Gru a ponte con carrello di sollevamento elettrico vs gru a ponte con carrello di sollevamento con argano aperto: guida alla selezione per progetti di sollevamento industriale

Sommario

Nella selezione delle attrezzature di sollevamento industriali, il tipo di meccanismo di sollevamento in un carroponte bitrave influisce direttamente sulla configurazione strutturale della gru, sulla classe di servizio, sui costi operativi e sull'adattabilità alle condizioni dell'officina.

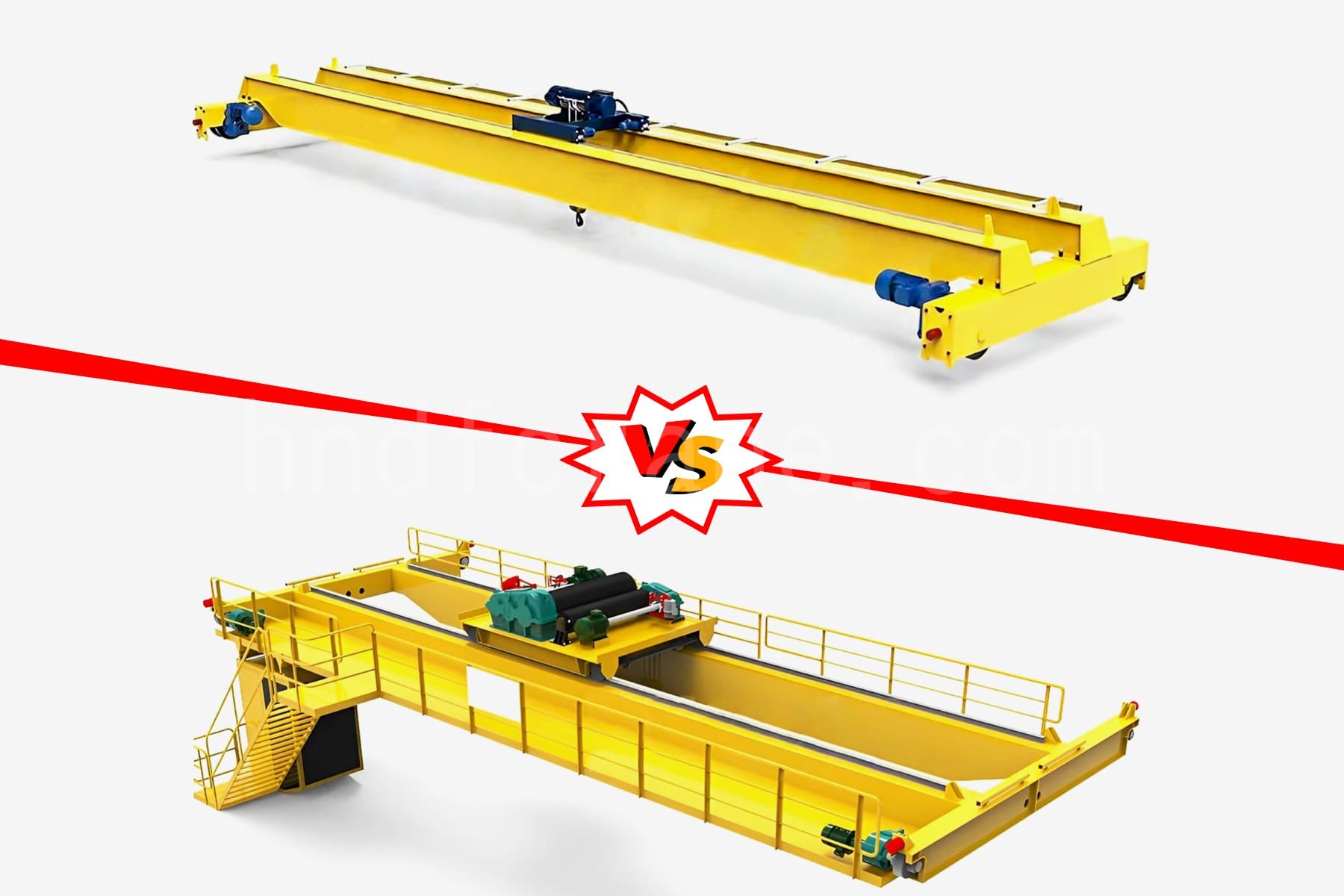

Nei progetti pratici, gru a ponte con carrello di sollevamento elettrico e carrello con argano aperto Le gru a ponte sono le due soluzioni più comuni.

Sebbene entrambe le opzioni possano avere la stessa capacità di sollevamento nominale, esistono differenze significative in termini di struttura, prestazioni e condizioni di lavoro applicabili. Questo articolo fornisce un confronto sistematico tra i due tipi di gru a ponte in base alle dimensioni chiave, aiutando gli utenti a prendere decisioni informate basate sulle condizioni di lavoro effettive.

