Top 10 Russian EOT Crane Manufacturers You Should Know

Table of Contents

The Russian EOT crane market continues to expand as the government prioritizes industrial growth and infrastructure modernization by 2025, driving strong demand across construction, oil and gas, mining, and manufacturing sectors. As essential equipment for heavy material handling and productivity improvement, eot crane russia is playing an increasingly important role in supporting this market growth. With ongoing investments in railways and airports, the demand for high-performance lifting solutions continues to rise.

At the same time, the russian EOT crane market shows a parallel development pattern of import and local manufacturers. Chinese brands in the import market by virtue of cost, production, delivery lead time and customisation ability to be competitive, while geographical and logistical advantages of Chinese products low transport costs, fast delivery; while local russian EOT crane manufacturers are familiar with low temperatures, snow and ice and other extreme climates, better able to provide cranes adapted to local conditions, and equipped with perfect after-sales, certification and parts support. It is based on this market situation; this article focuses on the Russian local and Chinese manufacturers to help industrial customers understand the most competitive crane brands and options.

Top 10 Overhead Crane Manufacturers in Russia

Iteco Crane

Iteco Crane is one of the largest russian EOT crane manufacturers, headquartered in Obninsk, Kaluga region. The company brings together a professional team of engineers and designers to produce high-quality, safe, and reliable lifting equipment — including overhead cranes, gantry cranes, cantilever cranes, and special-purpose cranes of various configurations.

Iteco operates a complete manufacturing cycle, covering design, metal cutting, machining, assembly, painting, and quality control within its own facilities. Its in-house design department uses advanced 3D modeling software to develop customized lifting solutions that meet specific industrial requirements. The company also provides technical services, such as installation, commissioning, maintenance, and spare parts supply.

Iteco's russian EOT cranes are widely used across construction, mining, manufacturing, and logistics sectors in Russia. With a growing focus on automation and modernization, these cranes are known for their durability, operational safety, and adaptability to demanding working environments.

URALKRAN

Uralkran is one of the russian EOT crane manufacturers of lifting and handling equipment, headquartered in Chelyabinsk. Since its founding in 1949, Uralkran has been dedicated to delivering high-quality, reliable crane solutions to clients across Russia and around the world. The company operates the largest design and technical research institute in the industry and maintains two modern production facilities, offering full lifecycle support from equipment selection, design, manufacturing, transport, installation, to after-sales service.

Today, Uralkran supplies russian EOT crane equipment monthly to strategically important facilities in Russia, providing modern domestic cranes capable of operating efficiently in all modes. Its products are widely used in metallurgy, nuclear energy, metal structures and building materials production, aerospace, shipbuilding, and cargo handling, meeting strong market demand for high-performance lifting solutions.

Product quality is ensured by the ISO 9001-2011 (9001-2008) quality management system, and the company continues to expand its production capacity to satisfy growing market needs. Leveraging its technical expertise and human resources, Uralkran can successfully operate across the entire lifecycle of lifting and handling equipment, from design and manufacturing to training and maintenance, helping clients improve operational efficiency and productivity.

NEW TECHNOLOGIES

New Technologies Group is a well-known russian EOT crane manufacturer, with over 80 years of production experience. The company supplies a wide range of lifting equipment for industries that require cargo handling, including industrial production, energy generation, port terminals, and shipyards. Its customers include industrial enterprises, ports, terminals, and shipbuilding facilities. Leveraging extensive resources and technical expertise, the group provides tailored lifting solutions and service programs for enterprises across various sectors.

The product portfolio of New Technologies Group includes electric chain hoists, cranes, rope balancers, hand hoists, trolleys, gantry cranes, loaders, mast stackers, and reach stackers. The company focuses on delivering efficient, safe, and reliable equipment to meet the material handling needs of diverse industrial environments. By combining long-term experience with components from leading global manufacturers, New Technologies Group has become a preferred russian EOT crane manufacturer for many companies in Russia and the CIS.

ЕВРОКРАН

ЕВРОКРАН is one of the leading russian EOT crane manufacturers, headquartered in the Moscow region. Since its establishment in 2009, the company has consistently been rated as “the most recommended crane manufacturer in Russia.” It operates its own production facilities with a complete manufacturing cycle, covering design, metal processing, electrical assembly, and testing—all under one roof to ensure consistent quality.

