Overview of Common Safety Devices for Overhead Cranes and Gantry Cranes

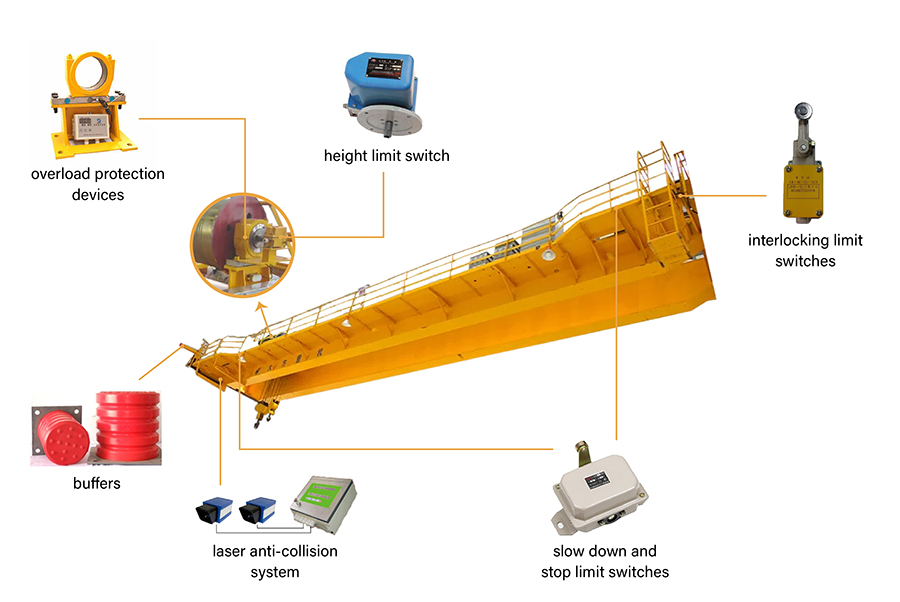

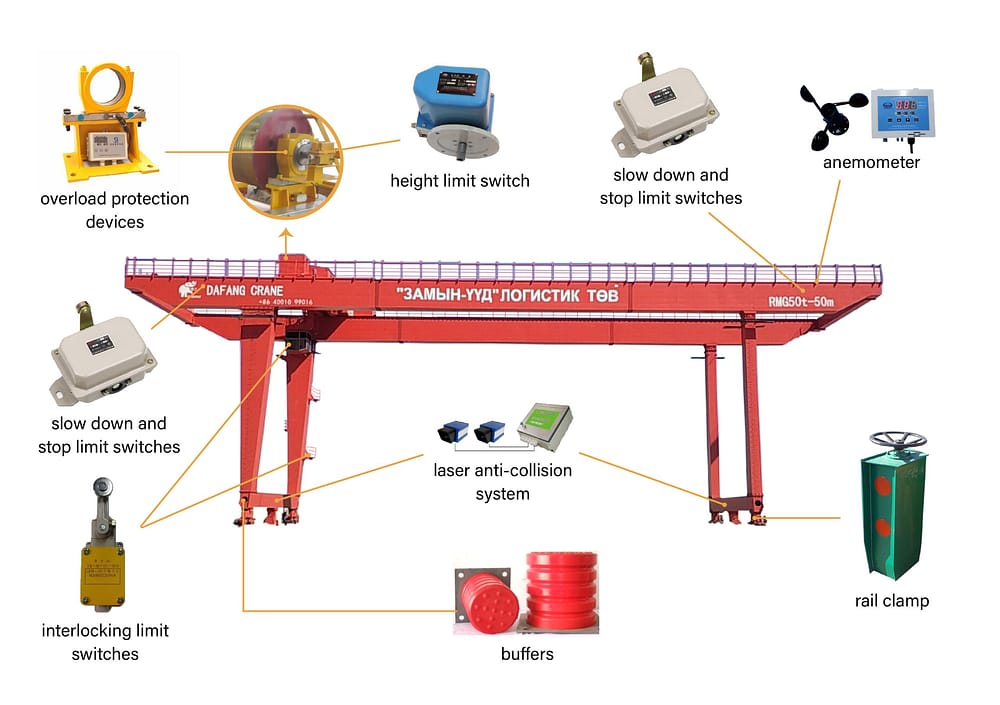

Crane safety devices play a vital role in the safe operation and running of cranes. There are many crane safety devices, we have selected several of the most commonly used safety devices for a comprehensive introduction, including crane overload protection devices, crane height limit switches, slow-down and stop limit switches, anti-collision devices for crane and wind protection for gantry cranes.

