Inleiding tot bovenloopkraanrailklemmen

Railklemmen voor kranen zijn meestal gemaakt van metaal. Ze zijn ontworpen om de rail stevig zijdelings te bevestigen, maar ook om enige beweging in de lengterichting en uitzetting door temperatuurschommelingen en andere factoren mogelijk te maken. De railklem kan worden aangepast aan de grootschalige, efficiënte en diverse eisen van de kraan; tegelijkertijd is de keuze voor verschillende draagbalken verschillend. Railklemmen voor kranen kunnen daarom worden onderverdeeld in geboute, lasbare en ingebedde uitvoeringen.

Classificatie van bovenloopkraanrailklemmen

Materiaal voor bovenloopkraanrailklemmen

| Materiaal | Q235-Smeedstukken | ZG35-Gegoten staal | QT500-7-Gietijzer |

| Chemische samenstelling (%) | C: 0,12-0,20, Mn: 0,30-0,70, Si: ≤0,3, P: ≤0,045, S: ≤0,045 | C:≤0,4,Mn:≤0,9,Si:≤0,5,P:≤0,04,S:≤0,04 | C:3,60-3,80、Mn:≤0,6、Si:2,50-2,90、P:≤0,08、S:≤0,025 |

Gelaste bovenloopkraanrailklemmen van kleine tonnagekranen (LHTZ)

Voordeel

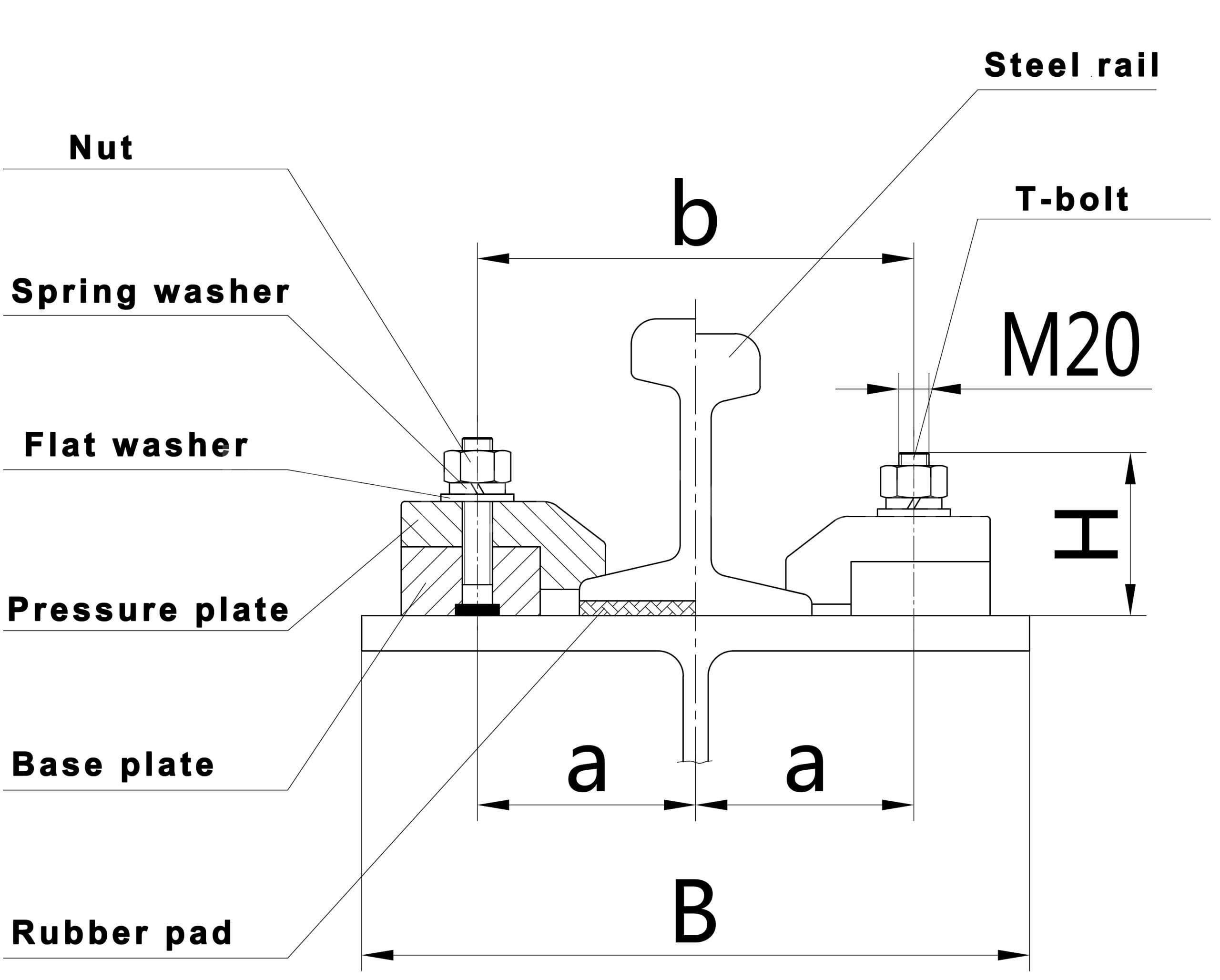

- De vereiste inbouwhoogte van de railpersen uit de LHTZ-serie bedraagt ≤65 mm (inbouwhoogte QU80, QU100, QU120 ≤75 mm); deze worden hoofdzakelijk gebruikt voor vaste installatie van smalle kraanbalken en kraanbanen met horizontale wielen en worden veel toegepast in moderne railklemsystemen.

