Steel Mill Crane: The Commonly Used Cranes In 6 Workshops

The steel industry relies heavily on efficient material handling systems to streamline operations, maximize productivity, and ensure safety. Among the key players in this process are cranes, which play a crucial role in moving heavy loads, facilitating production, and enhancing operational efficiency. In this article, we will explore the steel mill cranes and the types of cranes used in different workshops in steel mills.

Steel Mill Crane for Blast Furnace Workshop

The blast furnace is an ironmaking equipment, that is the first process of iron and steel smelting, mainly used trolleys, hoists and single girder overhead cranes, blast furnace slag cleaning requires the use of slag grab cranes.

QD Trolley

The QD trolley is mainly composed of the trolley frame, hoisting mechanism, trolley wheels, and control system. QD trolley is a medium-heavy lifting equipment, load capacity is 5t-800t, duty group M5-M8, compared with other types of trolleys, QD trolleys have a higher duty classification and are able to withstand harsher working environments. In steel mills, QD trolleys are usually installed at the top of the blast furnace for overhauling and maintenance of the blast furnace.

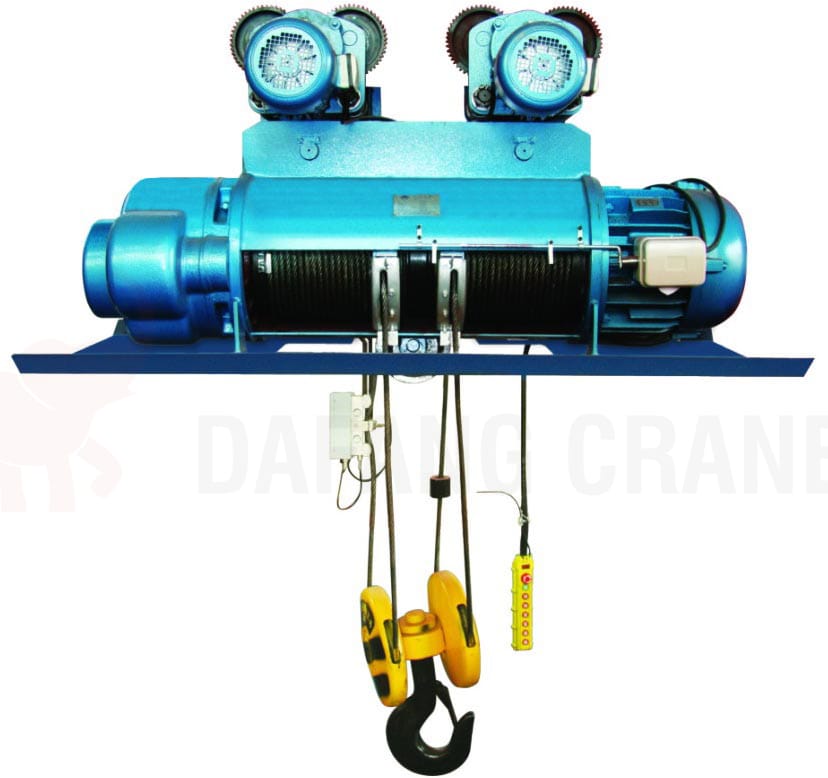

Hoist

Hoist is a special lifting equipment, that can be installed in the bridge cranes, gantry cranes, and jib cranes, and can also be slightly modified as a winch to use. With small size, lightweight, simple operation, easy use characteristics, generally used in industrial and mining workshops, warehousing, docks and other places. The blast furnace workshop generally uses manual or electric hoists for the lifting of small pieces of equipment.

LDA Single Girder Overhead Crane

LDA single girder overhead cranes are the most widely used cranes in workshops. These cranes are reasonable in structure, light in weight, and can be used with CD1 and MD1 hoists. The load capacity is up to 20t, and the duty group is A1-A3, which belongs to light-duty crane. It works in -25 ℃ – +40 ℃ temperature, with relative humidity ≤ 85% of the environment. This crane is mainly used in steel stock yard, mine, the concrete industry, warehouse, factory, harbor and ship building, etc. In the blast furnace workshop, LDA cranes are mainly used for lifting equipment in front of the furnace.

Slag Grab Crane

This crane is specially developed for cleaning blast furnace water slag in steel plants. It adopts full-automatic unattended design with automatic slag catching, precise positioning, anti-swaying, automatic avoidance and other functions. The shape, position, and center of gravity of the transported object can be identified by scanning. The equipment runs smoothly, the working curve is smooth, and the service life is prolonged, effectively reducing operation and maintenance costs and labor costs.