Overload Protection Devices

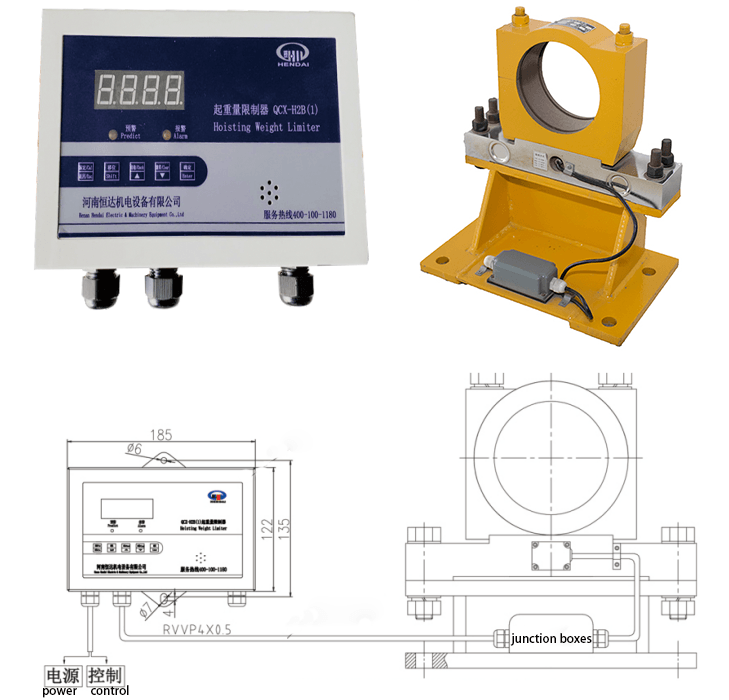

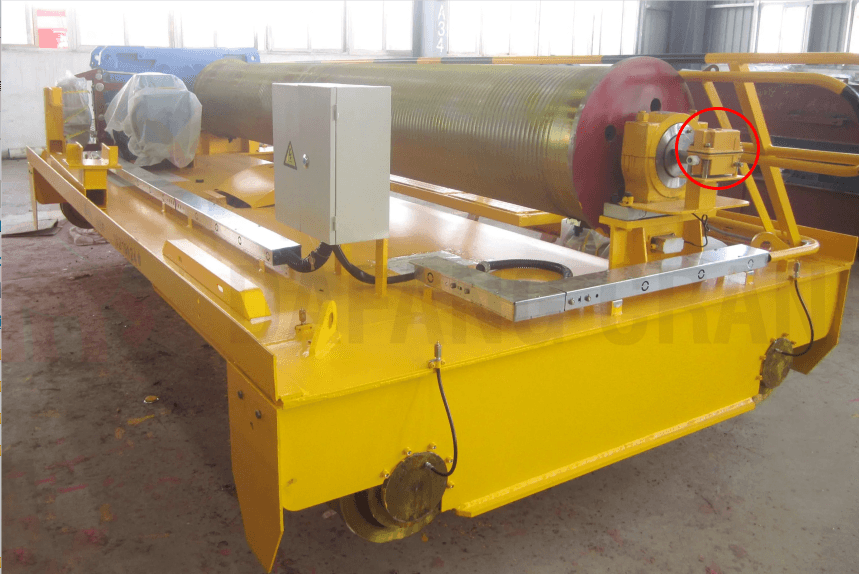

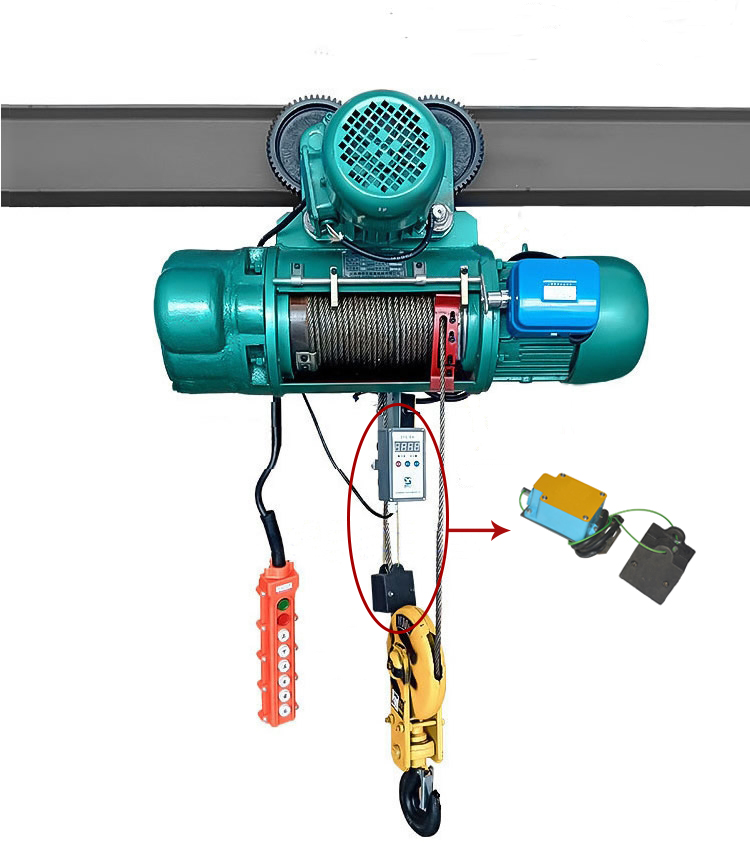

Overload limiter is a kind of safety protection device to prevent crane from overloading and crane parts from being damaged due to overloading during lifting operation, which is composed of crane load indicator and sensor. Overload limiter can be lifted to 95% ~ 100% of the rated lifting capacity, issued a prompt sound and light alarm signal, when the lifting capacity exceeds the rated lifting capacity, the overload limiter can automatically cut off the power supply of the lifting power, and issued a prohibitive alarm signal.

QCX-H2B(1) Overload Limiter

- Applicable to a variety of industry types of overhead cranes and gantry cranes.

- Single sensor signal input, single relay contact output.

- Simple and lightweight, easy to install, stable performance.

- Simple debugging, easy to use and on-site calibration.

- High measurement precision and accuracy, agile response, system self-test, strong anti-magnetic interference ability.

- Many additional functions can be added, convenient and other industrial control instruments or monitoring systems, such as docking, easy to follow up processing.

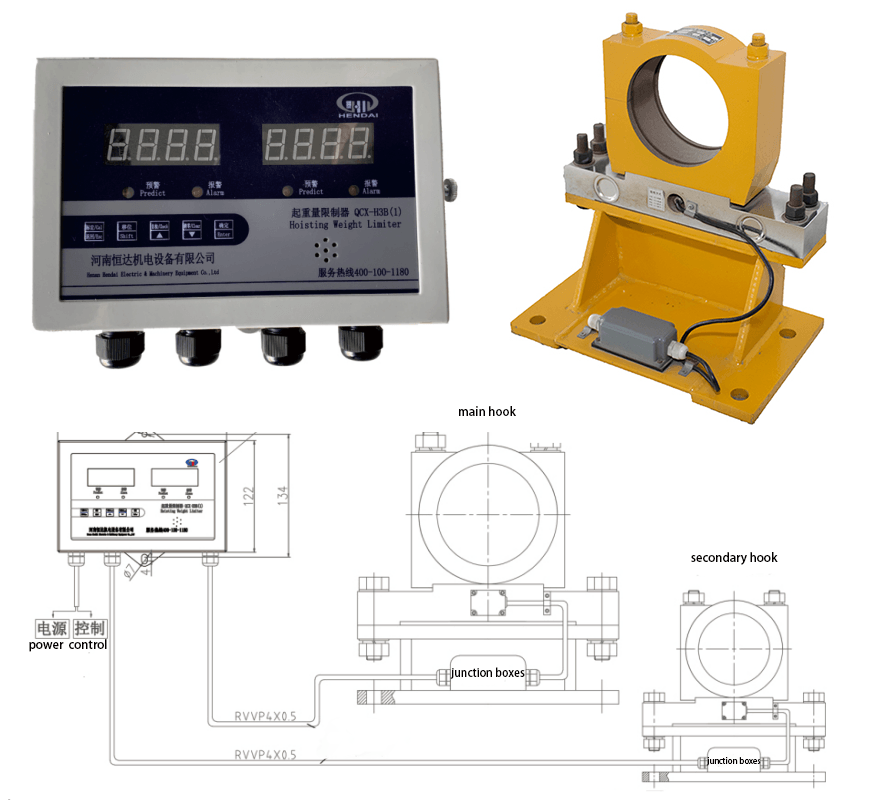

QCX-H3B(1) Overload Limiter

- Suitable for multi-type main and auxiliary hook cranes, gate hoist and other double hook combined cranes.

- Dual sensor signal input, the main and vice hook is displayed, two sets of relay contact output.

- Simple and lightweight, easy to install, strong stability.

- Simple debugging, easy to use and on-site calibration.

- It has high precision and accuracy, quick response, self check and strong anti-electromagnetic interference ability.

- Additional features can be more convenient and other industrial instrumentation or monitoring system docking, easy to follow-up treatment.

QCX-H2Z(1) Overload Limiter

- Applicable to all types of bridge gantry grab cranes.

- Two sensor signals combined input, total display, total control.

- Simple and lightweight, easy to install, stable performance.

- Simple debugging, easy to use and on-site calibration.

- Measurement precision, high accuracy, agile response, system self-test, strong resistance to electromagnetic interference ability.