- Het product heeft een tweeweg zelfborgende en verstelbare railfunctie, wat zorgt voor een stabiele positionering. Het kan worden gebruikt in combinatie met klembeugels voor kraanstops om de eindpositieveiligheid en botsbeveiliging te verbeteren.

- Afhankelijk van het model van de kraanrail wordt het bijbehorende model laswerk gekozen. Deze bevestigingsclips voor kraanrails zorgen voor compatibiliteit en een veilige bevestiging onder verschillende werkomstandigheden.

- Materiaal: De bovenste afdekplaat en de grondplaat zijn gemaakt van gegoten staal Q345 (16 mangaan), de bouten en moeren zijn gemaakt van staalsoort 8.8 en het aanhaalmoment van de bout M20 bedraagt 150 N·m. De maximale laterale kracht bedraagt 65 kN. Hierdoor zijn sterke en duurzame klemprestaties gegarandeerd.

- Dit product is bedoeld voor de installatie en het gebruik van smalle kraanbalkrails met lichte en middelhoge werksystemen. De basis van het vaste deel is aan de kraanbalk gelast. De keuze van het elektrodemodel moet worden afgestemd op het materiaal van de koppeling. De E4315- of E5015-elektrode moet worden gebruikt voor driezijdig lassen en de kwaliteit van de las moet voldoen aan de uiterlijke kwaliteitsnormen van de drielaagse las.

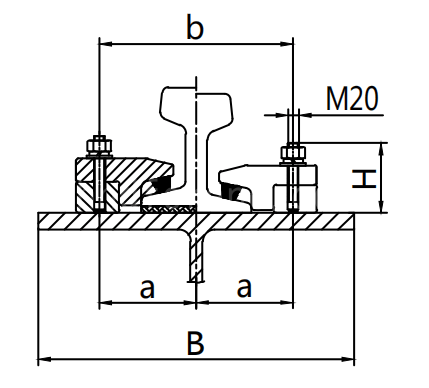

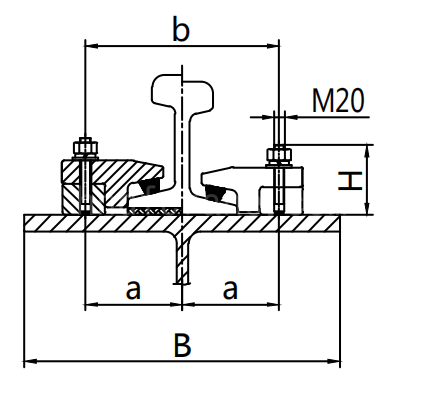

Technische parameter

| Afstand van bout aan centrum van het spoor een (mm) | Boutcentrum afstand b (mm) | Minimale breedte van bovenste vleugel rand B (mm) | Maximaal installatie hoogte H (mm) | |

