Product Introduction

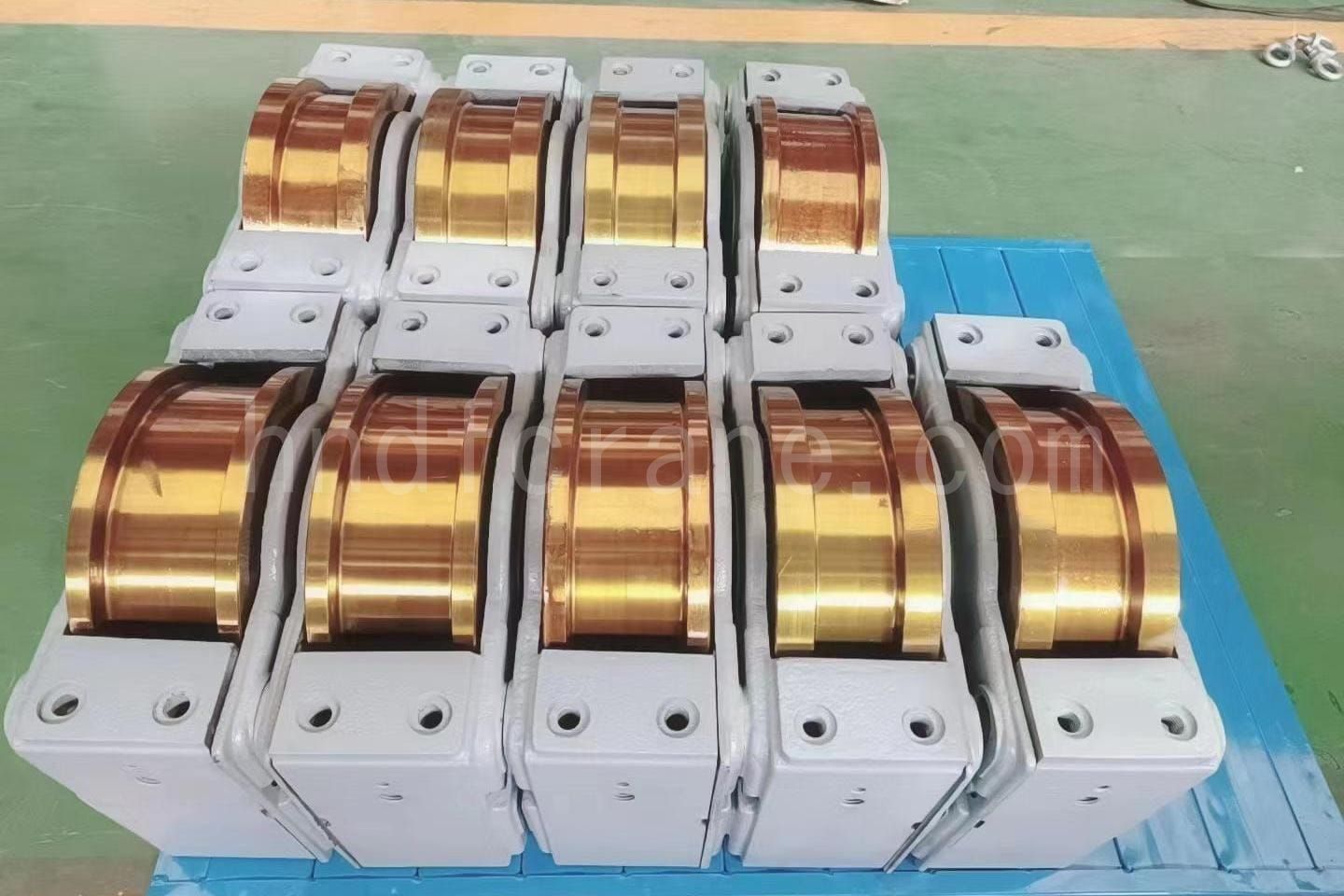

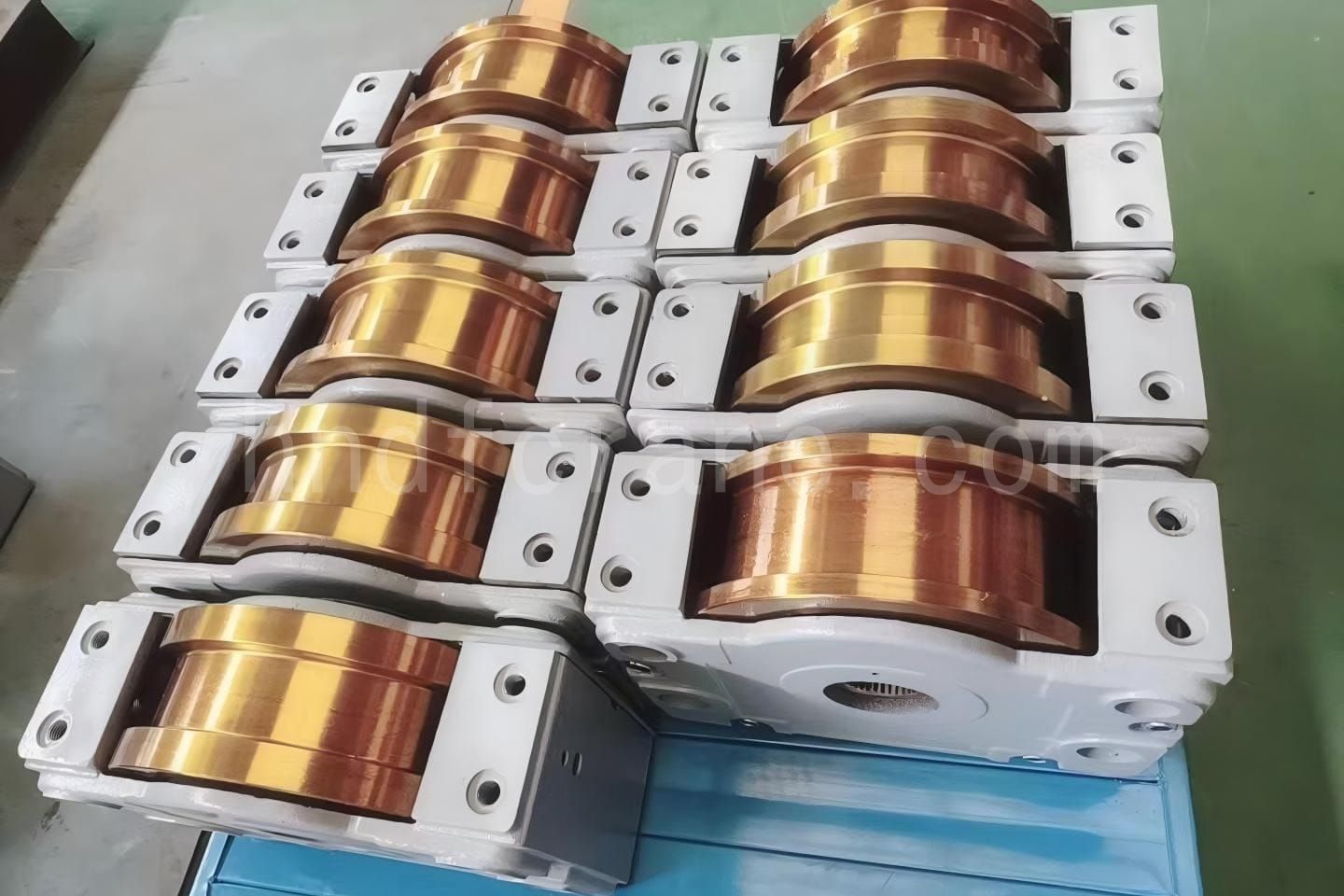

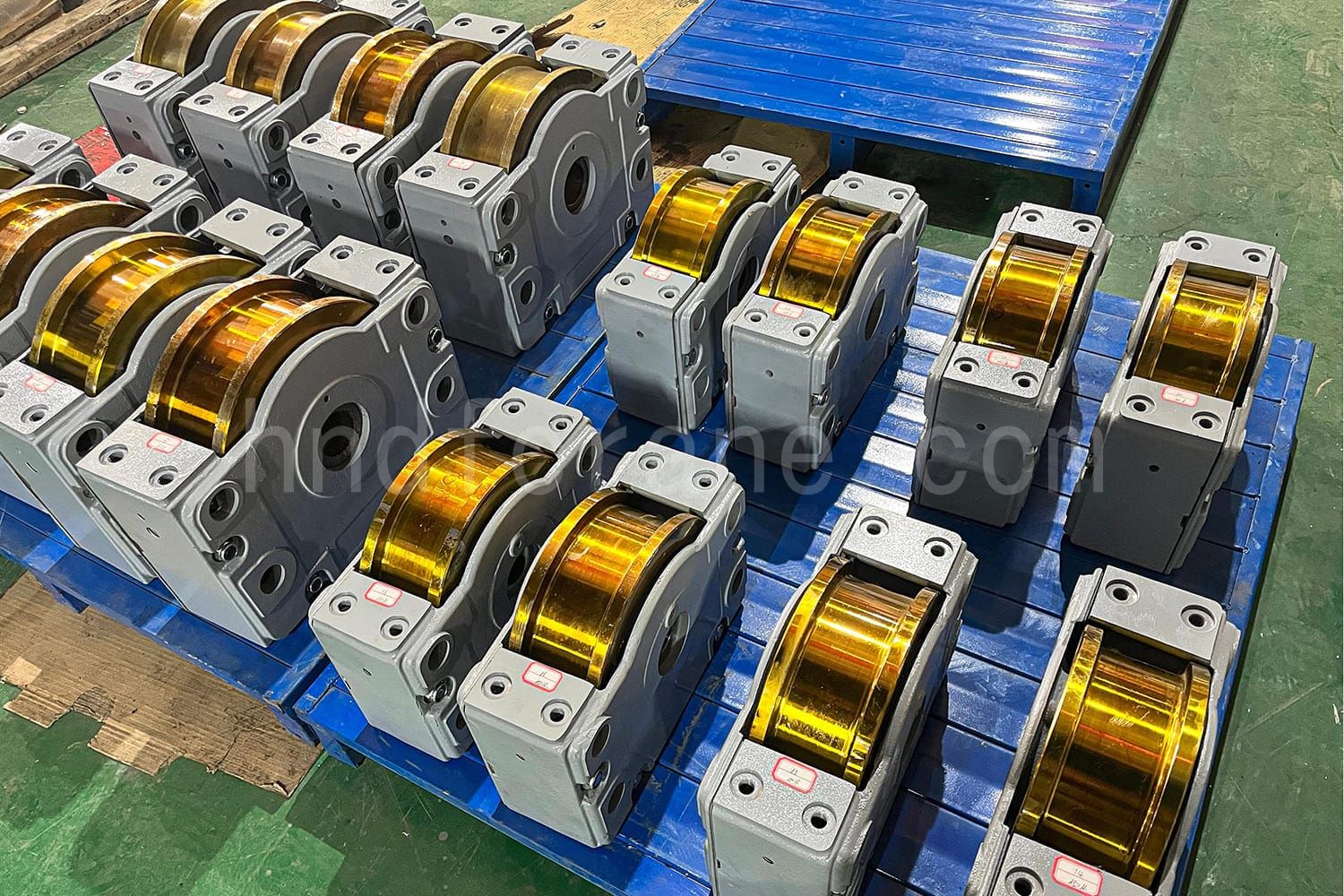

The DRS wheel block is a multipurpose travel wheel system designed for heavy material handling applications. It is available in various models, with single wheel load capacities ranging from 2.75 tons to 40 tons. Featuring a modular design, the DRS wheel block offers advantages such as compact structure, precise dimensions, smooth operation, and easy maintenance. A variety of wheel configurations are available, including double flange, single flange, no flange, and polyurethane wheels, making it adaptable to a wide range of complex operating conditions.

- Double flange DRS Wheel Block: The double flange DRS wheel block is equipped with flanges on both sides of the wheel to provide enhanced guiding capability and effectively prevent derailment. It ensures high running stability and is ideal for applications requiring strict rail guidance, especially under heavy loads or lateral forces.

- Single flange DRS Wheel Block: The single flange DRS wheel block provides lateral guidance through a flange on one side of the wheel. It is suitable for floor-running systems and can also be supplied with a center flange design to meet special application requirements.