Classe di servizio e condizioni di lavoro applicabili

La classe di servizio (Classe di Servizio) di una gru a ponte viene utilizzata per valutare in modo completo i carichi, la frequenza di sollevamento e il tempo di funzionamento che l'attrezzatura sopporterà durante la sua vita utile. Non è correlata solo alla capacità di sollevamento nominale, ma è anche strettamente influenzata da fattori quali il numero di sollevamenti giornalieri, il livello di carico medio (a pieno o parziale), il tempo di funzionamento continuo e la vita utile prevista.

Una classe di servizio più elevata indica che la gru è progettata per gestire operazioni più frequenti, più gravose e di lunga durata. Di conseguenza, i requisiti di resistenza strutturale, sistema di azionamento e ridondanza di sicurezza sono più elevati.

| Confronto | Gru a ponte con carrello di sollevamento elettrico | Gru a ponte con carrello ad argano aperto |

| Classe di servizio tipica | A3 | A3 – A8 (personalizzabile) |

| Significato di classe di servizio | Funzionamento intermittente con piccole variazioni di carico e bassa frequenza di sollevamento | In grado di funzionare ad alta frequenza, con carichi pesanti e in continuo |

| Frequenza di sollevamento | Da basso a medio | Da medio ad alto |

| Durata del funzionamento continuo | Principalmente operazioni di breve durata | In grado di funzionare ininterrottamente per lungo tempo |

| Rapporto di pieno carico | Carico completo occasionale, carico parziale per lo più | Alta percentuale di operazioni a pieno carico o quasi pieno |

| Intensità operativa | Da leggero a medio | Da medio a pesante |

| Caratteristiche strutturali e di progettazione della trasmissione | Progettazione integrata, focalizzata su economia e stabilità | Struttura ad alta resistenza adatta ad alte velocità e carichi di fatica |

| Capacità di sollevamento tipica | 5 – 20 tonnellate (alcuni modelli fino a 32 tonnellate) | 10 tonnellate – 200+ tonnellate |

| Applicazioni tipiche | Officine di lavorazione meccanica, linee di montaggio, cambi stampo, manutenzione attrezzature | Produzione di attrezzature pesanti, linee di produzione di strutture in acciaio, industrie energetiche e metallurgiche |

| Focus sulla selezione | Controllo dei costi, adattabilità dello spazio | Efficienza produttiva, durata e riserva di prestazioni |

Confronto dei meccanismi di sollevamento: carrello di sollevamento elettrico vs carrello di sollevamento aperto

