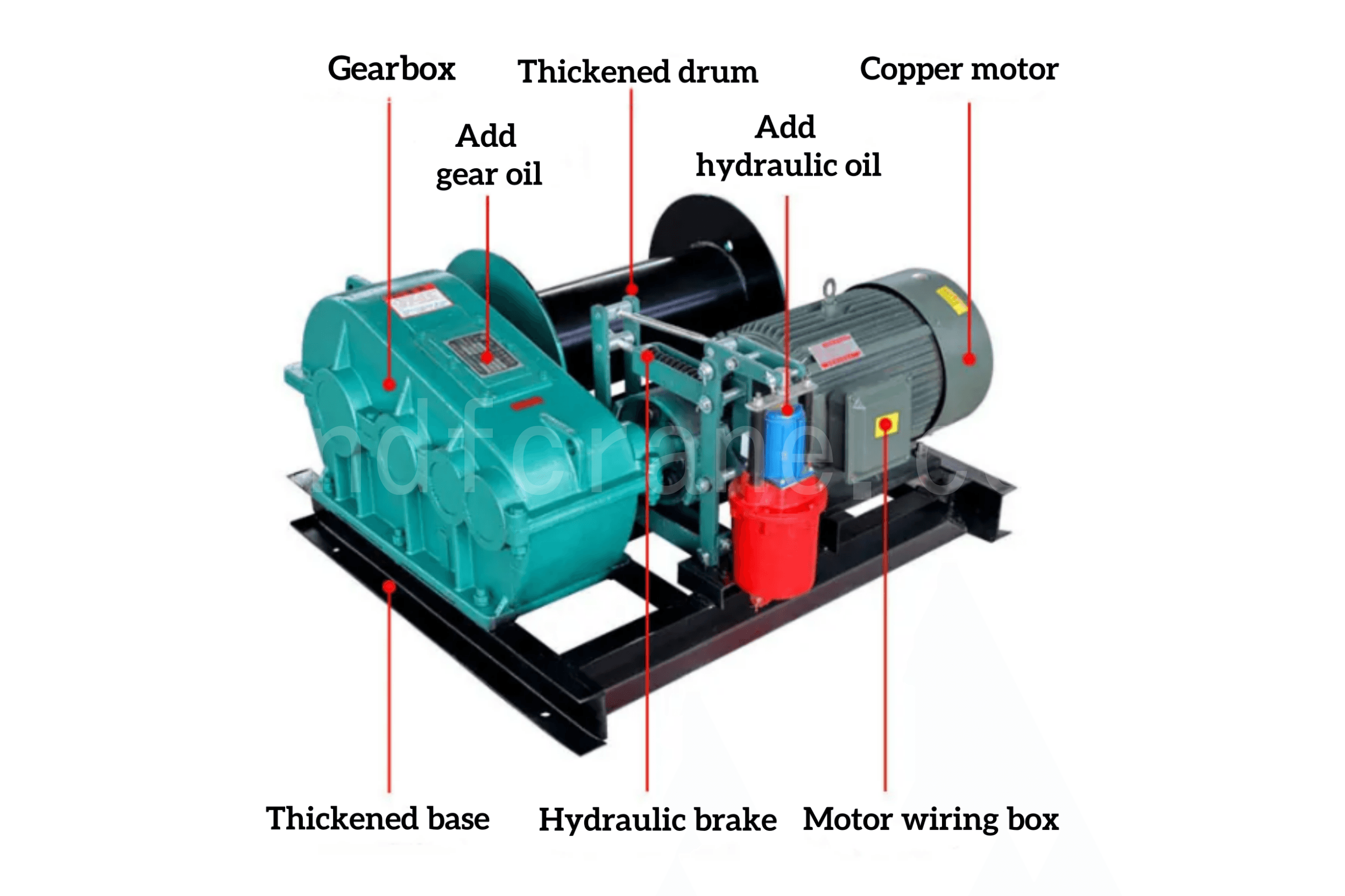

Komponenten einer elektrischen Hochgeschwindigkeitswinde

- Kupfermotor: Verwendet Wicklungen aus reinem Kupfer, die sich durch hervorragende Leitfähigkeit, effiziente Wärmeableitung und lange Lebensdauer auszeichnen und eine stabile Leistungsabgabe für die Winde gewährleisten.

- MotorverdrahtungskastenWird zum Verbinden und Schützen von Motorstromkreisen verwendet, wodurch die Inspektion und Wartung der Verkabelung bequemer wird.

- Hydraulische Bremse: Benötigt Hydrauliköl und gewährleistet eine präzise und stabile Bremsleistung, erhöht die Betriebssicherheit und verhindert das Durchrutschen der Last.

- Verdickte Trommel: Konzipiert für das Aufwickeln von Drahtseilen; die verstärkte Struktur bietet höhere Festigkeit und bessere Verschleißfestigkeit, wodurch sie größeren Zugkräften und häufigen Seilwickelvorgängen standhält.

- Getriebe (Getriebeöl erforderlich): Die Drehzahlregelung erfolgt über das Getriebe, wodurch die Geschwindigkeit und das Drehmoment der Winde an die jeweiligen Hubanforderungen unter verschiedenen Arbeitsbedingungen angepasst werden können. Getriebeöl reduziert den Getriebeverschleiß und verbessert die Getriebeeffizienz.

- Verdickter Boden: Bietet stabilen Halt für die gesamte Maschine; die verdickte Konstruktion erhöht die Stabilität und reduziert Vibrationen während des Betriebs.

Parameter der elektrischen Hochgeschwindigkeitswinde

| Modell | Nennzugkraft (kN) | Nenngeschwindigkeit | Seilkapazität (m) | Drahtseildurchmesser | Motormodell | Motorleistung (kW) | Gesamtabmessungen (mm) | Gesamtgewicht (kg) |

|---|---|---|---|---|---|---|---|---|

| JK0,5 | 5 | 22 | 190 | Φ7,7 | Y100L-4 | 3 | 620x701x417 | 200 |

| JK1 | 10 | 22 | 100 | Φ9.3 | Y112M-4 | 4 | 620x701x417 | 300 |

| JK1.6 | 16 | 24 | 150 | Φ12,5 | Y132S-4 | 5.5 | 945x996x570 | 500 |

| JK2 | 20 | 24 | 150 | Φ13 | Y132M-4 | 7.5 | 945x996x570 | 550 |

| JK3.2 | 32 | 25 | 290 | Φ15,5 | YZR180L-6 | 15 | 1325x1335x840 | 1011 |

| JK3.2B | 32 | 30 | 250 | Φ15,5 | YZR200L-6 | 22 | 1900x1738x985 | 1500 |

| JK5 | 50 | 30 | 300 | Φ21,5 | YZR225M-6 | 30 | 1900x1620x985 | 2050 |

| JK5B | 50 | 25 | 210 | Φ21,5 | YZR225M-8 | 22 | 2250x2500x1300 | 2264 |

| JK8 | 80 | 25 | 160 | Φ26 | YZR280S-8 | 45 | 1533x1985x1045 | 3000 |

| JK10 | 100 | 30 | 300 | Φ30 | YZR315S-8 | 55 | 2250x2500x1300 | 5100 |

Andere Typen

Die Funktion einer handbetriebenen elektrischen Schnellabseilwinde besteht darin, das Drahtseil oder die Last durch manuelle Steuerung gleichmäßig abzusenken. Dieses Gerät bietet einen sicheren und zuverlässigen manuellen Betriebsmodus in Situationen wie Stromausfall, Notfällen oder wenn präzises Handling erforderlich ist. Es verhindert effektiv ein schnelles Durchrutschen oder unkontrollierbares Absenken der Last und gewährleistet so einen gleichmäßigeren, sichereren und kontrollierteren Absenkvorgang.

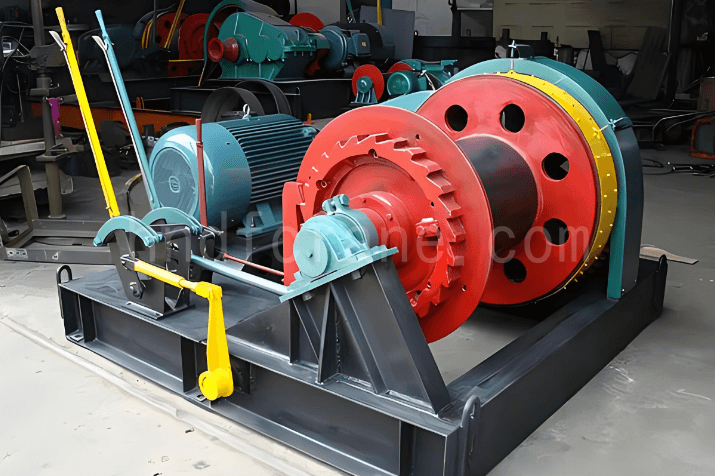

Die elektrische Doppeltrommel-Schnellwinde ist mit zwei Trommeln ausgestattet, die Drahtseile gleichzeitig oder unabhängig voneinander aufwickeln können. Dadurch wird die doppelte Zugkraft erreicht oder verschiedene Betriebsmodi ermöglicht. Sie eignet sich für Anwendungen, die eine höhere Zugkraft oder das gleichzeitige Heben mehrerer Lasten erfordern.

Kundenspezifische Anwendungen von Hochgeschwindigkeits-Elektrowinden

Die elektrische Hochgeschwindigkeitswinde dient primär zum Heben, Ziehen und Positionieren von Trägern, Bauteilen und Baumaschinen beim Brückenbau. Sie liefert eine stabile Antriebsleistung für die Bewegungs-, Hebe- und Montagevorgänge der Brückenmontagemaschine und gewährleistet so die sichere Platzierung der Brückensegmente und den reibungslosen Ablauf des gesamten Bauprozesses.