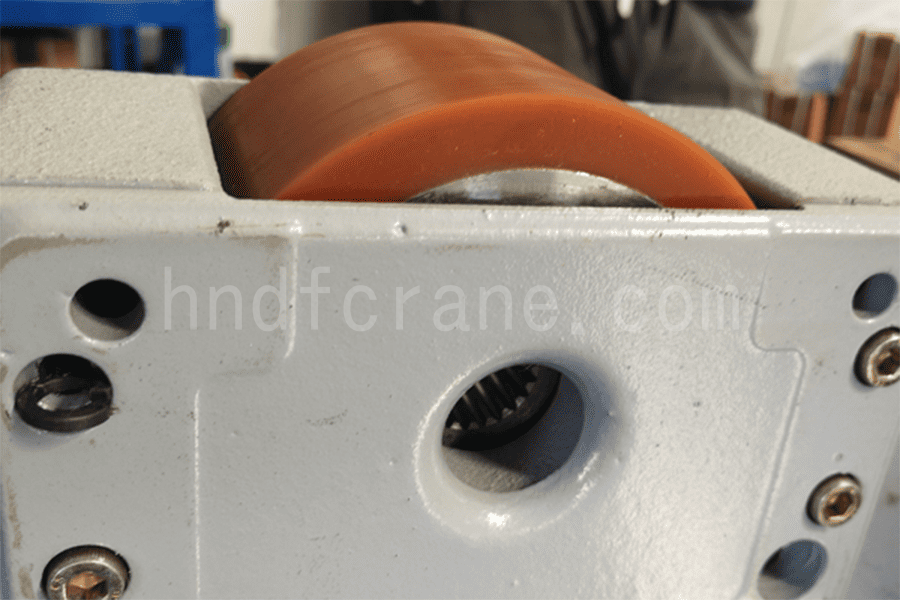

- Flangeless DRS Wheel Block: The flangeless DRS wheel block is designed for use with external guide mechanisms. When necessary, guide rollers can be added to ensure precise directional movement along the designated travel path.

- Polyurethane DRS Wheel Block: This DRS wheel block is fitted with a polyurethane tread, delivering excellent wear resistance, shock absorption, and chemical resistance. It supports low-noise operation and high acceleration, making it suitable for applications where running smoothness, environmental noise control, and dynamic performance are important.

- Polyamide DRS Wheel Block: Constructed with a polyamide wheel, this DRS wheel block features good mechanical strength, low rolling resistance, and reduced track wear. It is ideal for applications that require smooth operation and rail surface protection.

- V-shaped DRS Wheel Block: The wheel is designed with a V-shaped profile to match specific guide rails or track geometries. It provides precise guidance and high directional stability, making it suitable for applications that require defined guiding paths.

The main process for the DRS wheel block system starts with forging the rough wheel blank. Then, it is machined by a high-precision CNC lathe. The CNC lathe is automated and can accurately shape the wheel into different types, such as double-flanged, single-flanged, or flange-less wheels. After machining, the wheels go through a spline rolling process to fit different splined shafts for mechanical transmission. The wheels are then coated with anti-rust oil to prevent corrosion and protect the gearbox during long-term use. Finally, the wheels are installed into the gearbox housing. The housing has special positioning pins to keep screws from loosening and to make the whole gearbox stronger. This design helps the gearbox work well in tough and complex environments.

Features

- Modular design: The DRS wheel block system features a modular structure that simplifies installation and maintenance. Different modules can be combined based on actual needs to meet diverse application scenarios.

- Multiple sizes and models: The system is available in various sizes and models, including DRS112 to DRS500, with load capacities ranging from 2.75 tons to 40 tons. A wide selection of wheel types and profiles is offered, such as spherical wheels, prismatic wheels, and polyurethane-coated wheels, to accommodate different track and working conditions.

- High-strength materials: The wheel blocks are made of high-strength materials such as spheroidal graphite cast iron, providing excellent load capacity and wear resistance. This ensures reliable performance under heavy loads, high speeds, or complex environmental conditions.