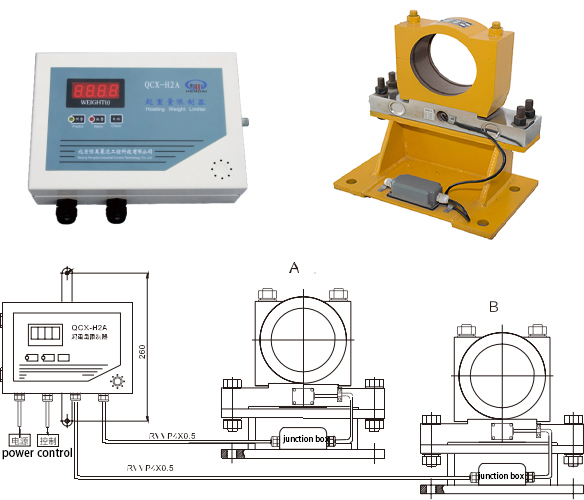

QCX-H2A Overload Limiter

- Applicable to many types of overhead cranes and gantry cranes with same tonnage double hook. Such as electromagnetic disk cranes, electromagnetic hanging beam crane, clamp crane.

- Double sensor signal input, total display, total control.

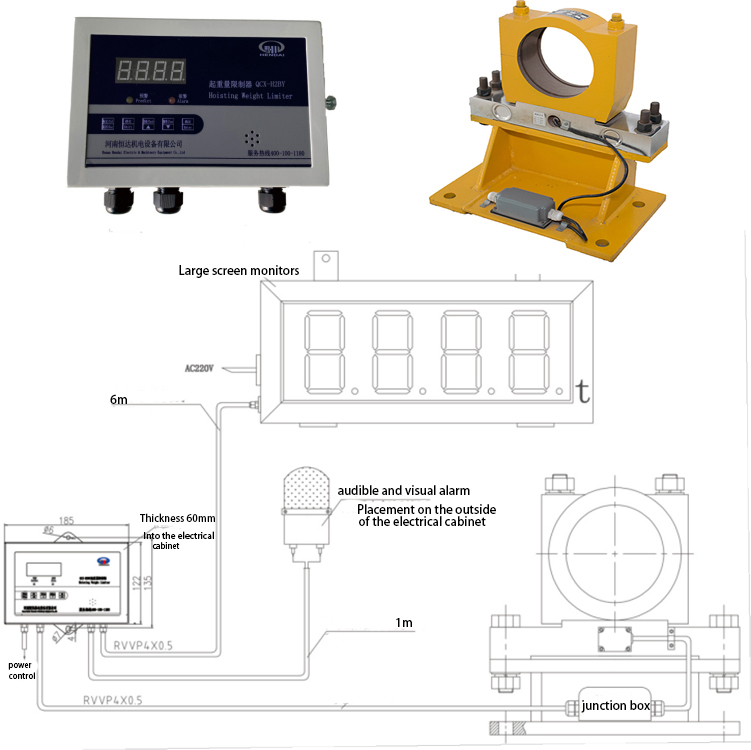

QCX-H2BY Overload Limiter

- Applicable to many types of remote-controlled overhead cranes and gantry cranes.

- Increased high-power external crane warning devices.

- Optional large screen display, easy to read data.

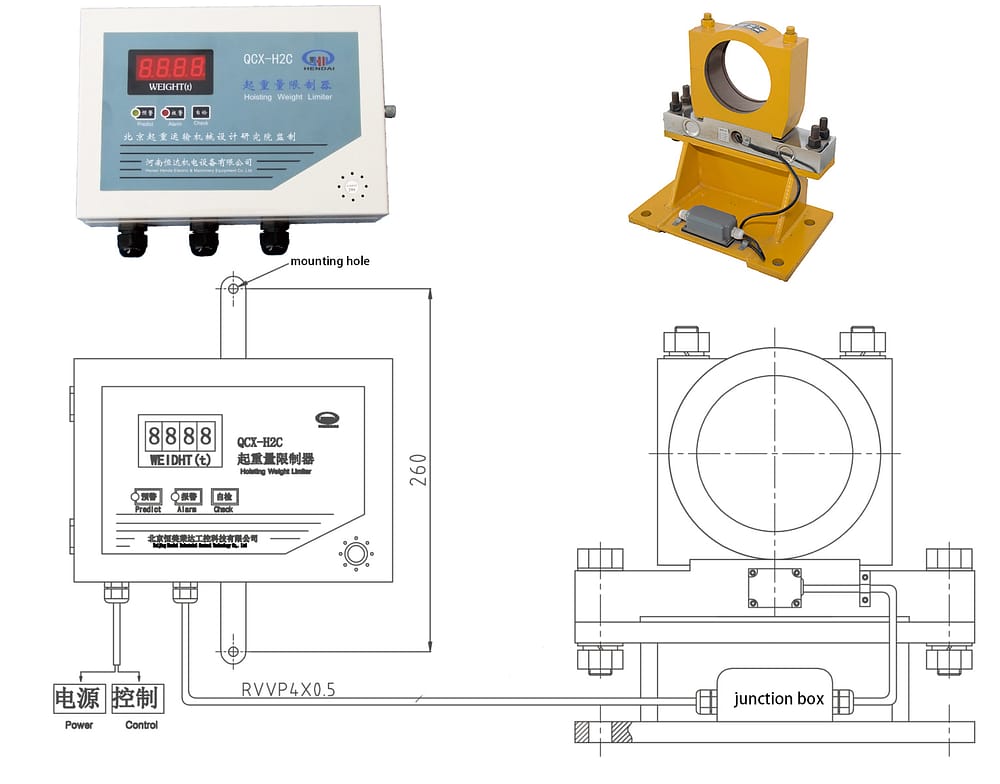

QCX-H2C Overload Limiter

- Mainly applicable to gantry crane on dam crest and the hoisting equipment which needs underload control output.

- With overload, underload control output function, underload point can be set arbitrarily.

