Dafang Crane Overhead Crane Design You Can Rely On: Optimized for Cost, Space, and Compliance

Table of Contents

Designing an overhead crane isn’t just about picking the right equipment—it’s about anticipating challenges before they arise. In this article, you’ll discover how Dafang Crane's engineering team delivers fully customized crane solutions that simplify installation, enhance safety and efficiency, and reduce overall ownership costs. From design philosophy to service capabilities and real-world case studies, we'll guide you through the complete journey—from concept to completion.

Why Overhead Crane Design Matters: Avoiding Unnecessary Spending

Overhead crane design is not just a technical task—it’s the foundation of safety, efficiency, maintenance costs, and long-term ROI. In many industrial facilities, poorly designed cranes lead to wasted space, frequent breakdowns, and costly structural modifications. At Dafang Crane, we take a site-specific approach to every project, offering one-on-one custom design solutions based on your working environment, load requirements, spatial constraints, and regulatory standards—ensuring reliable performance, perfect structural fit, and cost-effective results. Specifically reflected in:

- Reduce plant renovation: customize the hoisting plan according to the structure, eliminating the need for column or steel beam reinforcement.

- Speed up the delivery schedule by completing the drawings within 10+ days or less and putting them into production as soon as possible to minimize losses.

- Energy saving and consumption reduction: reasonable arrangement of motors and structures to reduce energy consumption and improve efficiency

Provide These Details to Get the Right Overhead Crane Design

To get your tailored overhead crane design started, please prepare the following:

Crane Type & Specs:

- Type (single/double girder, grab, hook, casting, etc.)

- Load, span, lifting height, frequency, voltage

Site Information:

- Workshop dimensions (L×W×H), roof clearance

- Obstacle details, track support type

Other Requirements:

- Anti-corrosion/explosion-proof needs

- Whether track exists or must be built

- Remote/onsite survey preference

- Estimated delivery deadline

Not sure? No problem—we offer measurement, evaluation, and expert advice.

Why Choose Dafang Crane Overhead Crane Design?

Choosing Dafang Crane overhead crane design means choosing a partner with:

- Decades of design experience

- Our engineers are licensed, certified, and internationally qualified registered Structural Engineer (China).

- Transparent workflow and engineering integrity

- End-to-end support from consultation to post-installation service

- 22 years in electric hoist and overhead crane design

- With 190+ patents, 160+ technical staff, and a track record of compliance, Dafang Crane ensures every project exceeds expectations, not just meets them.

- Deep compliance with GB, ISO, DIN, FEM standards. For example:

GB/T 3811-2008 《Design rules for cranes》

GB/T 6067.1-2010 《Safety rules for lifting appliances – Part 1: General》

Let us help you design a crane that fits perfectly, operates reliably, and delivers real long-term value.

Our Proven 10+ Day Engineering Design Process

| OVerhead Crane Type | Overhead Crane Structure Design Cycle |

|---|---|

| Ordinary single girder eot crane design (simple class) | 10days |

| Complex single girder overhead crane design and double overhead crane design (general-purpose category) | 15days |

| Non-standard customized class eot crane design (complex class) | 20days |

Take the example of a large square grab overhead crane to help you understand our full design process.

Phase 1: Requirement Discovery & Site Assessment (1–2 Days)

- Analyze key parameters: SWL, span, lifting height, voltage, class

- Identify constraints: obstacles, support type, extreme environments

- Flag risk points: long spans, explosion-proof needs, anti-sway control

Phase 2: Concept Sketch & Layout Plan (1–7 Days)

- 2D layout with safety clearances and rail dimensions

- Structural options (e.g., box-type girder, low headroom designs)

- Preliminary ANSYS simulation for torsional and bending resistance

Phase 3: Structural Verification & Client Confirmation (2–3 Days)

