Overhead Crane Wheels Block Assembly Product Introduction

Overhead crane wheels blocks assembly includes various wheel configurations categorized by rim form: double flange, single flange, and rimless crane wheels. The rim plays a critical role in guiding the overhead crane wheels blocks assembly and preventing derailment.

Typically, double flange overhead crane wheels blocks assembly are used for larger wheel diameters, while single flange overhead crane wheels blocks assembly are applied to smaller sizes. During installation, the rim is positioned on the outside of the crane rail. Rimless overhead crane wheels blocks assembly must be equipped with separate horizontal guide wheels to ensure proper guidance and prevent derailment—these guide components are often part of the crane end truck wheels or end carriage wheel assemblies.

According to tread type, overhead crane wheels blocks assembly are classified into cylindrical, tapered, and C-shaped drum wheels. The majority of overhead crane wheels blocks assembly and overhead trolley wheels utilize cylindrical or tapered treads, while C-shaped drum wheels are mostly used on LD single-girder overhead cranes running on the lower flange of I-beams. In trolley configurations, such as overhead crane trolley wheels, centrally driven trolleys typically have a conical active wheel and a cylindrical driven wheel; individually driven trolleys and all small trolley systems (e.g. hoist trolley wheels) use cylindrical treads. When tapered overhead crane wheels blocks assembly are used, they require curved-head tracks and are generally limited to configurations with two drive wheels and two driven wheels.

As for materials, forged crane wheels or forged steel crane wheels are recommended for mechanically driven systems exceeding 30 m/min and rated for medium-duty work or higher. These crane wheel assemblies should use materials not lower than ZG55 cast steel with surface quenching (flame or high-frequency), achieving a hardness of HB320–350 and a hardening depth of no less than 5 mm. For manually driven or low-speed machinery (under 30 m/min), cast iron eot crane wheels or crane rail wheels may be suitable, with hardness levels between HB180–240.

Our company offers a wide range of overhead crane wheels blocks assembly, crane end truck wheels, and customized crane wheel assemblies for various types of cranes, including gear overhead crane wheel assemblies, L block overhead crane wheel assemblies, and European overhead crane wheels. All components are produced using advanced welding and precision machining technologies, ensuring high structural integrity and dimensional accuracy. We also support non-standard customization to meet diverse project requirements and provide reliable, high-performance solutions.

How Much Does Overhead Crane Wheels Block Assembly Cost?

| Model | Drawing No. | Forged Wheel Piece | Idle Wheel Set | Active Wheel Set |

|---|---|---|---|---|

| Φ250 | L754, L755 | $110, $100 | $420 | $440 |

| Φ350 | L756, L757 | $175, $165 | $690 | $740 |

| Φ400 | L758, L759 | $248, $237 | $985 | $1,030 |

| Φ400*130 | L758, L759 | $268, $257 | $1,070 | $1,110 |

| Φ400*150 | L758, L759 | $278, $268 | $1,110 | $1,150 |

| Φ500 | L762, L763 | $400, $390 | $1,590 | $1,675 |

Dafang Crane provides the prices of some overhead crane wheels blocks assembly for your reference. download the PDF below to see more:

If you need more detailed specifications of the overhead crane wheels blocks assembly price, or other categories (end carriage wheel, hoist trolley wheel, crane rail wheels, crane wheel assembly) overhead crane wheels blocks assembly price, please contact us, we have professional engineers to provide you with a 1v1 quotation service.

Overhead Crane Wheels Block Assembly Classification

Detailed information can be downloaded in pdf to view:

Gear Overhead Crane Wheel Assembly

Manufacturing process:

The gear overhead crane wheel assembly is cast from the national standard of 45# steel. The axle is treated by gradient tempering process (hardness HB217-255) and has a built-in oiling channel to achieve low-maintenance operation with deep groove ball bearings; the rim is quenched by dual frequency to form an 8-12mm gradient hardened layer, the tread hardness reaches HB300-380 (10mm depth ≥HB260), the surface triple anticorrosive coating has passed the 2000-hour salt spray test. The standard configuration is 2 active wheels +2 driven wheel sets, long-term compression and wear resistance, good performance.

Features:

- Gear overhead crane wheels blocks assembly innovatively adopts the built-in bearing assembly structure, eliminating the traditional bearing box design and realizing material cost optimization.

