EOT Crane Load Testing: A Step-by-Step Guide

Overhead cranes are commonly used in modern industrial production and are widely used in many sectors. Lifting operation is a kind of accident-prone operation, the use of lifting machinery in the process of failure will cause great harm. Therefore, a safety inspection of cranes is required to identify their manufacturing quality and the possibility of safe operation. Load tests can test the quality of lifting machine products and safety performance indicators, such as the deformation of the crane metal structure, and the effective condition of the safety device. This article describes in detail the steps and methods of the load test of overhead cranes, including the preparatory work before the load test of overhead cranes, no-load test, rated load test, static load test, and dynamic load test.

Requirements for Load Test of Overhead Cranes

Environmental Requirements of The Test Site

In order to ensure the validity and reliability of the test, the test site must meet the following conditions:

- The test site is solid and level.

- The ambient temperature is -3℃~+36℃.

- If the test site is an outdoor environment, the instantaneous wind speed on the ground is less than 8.3 m/s.

Requirements for Test Loads

The test load can be a single unit or consist of several parts for different load test requirements. It can be a blocky individual unit of steel or other type (concrete) or a container with water or sand.

Method of measuring the mass of the test load:

- Direct method: the weight of the test block is weighed directly.

- Combination method: A series of weights with a certain mass for a reasonable combination, to get the weight required for the load test.

The error on the test load should be controlled within 1%.

Preparation Before The Test

- Remove all debris on both sides of the crane and trolley tracks.

- Clear the test site of equipment and materials unrelated to the test.

- Set up a cordon in the test site, on-site safety personnel to strictly check that unrelated personnel and equipment are not allowed to enter the test site.

- Check whether the connection bolts are tight, and check whether the compression bolts of the rail are tight.

- Check the lifting appliances and slings for load test, qualified for use.

- Prepare other equipment for load test, including assembling heavy basket, walkie-talkie, steel tape measure, clamp ammeter, electronic stopwatch, etc.

- Before the load test, install and debug the main beam strength and stiffness real-time detection and monitoring system device, real-time detection of the main beam strength and stiffness value in the experiment, and at the same time compared with the calculated value, the allowable value, dynamic display, exceeding the standard alarm.

EOT Crane Load Test Procedure

The EOT crane test includes no-load test, rated load test, static load test and dynamic load test. The order of the test should be noted, should be the first no-load test, after the rated load test, then static load test, and finally dynamic load test. The previous test is unqualified, can not carry out the next test, need to rectify the completion of the review of qualified to continue the test behind. In order to ensure the smooth running of the test, it is necessary to carry out a visual inspection of the whole machine before carrying out the test.

Visual Inspection

The visual inspection shall include compliance with the specifications and condition of all essential parts, such as the mechanisms, electrical equipment, safety devices, brakes, controls, lighting and signaling systems; the crane metal structure and its connectors, ladders, access roads, driver’s cab and walkway platforms; all guards; the hooks or other pick-up devices and their connectors; the wire ropes and their fixtures; and the pulley blocks and their axial fasteners. It is not necessary to disassemble any parts for inspection, but covers that should be opened during normal maintenance and inspection, such as limit switch covers, should be opened.

No-load Test

The no-load test is mainly a test of the operation and lifting mechanism of the overhead crane and trolley, and is carried out according to the following procedures:

- Before the test, use 500V megohmmeter to measure the insulation resistance of the main circuit of each organization, the control circuit, and the insulation resistance to the ground.

- Turn on the power supply, open the institutions so that the trolley along the full length of the main beam, the crane along the track run back and forth no less than 3 times, there should be no jamming phenomenon.

- Check whether the limit switch and buffer work properly, and whether the left and right limit positions of the spreader meet the requirements.

- Start the main and secondary lifting mechanism for the whole operation of the lifting range, check whether the operation is normal, whether the control system and safety devices meet the requirements and are sensitive and accurate, check whether the lifting range meets the requirements.

- During the no-load operation test, each mechanism should be started separately and operated in both forward and reverse directions for a cumulative time of no less than 5 minutes.

The results of the no-load test satisfy the following conditions before proceeding to the next operation:

- All safety devices are working reliably and effectively.

- All mechanisms are operating normally, and the brakes are reliable.

- The operating system and electrical control system are working properly.

- There is no rail gnawing phenomenon during the full-length operation of the crane and trolley along the track.

Rated Load Test

The purpose of the rated load test is to further test the relevant functional indicators of the crane through the rated load test. The test process is as follows:

- The main hoisting mechanism is loaded by 1.0 times the rated load, so that the crane and trolley running mechanism, hoisting mechanism to do joint action, only allowed to open the two institutions at the same time (but the main and secondary hoisting mechanism should not be opened at the same time).

- During the test, the speed of each organization (including speed regulation), braking distance and crane noise should be detected separately

- If the test object is a grab crane, the grabbing performance of the grab needs to be checked; if the test object is an electromagnetic crane, the lifting electromagnetic’s lifting capacity, the correctness of the electric control system, and the ability of the backup power supply to maintain magnetic field need to be verified.

Static Load Test

The purpose of the static load test is to check the bearing capacity of the crane and its various structural components. If no cracks, permanent deformation, paint peeling, or damage affecting the performance and safety of the crane are found, and there is no looseness or damage at the connection points, the test is considered qualified.

The static load test is carried out according to the following procedures and requirements:

- First, a static load test is performed on the main hoisting mechanism: the hoisting rated load (gradually increased to the rated load), the trolley runs back and forth along the full length of the bridge, and the crane operating mechanism is started (it is not allowed to start three mechanisms at the same time), and various performance indicators are checked to meet the design requirements. Unload the load and park the empty trolley at the limit position (the grab and lifting electromagnet should touch the ground), and set the test benchmark point.

- Stop the trolley at the middle of the bridge crane, first load it with 1.0 times the rated load, lifting 100 mm~200 mm from the ground to suspend, and then loaded without impact to 1.25 times the rated load, suspension time of not less than 10min. Unload the load and park the empty truck in the extreme position (the grab and lifting electromagnet should be grounded). Use the method of pulling steel wire to check that there should be no permanent deformation at the benchmark point of the main beam of the crane, and the actual upward arching degree F of the main beam should meet the requirements of the testing specifications, the test can be terminated. If there is permanent deformation, the test needs to be repeated from the beginning, but no more than three times, and there should be no permanent deformation again.

- After the test, visually inspect for permanent deformation, paint peeling, or damage that may affect the performance and safety of the crane. Check for looseness or damage at the connections. Additionally, the actual value of the upward deflection should not be less than 0.7S/1000, and the highest point of the upward deflection should be within the range of S/10 at the midpoint of the span.

- Check the static stiffness of the crane. Drive the trolley to the middle of the bridge, lift the rated load 200mm off the ground, and after the crane and load come to a stop, measure the upward deflection F1. Static stiffness =F-F1.

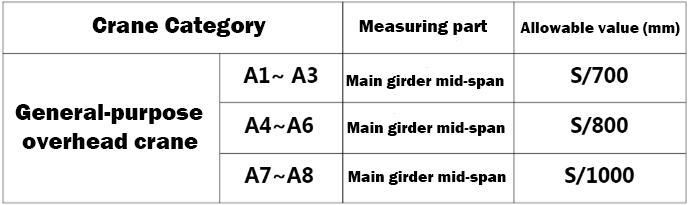

The allowable value for the static stiffness of the crane is:

- A1~A8: Duty classification of the crane

- S: Span of the crane

- Static stiffness of the crane: Should be measured within the range of S/10 at the middle of the main beam span.

Dynamic Load Test

The main purpose of the dynamic load test is to verify the functionality of the various mechanisms and brakes of the crane. If each component can complete its functional test and no damage is found in the subsequent visual inspection of the mechanisms or structural components, and there is no looseness or damage at the connections, then the result of the test is considered qualified.

The steps for the dynamic load test of a bridge crane are as follows:

- First, cut off the weight limiter to prevent it from operating.

- During the test, each mechanism should be tested separately. The lifting mechanism should be loaded with 1.1 times the rated load, and each action should be repeatedly started and stopped within its range of motion. In addition, a simultaneous motion test of two mechanisms (the main and secondary hooks should not be operated simultaneously) should also be conducted in the same manner.

- When the suspended test load is started in the air, the test load shall not be reversed.

- The test should be according to the machine’s motor connection duration rate to leave the operation of the intermittent time, according to the operating procedures for control. It is also necessary to ensure that the acceleration, deceleration, and speed are limited to the range of normal operation of the crane.

- According to the motor connection duration rate and its work cycle, the test time should continue for at least 1 hour.

- After the test, visually inspect the components of each mechanism or structure for damage, check for looseness or damage at the connections, and finally install the weight limiter to ensure that it operates normally.

Load tests for EOT cranes can check the quality and safety of crane products and reduce the occurrence of accidents. Load test includes no-load test, rated load test, static load test and dynamic load test. No load test is mainly on the bridge crane and trolley operation and lifting mechanism test; rated load test to further test the relevant functional indicators of the crane; static load test on the crane and its structural components of the bearing capacity of the calibration; dynamic load test to verify the function of the crane institutions and brakes.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China