This overhead crane companie serves over 1,300 industrial clients across machinery, metallurgy, shipbuilding, power generation, construction, and logistics sectors. With more than a decade of experience, the company has delivered over 2,600 cranes and 6,000 electric hoists, establishing itself as a trusted name in the Russian lifting equipment industry.

What sets Eurokran apart is its commitment to reliability, fast delivery, and engineering precision. The company is ISO 9001:2015 certified, and all products comply with GOST safety standards. Its in-house engineering team provides customized crane solutions and modernization services, including automation upgrades and smart control systems.

ЕВРОКРАН’s reputation is further strengthened by its quick production timelines, nationwide logistics network, and up to 5-year warranty coverage. With professional installation and commissioning teams, the company offers a fully managed end-to-end service—from design and production to delivery and on-site setup. Recognized by the Analytic Research Group for its high customer satisfaction, Eurokran continues to set the benchmark for quality and reliability in the Russian crane industry.

СИБКРАН

СИБКРАН, based in Krasnoyarsk, is a well-known russian EOT crane manufacturer for industrial and national economic needs. The company specializes in cranes, electric hoists, and bridge crane platforms, collaborating closely with mining, transport, construction companies, and warehousing facilities. СИБКРАН operates a modern workshop of over 4,000 m² with extensive production equipment, capable of fabricating metal structures of various sizes and configurations, including docks, warehouses, industrial plants, office buildings, exhibition centers, and supporting structures.

This russian EOT crane manufacturer employs multiple metalworking methods, including plasma cutting, manual flame cutting, band saw cutting, sheet bending, semi-automatic welding, and turning & milling. All production processes comply with applicable regulations and standards, supervised by trained professionals, and all staff are certified in safety procedures. СИБКРАН provides customized solutions, adjusting equipment specifications to meet customer requirements, ranging from small components to multi-ton structures. The company also offers installation, maintenance, and full technical support, ensuring safe and efficient crane operation, while cooperating with trusted metal suppliers to guarantee quality and timely delivery.

With extensive experience, a skilled workforce, and advanced technology, СИБКРАН can undertake complex projects and non-standard orders, delivering reliable and efficient lifting solutions. Customers can track production progress and visit the workshop, ensuring transparency and service quality. СИБКРАН’s certifications include TR TS 010/2011, ensuring compliance with safety and technical standards.

ТЕЛЬФЕР

ТЕЛЬФЕР is a well-known russian EOT crane manufacturer with over 12 years of experience in the market. It has established itself as a reliable partner, offering a wide range of bridge cranes, gantry cranes, jib cranes, cable systems, electric hoists, and trolleys, along with professional installation, commissioning, and maintenance services.

ТЕЛЬФЕР’s products are widely used across construction, energy, oil refining, mechanical engineering, metallurgy, and chemical industries, meeting diverse material handling needs. The company designs and manufactures cranes based on customer drawings and technical requirements, ensuring high reliability and stable performance. ТЕЛЬФЕР also provides modernization, repair, seasonal maintenance, and control system setup to ensure long-term safe and efficient operation.

Certified under ISO 9001-2011 quality management system and holding all necessary licenses and permits, including SRO and NAKS, ТЕЛЬФЕР delivers full-cycle services from design and manufacturing to installation, maintenance, and modernization. Its team of skilled specialists offers professional consultation to help clients select the most suitable crane solutions and ensures competitive pricing based on market conditions.

