Introdução ao produto de montagem de blocos de rodas de guindaste de pórtico

Em guindastes de pórtico, o conjunto de blocos das rodas do guindaste de pórtico desempenha um papel vital: ao mesmo tempo em que corre o mais suavemente possível sobre os trilhos, eles suportam o peso do guindaste. Isso, por sua vez, permite que o guindaste de pórtico opere normalmente, levantando a carga e transportando-a de uma extremidade da viga para a outra. Durante todo o processo, o conjunto de blocos das rodas do guindaste de pórtico está sob grande pressão, por isso deve ser forte e durável. O material do conjunto de blocos das rodas do guindaste de pórtico é geralmente aço fundido ZG430-640. Para melhorar a resistência ao desgaste e a vida útil da superfície da roda, a banda de rodagem deve ser submetida a um tratamento térmico de superfície, exigindo uma dureza superficial de HB300-350 e uma profundidade de têmpera não inferior a 20 mm.

O conjunto de rodas de pórticos geralmente possui flange simples ou dupla. Rodas de esteira com flange simples são mais comuns e são usadas principalmente em pórticos com menos de 5 toneladas. Esse tipo de roda também é frequentemente usado em pórticos de viga dupla. Rodas de flange dupla são usadas principalmente em pórticos pesados, pórticos de viga dupla e mecanismos de operação de guindastes. Elas também são muito adequadas para a fundição de mecanismos de operação de guindastes, vagões elétricos e muitos outros mecanismos.

Quanto custa a montagem do bloco de rodas do guindaste de pórtico?

O preço do conjunto de blocos de rodas de guindaste de pórtico geralmente é determinado pela pressão da roda, pelo grau de correspondência da esteira da roda e da viga final, pelo grau de correspondência da roda e da esteira e pelo tamanho do conjunto da roda e da viga final.

| Modelo | Desenho nº. | Peça de roda forjada | Conjunto de rodas ociosas | Conjunto de rodas ativas |

|---|---|---|---|---|

| Φ500 | L764 | $420 | $690 | $985 |

| Φ500 | L765 | $420 | $690 | $985 |

| Φ600 | L766 | $1,070 | $1,070 | $1,110 |

| Φ600 | L767 | $1,070 | $1,070 | $1,110 |

| Φ700 | L768 | $1,590 | $1,590 | $1,675 |

| Φ700 | L769 | $1,590 | $1,590 | $1,675 |

| Φ800 | L770 | $440 | $740 | $1,030 |

| Φ800 | L771 | $440 | $740 | $1,030 |

A Dafang Crane fornece os preços de alguns conjuntos de rodas de pórtico para sua referência. Baixe o PDF abaixo para ver mais rodas de pórtico à venda.

Se você precisar de especificações mais detalhadas sobre o preço do conjunto de blocos de rodas de guindaste de pórtico ou outras categorias (roda de carro final, roda de carrinho de elevação, rodas de trilho de guindaste, conjunto de rodas de guindaste), entre em contato conosco. Temos engenheiros profissionais para fornecer um serviço de cotação individual.

Classificação de conjuntos de blocos de rodas de guindaste de pórtico

A Dafang Crane fornece o seguinte conjunto de blocos de rodas de guindaste de pórtico para uso:

Informações detalhadas podem ser baixadas em pdf para visualização:

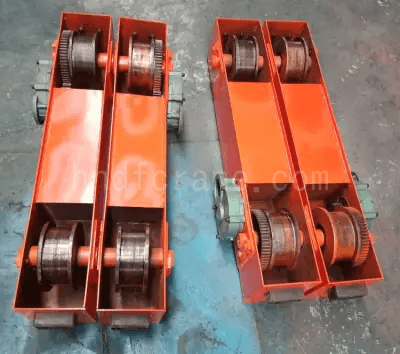

Conjunto de rodas de guindaste de pórtico de engrenagem

A posição de instalação do conjunto da roda do guindaste de engrenagem é aplicada ao guindaste de pórtico

Processo de fabricação:

Rodas fundidas para guindastes de pórtico. O material da roda é aço nº 45, a superfície é tratada termicamente e é usada em conjunto com acionamento de viga única. A qualidade é confiável e o preço é excelente. O conjunto de rodas de guindastes de pórtico com engrenagens geralmente utiliza tecnologia de fundição. O material da roda é aço nº 45, a superfície é temperada e tratada termicamente, e a dureza atinge HB300-350, o que garante a resistência e a resistência ao desgaste da roda.

Características:

O sistema de engrenagens integrado permite controlar com precisão o movimento do guindaste de pórtico, essencial em ambientes onde a precisão é crítica; a estrutura robusta garante um desempenho duradouro sob cargas pesadas; a caixa de engrenagens ajuda a otimizar a transmissão de potência, reduzir o consumo de energia e melhorar a eficiência geral. Como as engrenagens estão diretamente envolvidas na transmissão e engatam diretamente, a eficiência de transmissão das engrenagens e rodas é alta, e o torque é elevado.