- Fully enclosed housing: The five-sided enclosed design protects wheels and bearings from dust, debris, and environmental exposure. The robust housing material improves durability and ensures stable and safe operation.

- Smart monitoring system: An intelligent monitoring system can be integrated to track real-time operating conditions and maintenance status, helping users detect issues early and improve handling efficiency.

- Multiple connection methods: Four types of mounting connections are available, including top connection, pin connection, end connection, and side connection. These options allow flexible adaptation to various equipment structures.

- Easy installation: The unique asymmetrical housing design allows wheel replacement without dismantling the entire wheel block. Optional laser alignment systems are available to eliminate installation deviations.

- Low maintenance: The sealed high-strength housing effectively protects internal bearings and wheel cores from dust, impact, and splashes. High-quality materials and precision manufacturing ensure long service life with minimal wear.

- Customizable options: The wheel tread can be specially hardened to meet high-speed requirements. Optional horizontal guide rollers and buffers are available in various specifications to suit specific applications.

Specifications

DRS Wheel Block Price

Our DRS wheel blocks are available in a variety of models and configurations to suit different load requirements and installation needs. The table below provides an overview of standard model reference pricing. If you have special requirements or need a custom solution, feel free to contact us for a tailored quotation.

| Model | Stock Splines | Trend Width (mm) | Self-Weight (kg) | Max Wheel Pressure (KN) | Price (USD) |

|---|---|---|---|---|---|

| DRS112 | A30 | 60 | 8 | 27.5 | $114 |

| DRS125 | A35 | 60 | 10 | 50 | $119 |

| DRS160 | A45 | 65 | 18 | 70 | $166 |

| DRS200 | A50 | 65 | 35 | 100 | $260 |

| DRS250 | A65 | 75 | 61 | 160 | $401 |

| DRS315 | A65 | 90 | 121 | 220 | $580 |

| DRS400 | A90 | 100 | 214 | 300 | $1320 |

| DRS500 | A90 | 110 | 379 | 400 | $2121 |

DRS Wheel Block Application

The DRS wheel block system is widely applicable to equipment such as overhead cranes, gantry cranes, transfer carts, stackers, shuttle cars, and heavy-duty support platforms.

About Dafang Crane

Founded in 2006, Dafang Crane covers an area of approximately 1.05 million square meters and employs over 2,600 people. The company specializes in the design, research and development, manufacturing, and sales of overhead cranes, gantry cranes, electric hoists, crane components, and steel structures.

Dafang Crane places great emphasis on product quality and has established a comprehensive product testing center. The facility is equipped for non-destructive testing, metallographic analysis, and mechanical and chemical testing. The chemical laboratory features advanced analytical equipment capable of testing multiple elements—such as carbon, sulfur, manganese, and silicon—in raw materials like wheel steel. This ensures that the wheel products maintain stable quality and reliable performance.

Dafang Crane DRS Wheel Block Cases

DRS250 Driving and Driven Wheels Delivered to Bahrain

DRS250 Driving Wheels

- Article Number: DRS 250 A65-A-75-B-X

- Material: QT700-2

- Quantity: 2 sets

DRS250 Driven Wheels

- Article Number: DRS 250 NA-A-75-B-X

- Material: QT700-2

- Quantity: 4 sets

After receiving our quotation, the client spent over a month carefully evaluating the offer. Eventually, their Purchasing Department contacted us to place the order. We prioritized this project and completed production of all wheels within just one week, demonstrating our commitment to fast delivery and efficient manufacturing.

