Wprowadzenie produktów

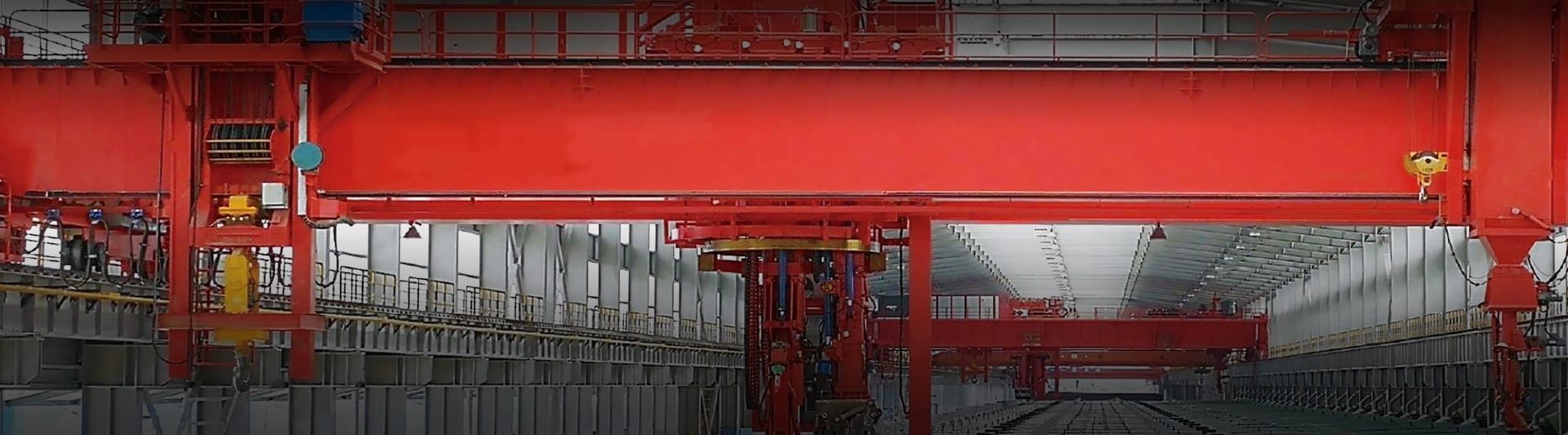

The Pot Tending Overhead Crane is a type of overhead crane and a heavy-duty lifting system specifically designed for prebaked anode aluminum electrolysis production lines. It is primarily used for critical process operations in the electrolysis shop, including anode replacement, busbar lifting, electrolytic cell maintenance, and material handling.

The crane is required to operate reliably under extremely harsh conditions, such as high ambient temperatures exceeding 80 °C around the electrolytic cells, strong magnetic fields with intensities up to 100 mT, and corrosive atmospheres containing HF-laden dust and gases. To ensure long-term stable performance, the Pot Tending Overhead Crane is engineered with anti-magnetic, heat-resistant, and corrosion-resistant features.

With a high level of functional integration, the aluminum electrolysis Pot Tending Overhead Crane is typically equipped with specialized attachments, including anode clamping devices, crust-breaking impact hammers, and spent anode grabs. These tools enable a wide range of operations such as precise anode positioning and installation, spent anode removal, and electrolyte crust breaking. Typical application scenarios include electrolytic cell overhaul, anode busbar transfer, and electrolytic cell start-up processes.

Advantages & Key Features of the Pot Tending Overhead Crane

The Pot Tending Overhead Crane is a core process handling system in prebaked anode aluminum electrolysis production, specifically engineered for high-temperature, strong magnetic field, heavy dust, and highly corrosive operating environments. Its main functions include:

- Crust Breaking – Crushing the electrolyte crust to facilitate spent anode replacement and feeding alumina and fluoride salts into the electrolytic cell.

- Material Charging – Feeding raw materials such as alumina and fluoride salts (particle size ≤ 10 mm) into the electrolytic cell through automatic or manual control.

- Anode Replacement – Removing spent anodes, including unscrewing, lifting, and lowering operations; lifting the spent anodes; installing new anodes with precise positioning and secure fastening.

- Slag Skimming / Spent Anode Pit Cleaning – Loosening and removing the lifting and fastening clamp bolts to clean residual anode fragments and solidified electrolyte from the anode pit.

- Molten Aluminum Handling – Vacuum operation of aluminum ladles, molten aluminum lifting, measurement (single ladle or accumulated weight), and data printing.

- Busbar Lifting – Lifting the anode busbar frame, equipped with dedicated safety alarm systems.

System Composition of the Pot Tending Overhead Crane

The Pot Tending Overhead Crane system mainly consists of the crane travel mechanism, bridge structure, tool trolley, aluminum handling trolley, hydraulic and pneumatic systems, electrical control system, and operating system.

- Crane Travel Mechanism

Drives the crane to move along the longitudinal rails of the electrolysis shop, enabling coverage of multiple electrolytic cells within the operating area. - Konstrukcja mostu

The main load-bearing structure of the crane, designed with high strength, anti-magnetic, and heat-resistant properties to withstand the harsh operating conditions of the electrolysis workshop. - Tool Trolley

As the core functional module, the tool trolley integrates the trolley travel mechanism, trolley frame, tool rotation system, crust-breaking mechanism, anode replacement mechanism, slag skimming system, material unloading system, and cab rotation system. It enables critical operations such as anode replacement, crust breaking, slag removal, and material unloading. - Aluminum Handling Trolley

Used for the extraction and transfer of molten aluminum, typically equipped with a dedicated vacuum lifting device to ensure the safe handling of high-temperature molten aluminum. - Hydraulic and Pneumatic Systems

Provide power for all actuators and functional mechanisms. - Electrical Control System

Incorporates PLC-based control, variable frequency drives (VFDs), and multiple safety protection systems. Advanced configurations support remote monitoring and automated operation, improving operational accuracy and safety. - Operating System

The crane supports both cab operation and remote-control operation. These two modes can operate independently or in coordinated control, meeting diverse production and operational requirements.

Application Areas of the Pot Tending Overhead Crane

The Pot Tending Overhead Crane is a heavy-duty lifting system specifically designed for the aluminum smelting industry. In modern smart factory environments, this equipment is increasingly integrated with electrolysis production control systems (such as pot control systems), overhead crane scheduling and management systems, as well as remote monitoring and automated operation platforms.

Typical application scenarios include:

- Primary Aluminum Producers

Used in prebaked anode aluminum electrolysis production lines, where it serves as a core process handling crane in the electrolysis shop. - Aluminum Carbon Plants (Selected Areas)

Applied in certain anode assembly workshops for auxiliary operations such as spent anode cleaning and new anode handling.

Application Cases