项目

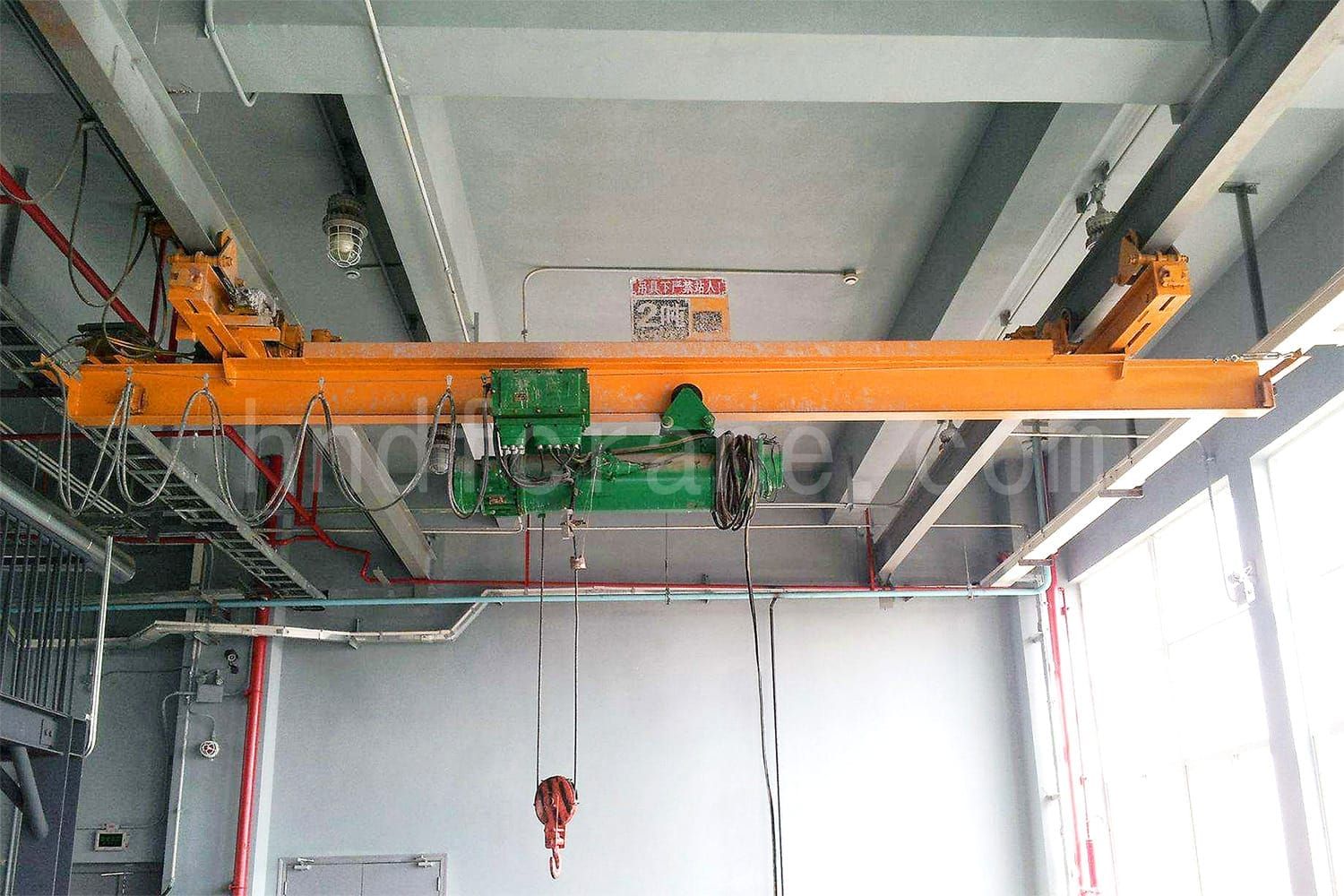

20T HD桥式起重机出口澳大利亚

- 应用: 金属车间起吊重型材料

- 起重能力: 20吨(10+10吨)

- 举升高度: 10米

- 跨度: 33.982米

- 工作电压: 未指定(可能是标准三相,例如 400V/50Hz)

4T HD桥式起重机出口澳大利亚

- 应用: 在澳大利亚卷材加工厂处理钢卷

- 起重能力: 4吨

- 举升高度: 5米

- 跨度: 5米

- 工作电压: 415V / 50Hz / 三相

- 订单内容: HD 4 吨桥式起重机,配备 NR 欧洲电动钢丝绳葫芦;包括钢结构

7T HD桥式起重机出口澳大利亚

- 应用: 在澳大利亚钢铁加工厂装载和运输钢材

- 起重能力: 6.3吨

- 举升高度: 7.5 米

- 跨度: 16.795米

- 工作电压: 415V / 50Hz / 三相

- 订单内容: 配备 NR 葫芦的 HD 6.3 吨桥式起重机

大方起重机澳大利亚服务保证

我们不仅是起重机出口商,更是您在澳大利亚桥式起重机生命周期各个阶段值得信赖的合作伙伴。作为本地区值得信赖的起重机供应商,大方起重机提供从项目设计安装到长期维护升级的专业支持。