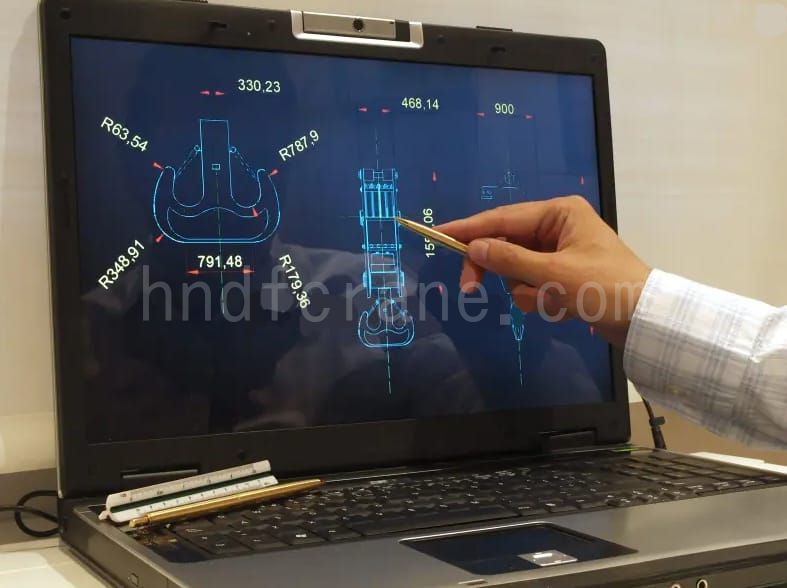

- Full ANSYS finite element analysis of girder stress and deflection

- Provide visual stress maps to enhance client confidence

Phase 4: Final Drawings & Technical Handover (2–3 Days)

- Triple-level design review: engineer, manager, third-party inspector

- Submit 3D BIM models, installation guides, slow-motion test videos

- Invite client to witness 125% SWL load test via live or recorded video

What You Receive: Comprehensive Design & Engineering Package

Our overhead crane design services go beyond basic schematics:

- Full set of structural drawings: main beam, trolley, cart, end beam

- Auxiliary structures: platforms, cages, control cabs, walkways

- Detailed vulnerable parts diagrams and installation guides

- Electrical system blueprints tailored to site voltage

- ANSYS FEA reports verifying compliance and safety

- Optional services: system renovation, remote survey, OSHA inspections

All deliverables are available in paper and digital formats. Overhead crane design strictly follow national and international standards (GB, ISO, DIN, FEM).