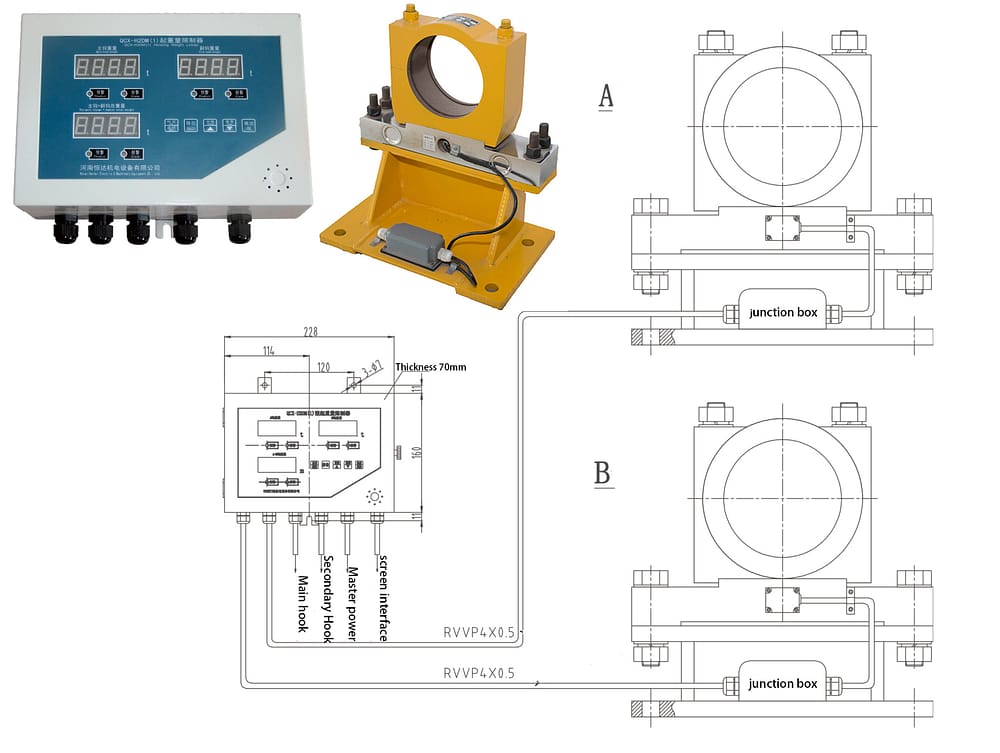

QCX-H2DM(1) Overload Limiter

- Suitable for bridge cranes and gantry cranes, composed of two parts: sensor and control instrument, with sub-display and subcontrol, total display and total control, and control of main and sub-hook crane lifting capacity.

- Adopting single-chip intelligent digital circuit, dual-channel high-bit AD chip acquisition inputs.

- The components used have been strictly screened, the machine performance is stable and reliable, easy to use, high precision.

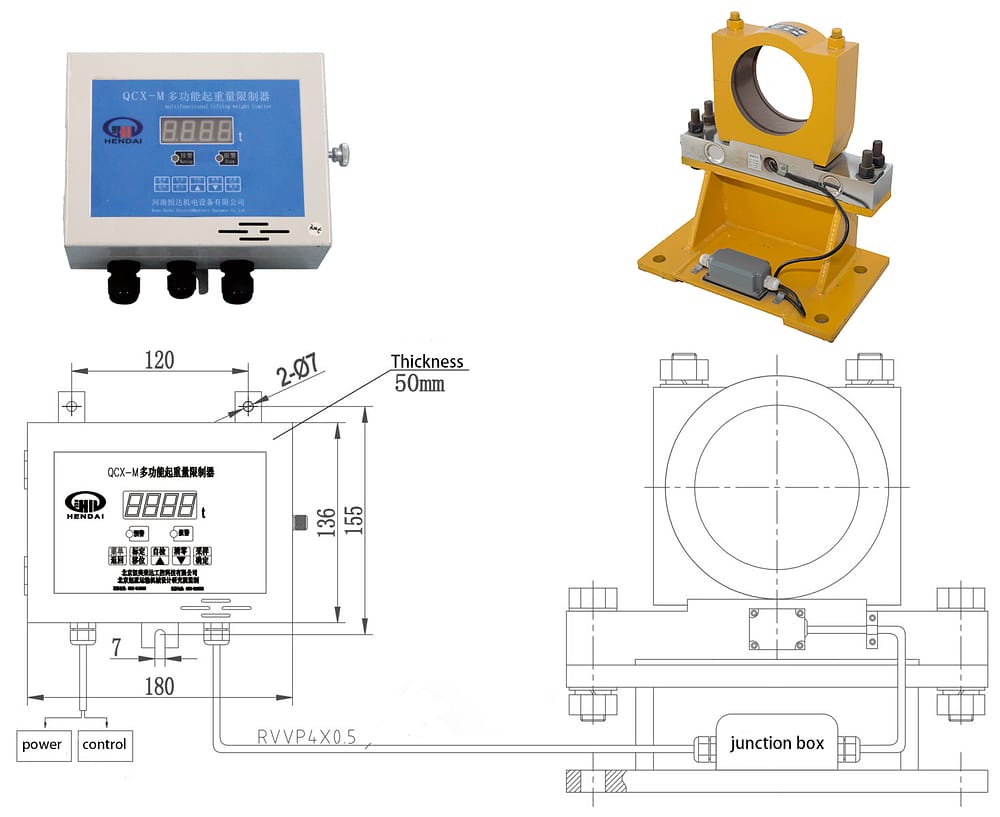

QCX-M Overload Limiter

- Applicable to overhead cranes and gantry cranes, based on ordinary lifting capacity limitation function, it increases the real-time recording function of the crane running condition.

- Real-time recording of crane loading process data information, overload times, load time, weight, end time, frequency of crane operation, etc., can be visualized in the computer software to see the detailed records of the crane’s work, the workload record charts and the work of the subcontracting frequency charts.

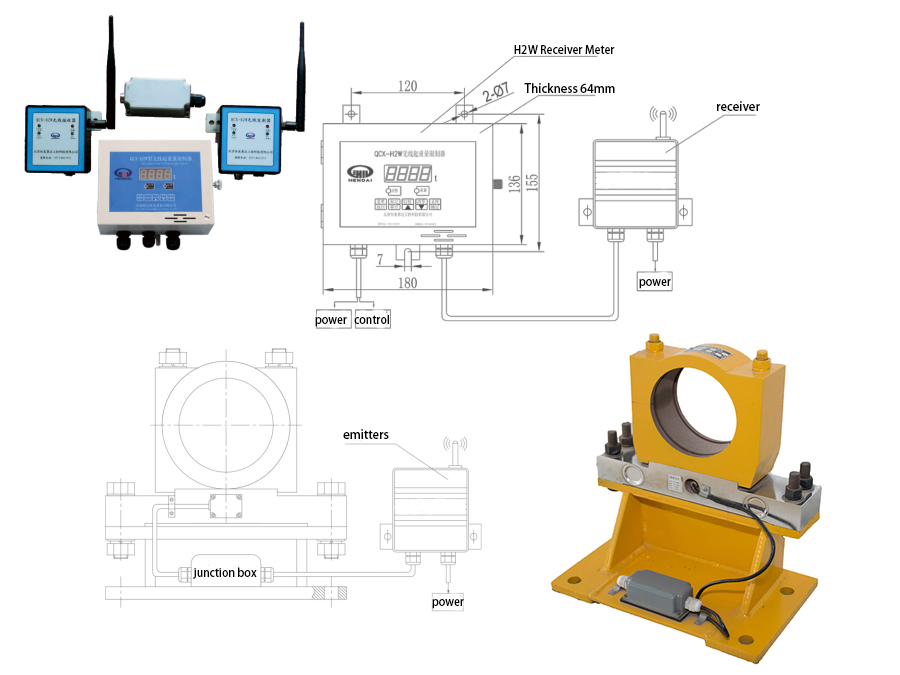

QCX-H2W Overload Limiter

- Wireless remote control, wireless transmission, suitable for occasions where it is not convenient to connect the cable line.