| LHTZ-12 | 71 | 142 | 196 | 65 |

| LHTZ-15 | 74 | 148 | 206 | 65 |

| LHTZ-18 | 74 | 148 | 206 | 65 |

| LHTZ-22 | 81 | 162 | 220 | 65 |

| LHTZ-24 | 80 | 160 | 218 | 65 |

| LHTZ-30 | 88 | 176 | 234 | 65 |

| LHTZ-38 | 93 | 186 | 238 | 65 |

| LHTZ-43 | 93 | 186 | 238 | 65 |

| LHTZ-50 | 102 | 204 | 256 | 65 |

| LHTZ-70 | 96 | 192 | 244 | 65 |

| LHTZ-80 | 120 | 240 | 300 | 75 |

| LHTZ-100 | 130 | 260 | 320 | 75 |

| LHTZ-120 | 140 | 280 | 340 | 75 |

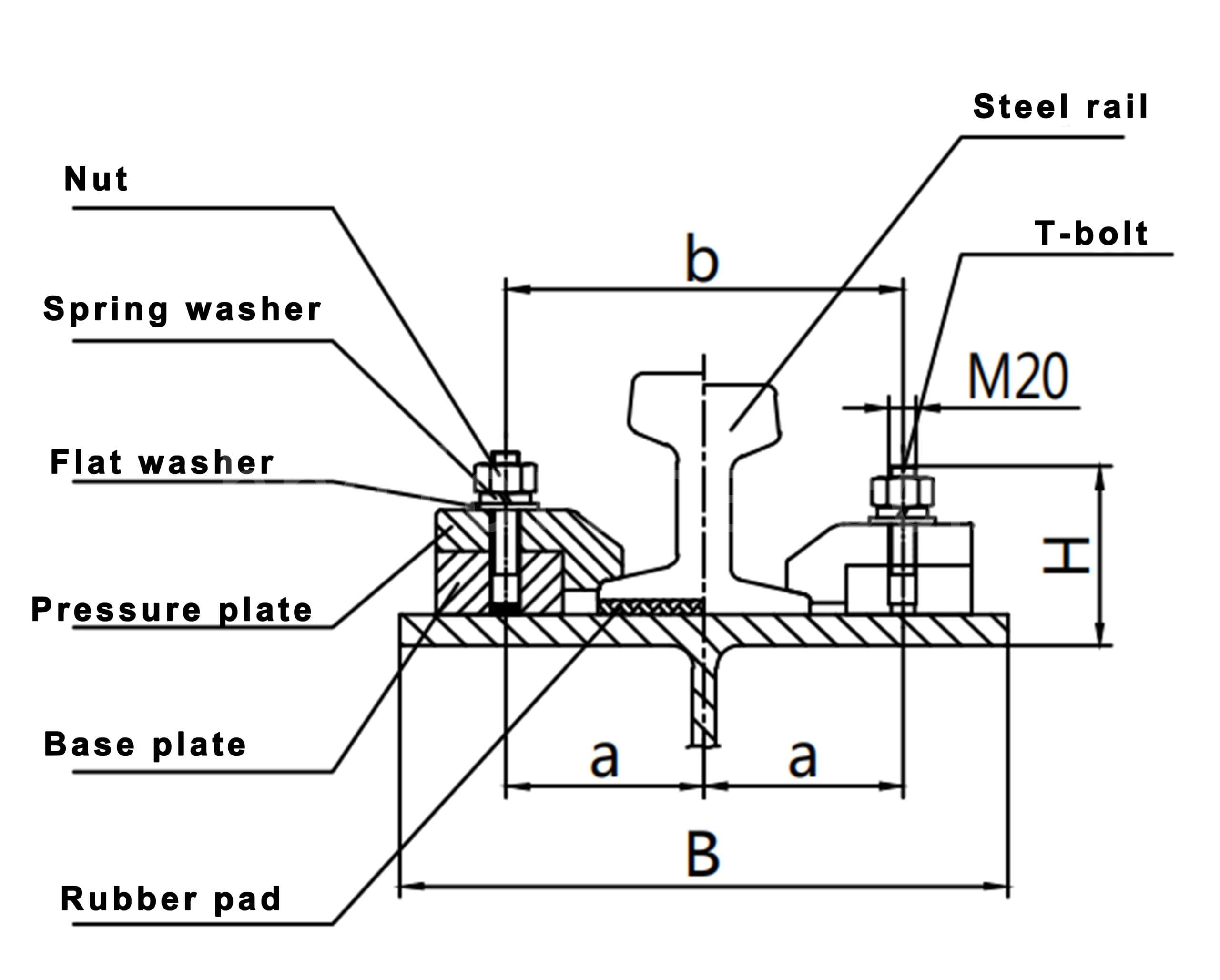

Gelaste bovenloopkraanrailklemmen van grote tonnagekranen (LHFC)

Voordeel

- Het wordt gebruikt in de metallurgie, bij zware machines en apparatuur, bij diverse walserijen, in havens, bij de scheepsbouw, bij non-ferrometalen, bij de lucht- en ruimtevaart en bij militair materieel, bij zwaar hijswerk, in ijzer- en staalbedrijven en in andere sectoren.

- Het wordt voornamelijk gebruikt voor het bevestigen van smallere kraanbalken en stalen rails met horizontale wielkraanbalken in zware werksystemen. Het is voornamelijk geschikt voor (Gn 150 ton~350 ton).

- Wordt voornamelijk gebruikt voor de volgende rupsmodellen: QU70, QU80, QU100, QU120.

- Afhankelijk van de eisen van de werkomgeving kunnen er wel of geen rubberen composietpads onder het spoor worden gelegd.

- Materiaal: De bovenste afdekplaat en de bodemplaat zijn gemaakt van Q345 (16 mangaan) laaggelegeerd gegoten staal. Bouten en moeren zijn van staalsoort 8.8 (45#).

- Standaardwaarde voor horizontale kracht: 80 kN-130 kN.

Technische parameter

| Afstand van bout aan centrum van het spoor (amm) | Boutcentrum afstand (Hmm) | Minimale breedte van bovenste vleugelrand (Bmm) | |

| LHFC-70 | 88 | 176 | 296 |

| LHFC-80 | 93 | 186 | 306 |

| LHFC-100 | 103 | 206 | 326 |

| LHFC-120 | 113 | 226 | 346 |

Flexibele gelaste bovenloopkraanrailklemmen met horizontale wielen (LHSTK)

Voordeel

- Het wordt voornamelijk gebruikt voor het heffen van gewicht onder de 100 ton, de omgevingstemperatuur bedraagt -20℃~70℃, de kraanbalk is smal en de multifunctionele kraanbaan met horizontale wielen is geïnstalleerd en wordt gebruikt.

- Bout M20 (kwaliteit 8.8), aanhaalmoment 150 N.m, maximale zijdelingse kracht 65 kN.

- Materiaal: De bovenste afdekplaat en de onderste plaat zijn allemaal gemaakt van Q345 laaggelegeerd gegoten staal. De samengestelde rubberen matten kunnen worden gelegd op basis van de werkomstandigheden en de werkomgeving. Ze verminderen lawaai in de werkplaats, absorberen schokken en hebben een goede beschermende werking op het spoor en de werkomgeving.