Dafang Crane Overhead Crane Design Cases

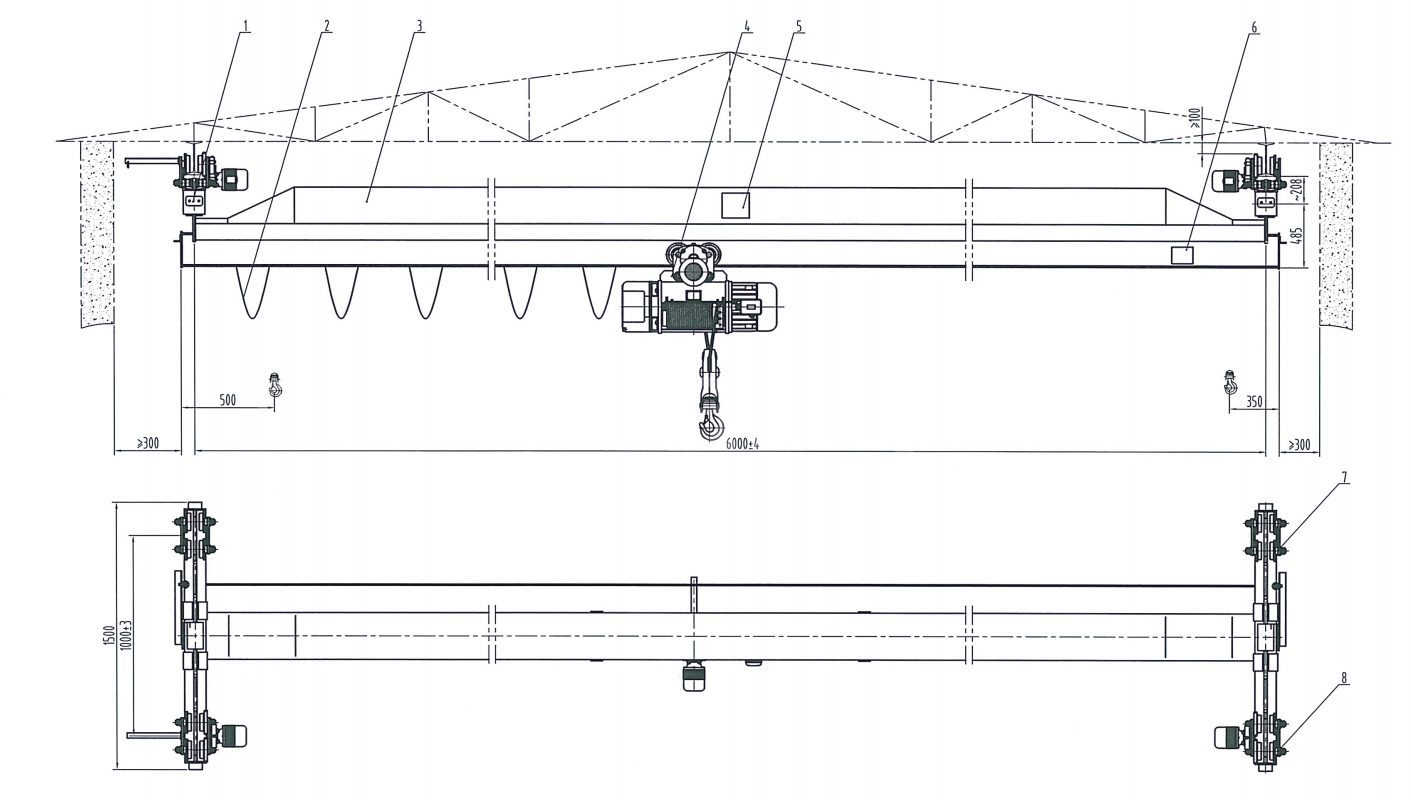

5 Ton Under Running Overhead Crane Design for Thermal Power Project

Challenge: Limited floor space, need to utilize roof steel structure

Project Overview:

This 5 ton under running overhead crane was individually designed by our certified crane engineers for a coal-power integration project at a thermal power plant. Every detail was tailored based on the building's structure, lifting requirements, and environmental conditions provided by the client, including all relevant CAD drawings of components. The basic parameters and factory environment data were carefully collected from the customer to ensure an accurate and customized design.Within just 15 days, our team completed the preliminary design sketches and provided the client with ANSYS finite element analysis to evaluate the main beam deflection, ensuring structural safety and compliance. The entire design process strictly adhered to relevant industry standards, guaranteeing that the final solution met both safety and performance requirements.

Crane parameters:

The crane features a 6-meter span and a 12-meter lifting height, powered by a ZDS 7.5kW dual-speed hoist (0.8/8 m/min) for smooth and precise load control. Travel is handled by compact YCD21-4/0.8kW motors at 20 m/min across both bridge and trolley tracks. Built with a 15mm wire rope and rated for ambient temperatures from -20°C to +40°C, the system was designed for reliable performance in demanding industrial environments.

Design Essentials:

Our engineers selected an under running configuration after a thorough evaluation of the building layout and functional goals. The plant's overhead steel structure provided sufficient load-bearing support, eliminating the need for floor-mounted columns and preserving ground space for operational flow. Given the moderate lifting height of 12 meters and the absence of overhead obstructions, our engineers determined that a ceiling-mounted solution would be the most practical and economical, ensuring optimal use of space and minimizing structural modifications. This decision reflects our design philosophy: tailor the crane to fit the facility, not the other way around.

Design Effects:

No civil remodeling was required, saving costs and keeping the total project cost at a competitive $4,178.This case exemplifies how our professional engineering team delivers reliable, custom crane designs that match each client’s unique working conditions and site constraints, leveraging advanced analysis tools, fast turnaround, and close collaboration with customers.

