Electric Wire Rope Hoist: Installation And Maintenance

Electric wire rope hoists are indispensable tools in various industries, providing efficient and reliable lifting solutions. This article aims to guide you through the process of installing and maintaining an electric wire rope hoist, ensuring its optimal performance and longevity.

Chapter 1: Introduction of Electric Wire Rope Hoist

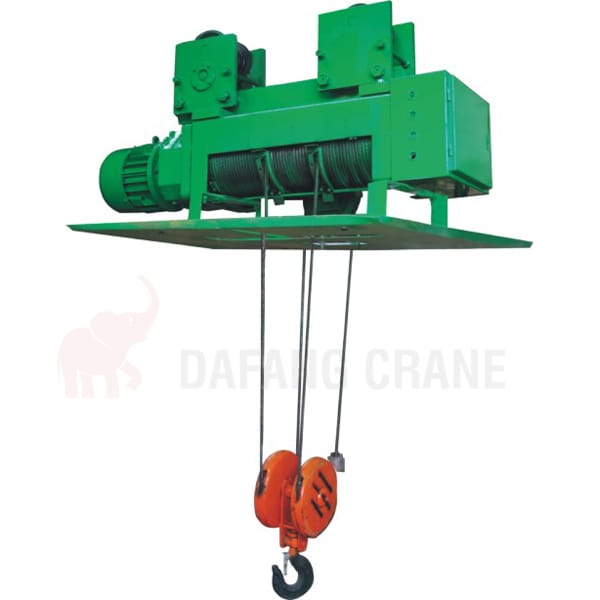

Electric wire rope hoists mainly include the following categories:

CD1 and MD1 Series Electric Wire Rope Hoist

This type is suitable for temperatures from -20°C to +40°C and humidity is no higher than 85%. The elevation is below 1000m, no fire, explosion danger, corrosive medium, and no dust environment work, it is banned to lift molten metal, poisonous, flammable and explosive goods. The applicable power source is AC three-phase, working grade: M3-M4.

The CD1 and MD1 series electric wire rope hoists are durable and compact lifting devices suitable for light to moderate lifting operations. CD1 hoists typically have a single lifting speed, while MD1 hoists offer dual lifting speeds, providing versatility in handling different load capacities. These hoists are commonly used in warehouses, workshops, and small-scale manufacturing units where space is limited, and lighter loads need to be lifted efficiently.

Metallurgical Wire Rope Electric Hoist

The product applies to such an environment where no fire, no explosive danger, and no corrosive media exist. And the temperature is no higher than 60°C, the wetness is no higher than 85%, the elevation is below 1000 m. The applicable power source is 3-phase alternating current (A.C for short, 50 Hz frequency and 380V voltage. The working grade is M6.

This electric hoist working principle is as same as CD/MD type. In order to protect operators and equipment to be safe, it is set many kinds of protection devices.

Metallurgical wire rope electric hoists are specifically engineered for demanding environments found in metallurgical plants and steel mills. These hoists feature heat-resistant components, including specialized ropes and hooks, to withstand high temperatures and harsh conditions. They ensure reliable lifting operations in extreme settings where conventional hoists may fail to meet the stringent requirements of the industry.

Explosion-proof Wire Rope Electric Hoist

This electric hoist is generally operated indoors, the working environment temperature is -20C~ + 40C, working environment atmospheric pressure is 0.08MPa-0.11MPa. The operating environment should ventilate well and have the necessary facilities to guarantee. Suitable gas environment explosion-proof dangerous areas are Area 1 and Area 2 according to GB 3836.14. Suitable dust environment explosion-proof dangerous areas are Area 21 and Area 22 according to GB 12476.1.

In industries where flammable gases, liquids, or dust particles are present, explosion-proof wire rope hoists are crucial for maintaining safety standards. These hoists are designed with robust enclosures and specially sealed components to prevent ignition sources and minimize the risk of explosions. They find applications in oil refineries, chemical plants, and hazardous environments where safety is paramount.