Technische parameter

| Afstand van bout aan het midden van de rail (amm) | Bouthartafstand (bmm) | Minimale breedte van bovenste vleugelrand (Bmm) | Maximale installatie hoogte (hmmm) | |

| LHTZ–12 | 71 | 142 | 196 | 65 |

| LHTZ–15 | 74 | 148 | 206 | 65 |

| LHTZ–18 | 74 | 148 | 206 | 65 |

| LHTZ–22 | 81 | 162 | 220 | 65 |

| LHTZ–24 | 80 | 160 | 218 | 65 |

| LHTZ–30 | 88 | 176 | 234 | 65 |

| LHTZ–38 | 93 | 186 | 238 | 65 |

| LHTZ–43 | 93 | 186 | 238 | 65 |

| LHTZ–50 | 102 | 204 | 256 | 65 |

| LHTZ–70 | 96 | 192 | 244 | 65 |

| LHTZ–80 | 120 | 240 | 300 | 75 |

| LHTZ–100 | 130 | 260 | 320 | 75 |

| LHTZ–120 | 140 | 280 | 340 | 75 |

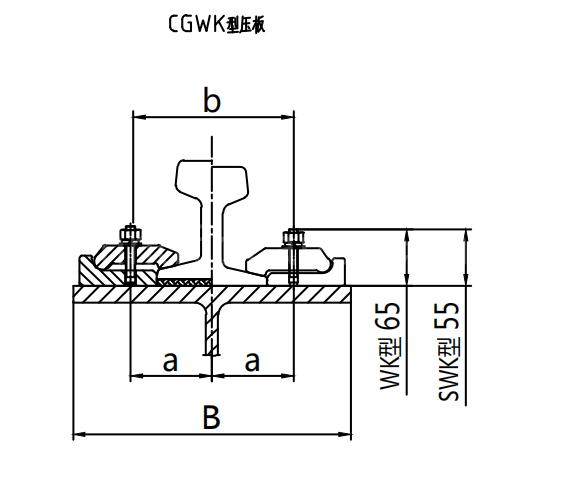

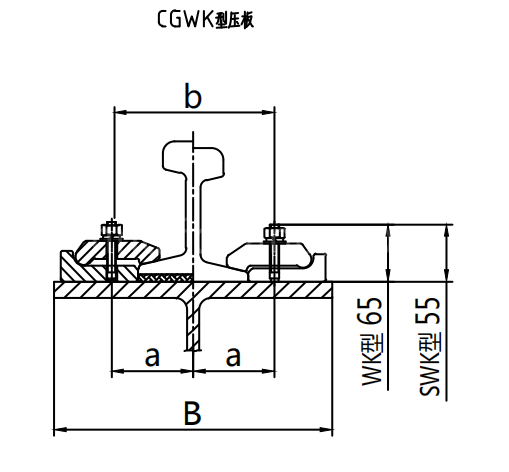

Railklemmen voor kranen (CGWK)

Voordeel

- Railklem van het type CGWK is hoofdzakelijk geschikt voor het bevestigen van kraanrails met een breedte ≤320mm op de flensplaat van de kraanligger.

- Railklem van het type SCGWK is hoofdzakelijk geschikt voor het bevestigen van kraanrails met een breedte ≤250mm op de flensplaat van de kraanligger.

- De grondplaat van het type CGWK en SCGWK railklem is voorzien van tweezijdige zijlas of driezijdige omrandingslas en las met de bovenste flensplaat van de stalen kraanbalk. Dit zorgt ervoor dat de horizontale en horizontale kracht van de kraan soepel en gelijkmatig wordt overgebracht op de kraanbalk en voorkomt defecten door een groot aantal gaten in de bovenste flensplaat van de kraanbalk.

- De grondplaten van het type CGWK en SCGWK bevinden zich op 1 mm afstand van de onderrand van de rails. Dit speelt een belangrijke rol bij het beperken van de verplaatsing van de rails naar links en rechts.

- Railpersen van het type CGWX en SCGWK zijn volledig gemaakt van laaggelegeerd hoogsterktestaal en de bouten zijn gemaakt van bouten van klasse 8.8. Het aanhaalmoment van het type CGWX is 220 Nm en de maximale zijdelingse kracht die op elke wieldruk wordt uitgeoefend, is 65 kN.

- Het aanhaalmoment van het type SCGWK bedraagt 128 Nm, de maximale zijdelingse kracht die op elke wieldruk wordt uitgeoefend bedraagt 45 kN.

Technische parameter

| De afstand van de bout aan de centrum van de spoorlijn (amm) | Afstand tussen de centrum van de twee bouten (bmm)) | Minimale breedte van bovenste vleugelrand (Bmm) | |

| SCGWK-TG22 | 64 | 128 | 204 |

| SCGWK-TG24 | 63 | 126 | 202 |

| SCGWK-TG30 | 71 | 142 | 218 |

| SCGWK-TG38 | 74 | 148 | 224 |

| SCGWK-TG43 | 74 | 148 | 224 |

| SCGWK-TG50 | 83 | 166 | 242 |

| SCGWK-TG70 | 77 | 154 | 230 |

| SCGWK-TG80 | 82 | 164 | 240 |

| De afstand van de bout naar het midden van de spoorlijn (amm) | Afstand tussen de centrum van de twee bouten (bmm) | Minimale breedte van bovenste vleugelrand (Bmm) | |