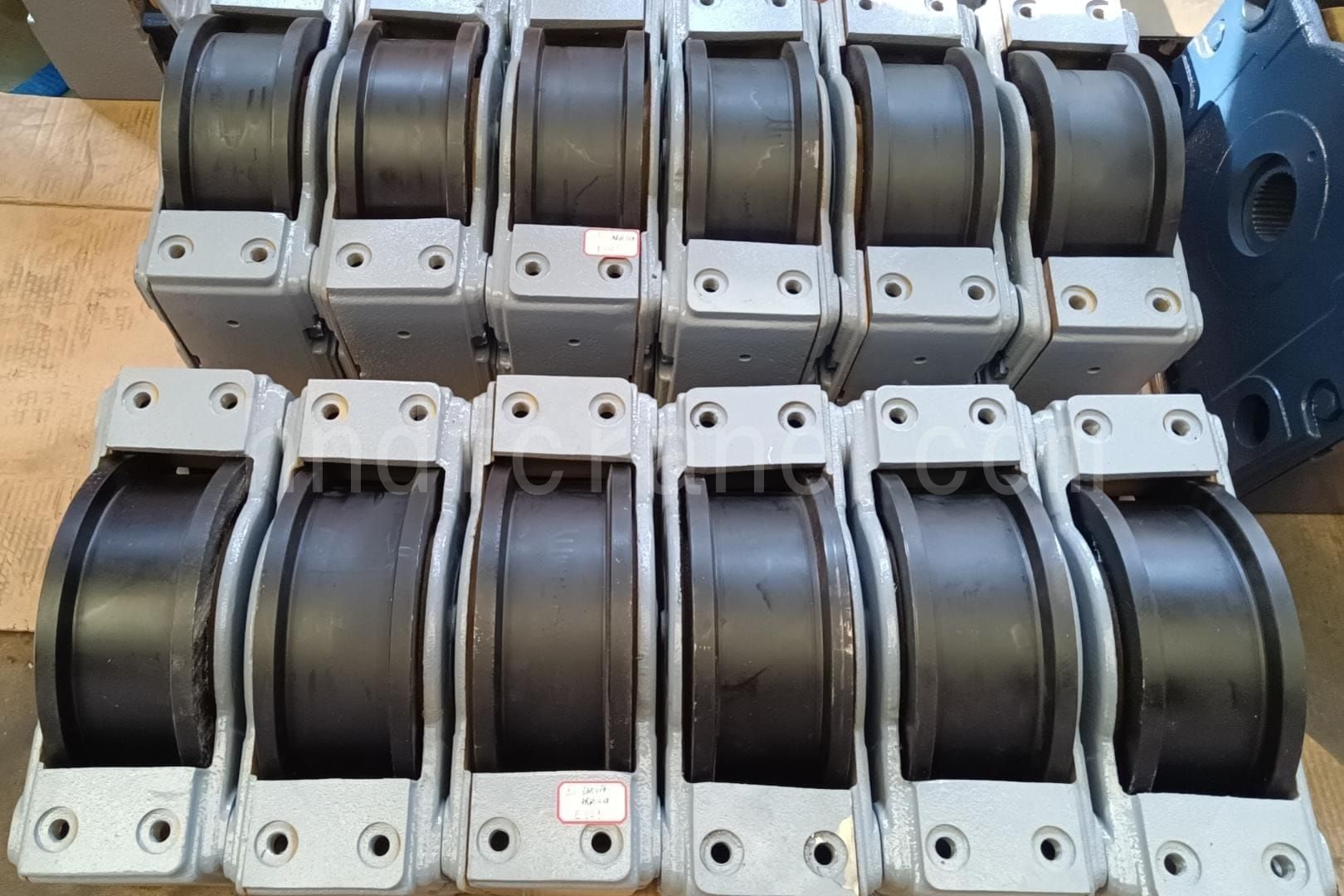

DRS250 Wheel Blocks Delivered to Singapore

- Model: DRS250-A65-A-75-K-X-A50

- Wheel material: 40CrMo

- Housing material: QT500

- Packaging: plywood crates

All wheel blocks were fully assembled and tested before delivery. The 40CrMo forged wheels ensure excellent wear resistance, while the QT500 cast housing provides structural reliability. During shipment, each unit was securely packed to ensure protection against impact and moisture.

DRS125 Wheel Blocks Delivered to America

- Model: DRS125-A35-A60-B-X

- Drive wheels: 4pcs

- Driven wheels:4pcs

- Motor:2 sets

The customer customized the purchase of 4 sets of DRS wheel blocks, which were used to support a compact drive system with flexible installation requirements. In response to the customer's space constraints and motor mounting needs, matching motors, splined shafts, torque brackets, and buffer systems were provided. Custom installation drawings were also prepared to ensure seamless on-site integration. The products were successfully delivered, and customer feedback was positive.