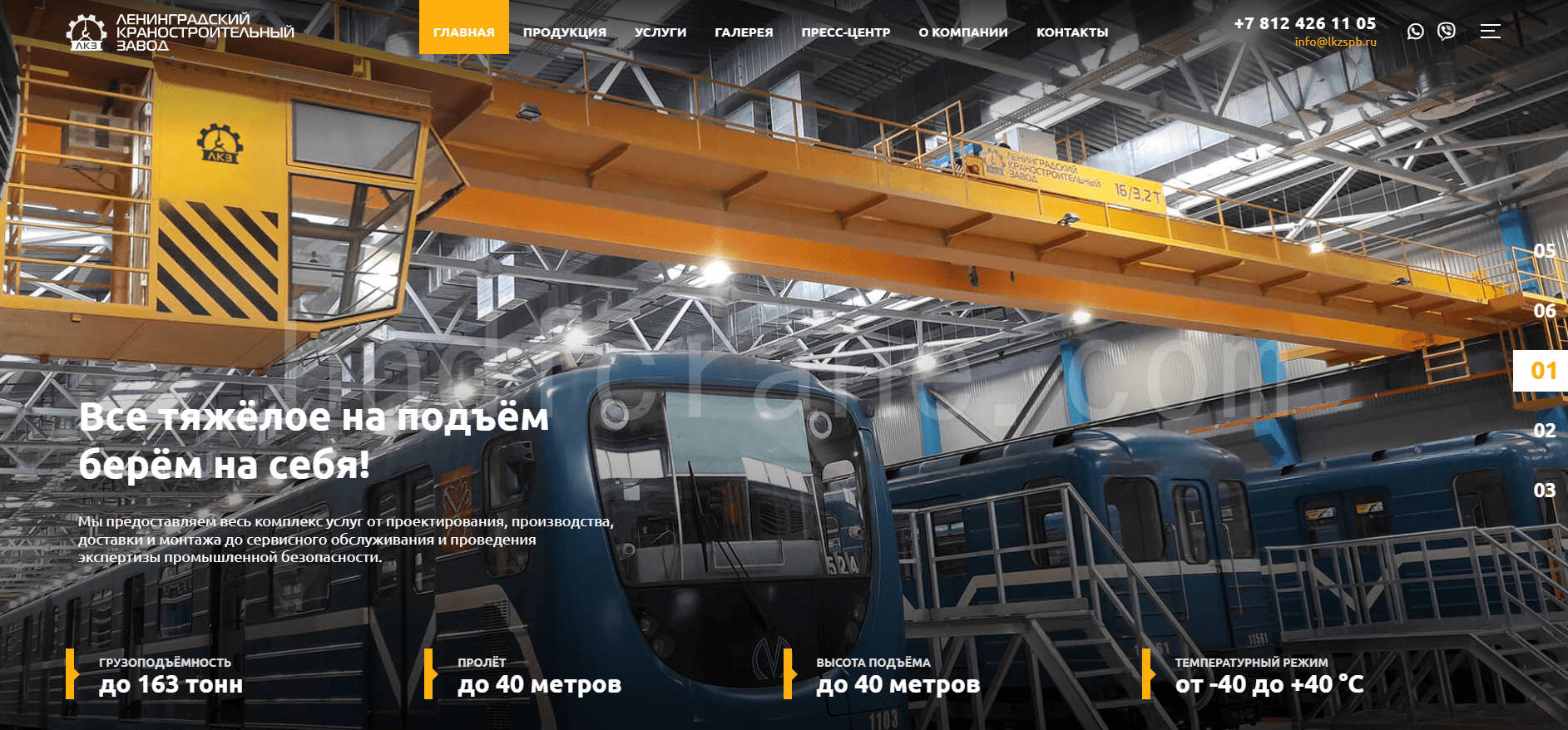

ЛЕНИНГРАДСКИЙ КРАНОСТРОИТЕЛЬНЫЙ ЗАВОД

Ленинградский краностроительный завод is a well-known russian EOT crane manufacturer with a strong market presence in Russia and neighboring countries. The company offers a wide range of equipment, including bridge cranes, gantry cranes, semi-gantry cranes, jib cranes, and cranes for railway transport applications. The equipment is recognized for its durability, reliable operation, and high performance, and is widely used across various industries.

In addition to manufacturing, Ленинградский краностроительный завод provides continuous equipment maintenance and technical support to ensure long-term stable operation. This russian EOT crane manufacturer emphasizes cost efficiency, maintaining high quality while keeping prices affordable for clients. With a professional team, diverse product selection, customized design capabilities, excellent technical service, and short lead times, Ленинградский краностроительный завод has established itself as a trusted and popular partner in the Russian crane market.