| CGWK-TG38 | 78 | 156 | 262 |

| CGWK-TG43 | 78 | 156 | 262 |

| CGWK-TG50 | 87 | 174 | 280 |

| CGWK-QU70 | 81 | 162 | 268 |

| CGWK-QU80 | 86 | 172 | 278 |

| CGWK-QU100 | 96 | 192 | 298 |

| CGWK-QU120 | 106 | 212 | 318 |

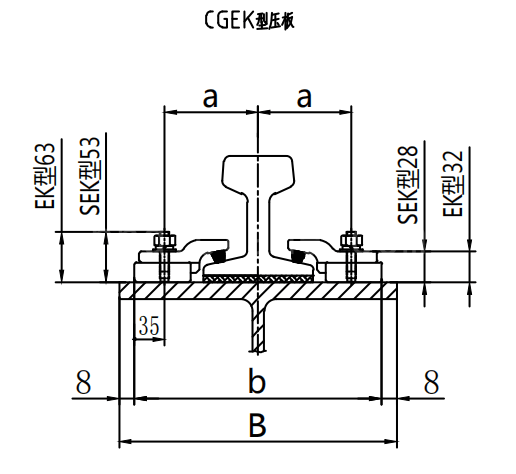

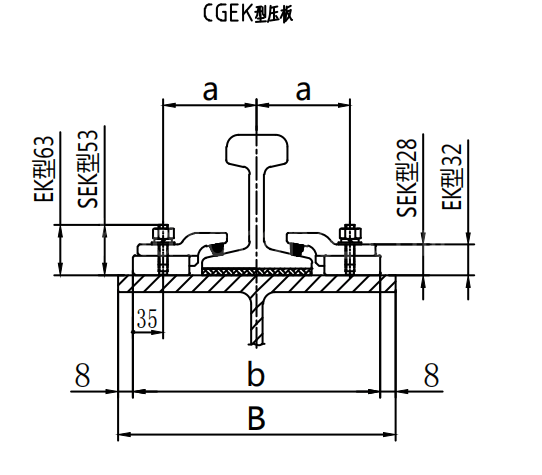

Samengestelde elastische en flexibele raildrukplaat (CGEK)

Voordeel

- Het wordt veel gebruikt in walserijen, continugieterijen, havens, koudwalsen en andere industrieën waar zware machines en apparatuur in de metaalindustrie worden gebruikt.

- De voorzijde van de CGEK- en SCGEK-type rails drukt in contact met de stalen rail en is voorzien van een elastische rubberen tong, die effectief geluid kan verminderen en de werkomgeving kan verbeteren.

- De railpers is smal en plat, wat een gunstige installatiemaat oplevert. De pers kan worden gebruikt voor alle soorten kranen, met of zonder geleidingswielen.

- De railpers is geheel precisiegegoten uit Q345-staal en de bouten zijn gemaakt van hoogwaardige bouten van klasse 8.8. Het aanhaalmoment van het CGEK-type is 220 Nm en is bestand tegen een maximale laterale kracht van 120 kN. Het aanhaalmoment van het SCGEK-type is 128 Nm en is bestand tegen een maximale laterale kracht van 80 kN.

Technische parameter

| een (mm) | b (mm) | |

| CGEK—TG38 | 88 | 266 |

| CGEK—TG43 | 88 | 266 |

| CGEK—TG50 | 97 | 284 |

| CGEK—QU70 | 91 | 272 |

| CGEK—QU80 | 96 | 282 |

| CGEK—QU100 | 106 | 302 |

| CGEK—QU120 | 116 | 322 |

| SCGEK—TG22 | 70 | 207 |

| SCGEK—TG24 | 69 | 205 |

| SCGEK—TG30 | 77 | 221 |

| SCGEK—TG38 | 80 | 227 |

| SCGEK—TG43 | 80 | 227 |

| SCGEK—TG50 | 89 | 245 |

| SCGEK—QU70 | 83 | 233 |

| SCGEK—QU80 | 88 | 243 |

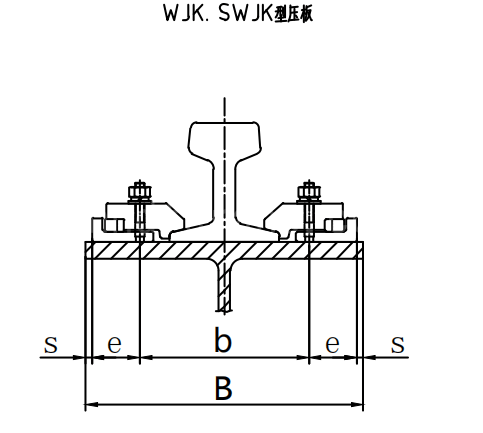

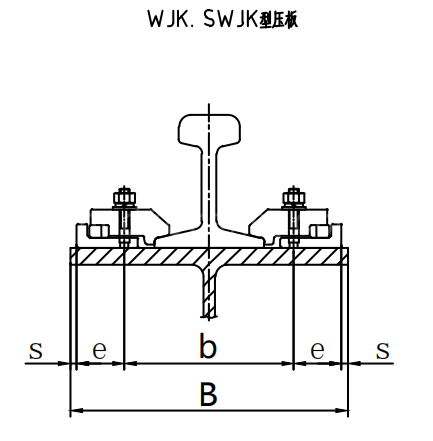

Bovenloopkraanrailklemmen (WJK)

Voordeel

- Standaard gelaste railklemapparaten worden momenteel veel gebruikt in China als bevestigingsmiddel tussen de balk van een stalen kraan en de rail. De materialen worden doorgaans onderverdeeld in twee typen: Q235-materiaal, boutklasse C, bestand tegen een maximale laterale kracht die op elk wiel wordt uitgeoefend van 45 kN; Q345-materiaal, boutklasse 8.8, bestand tegen een maximale laterale kracht die op elk wiel wordt uitgeoefend van 55 kN; de maximale installatiehoogte is 81 mm.