Com seu processo de fabricação avançado, estrutura simples e baixo custo, o conjunto de rodas de pórtico com engrenagens é adequado para sistemas de pórtico com cargas e frequências de operação médias. No entanto, em comparação com rodas bipartidas a 45° e rodas de caixa de canto, há uma certa lacuna na capacidade de carga e estabilidade operacional do conjunto de rodas de pórtico com engrenagens. O conjunto de rodas de estilo europeu adota tecnologia de forjamento e material de ferro dúctil de alta resistência, possui estrutura compacta, alta precisão de instalação e operação estável, sendo adequado para sistemas de guindaste modernos e de alta frequência. Portanto, ao escolher conjuntos de rodas, os usuários devem considerar as características dos vários tipos de conjuntos de rodas de acordo com os requisitos específicos da aplicação, condições de carga e ambiente operacional, e escolher os produtos mais adequados.

Aplicativo:

Os componentes de rodas de guindastes de engrenagem são geralmente usados em guindastes de pórtico de viga dupla com mecanismo de movimentação de dois guinchos, como guindastes de pórtico de topo de barragem, guindastes de contêineres e guindastes portuários, onde servem como rodas de guindastes portuários confiáveis.

O conjunto de rodas de guindaste de engrenagem é usado para rodas de transporte final

O conjunto de rodas de guindaste de engrenagem é usado para mecanismo de caminhada de guindaste de pórtico

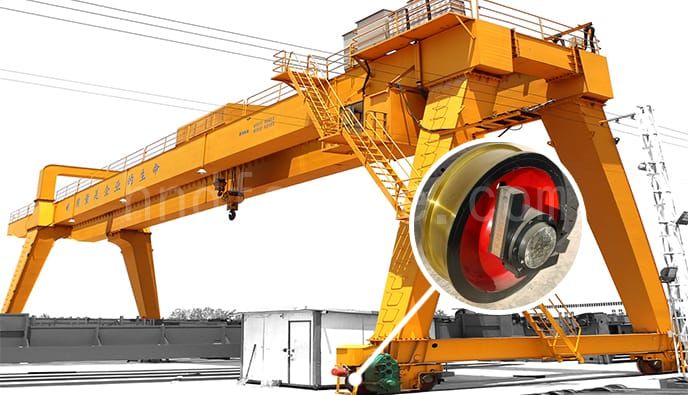

Roda de guindaste de pórtico europeu

Posição de instalação do conjunto de rodas do guindaste de pórtico europeu aplicado ao guindaste de pórtico

Processo de fabricação:

Rodas forjadas, feitas de ferro dúctil de alta resistência QT700. O processo de forjamento plastifica a peça metálica por meio de alta temperatura e alta pressão, de modo que a estrutura da roda seja densa, o grão seja refinado e os defeitos de fundição (como poros e escória) sejam eliminados, melhorando significativamente a resistência, a tenacidade e a vida útil da roda em fadiga. É muito adequado para guindastes de pórtico de estilo europeu com alta frequência, alta carga e operação de longo vão, como estruturas de viga única, viga dupla e meio pórtico.

Características:

O conjunto de rodas de estilo europeu consiste em quatro componentes principais: eixo, placa de roda, caixa de rolamento e rolamento. O design é compacto e eficiente, com alta precisão de montagem; seu design leve e compacto não só torna o conjunto de rodas mais fácil de instalar e transportar, mas também melhora a conveniência geral do usuário; o design é diretamente compatível com o redutor três em um, sem acoplamento, reduzindo as horas de trabalho de montagem e melhorando a eficiência do trabalho; devido à estrutura compacta e alta precisão de montagem, o conjunto de rodas tem muito pouco ruído durante a operação, criando um ambiente de trabalho mais silencioso e confortável; o uso de ferro dúctil de alta resistência aumenta a durabilidade e a capacidade de carga da roda, tornando o conjunto de rodas confiável para uso a longo prazo; o conjunto de rodas tem uma variedade de diâmetros disponíveis para escolher, ele pode atender às diferentes necessidades dos clientes e fornecer flexibilidade para diferentes aplicações.

Aplicativo:

Os conjuntos de rodas de pórtico europeu são comumente utilizados em pórticos de viga única, pórticos de viga dupla e semipórticos de estilo europeu. Essas rodas são normalmente instaladas no carro final para o deslocamento do guindaste principal e também podem ser integradas a sistemas como rodas de carrinho de elevação, rodas de trilho de guindaste e rodas de carrinho de pórtico, garantindo movimento suave e eficiente em diversas operações de elevação.

A roda do guindaste de pórtico europeu é usada como mecanismo de deslocamento principal dos guindastes de pórtico

A roda do guindaste de pórtico europeu é usada como mecanismo de deslocamento principal dos guindastes de pórtico

As rodas de guindastes de pórtico europeus são usadas no mecanismo principal de deslocamento dos guindastes de pórtico e também funcionam como rodas de trilhos de guindaste para uma operação suave e estável ao longo dos trilhos.

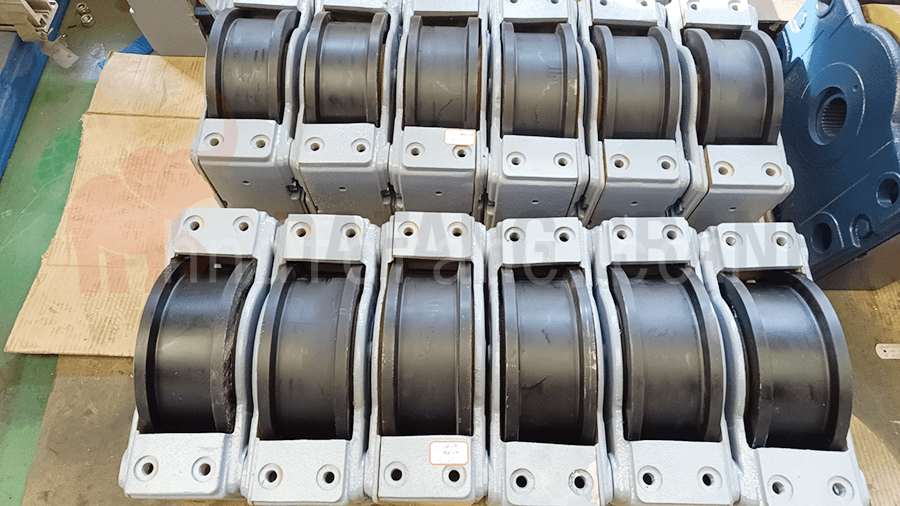

Conjunto de rodas de guindaste de pórtico em bloco L

A posição de instalação do conjunto de rodas do guindaste de pórtico em bloco L é aplicada ao guindaste de pórtico

Processo de fabricação:

Rodas fundidas, com diversas especificações e tipos de estrutura, Φ250, Φ350, Φ400, Φ500, Φ600, Φ700, Φ800 e outros diâmetros, estão disponíveis; três estruturas são fornecidas: flange dupla, flange simples e flange dupla para atender às necessidades de diferentes operações de esteira; a largura da ranhura da roda pode ser personalizada de acordo com o modelo da esteira, o que a torna altamente adaptável. Uma variedade de materiais de alta resistência está disponível; os materiais mais utilizados incluem:

- ZG430-640 (aço fundido): Boas propriedades mecânicas abrangentes, adequado para cargas pesadas;

- Aço nº 45: boa tenacidade, alta dureza e resistência após tratamento térmico;

- 50SiMn, 65Mn: forte elasticidade, alta resistência ao impacto, adequado para condições frequentes de partida e parada;

- 42CrMo: Aço de liga de alta resistência com excelente resistência ao desgaste e à fadiga.

Características:

Caixas de mancais angulares são componentes que conectam rodas e eixos, geralmente feitos de aço ou outros materiais de liga de alta resistência. Este componente suporta e suporta a carga rotativa das rodas durante a operação do guindaste. O design do mancal angular permite que as rodas suportem forças de diferentes direções para garantir a operação suave do guindaste. O design do conjunto de blocos de rodas de guindaste de pórtico com caixa de mancais angulares leva em consideração a capacidade de carga para garantir uma operação estável sob altas cargas.

Aplicativo:

O conjunto de rodas para guindastes de pórtico em bloco L é amplamente utilizado em diversos tipos de guindastes, como guindastes de pórtico e guindastes portuários. Essas rodas desempenham um papel vital para garantir o bom funcionamento do guindaste em diferentes ambientes de trabalho.

O conjunto de rodas do pórtico em bloco L é instalado no mecanismo de deslocamento do pórtico.

O conjunto de rodas de guindaste de pórtico em bloco L é instalado no mecanismo de deslocamento do guindaste de pórtico e também é adequado para uso como rodas de guindaste portuário.

O conjunto de rodas do guindaste de pórtico em bloco L é instalado no mecanismo de deslocamento do guindaste de pórtico e também pode ser usado como rodas de guindaste portuário para movimento confiável em operações de manuseio portuário.

