Small C Hooks

- Composed of the lifting body and counterweight iron.

- Lifting Body: The main part of the C hook is assembled from steel plates and steel pipes, forming a box-type cross-sectional structure. It offers excellent bending and torsion resistance, making the hook lightweight and durable with a long service life.

- Counterweight Iron: Serves to balance the hook, ensuring that the center of gravity of the hook and the lifted object lies on the same vertical line.

- Applications: Mainly used for handling steel coils, coil tempering, warehouse stacking and storage, as well as transportation and loading/unloading. Commonly used in steel plants. Custom designs can be provided based on specific operational requirements.

Double C Hooks

- Composed of the lifting body and connecting rigging.

- Lifting Body: Constructed from steel plates and steel pipes, with a box-type cross-sectional structure. It offers excellent resistance to bending and torsion, making the hook lightweight and durable with a long service life.

- Connecting Rigging: Connects the double hooks on both ends of the beam. The hooks are hung on a grooved steel beam and can be adjusted according to the width of the object.

- Applications: Used for handling horizontal steel coils, with adjustable positioning to accommodate coils of different widths.

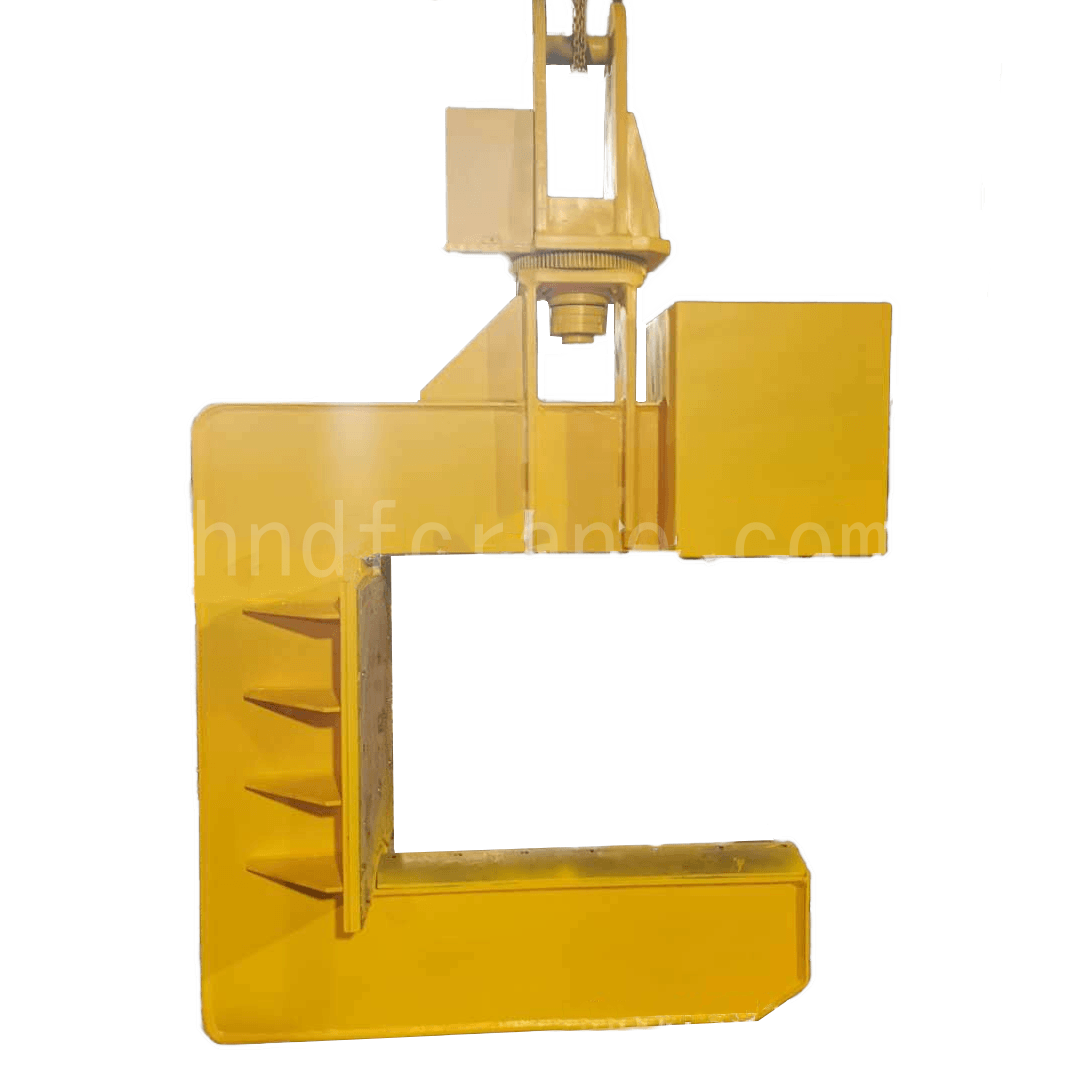

Rotating C Hooks

- Rotatable: Its rotation feature allows steel coils to be rotated at any angle, making loading, unloading, and repositioning more convenient.

- Electric Drive System: Equipped with an electric drive system that enables easy and safe rotation of the steel coils.

- Applications: Mainly used for horizontal lifting of steel coils. Suitable for coil handling, coil tempering, warehouse stacking and storage, as well as transportation and loading/unloading. Custom designs are available based on specific operational requirements.

Narrow Coil C Hooks

- The main body is assembled from steel plates and steel pipes, featuring a box-type cross-sectional structure. It offers excellent resistance to bending and torsion, making the hook lightweight and durable with a long service life.

- Mainly used for horizontal lifting of small-tonnage steel coils, with a load capacity range of 1–3 tons (customization available).

- Lightweight and flexible in handling, easy to assemble and disassemble. This hook is designed specifically for coils with small tonnage and short dimensions.

Fork C Hooks

- Mainly used for horizontal lifting of double steel coils and wire rods, composed of the lifting body and counterweight iron.

