Overhead Crane Mechanical Grabs vs Hydraulic Grabs: Which Suits Your Needs Best?

Table of Contents

What is the difference between the mechanical grabs and the hydraulic grabs?In terms of material handling, choosing the right grab can significantly affect efficiency and productivity.The two common types of grapple used in cranes are mechanical grapple and hydraulic grapple.Let’s explore their differences and understand when to choose each type.

First of all, let’s take a look at what is a hydraulic grab and a mechanical grab:

Classification

Overhead Crane Hydraulic Grabs

Electro Hydraulic Orange Peel Grabs

Electro hydraulic Clamshell Grabs

Electro Hydraulic Rectangular Grabs

Hydraulic Round Nose Bucket

Working principle

Overhead Crane Hydraulic Grabs

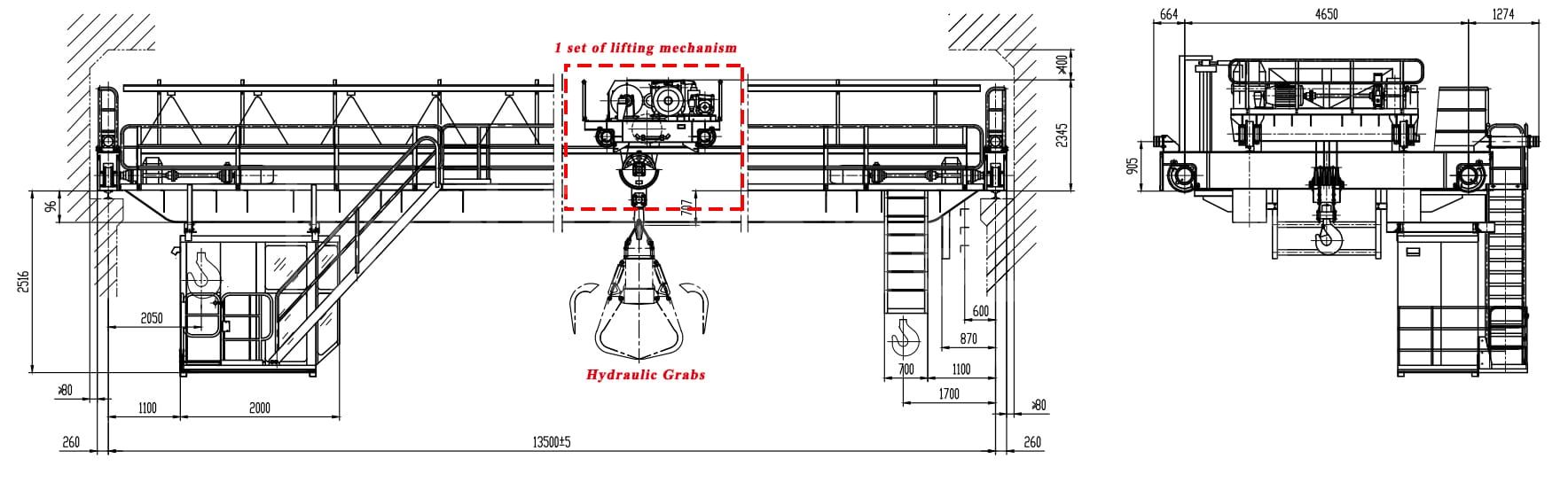

A set of lifting mechanisms, the hydraulic grab is installed under the hook using a hook, which is easy to disassemble, and the telescopic action of the hydraulic cylinder completes the opening and closing of the bucket.

It has a motor, a hydraulic pumping station, and a control valve, which is driven by an external power supply to open and close.

The hydraulic grabs are connected to the hydraulic circuit on the crane.

The operator can control the lifting, opening and closing, transfer and other actions of the hydraulic grab in the control room.