Roda de guindaste de pórtico bipartida em 45°

A posição de instalação do conjunto de blocos de rodas de guindaste de pórtico bipartido de 45° é aplicada ao guindaste de pórtico

Processo de fabricação:

Para rodas fundidas, os materiais comumente utilizados incluem aço forjado 42CrMo, que possui alta resistência e boa tenacidade, sendo adequado para uso pesado e de alta frequência. A banda de rodagem do conjunto de blocos de rodas de guindastes de pórtico é geralmente temperada e tratada termicamente, e a dureza da superfície pode atingir 50-56 HRC, o que melhora a resistência ao desgaste e a vida útil.

Características:

A roda de guindaste de pórtico bipartida em 45° é uma roda de guindaste especialmente projetada, geralmente utilizada em sistemas de guindastes com altos requisitos de estabilidade e capacidade de carga. Essas rodas adotam uma estrutura bipartida em 45 graus, que pode dispersar cargas de diferentes direções com eficácia, sendo adequadas para equipamentos de guindaste com altas cargas e operação de longo prazo. É comumente utilizada em guinchos, carrinhos e carretas de guindastes de pórtico. O conjunto de blocos de rodas de guindaste de pórtico bipartida em 45° é fácil de instalar e desmontar, mas o processamento é complexo.

Aplicativo:

A roda de guindaste de pórtico bipartida a 45° é amplamente utilizada em guindastes de pórtico, guindastes portuários, guindastes metalúrgicos e outros tipos de guinchos e mecanismos de movimentação de carrinhos. Esses dispositivos geralmente exigem alta capacidade de carga e operação frequente, portanto, a durabilidade e a capacidade de carga das rodas são particularmente importantes. Esta roda é particularmente adequada para equipamentos de guindaste utilizados em ambientes severos (como portos e siderúrgicas).

Roda de guindaste de pórtico bipartida de 45° usada em guindaste de pórtico

A roda do guindaste de pórtico bipartida em 45° é usada no mecanismo de deslocamento principal do guindaste de pórtico.

A roda do guindaste de pórtico bipartida em 45° é usada no mecanismo de elevação do guindaste de pórtico.

Caixas de montagem de blocos de rodas de guindaste de pórtico Dafang

Com mais de 20 anos de experiência na fabricação de guindastes e uma gama completa de componentes para guindastes, a Dafang Crane é uma fornecedora confiável de conjuntos de rodas para guindastes de pórtico, com sucesso comprovado em exportações. Já fornecemos conjuntos de rodas de alto desempenho para clientes em países como Marrocos, Sri Lanka, Brasil e Holanda. Com equipamentos avançados – incluindo máquinas de corte a plasma, soldagem automática, furadeira CNC e jateamento de granalha – garantimos precisão, durabilidade e consistência em cada produto. Escolher a Dafang Crane significa escolher um parceiro confiável para soluções de elevação eficientes e personalizadas que atendem aos padrões internacionais. A seguir, nossos cases de exportação.

Conjunto de blocos de rodas de guindaste de pórtico para aplicações portuárias exportadas para Marrocos

Especificações

- Quantidade: 136 conjuntos

- Tamanho: Ø292 × 138 mm

- Material: aço fundido C45

- Dureza da superfície: HB300–320

- Revestimento: Óleo antiferrugem

Essas rodas foram fabricadas sob medida para corresponder exatamente a uma amostra fornecida pelo cliente para uso em docas subaquáticas. Com rigoroso controle de material e dimensões e tratamento anticorrosivo completo, as rodas receberam excelente feedback, resultando em um novo pedido. A Dafang Crane forneceu rodas semelhantes para guindastes portuários para países como Estônia, Suécia, Brasil e Singapura.

Conjunto de blocos de rodas de guindaste de pórtico entregue ao Bahrein

Especificações

- Rodas motrizes: 2 conjuntos (DRS 250 A65-A-75-BX)

- Rodas motrizes: 4 conjuntos (DRS 250 NA-A-75-BX)

- Material: ferro dúctil QT700-2

- Tempo de produção: 1 semana

Após um mês de avaliação, o cliente confirmou o pedido por meio do Departamento de Compras. Todas as rodas foram entregues em uma semana, demonstrando a rapidez de resposta e a capacidade de produção estável da Dafang Crane.

Conjunto de blocos de rodas de guindaste de pórtico entregues ao Sri Lanka para guindastes portuários

Especificações

- Rodas motrizes: 4 conjuntos

- Rodas intermediárias: 4 conjuntos

- Aplicação: Guindastes portuários

- Localização do cliente: Sri Lanka

Fornecemos um conjunto completo de rodas de acionamento e polias para guindastes de pórtico a um cliente antigo no Sri Lanka. Como cliente recorrente, eles confiam em nossa qualidade estável e preços competitivos. Essas rodas foram fornecidas como substitutos confiáveis para sistemas de guindastes portuários, reforçando nosso compromisso com soluções duráveis e econômicas, além de parcerias de longo prazo.