- Lifting Body: Constructed from steel plates and steel pipes, featuring a box-type cross-sectional structure. It provides excellent resistance to bending and torsion, making the hook lightweight and durable with a long service life.

- Counterweight Iron: Serves to balance the hook, ensuring that the center of gravity of the hook and the lifted object is aligned on the same vertical line.

- Applications: Widely used in hot rolling and cold rolling workshops of steel mills, and also suitable for lifting horizontal coils in yards, docks, and similar locations.

Crane C Hooks for Wire Rod Coil

- Primarily used for the horizontal lifting and handling of wire rod coils and steel coils. It mainly consists of a lifting body and counterweight iron.

- Lifting body: Made of steel plates and steel pipes, assembled into a box-shaped cross-section structure. It offers excellent resistance to bending and torsion, resulting in a lightweight design with long service life.

- Counterweight iron: Serves to balance the lifting device, ensuring the center of gravity of both the hook and the lifted load aligns on the same vertical line.

- It can be specially designed according to specific application requirements.

Features of Crane C Hooks

- Low cost and easy maintenance.

- Counterweight structure ensures self-balancing during lifting operations.

- Requires specific spacing between steel coils or a defined lifting sequence.

- Hook curvy zones and coatings to avoid damage, under customer's request.

Maintenance of Crane C Hooks

- After use, the C hook must be placed on a designated rack and stored in a well-ventilated, dry, and clean facility under the care of authorized personnel.

- The surface of the C hook should be regularly protected against rust. It must not be stored in environments containing acids, alkalis, salts, chemical gases, or moisture.

- The C hook must not be stored in high-temperature areas.

- Rotating parts should be cleaned regularly, and lubricating oil should be applied periodically to prevent dry friction and jamming.

Application of Crane C Hooks

The crane C hook is a specialized lifting device commonly used for handling coil-shaped materials such as steel coils, aluminum coils, and copper coils. In addition to its primary function of coil handling, the crane C hook also serves in the following applications:

- Handling paper rolls.

- Lifting steel pipes and efficiently loading them into containers.

- Assist in the installation of sewage and flood discharge pipelines