Overhead Crane Mechanical Grabs

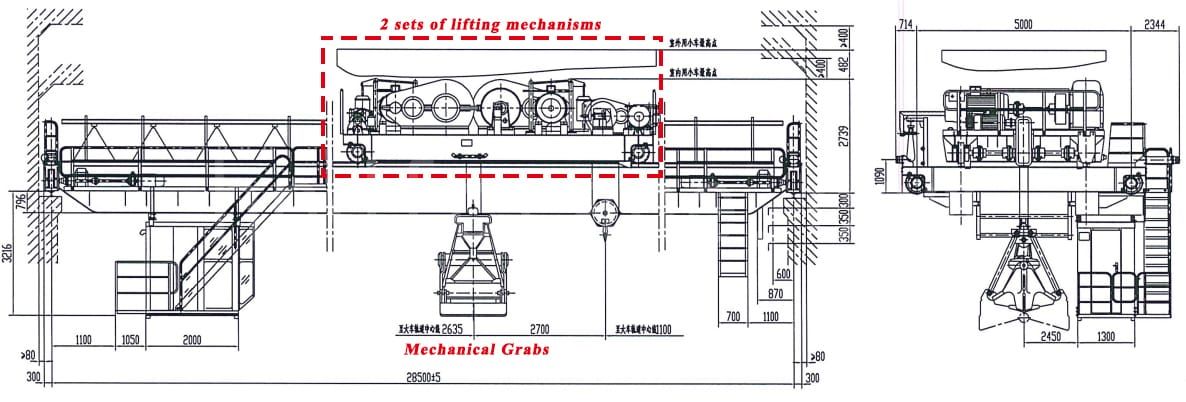

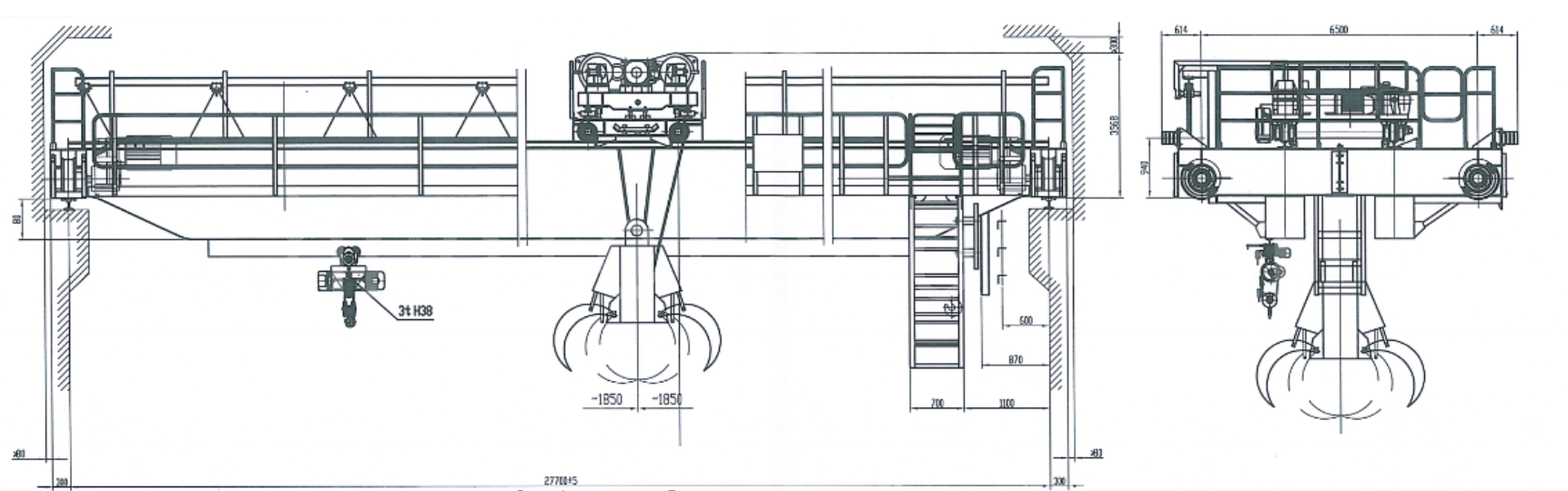

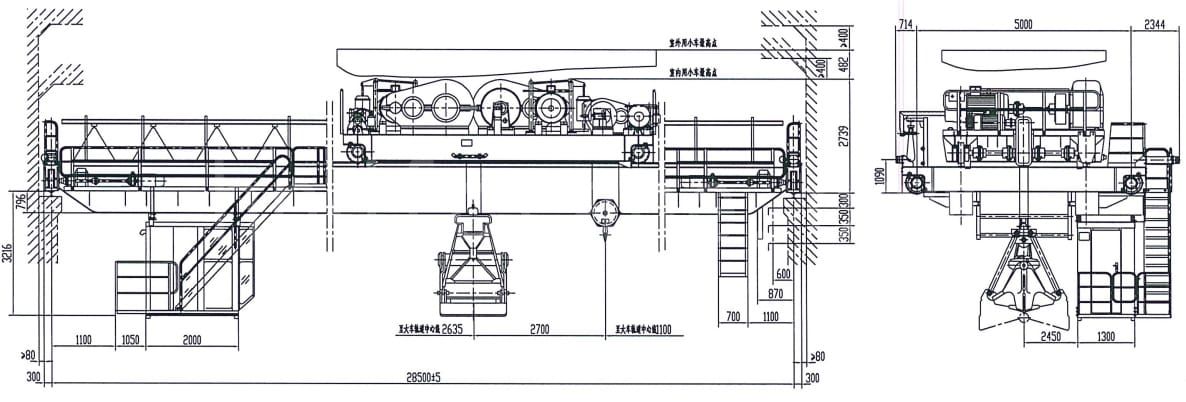

It needs to be equipped with 2 sets of lifting mechanisms to open and close the mechanical grabs through the reel.

The mechanical grabs relies on mechanical connecting rods, pulleys, and levers for grasping action

Operated by direct physical force, it consists of two or more hinged arms with sharp or serrated edges, similar to the jaw of a creature, which can tightly clamp the material.

No hydraulic power or electrical connection is required. The operator manually controls the movement of the mechanical grab.

Application

Overhead Crane Hydraulic Grabs

Domestic waste treatment:

Grab cranes used in waste disposal in domestic waste incineration and power generation projects mainly grab domestic waste.

This is an intelligent product that can realize unattended operations.

Scrap steel and large stones:

In scrap yards and stone processing plants, materials of various shapes and sizes can be precisely controlled and efficiently processed.

Old battery:

It is more suitable for fine operation and accuracy, and reduces the risk of battery damage.

Food processing industry:

Grab pickles, pickles, and wineries for brewing.

Stainless steel is usually used to reduce pollution.

River decontamination:

It is very suitable for fine cleaning tasks, providing precise control to remove debris without disturbing the riverbed too much.

Light industry:

Grasping plastics is very suitable for high-precision processing of plastics, suitable for classification and fine operation.

Overhead Crane Mechanical Grabs

Waste treatment and classification:

Mechanical grappling hooks are good at handling bulk materials such as logs, scrap metal, rocks and debris.

Waste management facilities use grabs to sort and transfer recyclables, green waste, and construction waste.

Dismantle and deconstruct:

During the demolition project, the mechanical grab removes the building structure by grabbing and pulling the material.

The removal of concrete, steel beams and other components minimizes the need for labor and shortens the project schedule.

Loading and unloading:

The grab can effectively handle bulk cargo such as coal, grain and aggregates.

Forestry operations:

Efficiently load and unload logs to assist in the logging and transportation of wood.

They keep operators away from fallen trees and heavy logs, thereby improving safety.

Maintenance

Overhead Crane Hydraulic Grabs

The hydraulic system has many mechanisms, and the maintenance is more cumbersome than the mechanical grabs.

The hydraulic system is more complex and the maintenance cost is higher, and it is prone to air intake and other failures during use.

Overhead Crane Mechanical Grabs

Compared with hydraulic grabs, mechanical grabs are simple to maintain and durable. Mechanical grabs are usually just a matter of wire rope wear. At that time, only the wire rope needs to be replaced.

The hydraulic grabs of the crane is controlled by a hydraulic system, which has the advantages of high precision and flexible operation. It is suitable for loading and unloading bulk cargo and occasions that require fine operation, but its structure is complex and the maintenance cost is high. The mechanical grabs relies on wire rope control, which is suitable for handling large pieces of materials and heavy-duty operations in harsh environments. The structure is relatively simple and the maintenance cost is low. When choosing, the type of grab to use should be determined according to the operation requirements, accuracy requirements, and operating environment.

How to choose the right grab

Clarify your purpose:before delving into the options, please clarify your specific requirements.Ask yourself:

- What materials do you want to deal with?(Logs, scrap metal, stone, etc.)

- What tasks will the grab perform?(Loading, sorting, dismantling, etc.)

- What type of device will it be connected to?(Gantry crane, overhead crane)

- What is the specific gravity of the material you grab?The number of cubes of the grab?

- According to the characteristics of the material being grabbed, the grab is usually divided into four basic types: light, medium, heavy and super heavy.

| The type of material to grab | Grab material | Capacity weight(t/m³) |

| Light | Coke, slag, grains, potatoes, medium-quality anthracite lime, cement, soil, gravel, clay, broken bricks, etc. | 0.5~1.2 |

| Medium | Peat, large pieces of anthracite coal, compacted coal, clay, limestone, gravel, salt, gravel, bricks, bauxite, flakes of iron oxide, cement, sand and bricks in water, etc. | 1.2~2.0 |

| Heavy | Limestone, heavy clay, small and medium-sized ores, hard rock, rod-shaped iron oxide, iron ore, lead concentrate powder, etc. | 2.0~2.6 |

| Overweight | Large ores, large manganese ore, sedimentary agglomerated lead ore powder, etc. | 2.6~3.3 |

- What is the tonnage of your crane equipped with a grab?

Accessory compatibility: Ensure that the grab is compatible with existing equipment.

Budget considerations: The price range of the grab is different.Balance your budget based on the function and durability of the grab.

Comments and suggestions: Research online, read user reviews, and seek suggestions from industry peers.

Go to the crane manufacturer for on-site inspection and testing before purchasing: test the grab under real conditions as much as possible.Evaluate its performance, ease of use, and overall functionality.

Keep in mind that choosing the right grab requires a balance between functionality, safety, and cost.By considering these factors, you will find the perfect grab that can increase productivity and ensure smooth operation.

Choose the appropriate hydraulic grabs and mechanical grabs according to the needs of different projects

We use 2 previous Dafangcrane projects to help you distinguish the selection.

Case1-Hydraulic grabs are used on overhead cranes

- Grab type: Electro Hydraulic Orange Peel Grabs , grab volume 4m3*A6

- Project type: Used in waste power generation projects, mainly used to deal with the mixing, dumping, handling, mixing, etc. of domestic waste to ensure uniform waste composition.Deal with 600t of garbage a day; the operation of the equipment is greater than 8000h.

- Material characteristics:

- The moisture content of domestic waste is 45%~65%

- The density of garbage in the grab is 0.6~0.9t/m3

- Garbage capacity (in the garbage compartment) 0.3~0.6t/m3

- Static accumulation angle 65 degrees

- Price reference: The hydraulic grabs are more intelligent and more complex than the mechanical grab, so the price is 4.1 times that of the mechanical claw grab.

- Why choose hydraulic grabs:

Material diversity: The composition of domestic waste is complex, the moisture content is high, and the material diversity is rich, which requires a flexible grab for processing.The hydraulic grabs are multifunctional and can effectively handle materials of different types and states.

Grasping accuracy and efficiency: The hydraulic grabs can accurately control the grasping force and angle, and adapt to the fine operations required in the garbage disposal process, such as mixing, dumping, handling and stirring, to ensure uniform garbage composition.

Strong processing capacity: 600 tons of garbage are processed a day, and the equipment runs for up to 8,000 hours. The durability and efficient performance of the hydraulic grab meet the needs of high-intensity operations.

Safety and stability: The hydraulic grabs operates smoothly, which can reduce the risk of material spilling and operation, improve work safety, and is suitable for handling domestic waste with high moisture content and large density changes.

Adapt to complex operating environments: The hydraulic grabs can maintain efficient operation in a changeable working environment, especially suitable for garbage disposal, which requires frequent operation and flexible response to various materials.

Long-term and high-frequency operations: The durability and stability of the hydraulic grab enable it to cope with long-term and high-frequency operations, reduce downtime, and improve overall work efficiency.

In summary, the choice of hydraulic grab is based on its comprehensive considerations of flexibility, high efficiency, durability and safety, which can effectively meet the complex and high-intensity operation needs of waste power generation projects.

Case2-Mechanical grabs are used on overhead cranes

- Grab type: Mechanical Four Rope Clamshell Grabs Bucket ,grab volume 4m3

- Material specific gravity:2t/m3

- Project type: Used in metal powder magnetic material companies, the grab wire rope adopts stainless steel temperature-resistant type.

- Price reference:The mechanical grab has a simple structure and costs about 24.39% of the hydraulic grab, making it the best choice if you are on a limited budget

- Why choose mechanical grab:

Good sealing: materials such as metal powder are easy to scatter during handling, and the mechanical grabs has a simple structure and good sealing, which can effectively prevent materials from spilling and improve the cleanliness and safety of operations.

Cost-effectiveness: The purchase and maintenance costs of mechanical grabs are low, and they are suitable for operations with limited budgets and long-term and high-frequency use.

Durability: The grab wire rope adopts stainless steel temperature-resistant type, which is suitable for material handling such as metal powders that have high requirements for temperature and corrosion resistance.

Applicable environment: For metal powder in a dry state, the gripping force and stability of the mechanical grabs are sufficient to meet the needs, and the operation is simple and easy to maintain.

Work efficiency: The mechanical grab can quickly and efficiently complete the grabbing and handling of materials, improve the overall work efficiency, and is suitable for the rapid operation needs of industrial production lines.

In summary, the choice of mechanical grab is based on its comprehensive considerations of closure, cost-effectiveness, durability, applicable environment and operating efficiency, which can effectively meet the actual needs of metal powder magnetic material companies.

Comprehensive comparison

It is recommended to choose mechanical grabs in the following cases:

- Harsh operating environment: In harsh environments with high dust and humidity, mechanical grabs are more reliable than hydraulic grabs and are less affected by environmental impact.

- Simplicity and cost-effectiveness are priorities: the mechanical grabs has a simple structure and low maintenance costs, which is suitable for projects with limited budgets.

- Easy maintenance: The mechanical grabs have a simple structure and a small maintenance workload, which can reduce downtime and improve operation continuity.

- Available equipment: If the existing lifting equipment does not have a hydraulic system, the mechanical grab can be used directly without additional modification or investment.

- Operation training: the operation of the mechanical grab is relatively simple, the training cost is low, and it is suitable for rapid deployment and use.

It is recommended to choose hydraulic grabs in the following cases:

- When greater gripping force is required: the hydraulic grabs are flexible in operation, the gripping force and angle can be accurately controlled, and the gripping force is stronger than that of the mechanical grabs.

- You operate hydraulic machinery: if you already have hydraulic equipment, the hydraulic grabs can be directly integrated to improve operating efficiency.

- Safe and efficient material handling is essential: the hydraulic grabs operate smoothly, reduce material damage and operational risks, and improve work safety and efficiency.

- There are automation requirements: the hydraulic grab can be integrated with the automation control system to achieve more intelligent operations and improve the overall production efficiency.

In short, mechanical grabs and hydraulic grabs have their advantages in material handling. Evaluate your specific requirements, consider available equipment, and make an informed choice. Whether you choose the robustness and simplicity of the mechanical grabs or the accuracy of the hydraulic grabs, remember that the right grab can increase productivity and ensure smooth operation.

Dafang Crane offers a wide range of hydraulic and mechanical grabs, including various types of automated grabs designed to meet diverse needs. Whether you’re looking for efficient solutions for heavy lifting or specialized applications, we have the right equipment for you. Click on the image link below to explore our full selection and find the perfect grab for your business needs.

15 Different Grab Buckets for Crane Applications.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China