Port Crane Wheel Block Assembly Introduction

Port cranes typically operate under high loads and frequent start-stop conditions. Their wheels are generally heavy-duty, made from high-strength alloy steel and reinforced through specialized heat treatment processes to ensure excellent compressive strength, wear resistance, and fatigue resistance.

Main types of port crane wheels include L block, 45° split bearing box, and European wheel assemblies. These wheel types are suitable for the following common types of cranes used in ports.

Port Crane Wheel Block Assembly Classification

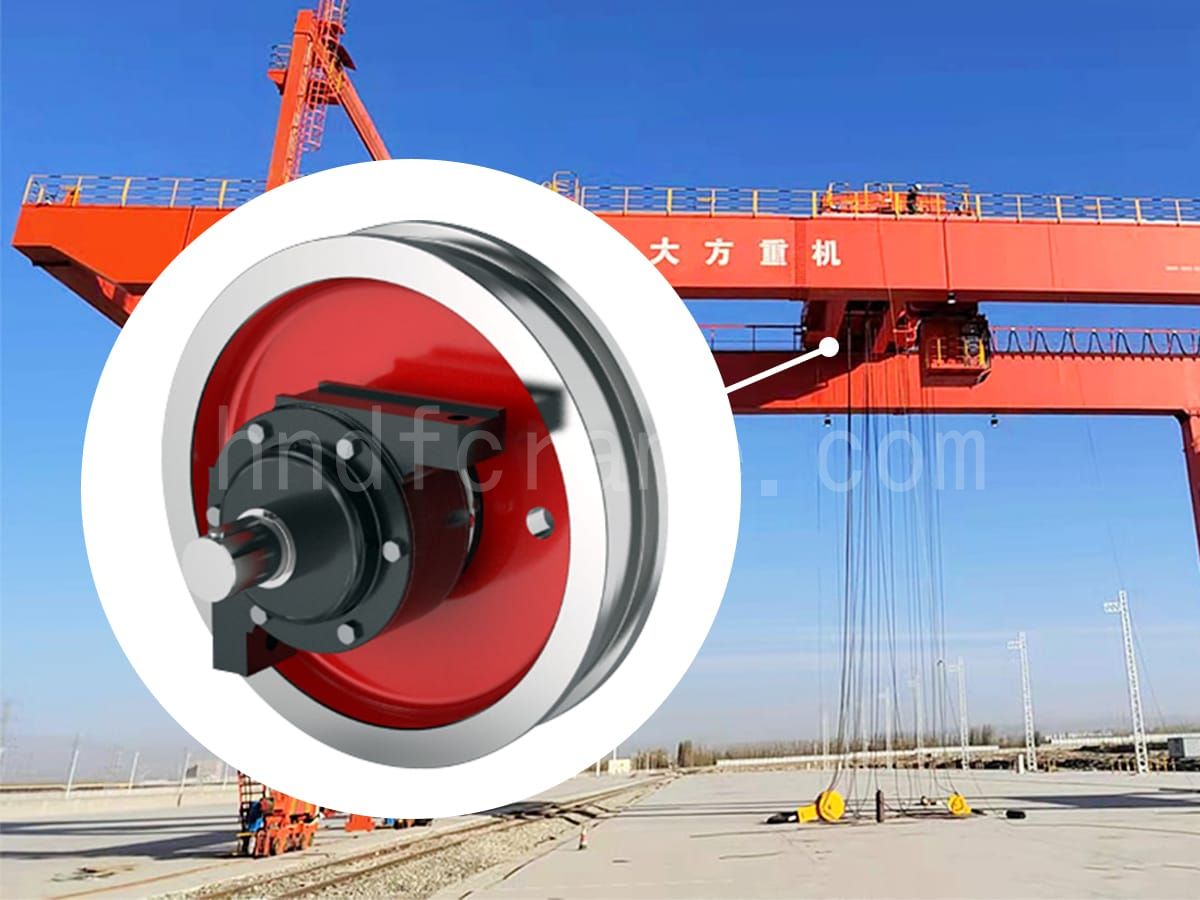

European Crane Wheel Assembly

European crane wheel assemblies have high material requirements, feature smaller wheel diameters, and reduce the overall height of the equipment. They also require high machining precision, with accuracy completely determined by the equipment itself.

Structure

The European crane wheel assembly mainly consists of four parts: wheel shaft, wheel rim, bearing housing, and bearings. European wheels require the wheel diameter to be as small as possible. They generally adopt a structure where the bearing housing is mounted onto the web plate of the frame. The bearing housing is connected to the frame with fasteners and bears a relatively large wheel load, requiring high material strength and assembly precision.

Features

- Lightweight, compact, and easy to install.

- Commonly use forged wheel rims, consisting of wheel shaft, wheel rim, bearing housing, and bearings.

- Designed to directly match with the integrated three-in-one gear motor, eliminating the need for couplings, which demands extremely high assembly precision.

- The wheel shaft is made of 40CrMo. After rough machining, it undergoes quenching and tempering treatment, with a hardness of HB300.

- The wheel rim is made of forged 42CrMo, interference-fitted and connected to the shaft with a flat key. It is also quenched and tempered, with a hardness of HB300 to HB380.

Application

European wheel assemblies feature a compact structure and smooth operation. They are commonly used in trolley travel mechanisms and whole-machine travel systems of port cranes, especially in applications requiring high running precision and easy maintenance. These wheel assemblies are easy to install and replace, capable of withstanding frequent start-stop operations and prolonged heavy-duty service, significantly improving the overall operational stability and reliability of port cranes.

L Block Crane Wheel Assembly

The L block crane wheel assembly is the preferred type. It has a simple manufacturing process, and the wheel alignment is manually adjusted to fully ensure precision and performance.

Structure

The L Block wheel assembly mainly consists of four parts: wheel shaft, wheel rim, L Block bearing housing, and bearings. The bearing support of the wheel assembly adopts an L Block structure, in which the L Block is fixed to the trolley frame or to the bent plate of the main girder end beam using bolts. This structure allows the wheel to be adjusted during use or maintenance to ensure both horizontal and vertical alignment of the wheel, thereby preventing rail gnawing caused by wheel misalignment.

Features

- Simple manufacturing and processing, low cost, widely used.

- Manual adjustment of installation errors to meet precision requirements; installation accuracy is greatly affected by manual operation.

- Many wheel assembly parts and large overall weight.

- Heavy wear and tendency for rail gnawing under heavy and frequent working conditions.

- When replacing the wheel assembly, the positioning key plate needs to be cut open and re-welded after readjustment, which requires a large amount of on-site welding work, reduces maintenance efficiency, and increases the time needed to replace the wheel assembly.

Application

The L Block wheel is simple to manufacture and is widely used in the running mechanism and trolley travel mechanism of port cranes. With strong load-bearing capacity and stable operation, it can adapt to the high-frequency, heavy-load working environment of port equipment. It is a key component to ensure the efficient and reliable operation of cranes.

45° Split Bearing Box Crane Wheel Assembly

The 45° split bearing box crane wheel assembly has a relatively complex manufacturing process. It requires integral machining of the end beam and features high machining precision. The wheel alignment is controlled through equipment-based machining, and the wheel assembly is relatively easy to disassemble.

Structure

The 45° split bearing box crane wheel assembly mainly consists of four parts: wheel shaft, wheel rim, 45° split bearing box, and bearings. The bearing support of the wheel assembly adopts a 45° split structure. The half-ring of the bearing box is first welded onto the trolley frame or the end beam of the main girder. Then, the matching surface between the half-ring and the circular part of the bearing box is integrally machined, which ensures the assembly accuracy of the wheel and the horizontal and vertical alignment of each wheel. After that, the wheel assembly is installed. This structure allows for convenient installation and disassembly, high assembly precision, and stable operation.

Features

- High machining and assembly accuracy, good overall integrity, convenient disassembly and maintenance, reducing maintenance time and cost.

- More even load distribution on the wheel, reducing local stress concentration and improving the durability and stability of the wheel.

- The manufacturing process is relatively complex, requiring integral machining of the end beam, with higher processing cost.

Application

The 45° split bearing box crane wheel assembly adopts an angled 45° split design, allowing wheels to be replaced and maintained quickly without disassembling the entire machine. This design balances structural strength and assembly flexibility. It is widely used in the trolley travel mechanism and overall travel mechanism of port cranes, especially suitable for working environments with frequent maintenance needs.

About Dafang Crane

Dafang Crane was established in 2006 and covers an area of approximately 1.05 million square meters, with more than 2,600 employees. The company focuses on the design, research and development, manufacturing, and sales of overhead cranes, gantry cranes, electric hoists, crane components, and steel structures.

Dafang attaches great importance to product quality and has built a complete product inspection center with capabilities in non-destructive testing, metallographic analysis, mechanical testing, and chemical analysis. The chemical laboratory is equipped with advanced analytical instruments to test multiple elements such as carbon, sulfur, manganese, and silicon in raw materials like crane wheel steel, ensuring consistent quality and reliable performance.

Dafang Crane Port Crane Wheel Cases

Crane Wheels Delivered to Sri Lanka for Port Cranes

- Project: 4pcs drive wheels and 4pcs idler wheels

- Country: Sri Lanka

We have had multiple successful collaborations with this client, who has consistently expressed satisfaction with both the quality of our products and our competitive pricing. These crane wheels are designed as reliable alternatives for port cranes. Our commitment to delivering durable and cost-effective solutions continues to strengthen our ongoing partnership with the client.

136 Sets of Port Crane Wheels Exported to Morocco

- Cast material wheel assembly

- Dimension: Ø292mm*138mm

- Material: C45

- Surface hardness: HB300-320

- QTY: 136 sets

The wheels are designed for use at the dock, operating underwater. Therefore, the customer required all wheels to be coated with anti-rust oil. We have supplied many similar wheels for port cranes, so we have extensive experience in this field.

The customer sent a sample from Morocco and requested that all wheels be made exactly the same as the sample. We disassembled the sample and compared it with the drawings to identify any differences. After discussing with the client, we confirmed which specifications should be followed.

Once the material and drawings were approved, we began production. When the customer received the wheels, they were very satisfied and said they would place an additional order for 136 sets.