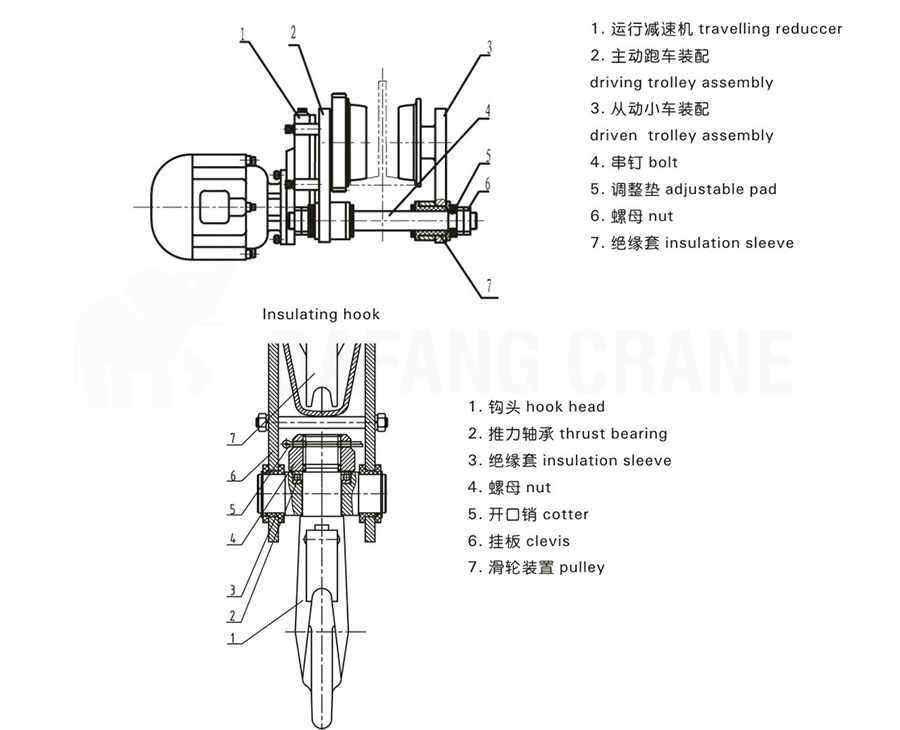

Insulated Wire Rope Hoist

Insulated wire rope hoists are designed for lifting operations in areas where electrical insulation is required. They feature insulating materials and coatings to safeguard against electrical hazards. These hoists are commonly used in power plants, high-voltage substations, and installations that involve working near live electrical equipment.

In order to ensure safety and reliability, insulation is adopted multi-level insulation, multilevel blocking way, often referred to as triple insulation. first-grade insulation chooses between the hook and pulley, second-grade insulation chooses between lifting trolleys and girders, and crane rail and support rail beam is the third-level insulation.

Chapter 2: Installation of Electric Wire Rope Hoist

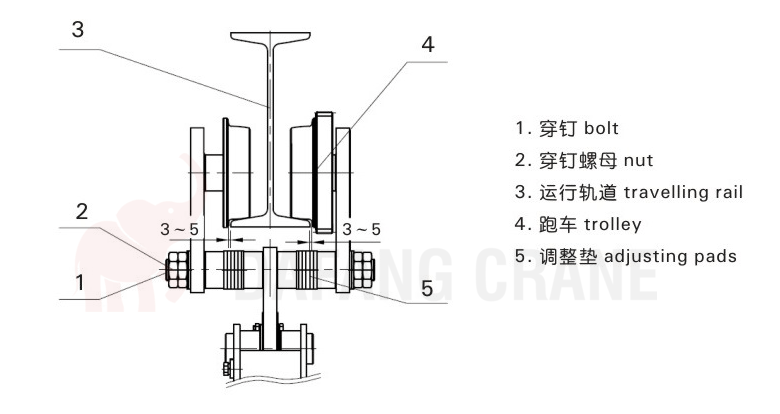

When installation, the electric trolley and driven trolley are adjusted by adjusting the cushion, making sure between wheel flange and rail flange have 3一5 mm clearance, keeping relative to orbit around the adjustment pads on both sides of the same number.

Earth wire connected framework should be set, and the grounding line is available from Φ4-5 mm of the bare copper wire or metal conductor cross section was not less than 25. For all electric power circuits of electrical installations, the resistance to ground control circuits shall not be less than 1M ohm per volt of operating voltage, and the value of ground connection resistance shall not be more than 4 ohms.