- Het gereduceerde raildrukapparaat is vooral geschikt voor bevestiging tussen de stalen kraanbalk en het spoor, met speciale eisen voor de installatiehoogte van de drukplaat (de maximale hoogte is 71 mm). Het materiaal is Q345, de bout is van klasse 8.8 en de maximale zijdelingse kracht die op elke wieldruk wordt uitgeoefend, is 40 kN; de algemene eisen komen overeen met die van gewone gelaste raildrukapparaten.

- De verdikte gelaste railpers wordt voornamelijk gebruikt voor het bevestigen van de kraanrail met elastische rubberen composietpads aan de onderkant van de rail. Over het algemeen verdeeld in twee typen: het gewone verdikte type en het gereduceerde verdikte type, met een installatiehoogte van respectievelijk 81 mm en 71 mm. Het gewone verdikte materiaal is Q235, de bout is van klasse C en de maximale laterale kracht die op elke wieldruk wordt uitgeoefend is 45 kN; het gereduceerde verdikte materiaal is Q345, de bout is van klasse 8.8, een hogesterktebout, en de maximale laterale kracht die op elke wieldruk wordt uitgeoefend is 40 kN; het voldoet aan de eisen voor het gebruik van een rubberen pad met een hoogte van 7 mm.

Technische parameter

| B mm) | 2e (mm) e=62 | 2s (mm) s=10(5) | Minimale breedte van bovenste vleugelrand (Bmm) | |

| WJK——TG38 | 194 | 124 | 20(10) | 338 (328) |

| WJK——TG43 | 194 | 338 (328) | ||

| WJK——TG50 | 212 | 356 (346) | ||

| WJK——TG60 | 230 | 374 (364) | ||

| WJK——QU70 | 200 | 344 (334) | ||

| WJK——QU80 | 210 | 354 (344) | ||

| WJK——QU100 | 230 | 374 (364) | ||

| WJK——QU120 | 250 | 394 (384) | ||

| SWJK-TG15 | 136 | 118 | 20(10) | 274 (264) |

| SWJK-TG22 | 150 | 288 (278) | ||

| SWJK-TG24 | 128 | 286 (276) | ||

| SWJK-TG30 | 164 | 302 (292) | ||

| SWJK-TG38 | 170 | 308 (298) | ||

| SWJK-TG43 | 170 | 308 (298) | ||

| SWJK-TG50 | 188 | 326 (316) | ||

| SWJK-TG60 | 208 | 346 (336) | ||

| SWJK-QU70 | 176 | 314 (304) | ||

| SWJK-QU80 | 186 | 324 (314) | ||

| SWJK-QU100 | 206 | 344 (334) | ||

| SWJK-QU120 | 226 | 364 (354) |

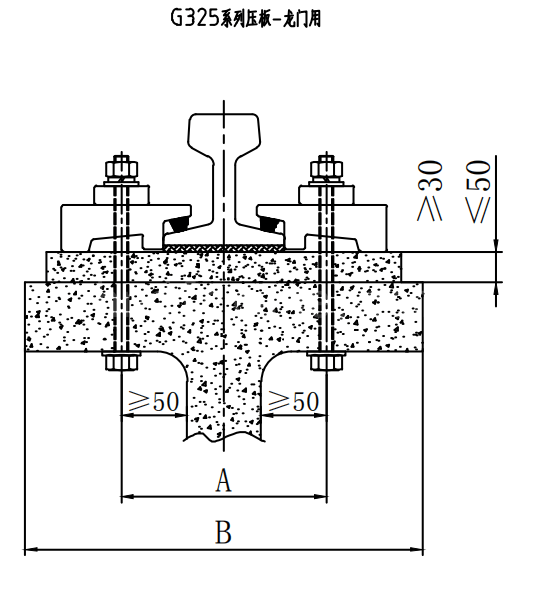

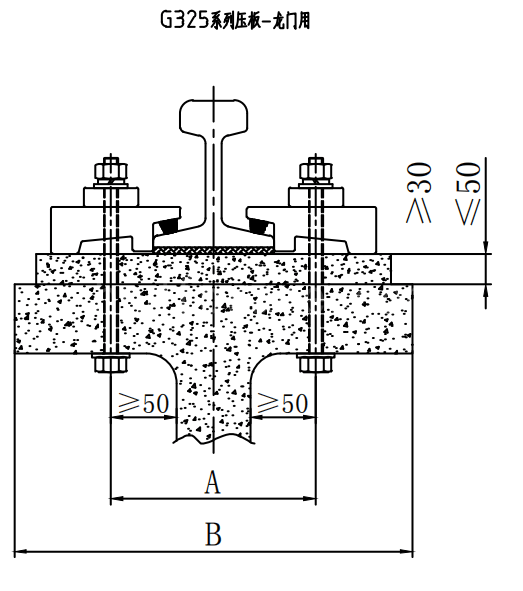

Betonnen constructie rail drukplaat en kunststof composiet rubberen pad

Voordeel

- Deze productserie is geschikt voor de elastische, vaste verbinding van stalen en betonnen kraanbalken. Het heeft de volgende eigenschappen: het vermindert de slijtage aan de bovenzijde van de rail, vermindert de impact van de kraan op de kraanbalk, vermindert de slijtage aan de kraanrand en vermindert het geluid.