Steel Mill Crane for Steelmaking Workshop

In the steelmaking workshop, cranes are used to add scrap and molten iron to the converter, lift and transfer ladles, and inspect and maintain equipment. It mainly uses charging overhead cranes, casting overhead cranes, ladle transfer cars and double girder overhead.

Charging Overhead Crane

Charge cranes or furnace cranes are vital in steel production. In the steelmaking plant, the charging crane feeds the electric arc furnace in the charging area and should be able to transport the hot metal to the turret station of the continuous casting machine or to the ladle furnace. The same crane can be used as a backup for the ladle crane if required. The charging crane is used to lift scrap, molten steel and other auxiliary materials to the converter and electric furnaces in the smelting shop.

Ladle Overhead Cranes

Ladle cranes are also known as casting cranes, mainly divided into double girder casting cranes and four girder casting cranes. Casting crane is the main equipment in the continuous casting process of steelmaking, mainly used for converter charging and cross to the converter to iron; in the refining across the ladle lifting to the refining furnace or in the steel acceptance across the ladle lifting to the continuous casting ladle on the rotary table, to complete the iron and steel smelting.

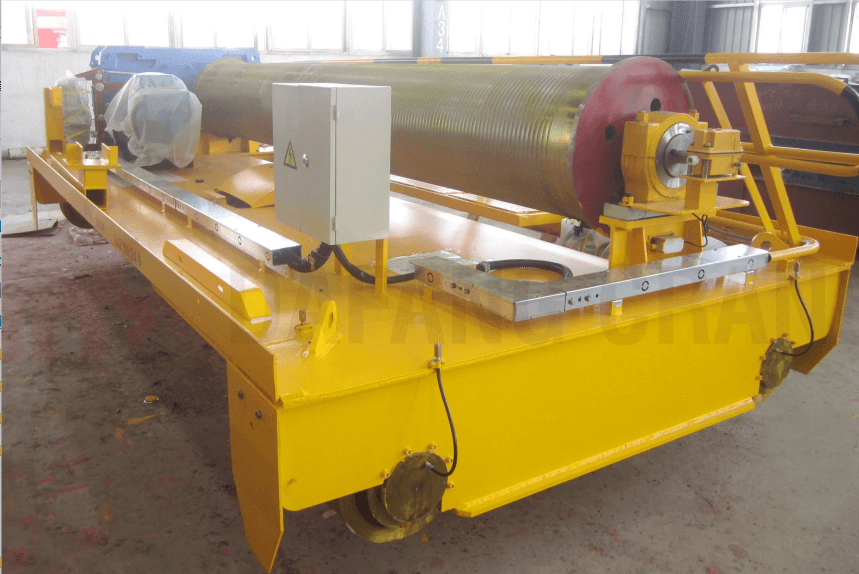

Ladle Transfer Cars

The ladle transfer car is a kind of transfer car used to transport specific high-temperature ladles. Due to the high temperature and high safety requirements, ladle transfer cars are higher than ordinary transfer trucks in terms of body materials, transmission system requirements and electrical control requirements. In steel mills, ladle transfer cars are often used to transfer rough steel from the converter to the secondary refining station.

QD Double Girder Overhead Cranes

The QD double girder overhead crane is designed for heavy-duty or severe working conditions in heavy machine shops, steel warehouses, foundries, steel mills, lumber yards, scrap yards and more. It can be used to safely lift and move heavy loads in extreme environments. In steelmaking shops, it is mainly used for equipment inspection in the converter area.

Steel Mill Crane for Rolling Workshop

Three types of cranes are mainly used in the steel rolling workshop, including coil handling cranes, electromagnetic hanging beam overhead cranes and QD double girder overhead cranes. QD double girder overhead cranes are mainly installed above continuous casting machines and rolling lines for inspection and maintenance work.

Coil Handling Cranes

Coil handling cranes are powerful and specialized lifting machines designed to handle the coil. These cranes are specifically engineered to safely lift, transport, and position heavy coils of various materials, such as steel, aluminum, and copper. They are equipped with specialized gripping mechanisms, such as C-hooks or lifting tongs, that securely hold and manipulate the coils throughout the handling process. The coil handling cranes can be equipped with intelligent features such as load positioning, sway control and overload protection to ensure efficient and safe movement of the coil. In the rolling shop, these cranes are used in the hot rolled steel coils and cold rolled steel coils caching area.

Electromagnetic Hanging Beam Overhead Cranes

Electromagnetic hanging beam overhead cranes are suitable for handling magnetic materials such as steel sections, bars, steel plates, billets, pipes, etc. They are commonly used in rolling production lines, finished product warehouses, steel yards, and discharging workshops. In the production line of continuous rolling workshop, electromagnetic beam cranes are mainly used to transport finished steel plates, billets and profiles from the roller table to the stack.

Steel Mill Crane for Scrap Warehouse

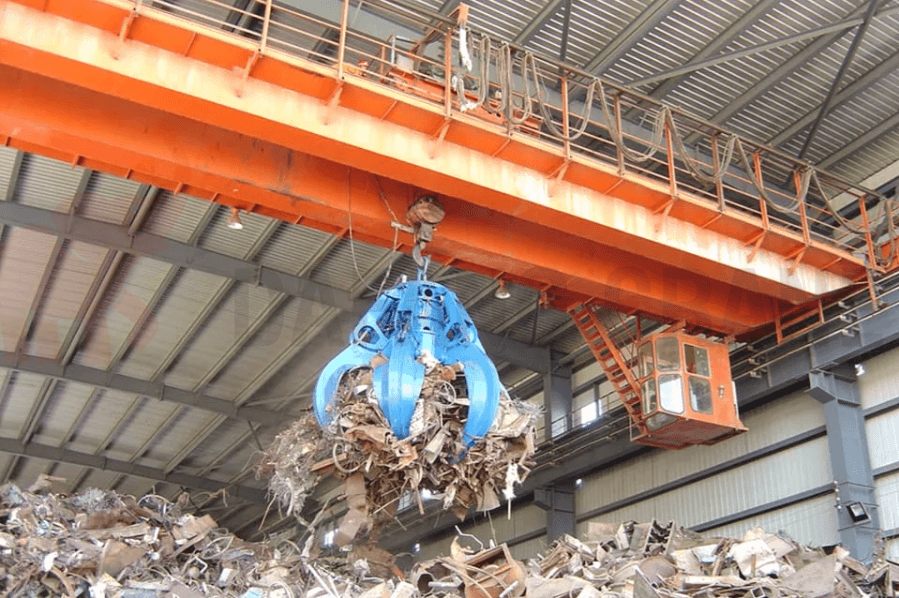

Grab Overhead Cranes

Grab cranes are lifting machines equipped with grabs, there are shell-type grabs and multi-lobed grabs. Grab cranes are widely used in ports, wharves, station yards, mines, etc. for loading all kinds of bulk cargoes, logs, minerals, coals, gravel, earth and stones.Scrap workshop mainly uses multi-lobe grab bucket overhead cranes, which are used to grab and sort scrap steel in steel mills.

Electromagnetic Overhead Cranes

The electromagnetic overhead cranes are equipped with accessible electromagnetic plates, the lifting capacity reaches 20t including the plate’s weight and magnetic weight. It is applied in metallurgy factories or outdoor places, which have fixed span and heavy work, to load and transport electromagnetic black metal materials (as steel ingot, merchant steel, big iron). Some stores also use it to handle materials, pieces of iron and scrap iron, scrap steel and so on. The crane consists of box shape bridge frame, crane traveling mechanism, trolley, electric equipment and electromagnetic plate. The operation is cabin operating, and have rain-proof equipment when outside. Electromagnetic overhead cranes are used for gripping scrap in steel scrap storage workshops.

Steel Mill Crane for Slab Warehouse

Slab Clamp Crane

Slab clamp cranes are specialized equipment for billet handling. It is mainly used for continuous casting billets across the production line to the billet warehouse to transport high-temperature billets, in the heating furnace or warehouse to transport room temperature billets, and slabs for stacking, loading and unloading vehicle operations.

Steel Mill Crane for Finished Product Warehouse

In finished product warehouses, two main types of cranes are used for loading and unloading vehicles and stacking operations for various profiles such as steel coils and plates. Electromagnetic hanging beam overhead cranes and coil handling cranes.

Dafang coil handling crane equipped with high-precision anti-sway, positioning, and other hardware systems, as well as a powerful control system, can easily cope with the various needs of intelligent material handling. In addition, this crane can be equipped with a variety of lifting devices, such as grippers, C-hooks, magnets, and other lifting devices according to the materials to be handled, and it can also be provided with a slewing function.

The lifting mechanism of Dafang electromagnetic hanging beam overhead crane adopts the classic parallel axis arrangement, the trolley running mechanism adopts the structure of centralized drive of low-speed shaft, and the large trolley running adopts the structure of independent drive on both sides. It is easy to operate, with perfect protection devices and convenient maintenance, and is widely used in metalworking workshops, assembly workshops, maintenance workshops, steel structure workshops and all kinds of warehouses.

Different scales and layouts of steel mills are not the same type of cranes used, so we list several cranes commonly used in steel mills. If you have any needs, please feel free to contact us, we will according to the actual layout of your factory building to design your exclusive crane solution!

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86-191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China