After Installing the electric wire rope hoist:

- Install and check the buffer block.

- Installation of power supply and controller.

- Adjust the limit switch used for lifting operations.

- Debug and complete commissioning record.

Chapter 3: Maintenance of Electric Wire Rope Hoist

Maintenance is to prevent and reduce fault occurred, the extension of the repair cycle, maintain good technical status, play the best efficiency, and prolong service life. In order to ensure the reliability and service life of the electric hoist, must take effective measures, the gourd lubrication and maintenance regularly, comply with the relevant matters needing attention in the process of operation, procedures, standards and specifications.

Maintenance Requirements

Electric wire rope hoist maintenance should meet the following requirements:

- Clean and ensure the overall cleaning of the gourd, no grease, no rust appearance.

- Fastening device in the movement of each fitting produce loosening due to vibration, must often check the tight, otherwise cause structure degradation.

- Adjusting mechanism will be damaged during working; change happens in an important part, it must be adjusted, such as brake friction ring (piece) of adjustment and travel switch.

- Lubrication is familiar with all lubricating points, timed to determine product quantity, Each bearing is in good lubrication.

- Abide by rules of safe operation, safety limit device, flexible and reliable braking device, grounding and insulation performance is good, prevent the happening of the accident.

Daily Maintenance

Daily maintenance is carried out by operators and maintenance personnel throughout the entire operating shift, a maintenance system, including pre-operation checks, inspections during operation, post-operation checks and adjustments.

1. Pre-operation Inspection

- Check whether the power supply system can supply power normally and safely.

- Check whether the operating handle is in the zero position.

- Check whether the controller and contactor are normal after the power is turned on.

- Whether there are defects in the hook and pulley.

- Whether the wire rope is in good condition, whether it is firmly fixed on the reel, and whether there is any de-grooving phenomenon.

- Whether the safety switch is sensitive and reliable, and whether the limit device is normal.

- After passing the inspection, put down the spreader and check whether there is any damage, macro crack, or abnormal wear and tear of the wire rope working device.

- Start each organization, check the drive, and transmission automatic device whether there is abnormal sound, each safety limit is sensitive and reliable.

- Check whether the lubrication of each part is good. If defects or abnormal phenomena are found, adjustments and overhauls should be made immediately, and should not be accommodated.

2. Inspection In Operation

- Parts of institutions and articulated point movement, sensory monitor whether there are abnormal vibrations and noise.

- Note the working condition of each security device at any time.

- Using the intermittent time of operation, check the motor, speed reducer bearing parts shell exterior temperature rise; adjust the brake clearance, and tighten the loose nut.

3. The Adjustment Inspection After Work

- According to the requirements of the different models will be electric hoist start at the designated parking location.

- Check if the wire rope is on the pulley groove, and whether there is wear and broken wires.

- Check brake braking condition, to adjust the brake clearance is not correct.

- Carefully check safety devices for misalignment, etc.

- Fill in the handover record after checking that the maintenance is complete.

Regular Maintenance

Regular maintenance is under the maintenance personnel, maintenance regularly, by the operator should be in the form of plan implementation. Time interval determined according to specific conditions of the use of metallurgical electric hoist frequent use, poor environmental conditions, dust pollution, physical wear and tear parts and structure corrosion phenomenon is serious, poor external cleaning, general interval 1 ~ 2 months for regular service.

Regular maintenance includes the following in addition to routine maintenance items:

- Remove the maintenance parts, protective cover, etc. specified in the maintenance specification, thoroughly clean and inspected.

- Check the adjusting mechanism parts fit clearance, fasten loose parts and components, replacement of wearing parts.

- Do good lubrication.

- Repair or replace the slight injury of parts.

Electric wire rope hoists are valuable tools for lifting heavy loads in industrial and construction settings. Proper installation, regular maintenance, and adherence to safety guidelines are essential for their effective and safe operation. By following the outlined procedures, operators can maximize the lifespan of the hoist while minimizing risks. Remember, always consult the manufacturer’s instructions and seek professional guidance when necessary. Feel free to contact us for any of your needs!

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China