- Tussen de rails en de kraanbalk zijn een rubberen tong en een rubberen composietpad aangebracht, waardoor de wrijvingskracht toeneemt, het spoor minder makkelijk verschuift en de kracht van de drukplaatbouten verbetert.

- De dwarsdoorsnede van de elastische rubberen composietpad is in het midden licht bolvormig, wat een rol speelt bij de schokabsorptie.

- De drukplaat is bevestigd aan de kraanbalk, raakt niet los en is niet gevoelig voor slijtage van de kraanbalk. De symmetrisch geplaatste drukplaat vormt een wigvormige structuur in de dwarsdoorsnede, waardoor de verschuiving van de rups naar links en rechts wordt beperkt.

- Tijdens het gebruik van de kraan is het toegestaan dat de kraan enigszins over de rail slingert.

Technische parameter

| Composiet rubberen pad type | Toepasselijk railtype | u (mm) | b (mm) |

| TD-24 | TG24 | 7-9 | 92 |

| TD-38 | TG38 | 7-9 | 114 |

| TD-43 | TG43 | 7-9 | 114 |

| TD-50 | TG50 | 8-10 | 132 |

| TD-70 | QU70 | 10-12 | 120 |

| TD-80 | QU80 | 10-12 | 130 |

| TD-100 | QU100 | 10-12 | 150 |

| TD-120 | QU120 | 10-12 | 170 |

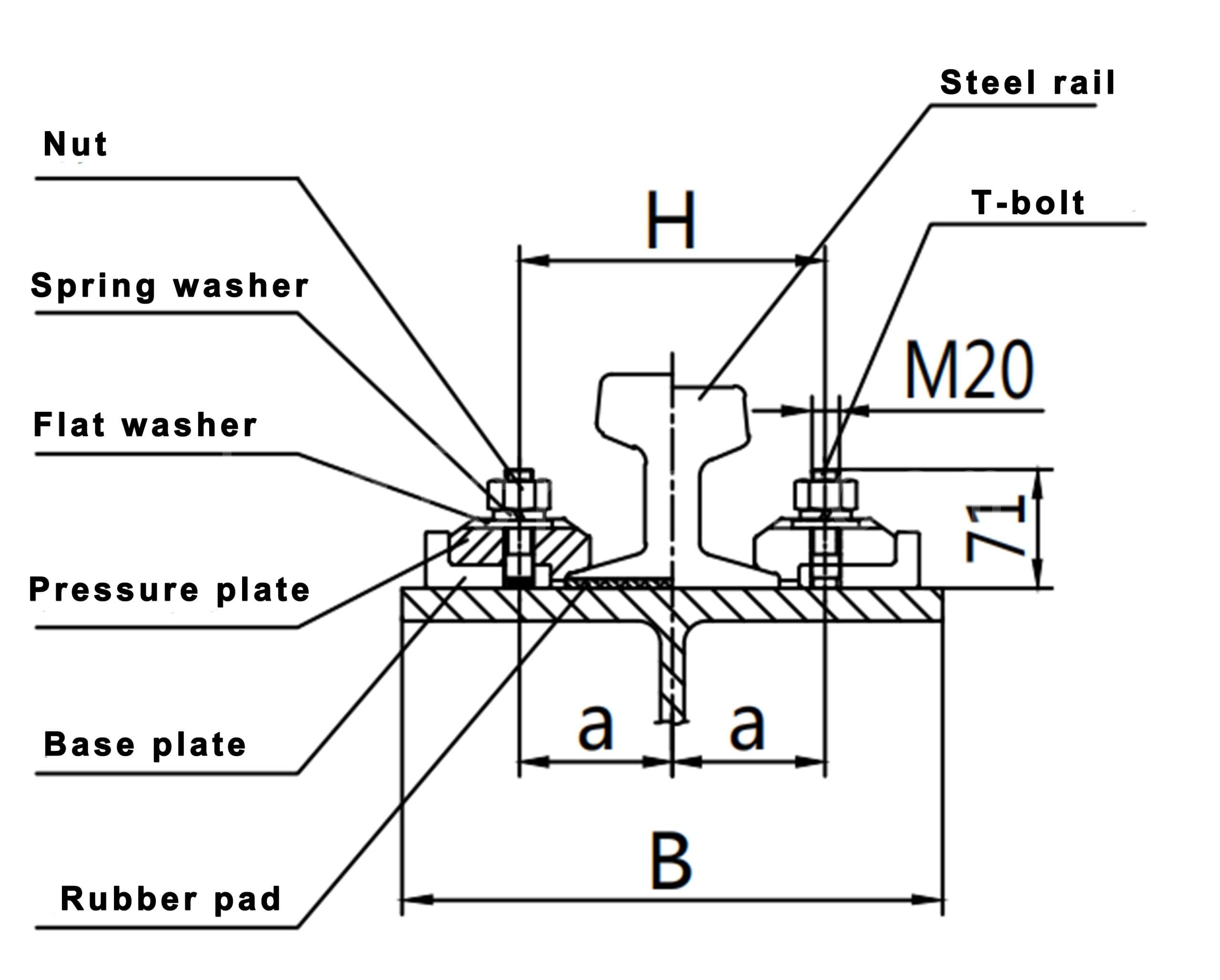

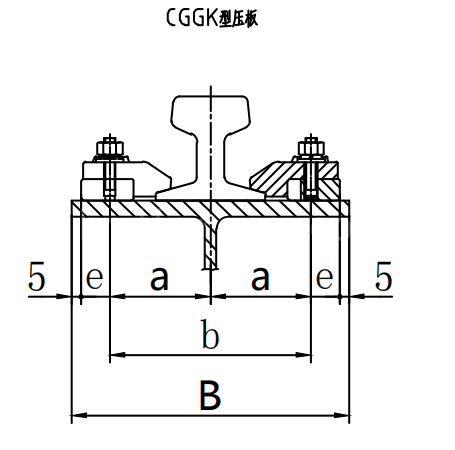

Bovenloopkraanrailklemmen (CGGK)

Voordeel

- Stalen railklem van het type CGGK is vooral geschikt voor het vastzetten van rails, waarbij speciale eisen worden gesteld aan de hoogte van de drukplaat (de maximale hoogte na installatie bedraagt 75 mm).