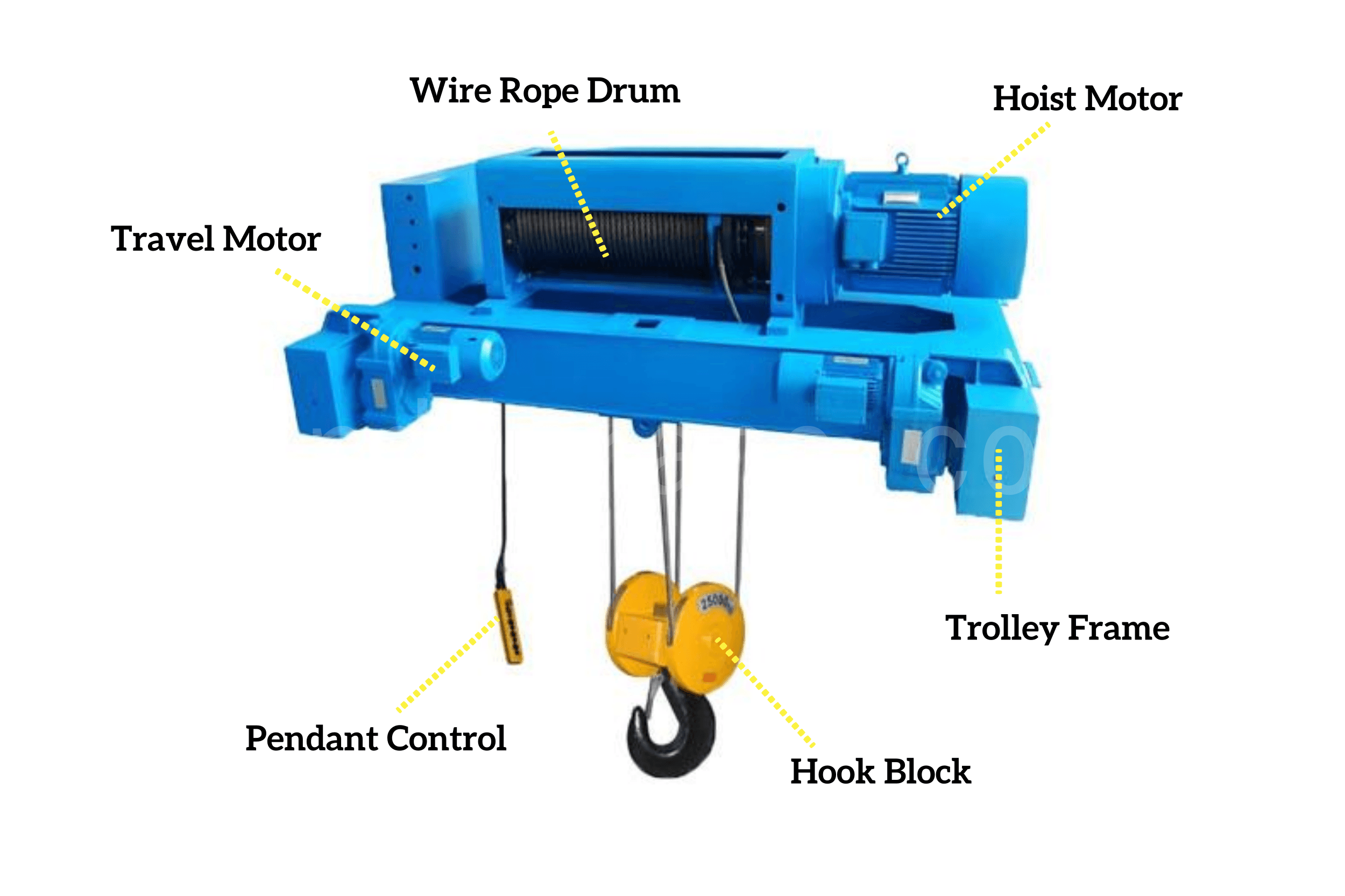

- Meccanismo di sollevamento integrato con altezza complessiva ridotta

- Design leggero e compatto, che aiuta a ridurre il peso totale della gru

- Elevato grado di standardizzazione, che consente una facile installazione e manutenzione

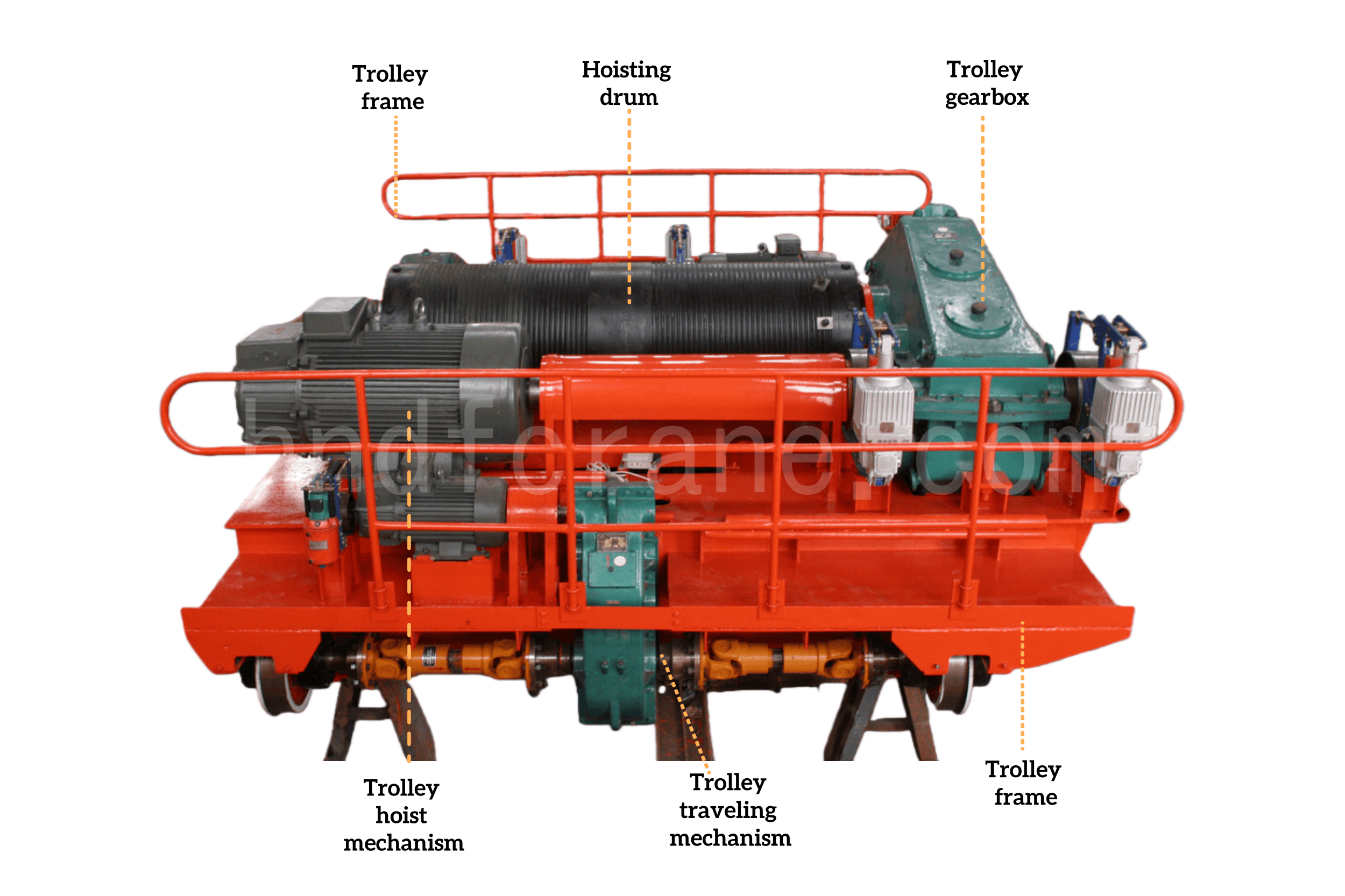

- Disposizione del meccanismo di sollevamento divisa, che garantisce una distribuzione uniforme del carico

- Struttura complessiva robusta e rigida con deformazione minima, che garantisce una maggiore sicurezza in caso di operazioni ad alta frequenza o con carichi pesanti

- Design facile da personalizzare in base alle specifiche condizioni di lavoro

Confronto prezzi: differenze di costo con le stesse specifiche

Prerequisiti: la capacità di sollevamento nominale, la campata, l'altezza di sollevamento e le configurazioni di base sono identiche.

Parametri operativi di base (stesse condizioni)

- Capacità di sollevamento: 16 t

- Campata: 10,5 m

- Altezza di sollevamento: 17 m

Confronto complessivo tra prezzo e prestazioni

| Articolo | Gru a ponte con carrello di sollevamento elettrico | Gru a ponte con carrello a fune metallica (argano) |

| Meccanismo di sollevamento | Carrello di sollevamento elettrico da 16 t | Carrello con verricello da 16 t |

| Prezzo di riferimento | 7.667 dollari USA | 23.000 dollari |

| classe di servizio | A3 | A3 |

| Velocità di sollevamento | 3,5 – 8 metri/min | 7,9 – 14,5 metri/min |

| Velocità di percorrenza del carrello | 20 metri/min | 44,6 metri al minuto |

| Velocità di spostamento della gru | 20 – 30 metri/min | 84,7 metri al minuto |

| Condizioni di lavoro applicabili | Movimentazione generale dei materiali a media e bassa frequenza | Funzionamento continuo, ad alta frequenza e con carichi pesanti |

Fattori chiave di impatto sui costi

- Il carrello di sollevamento elettrico stesso ha un costo unitario inferiore

- Le gru a ponte con carrello di sollevamento sono complessivamente più leggere, riducendo il consumo di acciaio per le travi principali e le strutture di supporto

- La struttura più semplice delle gru a ponte con carrello di sollevamento si traduce in minori costi di trasporto e installazione

- Le gru a ponte con carrello argano richiedono piattaforme e passerelle aggiuntive, aumentando i costi complessivi

Conclusione della selezione

La scelta di una gru a ponte non dovrebbe basarsi esclusivamente sulla capacità di sollevamento nominale. Dovrebbe invece considerare in modo completo la progettazione del meccanismo di sollevamento, la classe di servizio, l'intensità di esercizio, le condizioni dell'officina e il budget del progetto.

Quando la classe di servizio è A3 e l'intensità operativa e la frequenza di lavoro sono moderate, una gru a ponte con carrello di sollevamento elettrico è la scelta più economica e pratica.

Quando il progetto richiede una classe di servizio più elevata, velocità di sollevamento più elevate o una maggiore capacità di sollevamento, una gru a ponte con carrello a fune metallica (argano) può garantire prestazioni e adattabilità superiori.

Abbinando correttamente il tipo di meccanismo di sollevamento si ottiene l'equilibrio ottimale tra investimento in attrezzature ed efficienza operativa a lungo termine, garantendo al contempo sicurezza e affidabilità.

Invia la tua richiesta

- E-mail: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegramma: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Aggiungi: distretto industriale di Changnao, città di Xinxiang, provincia di Henan, Cina

WeChat

WeChat