Winden werden in Kohlebergwerken in Förderanlagen eingesetzt, hauptsächlich zum Heben von Erz, Personal, Ausrüstung und Material. Ihre Funktion besteht darin, den vertikalen Transport zwischen Übertage und Untertage zu ermöglichen, wodurch sie zu einem unverzichtbaren Bestandteil des Produktionssystems im Bergwerk werden.

Die Förderwinde dient hauptsächlich dem Transport von Material und Ausrüstung zwischen Untertagebau und Übertage sowie dem Heben und Senken von Personen. Durch das Auf- und Abwickeln des Drahtseils können Erz und Ausrüstung innerhalb der Mine gefördert oder abgesenkt werden, während gleichzeitig der vertikale Transport von Bergleuten ermöglicht wird. Sie ist ein zentrales Transportmittel, das den Untertagebau mit der Übertage verbindet und den reibungslosen Materialfluss für die Minenproduktion sicherstellt.

Auf einer Ramm- und Lochungsstelle bewegt die handbetriebene Hochgeschwindigkeits-Elektrowinde den Fallhammer über das Drahtseil auf und ab. Dadurch kann der Hammer angehoben und abgesenkt werden, um Boden- oder Gesteinsschichten aufzubrechen und Pfahllöcher zu formen. Die Winde ermöglicht außerdem die Einstellung der Hubhöhe und der Arbeitsfrequenz des Hammers und damit die Steuerung von Schlagkraft und -rate. Darüber hinaus kann sie beim Heben und Senken anderer Bauwerkzeuge und -materialien helfen und so die Bauarbeiten erleichtern.

DAFANG Services – Umfassende Unterstützung von der Entwicklung bis zum Kundendienst

Bei DAFANG bieten wir umfassende Serviceleistungen, um die zuverlässige Funktion jeder Winde und Hebelösung über ihren gesamten Lebenszyklus hinweg zu gewährleisten. Von der ersten Projektberatung über Installation und Schulung bis hin zur langfristigen Wartung bietet unser Team professionellen Support, der auf Ihre spezifischen Arbeitsbedingungen und Anwendungsanforderungen zugeschnitten ist.

- Kundenspezifische EntwicklungMaßgeschneiderte Windenkonstruktionen und Steuerungssysteme, die auf Ihre Projektanforderungen zugeschnitten sind.

- Technische BeratungProfessionelle Beratung zu Modellauswahl, Stromversorgungssystemen und Sicherheitskonfigurationen.

- Weltweite LieferungSchnelle Produktion, sichere Verpackung und zuverlässiger weltweiter Versand.

- Installation & Schulung: Installationsunterstützung vor Ort oder per Fernzugriff sowie Bedienerschulung.

- KundendienstSchnelle technische Unterstützung und zuverlässige Ersatzteilversorgung.

- Wartungslösungen: Beratung zur vorbeugenden Wartung und langfristige Servicepläne zur Sicherstellung einer stabilen Leistung.

Saudi-Arabien 4-Satz Marine Winch Projekt

Ein saudi-arabischer Kunde erwarb einen Satz Schiffswinden für den Einbau auf einem Schiff. Aufgrund der Anforderungen an Schutz und Langlebigkeit im feuchten Meeresumfeld war die Winde besonders geeignet. Nach erfolgreicher Werksprüfung und Erhalt der Prüfberichte zeigte sich der Kunde mit der Leistung der Winden äußerst zufrieden und gab die Lieferung frei. Die Auslieferung wird derzeit organisiert.

Windenkonfiguration:

- 3 × 2-Tonnen-Winden, Hubhöhe 150 Meter

- 1 × 5-Tonnen-Winde, Hubhöhe 80 Meter

- Anwendung: Installation auf einem Seeschiff

- Schutzart: IP65

- Motortyp: Marine-Motoren für verbesserte Korrosionsbeständigkeit

- Werksprüfung: Abgeschlossen und Prüfbericht an den Kunden übermittelt.

- Kundenfeedback: Vollkommen zufrieden mit den Testergebnissen

Unsere elektrischen Hochgeschwindigkeitswinden sind auf Effizienz, Zuverlässigkeit und Sicherheit ausgelegt und bieten eine stabile Hubleistung bei hohen Geschwindigkeiten für anspruchsvolle industrielle Anwendungen. Dank individueller Konfigurationen, robuster Steuerungssysteme und bewährter Fertigungskompetenz bietet DAFANG Lösungen, die den spezifischen Anforderungen jedes Projekts gerecht werden. Wenn Sie eine Hochleistungswinde suchen, die langfristige Stabilität und Produktivität gewährleistet, ist unsere elektrische Schnellwinde die ideale Wahl. Kontaktieren Sie uns jederzeit für individuelle Empfehlungen und professionelle Unterstützung Ihrer Hebevorgänge.