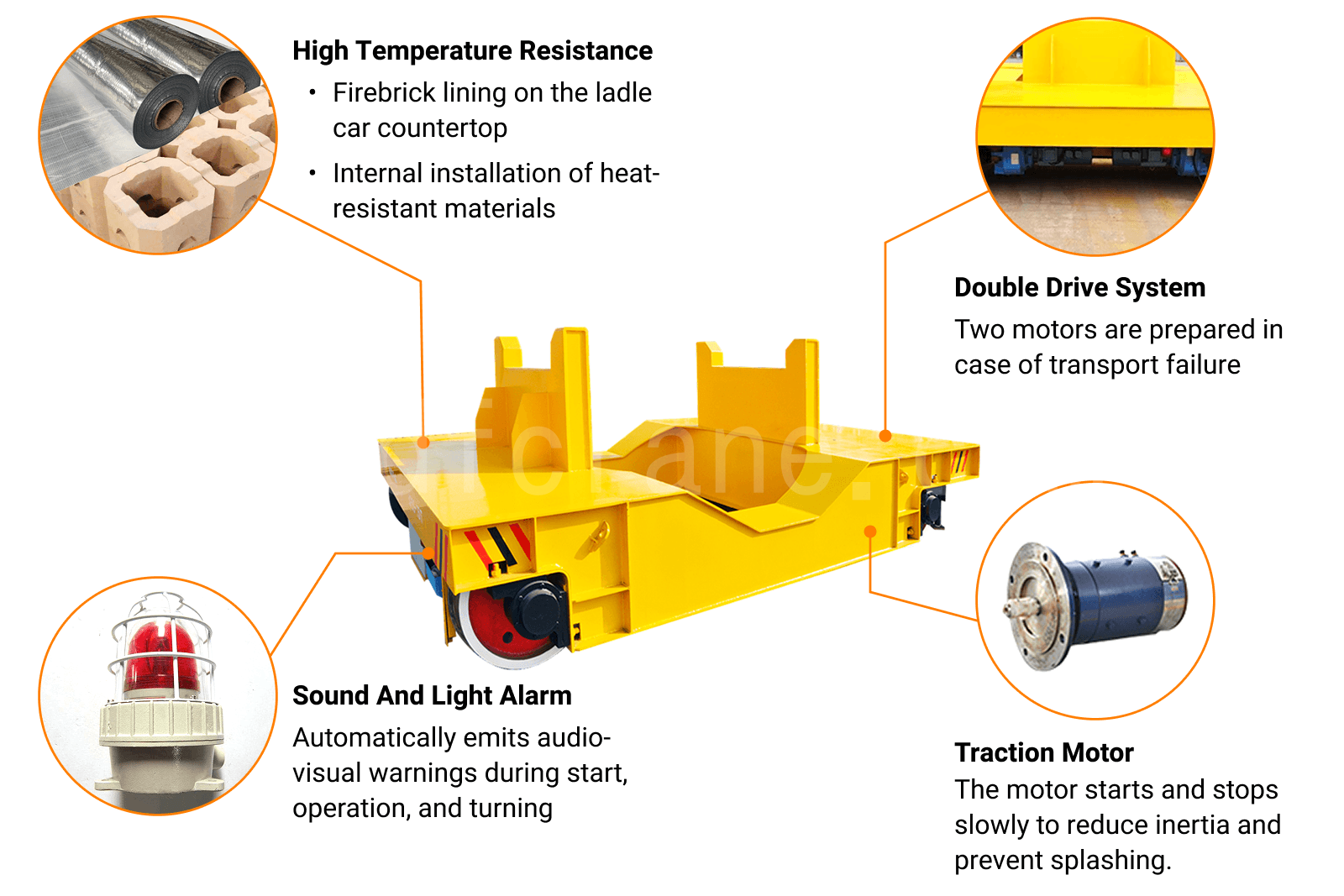

Ladle Transfer Carts Specially Designed for High-Temperature and Safety

- To prevent heat radiation from the high-temperature ladle, the ladle transfer car body is equipped with thermal insulation materials.

- To avoid splashing of molten steel or slag, the traction motor on the ladle transfer car is designed for slow start and stop, maintaining a speed range of 0 to 20 meters per minute.

- To ensure reliable ladle transportation, a dual-drive system is typically used. If one system fails, the other will immediately take over to maintain continuous operation.

- To prevent the ladle from shifting, clamping fixtures can be added on the platform according to the ladle’s diameter.

Key Components of Ladle Transfer Cart

Frame

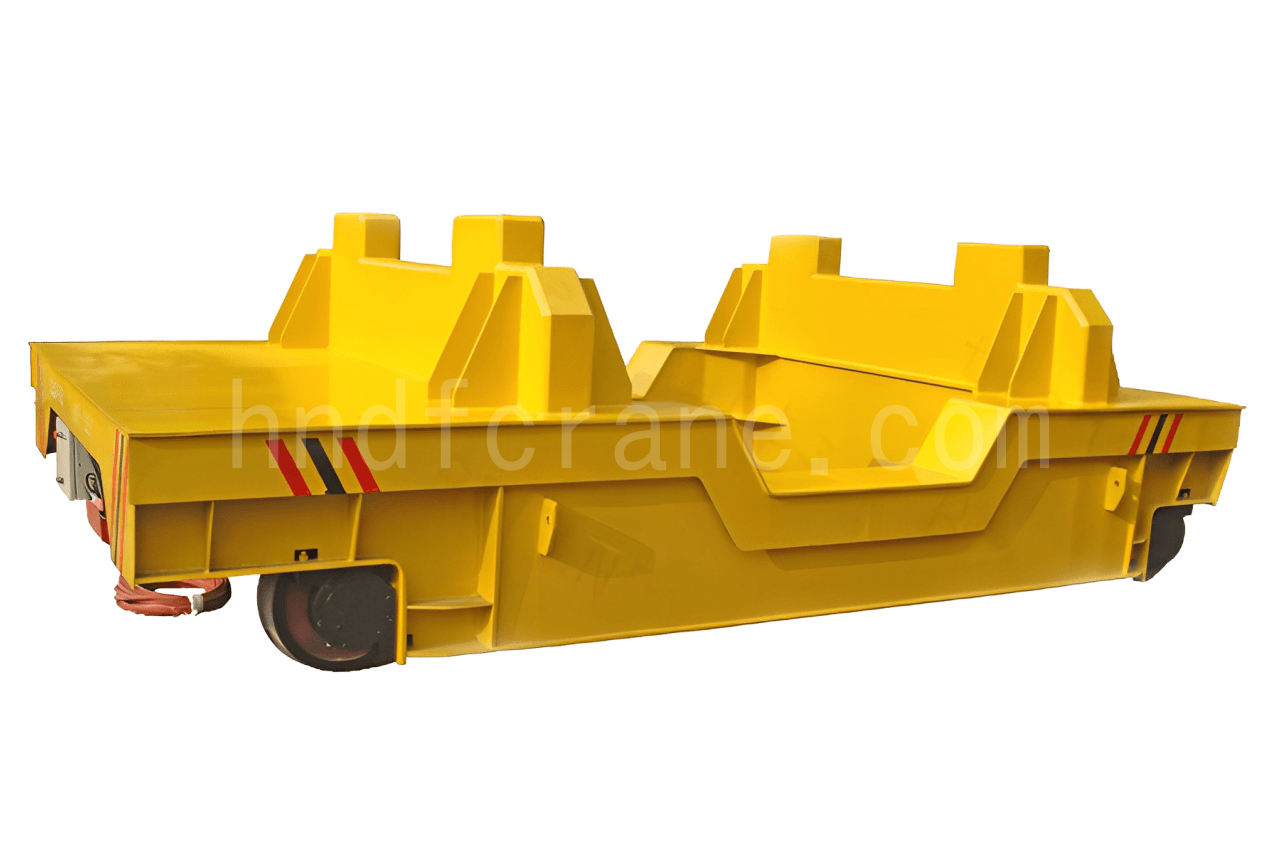

- The platform is made of 10 mm thickened Q235 steel plate to ensure structural integrity and prevent deformation during operation.

- The platform is lined with refractory bricks and other heat-resistant materials to effectively block radiant heat from molten steel, protecting electrical systems and structural components from damage.

- Clamping fixtures can be added to the platform based on the ladle’s diameter to ensure stability during transport and prevent shifting or tipping.

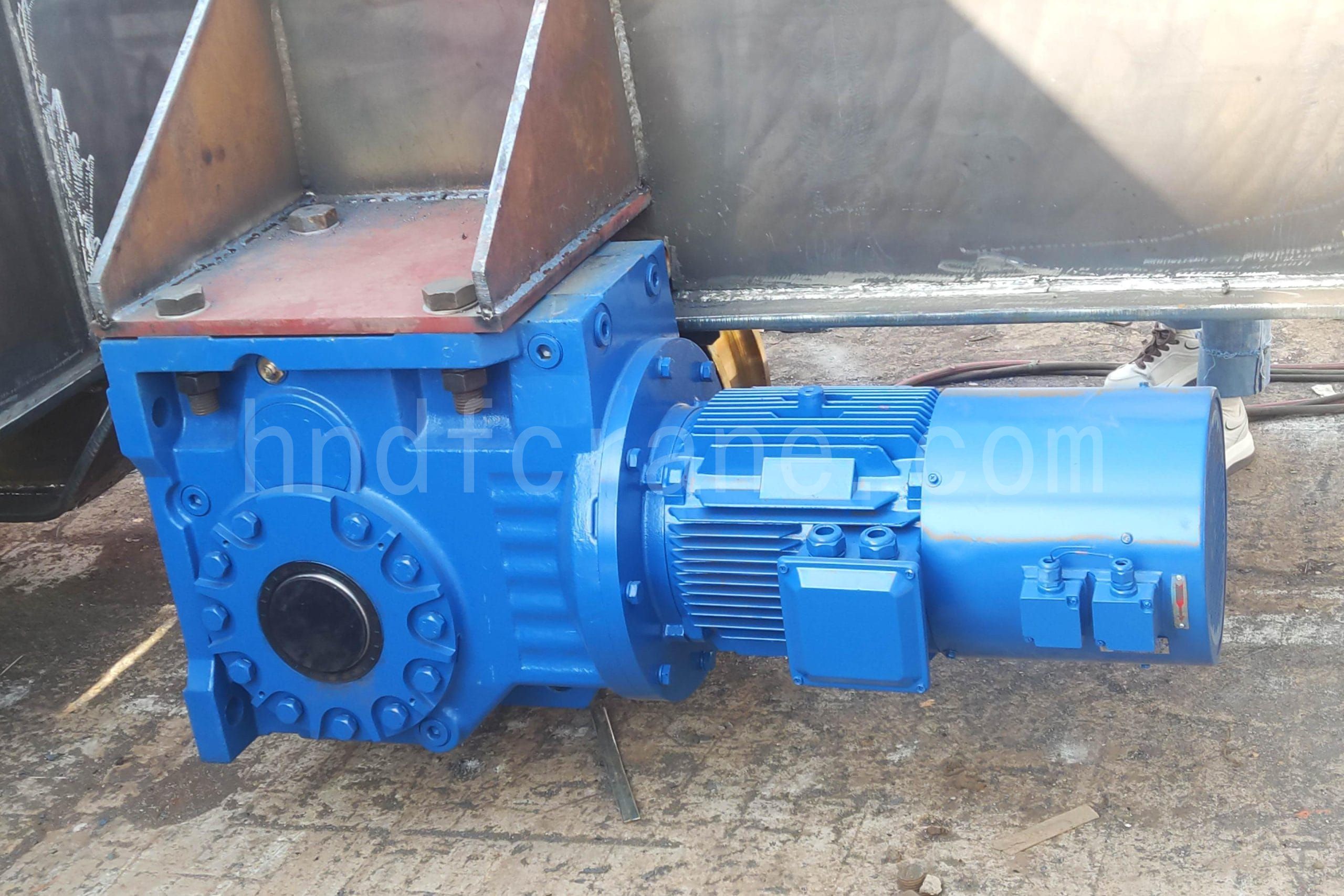

Drive Mechanism

- Variable frequency control enables soft start and soft stop, preventing splashing of molten steel caused by inertia during transport.

- A dual-drive system ensures that if one drive system fails, the other will immediately take over to maintain continuous operation.

- High-temperature-resistant motor with H-class insulation and IP54 protection rating.

Cast Steel Wheels

- The wheels are made of high-strength cast steel ZG45, processed through forging to achieve a dense structure and excellent compressive strength.

- The wheel surface is smooth and free of cracks or defects, ensuring stable performance under heavy-load operating conditions.

- The wheels offer excellent steering capability and wear resistance.

Remote Control

- Wireless remote control enables long-distance operation.

- Operators can perform start, stop, steering, and speed adjustments from a safe area, avoiding close contact with high-temperature ladles and significantly reducing the risk of injury.

Alarm

- The system automatically emits audible and visual warning signals during startup, operation, and steering.

- These signals alert nearby personnel to stay clear, helping to prevent collisions and enhance operational safety.

Ladle Transfer Cart Power Supply Types

Low-Voltage Rail Power Supply

- Suitable for applications involving frequent use of transfer carts or medium-to-long distance transportation.

- Requires higher standards for rail installation, including insulation treatment along the running track.

- Ladle transfer carts typically use low-voltage rail power supply.

Battery Power Supply

- Does not require complex rail installation, and the travel distance is not limited by power supply lines.

- Not ideal for applications involving very frequent use or long-distance transportation.

- Requires regular charging and maintenance of the battery system.

Cable Reel Power Supply

- Suitable for applications with frequent use or long-distance transportation.

- Requires minimal rail installation effort.

- Due to the size of the cable reel, some cart models may have a higher platform.

- The dragged cable may obstruct the passage of personnel or other vehicles within its range.

Cable Chain Power Supply

- Compared to cable reel powered transfer carts, these carts have a lower platform height and are generally more cost-effective.

- The operating distance is limited by the cable length, typically around 20 meters.

Application of Ladle Transfer Carts

The ladle transfer carts can be used in steel plants, foundries, and similar facilities for transporting ladles, molten steel, aluminum pots, slag, and other high-temperature materials.

Transporting Molten Steel from Steelmaking Furnace to Continuous Caster

In steel plants, after the steelmaking process is completed in the furnace, molten steel is poured into a ladle and then transported to the continuous caster by a ladle transfer cart for slab casting. Since the steelmaking furnace and the casting area are relatively far apart, and molten steel is high-temperature and highly fluid, the transfer process demands very high stability and safety.

Advantages:

- Low center of gravity and smooth operation help prevent molten steel from splashing due to vibration.

- The ladle transfer cart is specially designed for high-temperature molten steel, featuring a robust and heat-resistant structure that ensures the safety of both personnel and equipment during transport.

- Capable of carrying ladles up to 300 tons, significantly improving transfer efficiency.

Slag Transport and Tipping

The ladle transfer carts can be used to load slag generated during the smelting process in electric arc furnaces or medium-frequency furnaces and transport it to slag pits or slag yards for dumping or cooling. Some models can be equipped with a hydraulic tilting mechanism for tipping operations.

Advantages:

- Tipping operation: Optional hydraulic tilting device allows quick slag dumping at designated locations, reducing manual intervention.

- Reduced high-temperature work risks: Replaces traditional lifting methods, avoiding direct contact with hot slag, lowering labor intensity, and enhancing overall safety.

- Robust structure designed specifically for high-temperature environments, suitable for frequent slag transportation and handling tasks.

Molten Steel Transfer in Foundry Workshop

In foundry workshops, ladle transfer carts are used to transport molten steel from the tapping area or molten steel ladles to various pouring points, sand mold areas, or pouring platforms, supplying molten metal for mold casting. This process often requires precise control of pouring time and molten steel temperature.

Advantages:

- Smooth operation: The cart runs at a steady speed to prevent molten steel fluctuations and splashing.

- Flexible transfer: Adaptable to complex workshop layouts including curved tracks, turntables, and cross tracks, supporting multi-station operations.

- Accurate positioning: Equipped with positioning control systems for quick docking with pouring platforms or mold stations.