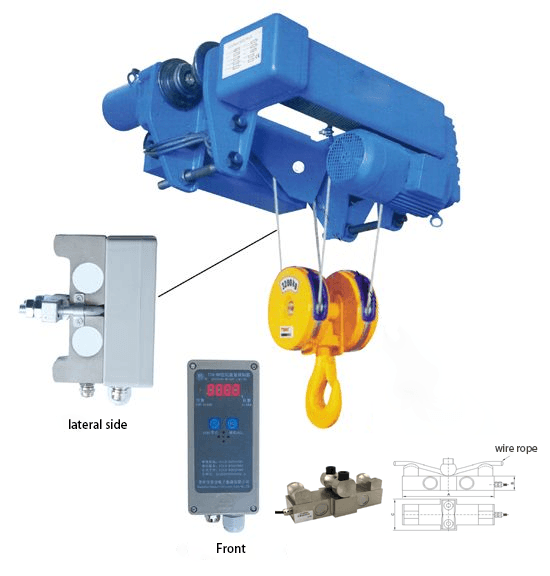

Pressure-side Overload Limiters

- Simple and compact structure, easy to install and maintain, wide range of applications, Applicable to a variety of types of CD, MD electric hoist.

- Installed near the fixed end of the wire rope, through the sensor to measure the tension of the wire rope to determine the lifting load.

Shaft Pin Overload Limiters

- Compact and takes up no external space, commonly used in European double girder cranes.

- Installed in the electric hoist pulley, through the deformation of the shaft pin sensor sensing the size of the force.

Height Limit Switch

The height limit switch can limit the rising and falling height of the spreader. When the spreader rises to the upper limit position, the limiter can automatically cut off the power source to stop the operation of the lifting mechanism, prevent the hook from continuing to rise, prevent the spreader from punching the top and pulling off the lifting steel wire rope, to avoid accidents of falling heavy objects. When the spreader descends to the lower limit position, it can automatically cut off the power source for descending, to ensure that the winding of wire rope on the reel is not less than the number of safe turns stipulated in the design.

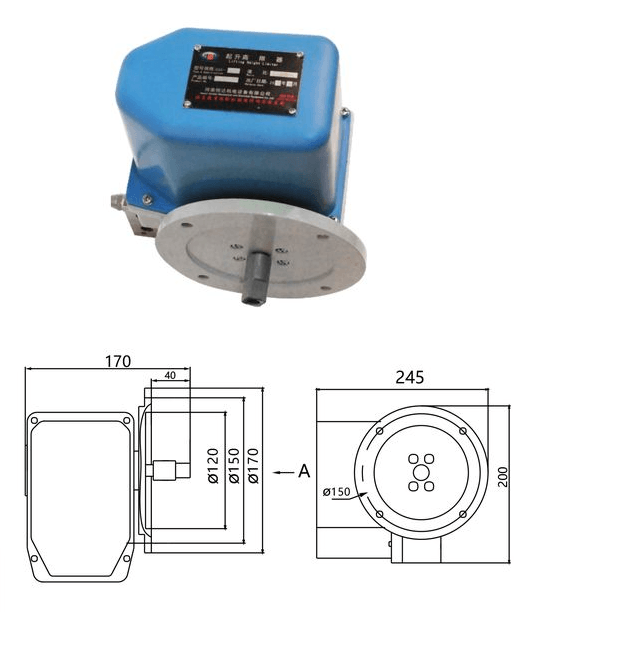

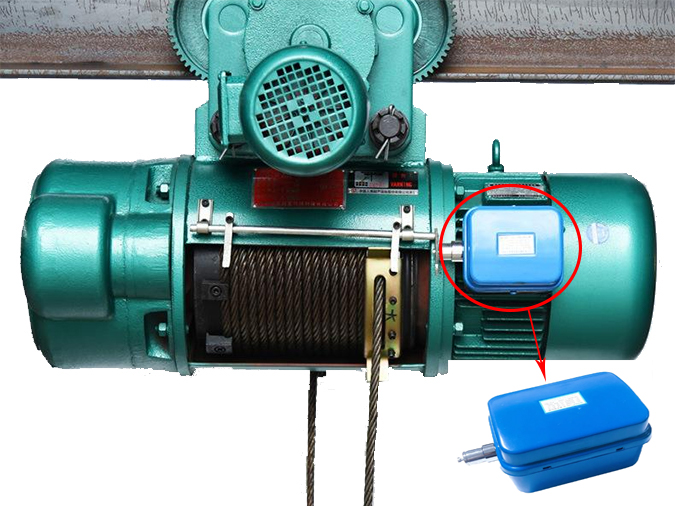

QGX Height Limit Switch

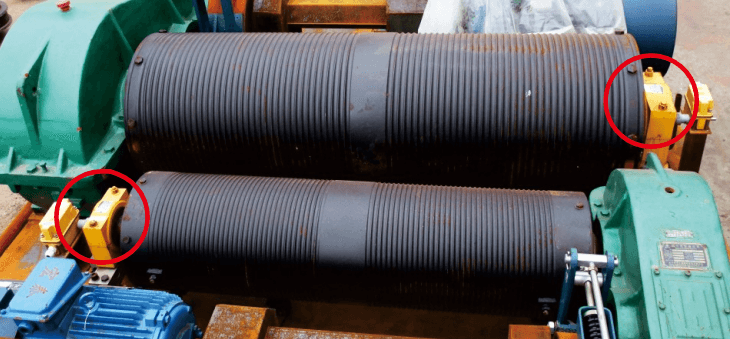

- Used for bridge gantry crane winch trolley, mounted on the end of the drum shaft.

- Light weight, small size, easy to install and debug, high sensitivity and reliability, long service life, can play a role in limiting the rise and fall.

- The worm gear is connected with the reel as a transmission mechanism, and a cam is installed on the center shaft of the worm gear. When the reel rotates, the cam rotates with it, and when it turns to the set position, the cam’s flange part contacts with the limit switch, which causes the limit switch to act, cuts off the upward or downward power source, and stops the spreader at the limit position.

- Transmission ratio: 40:1, 80:1, 120:1

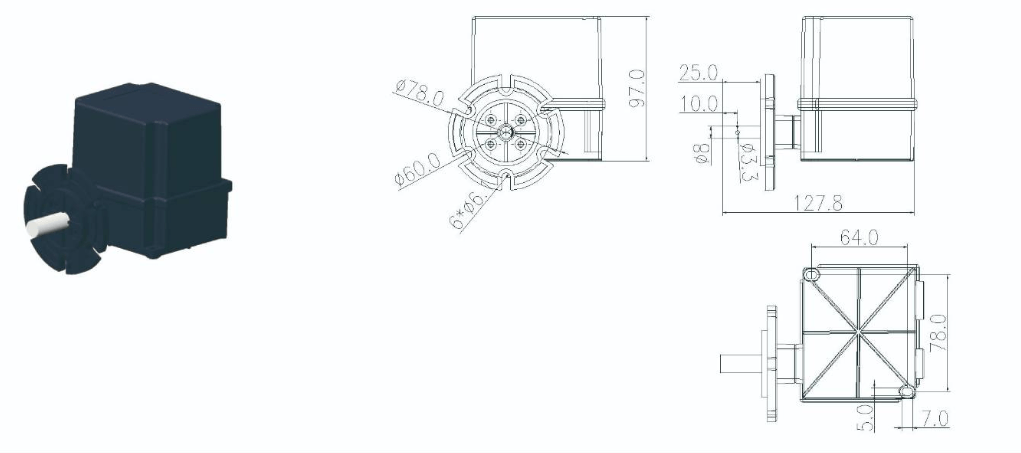

QGX-DE Height Limit Switch

- Applicable to all kinds of European crane trolley and European electric hoist, can play a role in limiting the rise and fall.

- Multi-point control

- Stylish and compact appearance, single-pole transmission, high reliability, high efficiency, small energy loss, small transmission gap

- Transmission ratio: 50:1, 100:1, 200:1

Brokenfirelimiter

- It is suitable for CD, MD, HC type wire rope electric hoist, which can play a role in limiting the rise and fall.

- When the lifting mechanism rises (falls) to the limit position, the wire rope on the drum drives the rope guide to move left (right) to touch the drive rod touch block, so that the drive rod moves left (right) to make the fire-breaking switch to cut off the power supply.

Hammer Height Limit Switch

- It can be used for electric hoist and crane winch trolley, and can only limit the height of rise.

- Under normal condition, the weight hammer is in free drooping state, the trigger lever extends outward, the limit switch closes, and the hoisting mechanism operates. When the hoisting mechanism continues to run upward beyond the specified range, the pulley block will lift the weight hammer, the suspension rope of the weight hammer will slacken, the trigger lever of the limiter will be retracted, the limit switch will be disconnected, and the power supply of the hoisting control will be cut off.

Slow Down and Stop Limit Switches

When the running mechanism is close to the limit position, the travel limiter can automatically cut off the forward power source and stop the movement to prevent the travel overrun. Rail crane (or trolley) running mechanism near the end of the track must be set up to run the mechanism travel limit switch, generally by the limit switch and trigger switch safety ruler supporting the use.

- Commonly used in overhead cranes and gantry cranes

- Using the safety ruler of the crane or trolley and its contact collision to realize the switching on or off control circuit.

- Applicable to European overhead cranes and European gantry cranes.

- Using the collision of the crane’s moving parts to make the contact action to realize the connection or disconnection of the control circuit, to achieve certain control purposes.

- Large contact capacity, compact structure, reliable and durable, high protection level, long service life.

Interlocking Protection Devices

The interlocking protection device links the state of the interlocking switch with the movement of a certain working mechanism of the crane, in the switch open state, the corresponding working mechanism which is constrained by it cannot be started, and only in the switch closed state, the movement of the working mechanism which is interlocked can be executed; when the mechanism is in the process of movement, if the corresponding hatch switch is opened, the shutdown instruction will be given. Interlocking limit switches prevent people from operating the crane without the driver’s knowledge at the moment of crossing in and out of the crane or when someone is doing equipment maintenance on the crane’s main girder, causing the mechanism to operate and injure people.

- Installed on the crane doors which people can pass.

- Installed on the door of the driver’s cab to control the movement of the crane operating mechanism.

- Installed on the hatch door or passageway railing door of the bridge main girder boarded by the driver’s office, controlling the movement of the trolley running mechanism.

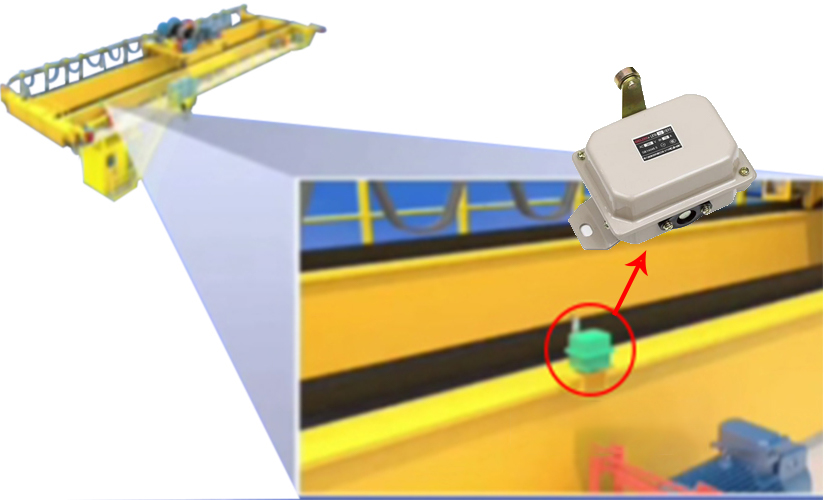

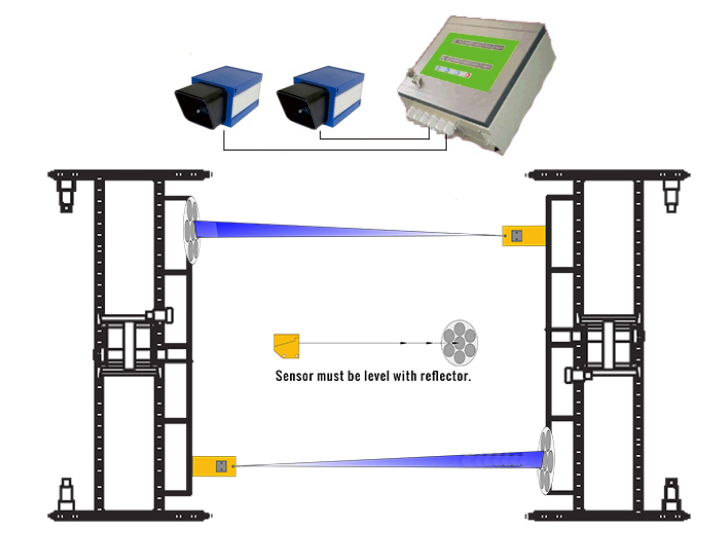

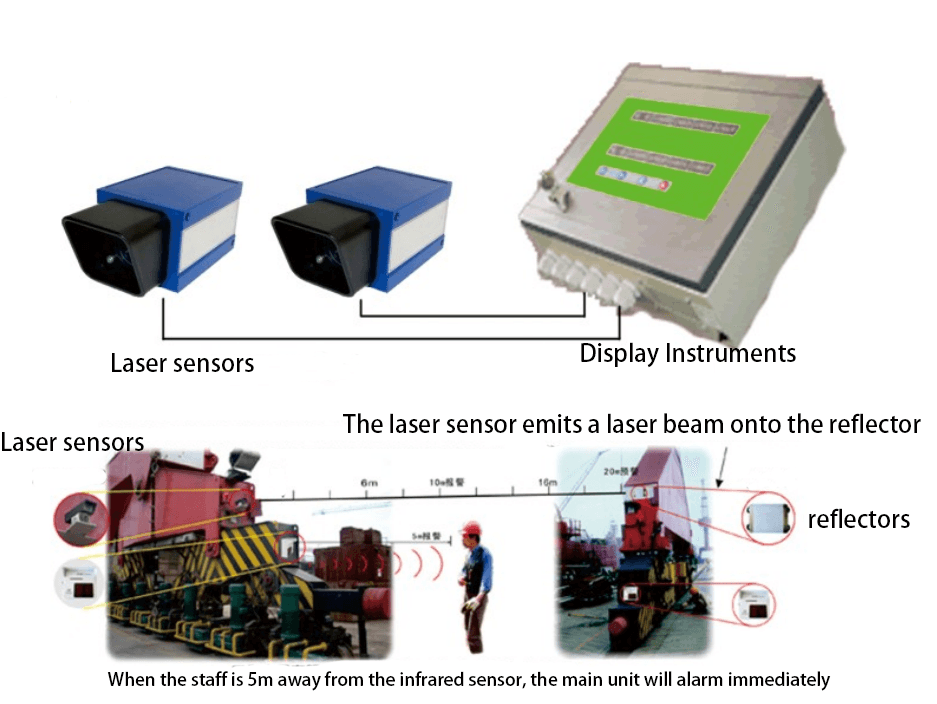

Anti Collision Device for Overhead Cranes and Gantry Cranes

Crane laser anti-collision system can use laser sensors to calculate the distance of the approaching object, when it reaches the non-safety distance early warning deceleration, alarm stop, to prevent the crane collision. When two or more sets of lifting machinery or lifting trolley run on the same track, anti-collision devices should be installed.

- Suitable for overhead cranes and gantry cranes.

- Measuring range from 0.2m to 200m.

- Accuracy up to 1.5mm, regardless of the distance can maintain the accuracy of 1.5mm.

- Can be set to continuous mode, when all the configuration information is stored in the device, without any control unit, turn on the power, the device can carry out uninterrupted measurement, and is suitable for any application environment.

Buffer

It is a safety device configured at the end of the metal structure of the bridge crane, with the function of absorbing the kinetic energy of the collision of the running mechanism and slowing down the impact. Commonly, there are polyurethane buffers, rubber buffers, spring buffers and hydraulic buffers.

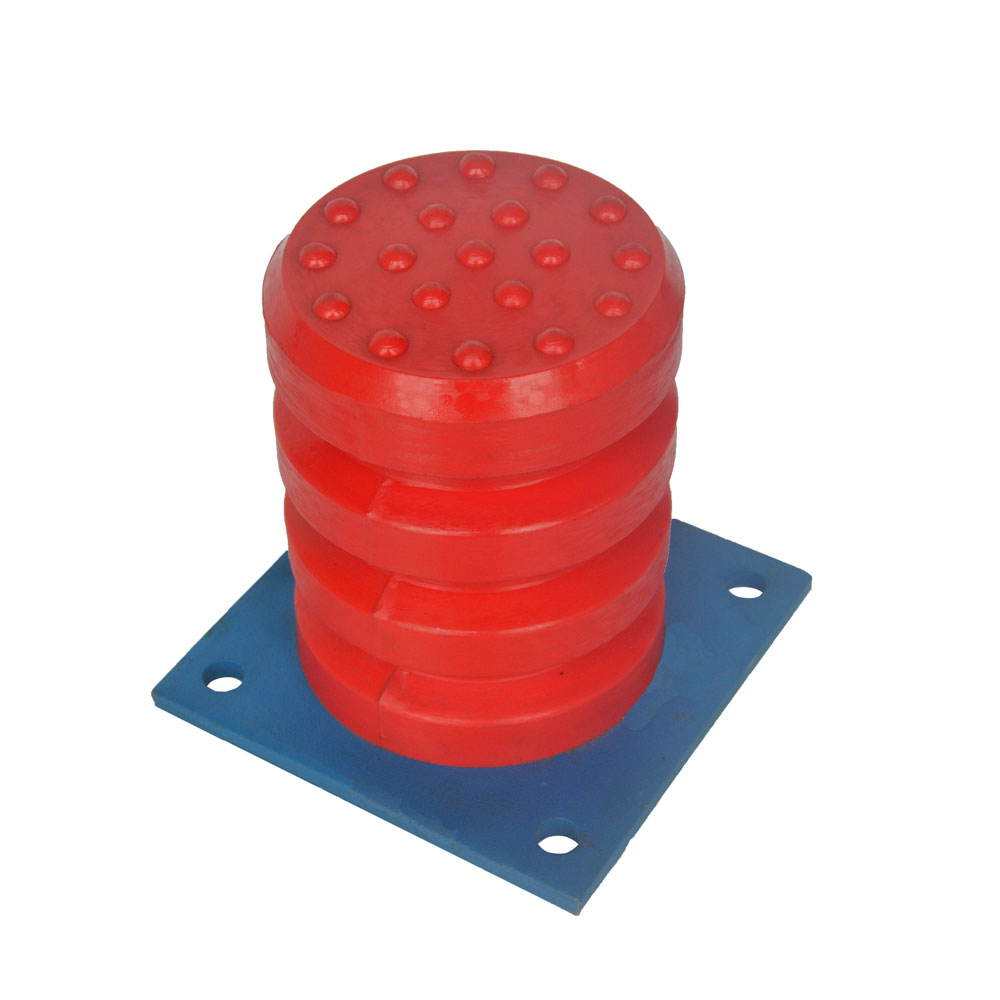

Polyurethane Buffer

- Large energy absorption, good buffer performance.

- Oil-resistant, aging-resistant, acid-resistant, corrosion-resistant, high and low temperature-resistant.

- Insulation and explosion-proof, lightweight, simple structure, low price, no noise, no sparks, easy installation and maintenance, long service life.

- It has been widely used in the international market, and can replace rubber and spring buffers in general cranes.

Rubber Buffer

- Cushioning is achieved by utilizing the elastic deformation of rubber during a collision. Since it absorbs less energy, it is generally used for cranes with low movement speeds.

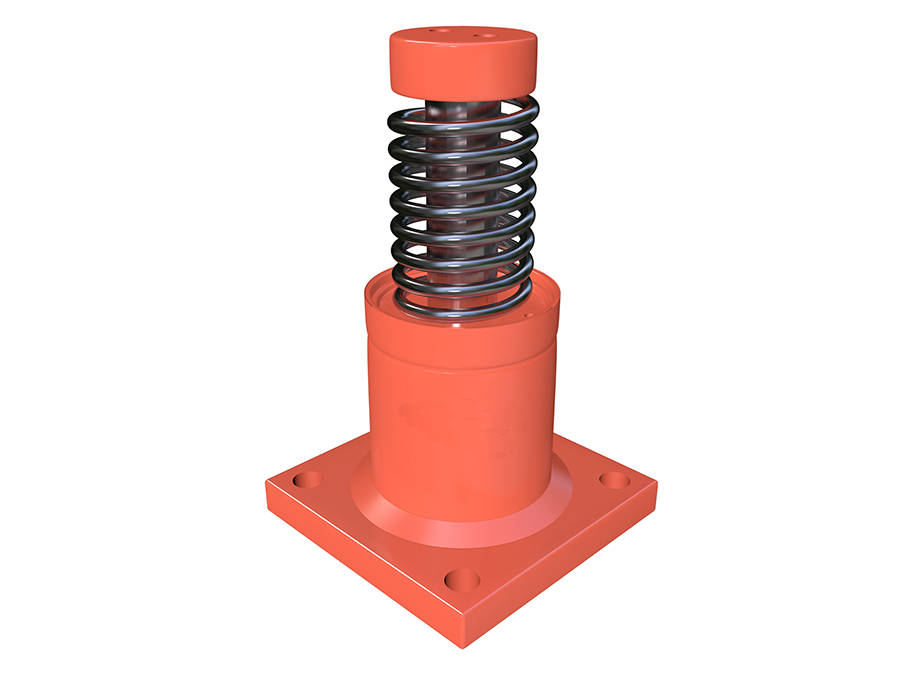

Spring Buffer

- The spring buffer can quickly convert most of the kinetic energy of the impact into the compression potential energy of the spring, which is suitable for cranes with medium movement speed.

- Simple structure and maintenance, no special requirements for the working temperature, large absorption capacity.

Hydraulic Buffers

- Through the cylinder piston squeezing oil work to consume the kinetic energy of the impact, suitable for greater speed of movement of the crane

- Advantage is that it can absorb more impact kinetic energy, no rebound effect

- The disadvantage is the complexity of the structure, by the ambient temperature on the performance of the oil has a greater impact on the function of the buffer will also be affected.

Wind Protection Devices

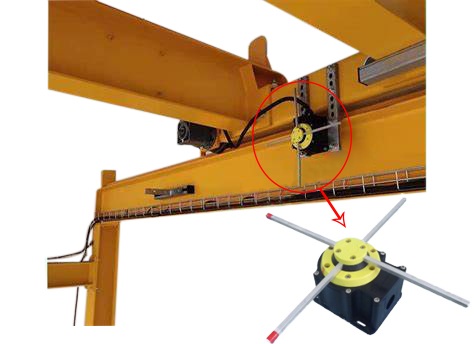

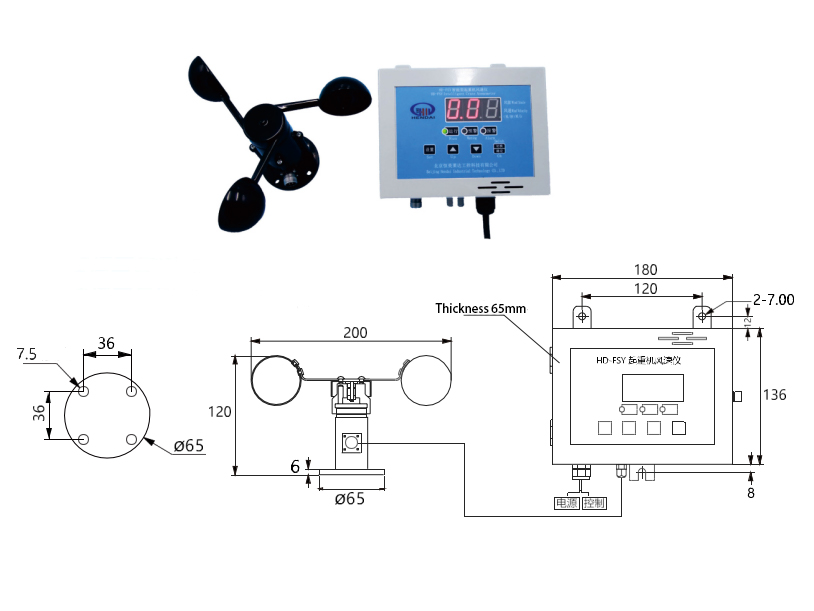

Anemometer

- Mainly applicable to gantry cranes and other cranes operating outdoors.

- It consists of two parts: intelligent measuring and controlling instrument and wind speed detecting sensor, which can accurately indicate and warn the wind speed and intensity on the site.

- When the wind speed exceeds the pre-warning wind speed, the instrument issues sound and light alarms, prompting the operator to pay attention. When the wind speed exceeds the preset upper limit, it can automatically sound and light alarm, and issue control instructions to stop the crane lifting function.

Rail Clamp

Rail clamps include manual rail clamps, semi-automatic rail clamps, automatic rail clamps, and self-locking rail clamps.

- Manual rail clamps: Simple in structure, easy to maintain, but due to low clamping force, they have poor safety and are only suitable for small and medium-sized cranes.

- Semi-automatic rail clamps: Semi-automatic rail clamps are dual-use clamps with both electric and manual functions. They primarily operate electrically, with the clamping force generated by the electric motor through the screw and nut, compressing the spring. The clamping force is significant, and it is equipped with an end switch that automatically stops the electric motor after clamping the track. In the event of electrical failure or power outage, manual clamping is required. Compared to electric hammer-type rail clamps, this type of rail clamp is lighter but has the drawback of difficulty in aligning the jaws during installation.

- Electric hammer-type rail clamps: These clamps operate automatically, providing strong anti-slip force and reliable safety. In case of strong wind or temporary crane inactivity, the power is cut off to secure the crane. The drawback is its larger weight, with the wedge-shaped hammer weight reaching 2%-3% of the total weight of the crane. Wear can occur at the contact point between the hammer and rollers.

- Electric spring-type rail clamps: Electric spring-type rail clamps use springs to compress the elbow lever for closure. To release the clamp, a winch is used to further compress the spring through a pulley system. Compared to electric hammer-type rail clamps, they are lighter.

- Electric hydraulic rail clamps: These clamps use a spring to clamp and a hydraulic cylinder to release. They provide a large clamping force, ensuring safety and reliability. However, they have a larger size, and the processing requirements for hydraulic system components are higher. They are commonly used in large port cranes.

- Self-locking rail clamps: These are manually operated rail clamps that utilize the self-locking principle. The clamping force is generated by wind force and increases with the intensity of the wind.

Windbreak

- Suitable for gantry cranes working in the open air such as ports, wharves and railroads. When in use, the wedge-shaped tongue is inserted between the tread of the wheel and the top surface of the track, and the slope of the iron wedge prevents the wheel from sliding.

- When energized, the electric-hydraulic pusher moves, and its push rod rises quickly, and lifts the iron wedge through the lever and transmission mechanism, so that the crane works normally; when the power is cut off, the push rod of the pusher is under the action of the spring force, and the iron wedge is placed on the rail through the lever, and the wheel is wedged to death in the case of sudden windstorms, and it serves as a safety protection function.

Anchoring Device

- Crane anchoring devices are mainly pin-type, chain-type, top bar-type, anchor plate type.

- Cranes used in the open air, when the wind speed exceeds 60m/s, anchoring device must be used. Anchoring device construction is simple, safe and reliable, more with automatic rail clamps and other complementary use, as complementary equipment for automatic wind protection devices.

- Anchoring device can only be set along the crane track a number of fixed anchor points, when the wind came to the crane runs to the nearby anchor seat (pit) and is locked, so it is inconvenient to use, especially in the sudden windstorm is difficult to do promptly to stop.

From limit switches and overload protection to collision avoidance and wind protection, these safety measures are the pillars of safeguarding in high-risk environments. By understanding and installing these devices, the industry can improve safety, reduce potential risks and maintain the efficiency of crane operations.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China