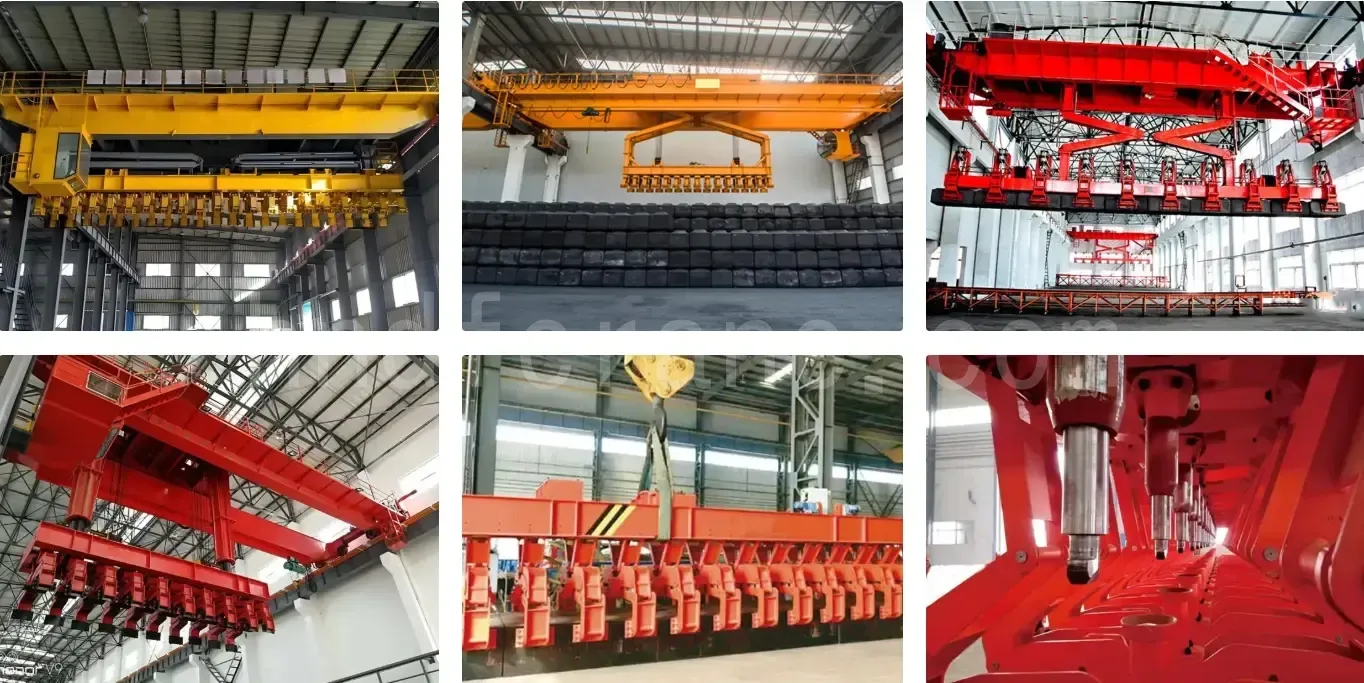

Product Introduction

Anode Carbon Block Stacking Crane is a type of overhead crane used as material handling equipment in carbon plants and aluminum electrolysis plants. It is mainly applied for the stacking and transportation of green anode blocks, baked anode blocks, and rodded anode blocks (typically handled in groups of 19 blocks). It can also be used for removing defective blocks and inserting qualified blocks.

Anode Carbon Block Stacking Crane Advantages & Features

- Operating Modes: Supports cabin operation, remote control (wireless control), and combined cabin + remote control with dual-mode switching.

- Control System: PLC + VFD + HMI architecture. PLC options include Allen-Bradley ControlLogix 5000 or Siemens S7-1500; VFD options include Emotron VFX48, ABB ACS880, or Schneider ATV71. The industrial-grade HMI touch screen supports parameter setting and real-time status monitoring.