- Its modular wheel body is equipped with a maintenance-free bearing chamber (suitable for general models such as 314/412), and the industry-wide use of spare parts is realized through the ISO standard interface, which significantly reduces the cost of the whole life cycle.

- This type of overhead crane wheels blocks assembly should be noted that the integrated design requires professional maintenance support during the gauge calibration phase, and the overall replacement of the wheel set needs to be combined with special disassembly and assembly tooling.

- This type of overhead crane wheels blocks assembly are recommended to purchase the original maintenance tool box to improve maintenance efficiency.

Application:

The gear This type of overhead crane wheels blocks assembly are used in the walking mechanism of single girder overhead crane cart.

Gear overhead crane wheel assembly is used for the end beam of a single girder overhead crane

Gear overhead crane wheel assembly is used for the end beam of a single girder overhead crane

Gear overhead crane wheel assembly is used for the end beam of a single girder overhead crane

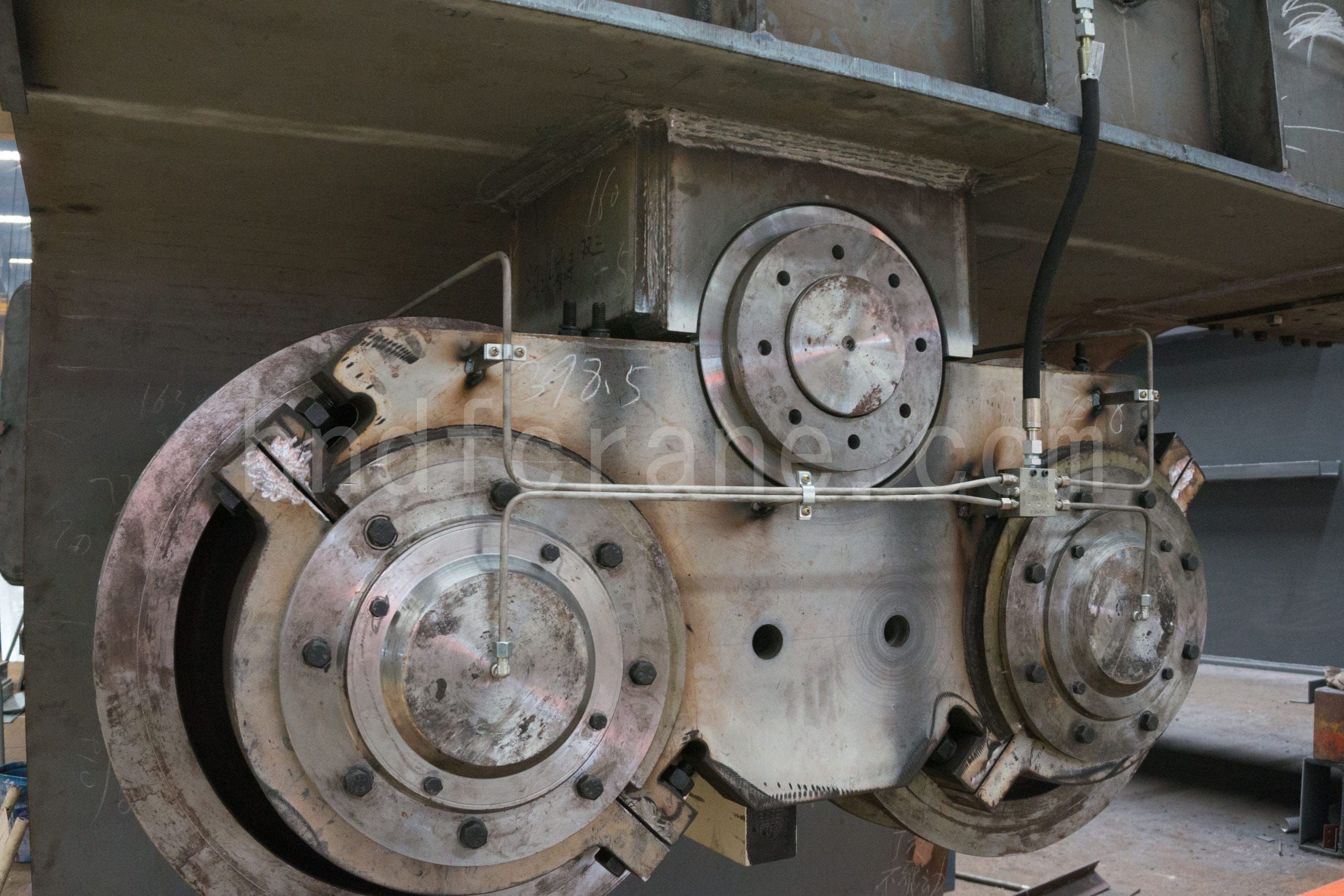

European Overhead Crane Wheels Blocks Assembly

Manufacturing process:

Forged steel overhead crane wheels blocks assembly, forged crane wheels are mainly composed of four parts: axle, wheel, bearing box, and bearing. It is usually made of high-strength alloy steel and heat-treated to improve bearing capacity and wear resistance. In the manufacturing process, more overall boring and milling, and precision assembly processes are used, and some designs are directly connected to the reducer, which requires higher accuracy. Depending on the use scenario, the bearing and box structure are also different. In practical applications, the selection needs to be based on specific working conditions.

Features:

- The overhead crane wheels blocks assembly are light in weight, small in size, and easy to install.

- Forged wheels are mainly composed of four parts: axle, wheel, bearing box, and bearing.

- Due to the need to cooperate directly with the three-in-one reducer, there is no need to connect through a coupling, and the assembly accuracy is high.

- The bearings are imported NSK and SKF bearings, which have a long service life.

Application:

The European overhead crane wheel has been widely used in single girder overhead crane and double girder overhead crane, and has achieved good application results, which have been recognized by many users. Due to the excellent performance of such wheel sets, there will be more and more applications in the lifting industry.

The European overhead crane wheel is used for the beam end of the overhead crane

The European overhead crane wheel is used for the beam end of the overhead crane

The European overhead crane wheel is used for the beam end of the overhead crane

L Block Overhead Crane Wheel Assembly

Manufacturing process:

The L block overhead crane is manufactured using an integral forging process. The key components include overhead crane wheels blocks assembly, and axles, all of which are made of high-strength 42CrMo alloy steel forgings to ensure excellent mechanical properties and fatigue resistance. The bearing configuration is SKF brand roller bearings (model 24040 CC/W33), which have good carrying capacity and operating stability. After the wheel surface is heat-treated, the surface hardness reaches 45-50 HRC, and the depth of the hardened layer reaches 6-8mm, which effectively improves the wear resistance. Usually, the weight of the whole set of overhead crane wheels blocks assembly is about 1800kg, the structure is stable, and it is suitable for heavy-duty working conditions. The surface spraying adopts one epoxy primer and two polyurethane topcoats, the total thickness is controlled at 80–120µm, and the coating scheme can also be customized according to customer needs, taking into account anti-corrosion and aesthetics.

Features:

- L-shaped cranes are often equipped with L block overhead crane wheel assembly, which is designed to withstand heavy-duty and high-frequency operating conditions.

- Its structure allows the installation error to be fine-tuned manually, thereby ensuring the accuracy and operating stability of the overall assembly.

- Considering the relatively long transportation time, our wheels choose wooden box packaging as the packaging material.

- The surface of the wheels is covered with plastic film and wrapped in rainproof cloth.

Application:

Overhead cranes, rail transshipment vehicles ; transportation; rolling mills and aviation vehicles; railway locomotives and trains; construction machinery, etc.

L block overhead crane wheel assembly on heavy duty crane

L block overhead crane wheel assembly is used for the end beam of the double girder overhead crane

45°Split Overhead Crane Wheel

Manufacturing process:

Cast wheels are typically made from high-strength materials such as forged 42CrMo steel, known for its excellent toughness and durability under heavy loads and frequent operation. The overhead crane wheels blocks assembly tread is commonly quenched and heat treated, resulting in a surface hardness of 50–56 HRC, which significantly enhances its wear resistance and extends its operational lifespan.

Features:

- The bearing seat adopts a 45-degree angle split structure, which helps to disperse the contact stress in the operation of the wheel and extend its service life.

- The design optimizes the force distribution, reduces the local stress concentration, and improves the overall durability and structural stability.

- This type of overhead crane wheels blocks assembly can also maintain good operating performance under complex operating conditions such as high temperature, high humidity, and dust.

