Petits crochets en C

- Composé du corps de levage et du contrepoids en fer.

- Corps de levage : Le corps principal du crochet en C est composé de plaques et de tubes d'acier, formant une structure transversale en caisson. Il offre une excellente résistance à la flexion et à la torsion, ce qui le rend léger et durable, avec une longue durée de vie.

- Contrepoids en fer : Sert à équilibrer le crochet, en s'assurant que le centre de gravité du crochet et de l'objet soulevé se trouvent sur la même ligne verticale.

- Applications : Principalement utilisé pour la manutention et la trempe des bobines d'acier, l'empilage et le stockage en entrepôt, ainsi que le transport et le chargement/déchargement. Couramment utilisé dans les aciéries. Des conceptions sur mesure peuvent être réalisées en fonction des exigences opérationnelles spécifiques.

Crochets doubles en C

- Composé du corps de levage et du gréement de liaison.

- Corps de levage : Fabriqué à partir de plaques et de tubes d'acier, avec une structure transversale en caisson, il offre une excellente résistance à la flexion et à la torsion, ce qui rend le crochet léger et durable, avec une longue durée de vie.

- Système de connexion : les crochets doubles sont fixés aux deux extrémités de la poutre. Les crochets sont suspendus à une poutre en acier rainuré et peuvent être ajustés en fonction de la largeur de l'objet.

- Applications : Utilisé pour la manipulation de bobines d'acier horizontales, avec positionnement réglable pour s'adapter à des bobines de différentes largeurs.