- De CGGK-grondplaat maakt gebruik van driezijdig lassen en lassen met de bovenste flensplaat van de stalen kraanbalk, waardoor de zijdelingse kracht van de kraan soepel en gelijkmatig wordt overgebracht op de kraanbalk. Het nadeel van verzwakking van de dwarsdoorsnede van de flens, veroorzaakt door een groot aantal openingen in de flens op de kraan, wordt vermeden. Daardoor worden de dwarsdoorsnedesterkte en het draagvermogen van de kraanbalk effectief verbeterd.

- Gemaakt van gegoten staal, dat verstelbaar is, kan de nauwkeurigheid van de spoorinstallatie verbeteren, kan de afwijking van de middenlijn van de spooroneffenheden verminderen en heeft een zelfborgende functie om losraken tijdens gebruik te voorkomen.

- De vrijheid van demontage en montage biedt gunstige voorwaarden voor constructie, installatie en onderhoud.

- Het aanhaalmoment van bout M20 bedraagt 150N.

- De maximale zijdelingse kracht die op elke wieldruk wordt uitgeoefend, bedraagt 80 kN.

Technische parameter

| een(mm) | b(mm) | 2e(mm) | 2s(mm) | B(mm) | H | |

| e=35 | s=10 | B=b+2e+2s | (mm) | |||

| CGGK-QU80 | 110 | 220 | 70 | 20 | 310 | 75 |

| CGGK-QU100 | 120 | 240 | 330 | 75 | ||

| CGGK-QU120 | 130 | 260 | 350 | 75 |

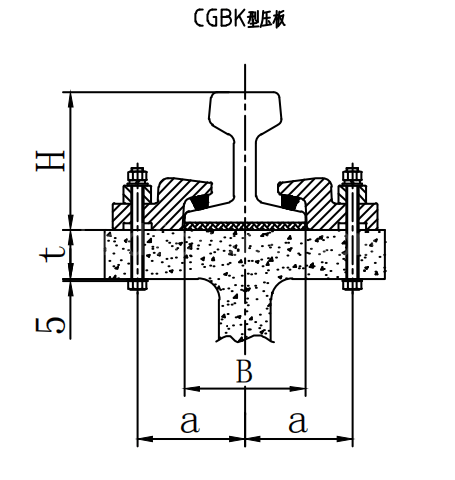

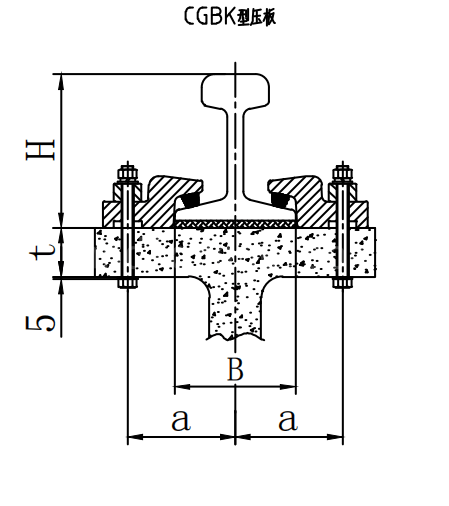

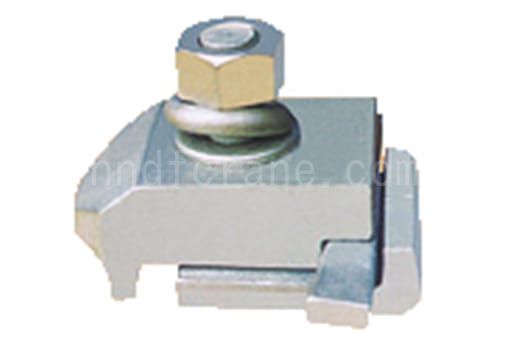

Baosteel Standaard Bovenloopkraan Rail Clips (CGBK)

Voordeel

- Dit product kan worden gebruikt voor geperforeerde stalen kraanbalken en gewapend betonnen kraanbalken.

- Eenvoudig te installeren, aan te passen en te vervangen stalen rails.

- Door de rol van de rubberen tongpers en de samengestelde rubberen pads heeft het een dempende en geluiddempende functie.

- Wanneer de kraan een zeer zwaar werksysteem is, moeten de onder de stalen rails gelegde rubberen composietplaten worden vervangen door stalen platen met een dikte van 6 mm (materiaal is Q235).

- Het materiaal van dit product is precisiegegoten Q235-staal, de bout is een C-klasse bout van M22 en het aanhaalmoment is 170 N.M. De maximale laterale kracht bedraagt 80 kN.

Technische parameter