- 维护

考虑到澳大利亚多样的气候(从潮湿的沿海地区到干燥的内陆地区)以及采矿和制造设施的苛刻条件,我们提供量身定制的维护指南,涵盖防腐保护、电压波动下的电气稳定性以及定期安全检查,以确保起重机安全可靠地运行。

- 备件供应

为了最大程度地减少停机时间,我们确保关键部件的及时交付。备件根据供应澳大利亚的起重机型号进行准备,并通过悉尼、墨尔本和布里斯班等主要港口的物流渠道,以加快运输速度。

- 培训支持

为了满足当地劳动力的需求,大方起重机提供英文手册和现场或虚拟培训课程,确保采矿和制造业起重机的安全高效运行。

- 技术支援

我们的专家团队提供及时的远程视频协助,并与澳大利亚当地服务合作伙伴合作提供现场故障排除,最大限度地减少设备停机造成的延误。

澳大利亚十大桥式起重机制造商

对于探索澳大利亚桥式起重机市场的买家(尤其是那些优先考虑现场支持或快速售后服务的买家),搜索“我附近的桥式起重机制造商”可以得到实用的选择,并且有几家本地制造商脱颖而出,成为有用的参考:

- 艾尔贝克起重机

- JDN 单臂起重机

- 澳大利亚桥式起重机(AOC)

- 起重机和起重设备总计

- 克兰维护

- Capital Cranes & Hoists (Aust) Pty Ltd

- 克兰泰克

- 詹姆斯·克兰

- 澳大利亚起重机系统有限公司

- 贵族

澳大利亚本地供应商的优势

- 高效的本地化服务: 凭借深厚的区域市场根基,他们精通AS 1418起重机安全标准和采矿作业规范。他们能够在48小时内为西澳大利亚皮尔巴拉铁矿区和昆士兰煤矿等偏远矿区提供现场维护服务,最大限度地减少停机损失。

- 全面的合规保证:他们深入理解澳大利亚安全工作局 (Safe Work Australia) 制定的运营标准,以及高温和多尘环境下的设备防护要求。这确保交付的设备能够直接满足矿场准入标准。

- 标准设备的快速交付:储备10~60吨常规桥式起重机,满足中小型矿山车间日常维护、设备更换的紧急需求,缩短设备投产周期。

中国出口商对澳大利亚的优势

- 技术领先,场景适应性强:他们在智能起重解决方案方面表现出色。例如,配备物联网远程诊断系统的起重机可以实时监控皮尔巴拉地区高温环境下的设备运行参数。经ATEX认证的防爆型号适用于液化天然气加工厂等高风险环境。在澳大利亚沿海高盐雾矿区,采用特殊防腐工艺,使设备使用寿命延长超过30%。

- 覆盖全场景的全面产品组合:其产品范围涵盖从1吨轻型电动葫芦到1000吨超重型双梁桥式起重机,从矿山破碎车间专用起重机到港口散货装卸龙门起重机。他们满足锂矿、铜矿和金矿的定制化需求,尤其擅长为大型矿场提供一体化起重解决方案。

- 成熟的端到端交付保证:利用中澳自贸协定(ChAFTA)原产地规则,符合条件的产品可享受0%关税。通过预制符合ISPM 15标准的木质包装,并提前完成澳大利亚生物安全预检,确保从中国港口到澳大利亚纽卡斯尔、弗里曼特尔等港口的物流顺畅。大型设备的运输周期稳定控制在45-60天。

买家决策考虑因素

澳大利亚中小型矿山或需要紧急更换设备的场景通常更倾向于选择本地供应商提供即时服务。相比之下,大型矿场在新项目开发或设备升级时,往往会优先考虑中国出口商,因为他们拥有先进的技术和全场景覆盖能力。例如,在西澳大利亚锂矿扩建项目中,中国定制的大跨度双梁起重机恰好满足了50吨级选矿设备的高频转运需求,其智能能源管理系统则降低了矿区用电成本。

对于兼顾技术先进性和场景适应性的桥式起重机,中国出口商的定制化解决方案为澳大利亚采矿业提供了长期可靠的设备支持。

发送您的询问

- 邮箱: sales@hndfcrane.com

- 微信: +86 191 3738 6654

- 电报: +86 191 3738 6654

- 电话:+86-373-581 8299

- 传真:+86-373-215 7000

- 地址:中国河南省新乡市长脑工业区

微信

微信