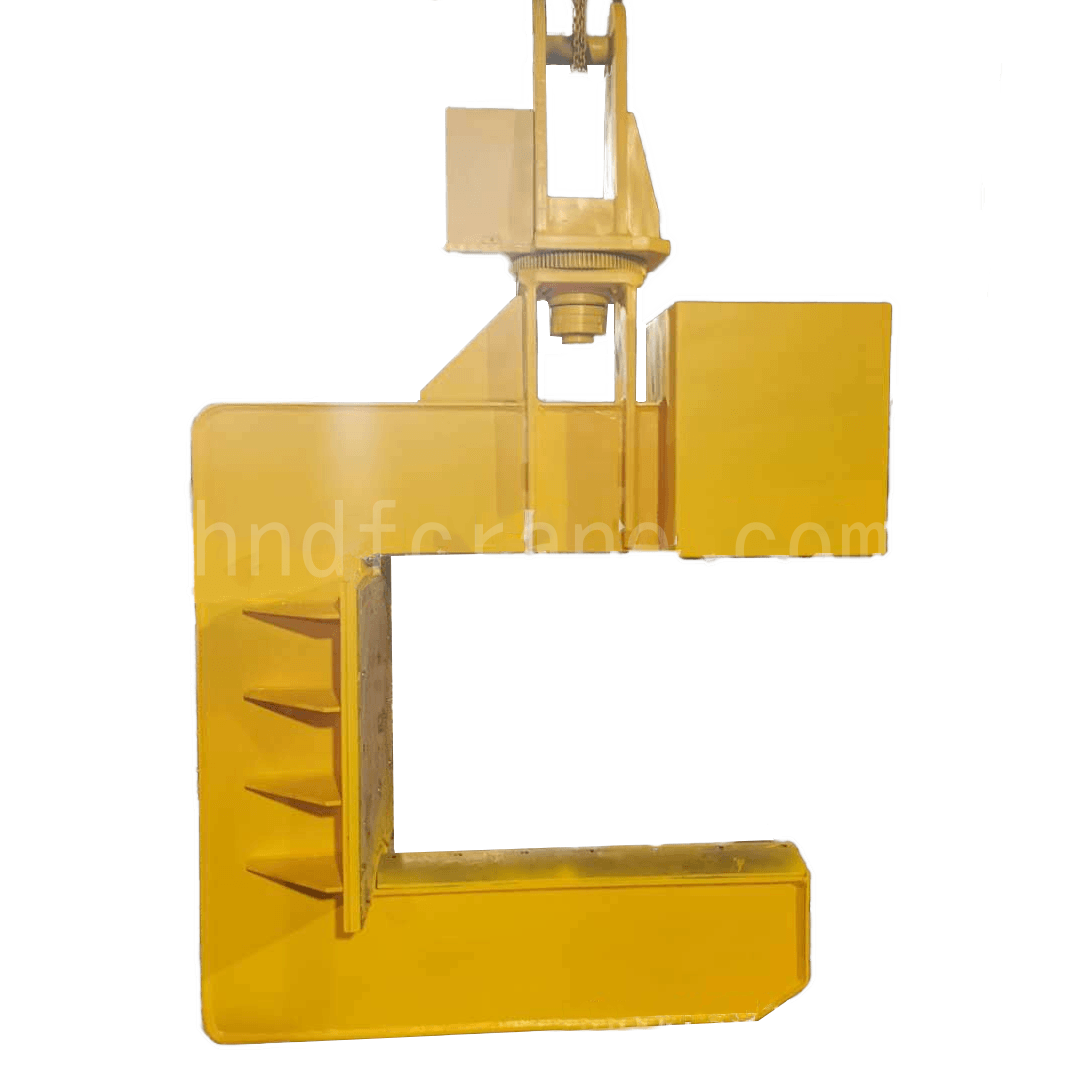

Crochets rotatifs en C

- Rotatif : sa fonction de rotation permet aux bobines d'acier d'être tournées à n'importe quel angle, ce qui rend le chargement, le déchargement et le repositionnement plus pratiques.

- Système d'entraînement électrique : Équipé d'un système d'entraînement électrique qui permet une rotation facile et sûre des bobines d'acier.

- Applications : Principalement utilisé pour le levage horizontal de bobines d'acier. Convient à la manutention et au trempage des bobines, à l'empilage et au stockage en entrepôt, ainsi qu'au transport et au chargement/déchargement. Des conceptions sur mesure sont disponibles pour répondre à des exigences opérationnelles spécifiques.

Crochets en C à bobine étroite

- Le corps principal est composé de plaques et de tubes d'acier, présentant une structure transversale en caisson. Il offre une excellente résistance à la flexion et à la torsion, ce qui rend le crochet léger et durable, avec une longue durée de vie.

- Principalement utilisé pour le levage horizontal de bobines d'acier de petit tonnage, avec une plage de capacité de charge de 1 à 3 tonnes (personnalisation disponible).

- Léger et maniable, facile à monter et à démonter, ce crochet est spécialement conçu pour les bobines de faible tonnage et de faible encombrement.

Crochets de fourche en C

- Principalement utilisé pour le levage horizontal de bobines d'acier doubles et de fils machine, composé du corps de levage et du contrepoids en fer.

- Corps de levage : Fabriqué à partir de plaques et de tubes d'acier, avec une structure transversale en caisson, il offre une excellente résistance à la flexion et à la torsion, ce qui rend le crochet léger et durable, avec une longue durée de vie.

- Contrepoids en fer : Sert à équilibrer le crochet, en s'assurant que le centre de gravité du crochet et l'objet soulevé sont alignés sur la même ligne verticale.

- Applications : Largement utilisé dans les ateliers de laminage à chaud et à froid des aciéries, et également adapté au levage de bobines horizontales dans les chantiers, les quais et les endroits similaires.

Crochets de grue en C pour bobines de fil machine

- Principalement utilisé pour le levage et la manutention horizontaux de bobines de fil machine et d'acier. Il est principalement composé d'un corps de levage et d'un contrepoids en fer.

- Corps de levage : Fabriqué à partir de plaques et de tubes d'acier, assemblés en une structure à section carrée, il offre une excellente résistance à la flexion et à la torsion, ce qui lui confère une conception légère et une longue durée de vie.

- Contrepoids en fer : Sert à équilibrer le dispositif de levage, en garantissant que le centre de gravité du crochet et de la charge soulevée s'alignent sur la même ligne verticale.

- Il peut être spécialement conçu en fonction des exigences d'application spécifiques.

Caractéristiques des crochets en C de grue

- Faible coût et entretien facile.

- La structure du contrepoids assure l'auto-équilibrage lors des opérations de levage.

- Nécessite un espacement spécifique entre les bobines d'acier ou une séquence de levage définie.

- Accrocher les zones courbes et les revêtements pour éviter les dommages, sous demande du client.

Entretien des crochets en C des grues

- Après utilisation, le crochet en C doit être placé sur un support désigné et stocké dans un local bien ventilé, sec et propre sous la surveillance d'un personnel autorisé.

- La surface du crochet en C doit être régulièrement protégée contre la rouille. Il ne doit pas être stocké dans des environnements contenant des acides, des alcalis, des sels, des gaz chimiques ou de l'humidité.

- Le crochet C ne doit pas être stocké dans des zones à haute température.

- Les pièces rotatives doivent être nettoyées régulièrement et de l'huile lubrifiante doit être appliquée périodiquement pour éviter les frottements à sec et les blocages.

Application des crochets de grue en C

Le crochet en C de grue est un dispositif de levage spécialisé couramment utilisé pour la manutention de matériaux en bobines, tels que les bobines d'acier, d'aluminium et de cuivre. Outre sa fonction première de manutention de bobines, le crochet en C de grue est également utilisé dans les applications suivantes :

- Manipulation de rouleaux de papier.

- Levage de tubes en acier et chargement efficace dans des conteneurs.

- Aider à l'installation de canalisations d'égouts et d'évacuation des eaux de crue