- High Automation Level: Fully automatic operation covering block gripping, placing, destacking, and truck loading. Intelligent positioning with laser and/or encoder alignment ensures high accuracy (±2 mm).

- Remote Monitoring & Data Management: Wireless communication between the crane and the central control room enables remote monitoring. Supports remote program upload and download, as well as data logging such as carbon block operation reports and fault log storage and analysis.

- Energy-Saving Mechanical Gripper Design: Purely mechanical structure with no electric drive required. Combined with variable-frequency speed control for energy efficiency. Modular design allows easy maintenance and servicing.

Anode Carbon Block Stacking Crane Structural Composition

The Anode Carbon Block Stacking Crane mainly consists of the bridge girder, gripper lifting mechanism, opening/closing mechanism, and electric hoist lifting and traveling system. It features closed-circuit monitoring, automatic detection, automatic positioning, automatic gripper leakage detection, and automatic calculation of carbon block stacking height.

Functions & Features of Main Components:

- Bridge Girder Assembly: High-strength box-girder structure design, equipped with anti-torsion end carriage assemblies.

- Clamping & Lifting System: The main winch mechanism adopts a dual-brake configuration. A 4:1 reeving system using movable and fixed pulley blocks increases lifting force, while balance sheaves ensure uniform wire rope tension. The hydraulic clamping device provides pressure feedback functionality.

- Traveling Mechanism: Equipped with a VFD-driven electric hoist, dual-rail guiding system, and redundant limit protection system.

- Intelligent Control System: Automatic laser positioning with ±2 mm accuracy, real-time load weighing with 0.5% accuracy, adaptive calculation of stacking height, and fault self-diagnosis functions.

- Auxiliary Systems: Centralized automatic lubrication, closed-circuit monitoring system, and anti-sway control module.

Anode Carbon Block Stacking Crane Gripper

The gripper of the anode carbon block stacking crane is its core component. It features a fully mechanical design and consists of a high-strength alloy steel gripper beam and 19 independent integral grippers, offering three key technical advantages:

- Pure Mechanical Transmission System:

A four-link gravity self-locking mechanism enables opening and closing without any external power supply. An overload protection device is integrated to ensure stable and reliable clamping force. - Optimized Design Features:

Includes ±50 mm adjustable pitch for the integral grippers, a modular quick-change structure, wear-resistant liners with a service life exceeding 50,000 cycles, and a dual anti-loosening safety mechanism. - Outstanding Maintenance Advantages:

Equipped with maintenance-free bearings and visual wear indicators, the design allows independent removal of individual grippers. Average maintenance time is controlled within 30 minutes per unit.

This gripper is especially suitable for the harsh operating conditions of aluminum electrolysis workshops, ensuring safe operation while significantly reducing maintenance costs.

Anode Carbon Block Stacking Crane Working Principle

The anode carbon block stacking crane performs automatic clamping of anode block groups through a PLC control system. First, based on the vertical position data provided by the positioning system, the main winch is controlled to lower the gripper. Once a slack rope signal is detected, the clamping grippers are activated.

The weighing module monitors the carbon block weight in real time and feeds the data back to the PLC. After the load is verified by weight confirmation, the main winch lifts the load to a preset safe height, completing the entire clamping process.

The stacking crane system achieves fully automatic operation with accurate positioning, secure clamping, and reliable weight verification.

Application Fields

The Anode Carbon Block Stacking Crane is widely used in aluminum electrolysis plants and carbon product enterprises. Typical application scenarios include:

- Aluminum Electrolysis Industry: Automated stacking and transfer of anode blocks in anode assembly workshops; warehouse management for spent electrodes and raw anode carbon blocks in electrolysis shops; and serving as a core piece of equipment in intelligent logistics systems for anode block storage facilities.

- Carbon Product Industry: Finished product stacking on prebaked anode production lines, loading and unloading operations in anode baking workshops, and logistics systems for graphite electrode production.

- Special Application Scenarios: Carbon block handling in high-temperature environments (baking areas), operation in corrosive gas environments, and automated warehousing systems requiring high positioning accuracy.