АО «Великолукский опытный машиностроительный завод» Торговая марка VELKRAN

Великолукский опытный машиностроительный завод, founded in 1981, has been the largest Northwestern russian EOT crane manufacturer. The factory is known for VELKRAN brand cranes, STEELBEAR trailers and agricultural machinery, and Arsenalum automated warehouse equipment, while also producing customized solutions based on client drawings or specifications. With over 20,000 m² of production space and more than 500 skilled professionals, Великолукский опытный машиностроительный завод combines strong manufacturing capacity with a flexible in-house design team to meet a wide range of client-specific requirements.

Великолукский опытный машиностроительный завод products are recognized for their high quality, durability, and reliability, earning strong customer trust in the market. The factory’s long-term expertise enables it to handle major overhauls, complete and large-scale repairs, single-part manufacturing, modernization, and installation projects. Production processes cover metal inventory and laboratory management, mechanical and thermal processing, welding and weld inspection, electrical assembly, control system testing, painting and packaging, transportation and installation, and utilize advanced equipment such as Yamazaki Mazak multifunctional machines from Japan to ensure quality and efficiency.

By delivering high-quality lifting equipment, Великолукский опытный машиностроительный завод has established a stable brand reputation, strong competitiveness, and reliable lifting solutions for clients across Russia.

Gruzopodyem

Gruzopodyem is a renowned russian EOT crane manufacturer and auxiliary technological equipment, with over ten years of industry experience. The company's headquarters and production facility are located in Kazan, and it operates a certified non-destructive testing laboratory to ensure that all equipment meets high-quality standards and the Technical Regulations of the Customs Union. The product range includes cranes and attachments, auxiliary technological equipment, equipment for the oil and gas industry, welding rotators, explosion-proof devices, and crane spare parts, with general industrial, fireproof, and explosion-proof versions.

As a leading domestic manufacturer, Gruzopodyem supplies major Russian enterprises, including Severstal, Uralkali, RUSAL, STFC KAMAZ, ALROSA, Tatneft, VSMPO-AVISMA, Danieli-Volga, and exports to CIS countries. The company's greatest value lies in its cohesive, skilled, and experienced team. Many employees have worked over 5-7 years, continuously improving their expertise in lifting equipment, which ensures reliability, fast order fulfillment, and high-quality production. Gruzopodyem places strong emphasis on human resources, considering team stability a key driver for progressive development.

БИЗНЕС КРАН

Бизнес Кран is a well-known russian EOT crane manufacturer, offering design, supply, installation, and maintenance services across Russia, the CIS countries, as well as Europe and Asia. The company focuses on providing efficient and reliable crane solutions to support automation in various industrial and warehousing operations, enhancing client profitability.

Бизнес Кран collaborates with leading international component manufacturers to ensure quality and advanced technology. Its supplied products include CARIBONI (Italy) conductor systems, NANTE (China) conductor systems, STAHL CRANE Systems GmbH (Germany) electric hoists, SKLADOVA TECHNIKA (Bulgaria) electric hoists, ELMOT (Bulgaria) electric hoists, EUROLIFT warehouse and lifting equipment, and TELEKRANE (Taiwan) radio controllers. With a highly qualified expert team, the company provides development, design, manufacturing, installation, and full lifecycle maintenance across Russia, ensuring safe, efficient, and reliable crane operation.

Emphasizing customer experience, Бизнес Кран delivers affordable pricing, fast delivery, and excellent service. Equipped with modern machinery and a professional workforce, the company achieves outstanding results in bridge cranes, jib cranes, and gantry cranes, earning trust from clients both domestically and internationally.

Market Overview: Chinese EOT Crane Manufacturers in Russia

In recent years, Chinese EOT crane manufacturers have gradually expanded their presence in the Russian market, responding to the country's steady demand for modern and cost-effective lifting equipment. With the modernization of Russia's industrial infrastructure and the replacement of outdated machinery, Chinese-made overhead and gantry cranes have become increasingly visible across various sectors. Brands such as Kuangshan, Weihua, and Nucleon have introduced a range of cranes that combine international safety standards, efficient production cycles, and customized design options, catering to the diverse lifting requirements of Russian clients. Their integrated service systems—covering engineering design, manufacturing, logistics, and after-sales support—have helped simplify procurement for both distributors and end users.

While the russian EOT crane industry remains competitive, Chinese suppliers are increasingly recognized for their reliable performance and value-driven solutions. Their growing participation not only enriches the local supply landscape but also offers Russian enterprises a wider choice of modern lifting technologies.

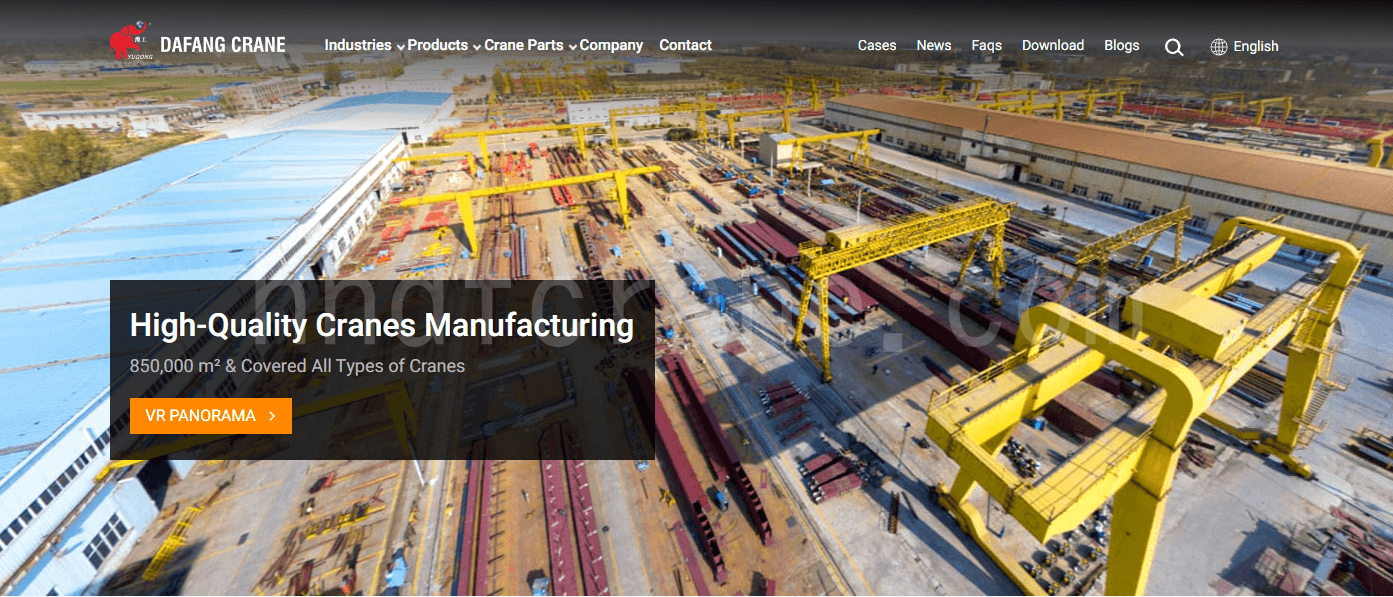

Dafang Crane in Russia: Delivering Reliable and Custom Made Overhead Crane Solutions

Dafang Crane is a top 10 EOT crane manufacturer in the world and a leading Chinese crane manufacturer with comprehensive testing and production capabilities, serving customers globally, including Russia. The company is equipped with advanced inspection equipment, such as nondestructive testing, metallographic analysis, hardness and mechanical testing, and chemical analysis, as well as modern production machinery, including 1500t press beveling machines, shot blasting machines, plasma cutting machines, submerged arc welding machines, and boring & milling machines.

Dafang's manufacturing licenses cover all types of cranes: gantry cranes, semi-gantry cranes, bridge cranes, jib cranes, electric hoists, casting cranes, engineering cranes, and beam handling machines. With a large factory area, diverse product range, fast delivery, and competitive pricing, Dafang has become one of the most competitive crane manufacturers in the global market.

The company produces over 70,000 cranes annually on more than 850,000 square meters of production space, exporting over 31,500 cranes per year to more than 110 countries. A dedicated R&D team of 300 engineers develops intelligent crane solutions, including driverless bridge cranes, battery-powered transfer carts, fully automated slag grab cranes, AGV trolleys, and double-girder jib cranes, addressing diverse industrial applications.

Dafang emphasizes high-quality production and reliability, with steel pre-treatment, comprehensive shot blasting, precise welding, lightweight yet durable design, pre-installed electrical components, and strict quality checks at each stage. The company also provides rapid delivery, flexible transportation, spare parts availability, and on-site installation and maintenance within 48 hours, making it well-suited for the Russian market where reliability, service, and timely support are critical.

Dafang Crane Overhead Crane Projects in Russia

European Type Overhead Crane Delivered to Russia

Application: Port-side handling – fitting a long-span crane into limited transportation options

Lifting capacity: 7 tons

Span: 14.2 m

Notes:

- Customer required the main beam to remain uncut.

- Port of Vladivostok is only serviced by container vessels; initial shipping options were limited.

- Alternative bulk carrier transportation was arranged successfully.

- Factory completed production within one month; a dedicated truck was arranged to ensure timely delivery during the Chinese New Year.

LD Overhead Cranes Delivered to Russia

Application: Assembly operations of the warehousing and logistics center

Capacity: 12.5 tons

Span: 14.5 m

Notes:

- Two sets were loaded into one 40ft container.

- Design modified several times to meet client’s precise size requirements.

- Client satisfied with final offer and professional discussion, resulting in order confirmation.

Single Girder Overhead Cranes Delivered to Russia

Application: Handling heavy components in assembly and production areas

Capacity: 16 tons

Span: 16.5 m

Notes:

- Production completed and product/package images shared with client; client satisfied with product and service.

Import vs. Local: Which Option Is Better for You?

The Russian EOT crane market is highly competitive, with both domestic and international manufacturers serving industrial clients.

Chinese manufacturers such as Dafang Cranes stand out for their advanced technology, strong production capacity, and expertise in intelligent lifting systems. Their cranes operate reliably in low-temperature and harsh industrial environments, making them a preferred choice for manufacturing and warehouse projects that demand precision, automation, and customization.

Local Russian manufacturers, on the other hand, specialize in rugged cranes tailored to regional conditions. They typically provide fast after-sales service, on-site maintenance, and flexible financing options. Their products comply with Russian certification standards and are well-suited for projects requiring local support or quick service turnaround.

In short:

- Choose imported cranes (e.g., from China) for technological advancement, smart operation, and customized requirements.

- Choose local cranes for quick service, local certification, and projects in remote or extreme-climate regions.

Additionally, many construction, manufacturing, and logistics companies are turning to leasing models to reduce upfront investment and improve flexibility. When deciding between imported and local cranes, it's essential to balance performance, cost, service support, delivery time, and operational flexibility according to project needs.

Conclusion

The russian EOT crane market offers a wide range of options for buyers. Top 10 local russian EOT crane manufacturers produce durable, cost-effective cranes suited to regional conditions, with fast delivery, professional after-sales service, and Russian certifications, making them reliable for projects that require local support.

Chinese manufacturers, such as Dafang Cranes, offer advanced technology, enabling cranes to operate efficiently even in low temperatures and harsh conditions, with flexible designs and competitive pricing. These solutions are especially suitable for high-tech, heavy-duty, or customized applications.

When deciding between imported and local cranes, buyers should consider lifting capacity, operating environment, delivery schedule, service support, and leasing flexibility. Many find that combining both options works best: local cranes for routine operations and certified projects, and Chinese imports for specialized, high-precision, or cost-sensitive tasks.

By understanding the strengths of both local and Chinese manufacturers, buyers can make informed decisions and select the crane solutions that best match their operational needs.

Send Your Inquiry

- Email: sales@hndfcrane.com

- WhatsApp: +86 191 3738 6654

- Telegram: +86 191 3738 6654

- Tel: +86-373-581 8299

- Fax: +86-373-215 7000

- Add: Changnao Industrial District, Xinxiang City, Henan Province, China

WeChat

WeChat