- The 45-degree split structure facilitates the disassembly, assembly, and replacement of the wheels, effectively reducing the difficulty of maintenance and operation and maintenance costs.

Application:

45°Split overhead crane wheel form end carriage no bolts

45°Split overhead crane wheel installed on the overhead crane

45°Split overhead crane wheel form end carriage installed on the overhead crane

Hoist Trolley Wheels

Manufacturing process:

These trolley wheels feature easy assembly and excellent travel performance, and are made from high-strength materials such as ZG340-640 (CL60) cast steel, alloy steel, carbon steel, and stainless steel. They undergo advanced medium-frequency quenching heat treatment to enhance load capacity, with tread and inner rim hardness reaching HB 300–380. The hardened layer is at least 20 mm deep, with a minimum hardness of HB 260. Certified by ISO, CE, and BV standards, these wheels support OEM customization and come with a 6-month warranty.

Features:

- Such wheels adopt a cylindrical tread structure, which is suitable for supporting flat-bottomed structures such as H-shaped steel and box beams.

- This design helps to reduce the stress concentration when the wheels and rails are in contact, and improves the fatigue resistance of the overall metal structure, thereby improving the reliability of equipment operation.

- Hoist trolley wheels bearing adopts a 45° split structure. First, the half ring of the bearing bracket is welded to the small frame, and then the overall half ring is matched with the round body of the bearing box to verify the assembly accuracy of the wheel set and the horizontal and vertical deflection of each wheel set, and then the wheel set is installed.

- This structure is easy to install and disassemble, has high assembly accuracy, and stable operation.

Application:

Hoist trolley wheels are used for single-beam bridge end beam runway and hoist sports car wheels.

Hoist trolley wheels are used for single-beam bridge end beam runway and hoist sports car wheels

Hoist trolley wheels are used for explosion-proof electric hoist sports car wheels

Dafang Crane Overhead Crane Wheels Block Assembly Cases

European Overhead Crane Wheels Blocks Assembly Exported to Thailand

Detailed specifications:

- Ø400x140mm Forged wheel

- Wheel material: Forged 42 CrMo;

- Surface hardness: 50-56 HRC

- Weight: 340 kg/pcs

A batch of Ø400×140mm european overhead crane wheel was successfully delivered to Thai customers. This type of wheel is made of high-strength forged 42CrMo alloy steel. After advanced quenching and heat treatment technology, the surface hardness reaches 50-56 HRC, and the weight of a single piece is about 340 kg. It has excellent wear resistance and carrying capacity.

In the manufacturing process, european overhead crane wheel uses precision forging and heat treatment processes to ensure stable performance under complex operating conditions such as heavy loads and high-frequency operations. Its cylindrical tread design helps to reduce the contact stress with the track, improve the fatigue resistance of metal parts, and extend the service life.

This type of European overhead crane wheel is widely used in bridge crane equipment with high operating accuracy and stability requirements, especially for european type overhead crane systems, which are commonly used in industrial scenarios such as manufacturing, warehousing, logistics, and heavy-duty processing.

Gear Overhead Crane Wheels Blocks Assembly Exported to Poland

We recently delivered a batch of gear-driven overhead crane wheel assemblies to a client in Poland, designed for use with LD type single girder overhead cranes. These wheels are made from ZG340-640 (CL60) cast steel and undergo medium-frequency quenching heat treatment. The tread surface reaches a hardness of 50–56 HRC with a hardened layer depth of no less than 20mm, ensuring excellent wear resistance and extended service life.

Each assembly is equipped with SKF bearings and Q355B bearing housings, offering a compact structure and ease of installation and maintenance. Prior to shipment, the products were tested using ultrasonic and magnetic particle inspection and certified by BV and other international standards, guaranteeing reliable performance under medium-load, high-frequency operating conditions.

Gear Overhead Crane Wheels Blocks Assembly Exported to the Netherlands

We've completed and shipped a batch of gear-driven overhead crane wheel assemblies to our client in the Netherlands. The products are made from ZG340-640 (CL60) cast steel, with a hardened tread (50–56 HRC, depth ≥20mm) to ensure durability under frequent operation. All components passed ultrasonic and magnetic particle inspections, with BV certification confirming quality. The project was completed on time and is now en route to the Netherlands. Thanks to our client’s trust, this delivery reflects our commitment to reliable, high-performance crane solutions.