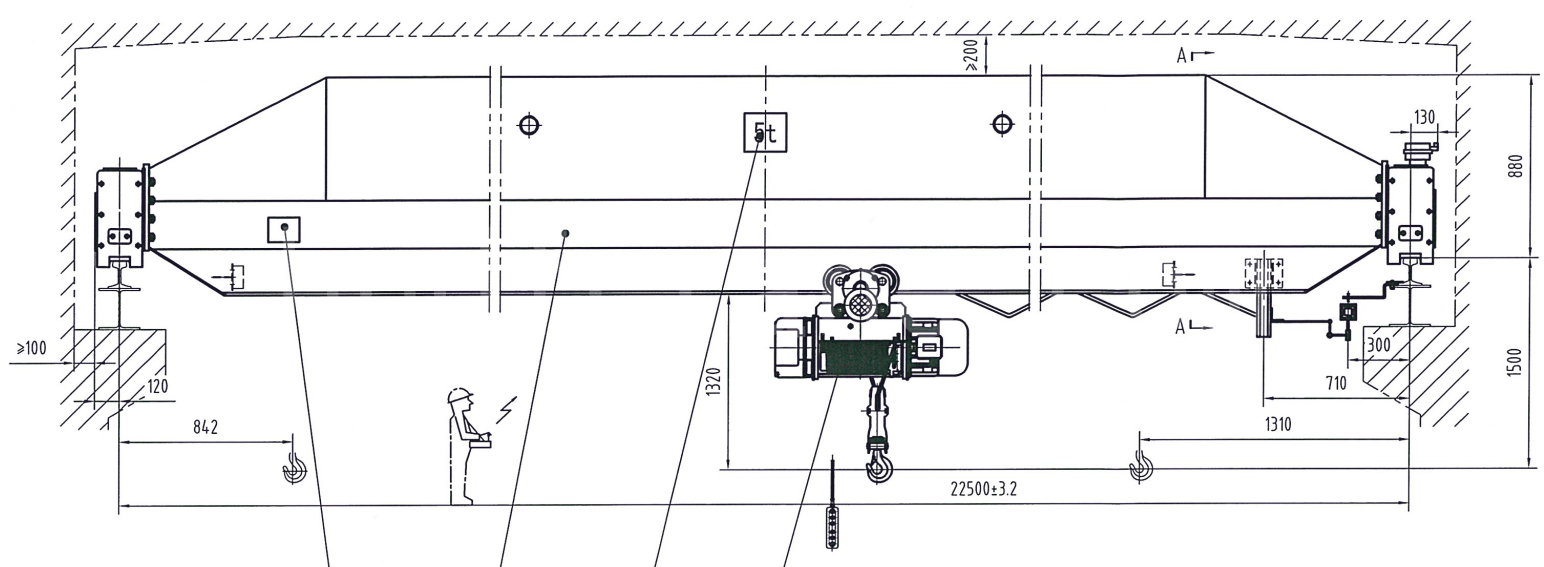

5 Ton Top Running Overhead Crane for Water Plant Expansion

Challenge: Need to maximize hook height to avoid top pipes

Project Overview:

For this project, our licensed crane engineers delivered a tailored top running overhead crane solution specifically designed to meet the operational needs of a water treatment facility. While the equipment zone offered generous floor space and did not require intricate layout flexibility, the client placed high importance on lifting stability, maximum hook height, and efficient use of crane span to accommodate large processing units and overhead pipelines.

The client provided us with detailed CAD drawings, site measurements, and equipment layout data at the start of the project. Based on this foundation, our engineering team quickly developed a custom solution that aligned with both the facility's constraints and the required lifting performance. Within just 15 days, we completed a full preliminary design proposal, including an ANSYS finite element analysis of the main beam deflection to ensure the structure would perform reliably under load.

Crane parameters:

The final crane system features a lifting height of 6.9 meters and is equipped with a 7.5 kW hoisting motor, 15 mm wire rope, and a travel speed of 20 m/min—an optimized combination for stable and efficient operation. The top running design allows the hoist to operate along the upper flange of the main beam, providing superior hook height compared to under running systems. This was essential for navigating over plant structures with minimal interference while maintaining full operational clearance.

Design Essentials:

Through detailed analysis of the building’s vertical space and lifting paths, our engineers identified a top running overhead crane, an up-running structure, to improve rigidity and passage. By utilizing the factory’s overhead load-bearing structure, the design achieves high lift clearance and enhanced system rigidity, avoiding obstruction by ground infrastructure.

Design Effects:

Making full use of vertical space, stable lifting, and reliable performance. This case demonstrates how our engineering team delivers not just standard equipment but complete technical solutions that are responsive to each customer's real-world needs. From early design evaluation to structural simulation and final implementation, we adhere to strict engineering standards while ensuring each project remains practical, efficient, and cost-effective.

Custom Crane Design Is an Investment in Efficiency

From initial site evaluation to the final BIM model and load test, every aspect of Dafang Crane’s design of eot crane service is focused on one goal: creating the best-fit solution for your facility. With fast turnaround, expert engineering, and cost-saving results, our approach is designed to maximize both safety and ROI.

If you’re seeking a bridge crane that aligns with your environment, operations, and business objectives—you’re in the right place.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat