Largest Overhead Crane in the World and Top Heavy Overhead Crane Manufacturers

Table of Contents

The 1300t overhead crane developed by TZCrane is currently the world’s largest overhead crane in terms of single-lifting point capacity. It is used to install million-kilowatt hydropower units at the Baihetan and Wudongde hydropower stations. This project places extremely high demands on the crane’s load-bearing capacity and precision control, representing the advanced manufacturing level of ultra-large overhead cranes. This article will introduce the technical features and application scenarios of the 1300t biggest overhead crane, and discuss outstanding suppliers capable of manufacturing large-scale overhead cranes.

1300T Largest Overhead Crane Introduction

The 1300t overhead crane is currently the world’s largest single-lifting-point overhead crane. It was recognized by the China Heavy Machinery Industry Association as the “2024 World’s Most Advanced Technological Achievement in Heavy Machinery”, marking a major breakthrough for China in the field of large-scale lifting equipment.

This crane is enormous, measuring 31.3 meters in length, 18 meters in width, and 8.9 meters in height. It covers an area larger than a standard basketball court and stands nearly as tall as a three-story building. It truly lives up to its name as a steel giant. With a maximum lifting capacity of 1300 tons, it can easily lift more than 1000 compact cars, showcasing excellent load-bearing strength and precise control performance.

Beyond its impressive capabilities, the largest bridge crane also incorporates multiple technological innovations, representing a key milestone in the advancement of China’s heavy machinery manufacturing.

1300T Largest Overhead Crane Technical Highlights

- A multi-drum, double-fold line, multi-layer winding hoisting mechanism was adopted to resolve the contradiction between extremely large lifting capacity, long lifting height, and compact structure, significantly enhancing the safety of the hoisting system.

- Based on the principle of folded-line winding, a mathematical model for the guide ring's trajectory was established for the first time, improving the operational stability of the equipment.

- A digital prototype of the ultra-large overhead crane was developed, improving both the technical performance and economic efficiency of the crane.

- An intelligent control system for ultra-large cranes was created, enabling regenerative energy and position feedback, precise positioning, automatic deviation correction, and enhancing automation and digitalization levels.

- Breakthroughs were made in the seismic analysis and optimization of the entire crane under large critical loads.

- Integrated technological breakthroughs were achieved in the structural design and manufacturing process of key large components such as the main girders.

1300T Largest Overhead Crane Application

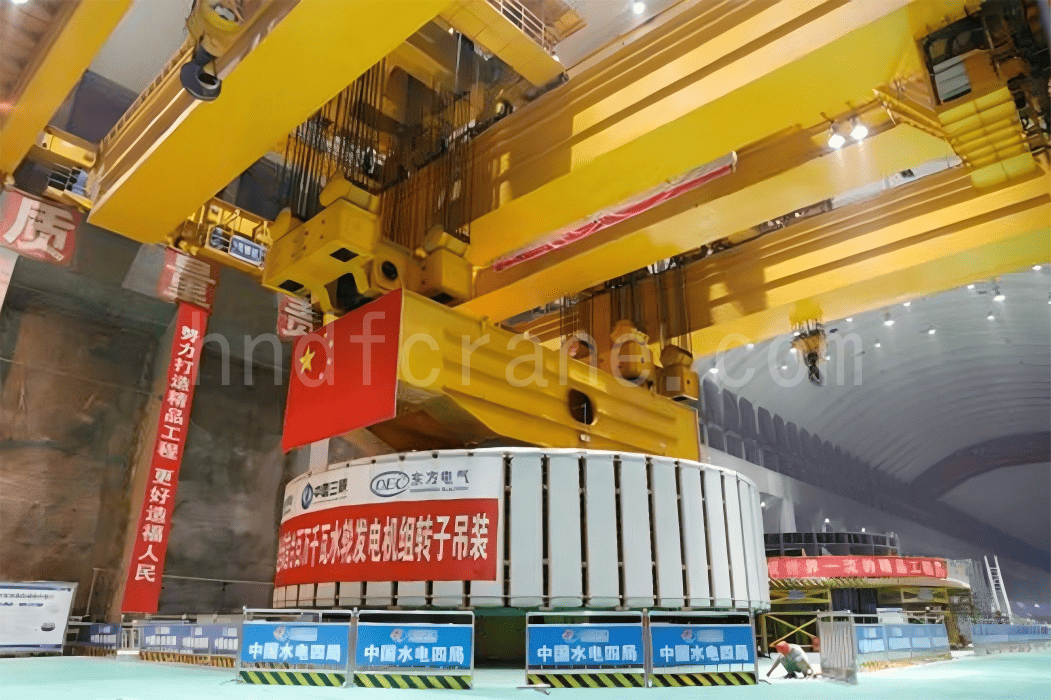

Lifting the Rotor at Wudongde Hydropower Station

Wudongde Hydropower Station ranks as China's fourth largest and the world's seventh largest hydropower facility. The underground powerhouse is equipped with twelve 850 MW hydro-generator units, delivering a total installed capacity of 10.2 GW.

On December 16 and 18, 2019, two 1300t overhead cranes successfully lifted the rotors of the first 7# on the right bank and the first 6# on the left bank, respectively:

- Rotor dimensions: diameter 17.8 meters, height 3.4 meters

- Rotor weights: 1,882 tons and 2,100 tons, respectively

- Technical challenges: complex rotor structural design, numerous assembly procedures, and stringent technical requirements resulted in extremely high installation difficulty

The two 1300t overhead cranes, like the giant arms of a colossal figure, smoothly lifted the rotors and precisely positioned them into the machine pit after 1 hour and 25 minutes.

Lifting the Rotor at Baihetan Hydropower Station

Baihetan Hydropower Station is the world’s second largest, second only to the Three Gorges Project. It is equipped with 16 turbine-generator units rated at 1 million kW each, with a total installed capacity of 16 million kW and an average annual power generation of approximately 62.443 billion kWh.

On June 28, 2021, two 1300t overhead cranes successfully completed the world's first lift of a 1 million kw hydropower unit rotor at Baihetan Station.

- Rotor dimensions: diameter approximately 16.5 meters, height approximately 3.86 meters

- Rotor weight: ranging between 2,300 and 2,440 tons

- The lifting operation was carried out collaboratively by two 1300t overhead cranes to ensure precise and safe installation.

Reliable 1300T Large Overhead Crane Manufacturers

These are large overhead crane manufacturers capable of producing cranes over 1,000 tons. They have strong expertise and reliable quality, leading the industry in heavy lifting solutions.

TZCrane: Heavy Lifting Equipment Experts

TZCrane, established in 1950, is one of the pioneers of China’s heavy equipment manufacturing industry. The company has long focused on the production of large castings and forgings, metallurgical machinery, mining equipment, and heavy-duty lifting machinery. Its products have been exported to over 70 countries and regions worldwide.

In the field of heavy-duty cranes, TZCrane boasts world-class R&D and manufacturing capabilities. It has developed a number of flagship products, including a 500t+500t double-trolley overhead crane, a 550t casting crane, and a 1,300-ton overhead crane. These cranes are widely used in key sectors such as energy, electric power, water conservancy, metallurgy, transportation, and aerospace. Among them, the successful development of the 1,300-ton overhead crane marks TZCrane's entry into the ranks of global leaders in ultra-large capacity overhead lifting equipment.

As China's largest production base for heavy-duty cranes, TZCrane has a comprehensive innovation system and advanced manufacturing platform. It operates a national-level technology center, a post-doctoral research station, and a provincial key laboratory. The company excels in structural mechanics simulation, intelligent control, digital prototyping, and remote operation and maintenance, enabling multi-disciplinary innovation. It is also equipped with large-scale five-face machining centers and heavy-load testing platforms, ensuring precise execution from design to finished product.

WEIHUA Crane: Global Leader in Overhead Crane

Established in 1988, Weihua Crane has grown into a major player in the global lifting equipment industry. With a strong focus on overhead cranes, gantry cranes, port machinery, electric hoists, gear reducers, and bulk material handling systems, Weihua has evolved into one of the world's most recognized crane manufacturers. Its overall capabilities consistently rank among the industry's best.

Weihua has a strong track record in delivering large capacity lifting solutions. The company has successfully developed and supplied the world's first 3,600t gantry crane, China's first 3,000t gantry crane, a 2,500t heavy gantry crane, China's first 1,200t ship-handling crane, and the first 1,000t overhead crane in Henan Province.

Quality lies at the heart of Weihua's operations. The company has built a comprehensive quality assurance system backed by advanced testing facilities. With over 300 sets of testing equipment—including a 1,000-ton load test platform and a 100-ton electric hoist testing rig—Weihua maintains strict quality control across 180 critical checkpoints, from raw material intake to final product delivery. This ensures that every component meets the highest standards of precision and reliability.

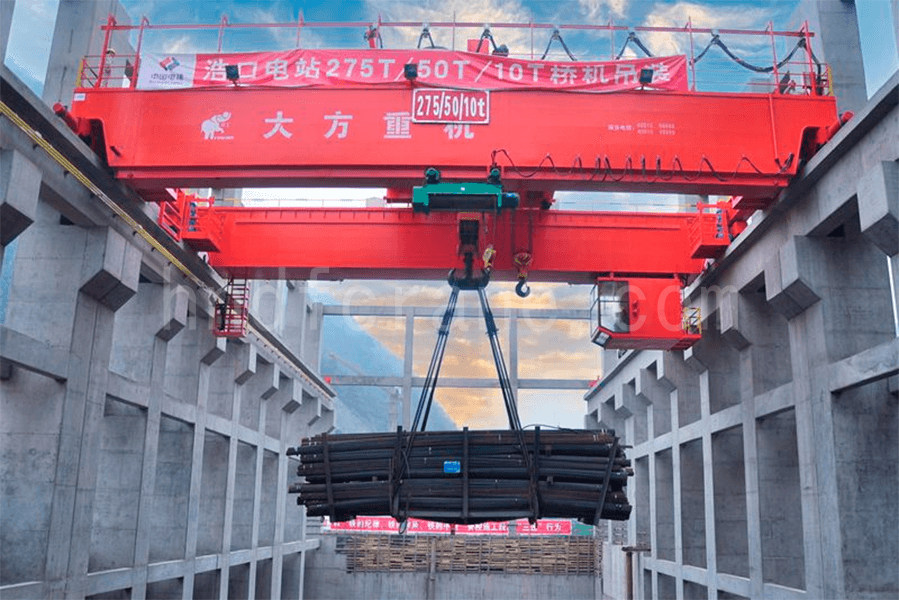

Dafang Crane Large Overhead Crane

Dafang Crane, established in 2006 with a registered capital of 1.37 billion RMB, spans 105 hectares and employs more than 2,600 people. The company specializes in the research, design, manufacturing, and sales of single and double girder overhead and gantry cranes, electric hoists, and related lifting equipment. With a designed annual production capacity of 100,000 units, Dafang exports to over 60 countries and regions, including the United States, Russia, and Southeast Asia.

Dafang has developed a strong portfolio of landmark products that are widely recognized across various industries. These include a 1,600t movable formwork system, 400+400 ton gantry cranes, a 500t beam launcher, 275t European cranes, 225t foundry overhead cranes, 100t slab tong cranes, 100t gantry crane with shield for tunnel boring, and container gantry cranes. Many of these products lead the market in terms of technology and scale.

At the core of Dafang's philosophy is a commitment to delivering high-tech solutions that are safe, efficient, energy-saving, and environmentally sustainable. The company has established advanced workshops for electrical assembly and automated production lines for both single and double girder cranes. By implementing standardized design, modular manufacturing, and a streamlined production management system, Dafang not only guarantees product quality but also effectively controls manufacturing and delivery costs—providing customers with reliable solutions at competitive prices.

Conclusion

This article introduces the technology and applications of the world's largest overhead crane with a single lifting point, along with reliable manufacturers of large-scale overhead cranes, hoping to provide useful insights for you.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat