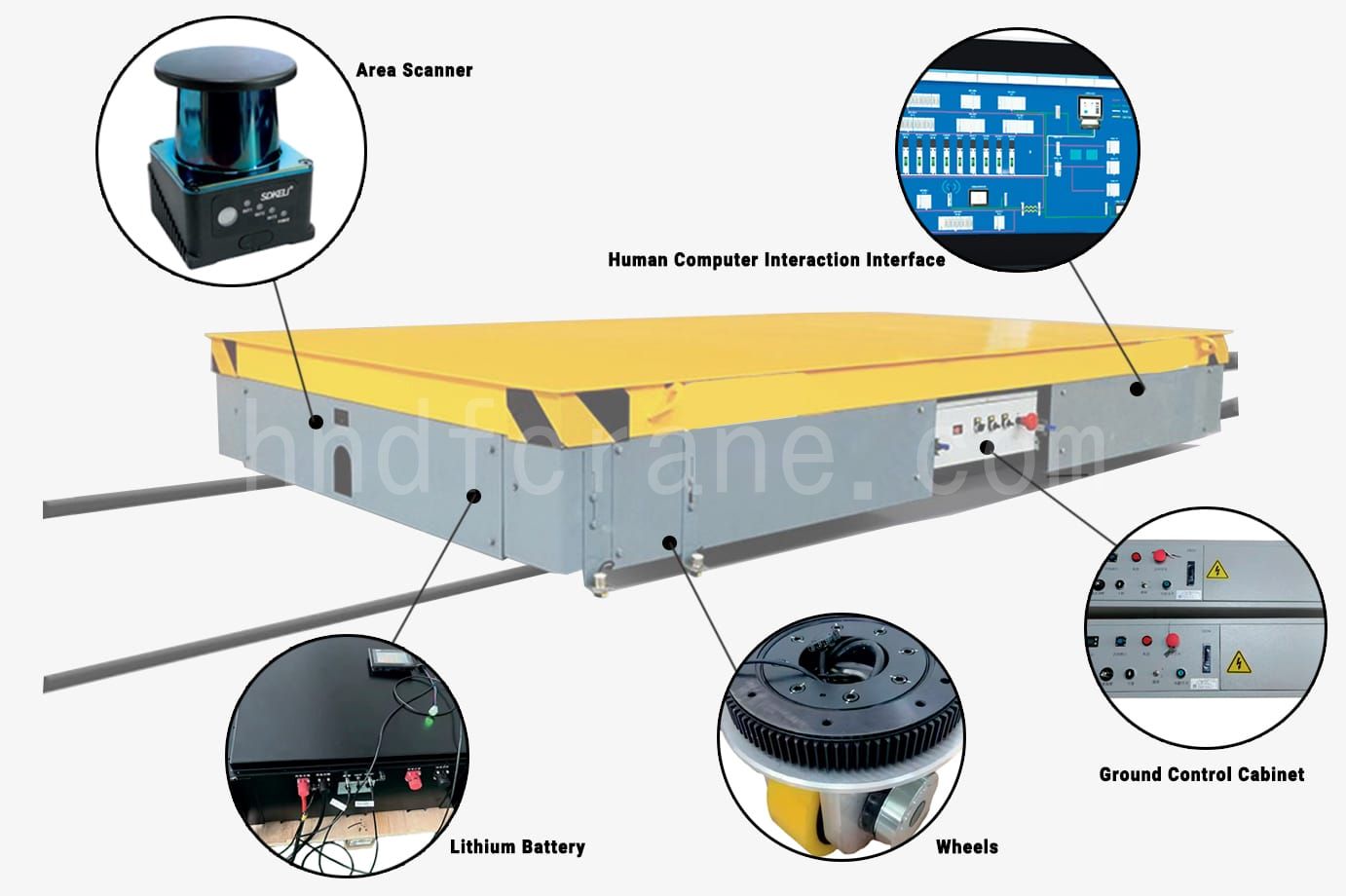

Built with Quality Components for Smart Performance

RGV Transfer Carts Wheels

- Integrated Drive Unit

Combines drive motor, reducer, steering motor, and steering gearbox into one compact system. - Synchronized Operation

Enables coordinated movement for improved control and efficiency. - Precision for Heavy Loads

Suitable for high-load applications requiring accurate positioning.

RGV Transfer Carts Lithium Battery

- Lithium Battery System

Uses proven commercial batteries for safe and reliable performance. - High Power Output

Delivers stable power to support heavy-duty transport. - Fast Charging Capability

Enables short charging times to reduce downtime and improve efficiency. - Long Cycle Life

Enhanced charge-discharge performance extends battery life and reduces maintenance costs. - Maintenance-Free Design

No regular maintenance is required, reducing manual intervention and operating costs.

RGV Transfer Carts Area Scanner

- Area Coverage Scanning

Continuously monitors the transport path to detect obstacles and pedestrians. - Auto Obstacle Avoidance

Stops immediately when objects or people are detected to prevent collisions.

Human Computer Interaction Interface

- Real-Time Status Display

Industrial touchscreen provides clear visibility of vehicle status and key data. - User-Friendly Operation

Enables local control and parameter adjustment with intuitive interface.

Ground Control Cabinet

- Integrated Control Elements

Equipped with a touchscreen, power indicators, and main power switch for efficient local management. - System Communication Interface

Supports data exchange and remote control with upper-level systems.

RGV Transfer Carts for Versatile Industrial Applications

RGV Transfer Carts for Steel Pipe Industry

In the steel structure and pipe processing industry, long, round, and irregular steel pipes pose significant challenges for internal logistics due to their large size, instability, and non-standard shapes. Rail transfer carts, also known as automated transfer carts, offer an efficient and reliable solution for transporting such materials.

These carts can be equipped with roller decks or V-shaped frames to securely support pipes during movement, preventing roll-off and ensuring operational safety. Designed for multi-station workflows, they enable seamless transfers between cutting, beveling, welding, and coating stations—helping maintain steady production rhythms.

Compared to forklifts or manual handling, these automated transfer carts reduce labor intensity and safety risks, making them ideal for high-frequency, long-duration operations. With wireless control or autonomous navigation options, they are compatible with various power systems such as low-voltage rails or lithium batteries, achieving both energy efficiency and long runtime.

This type of RGV transfer cart is widely used in steel fabrication, heavy equipment manufacturing, and pipeline production. It is particularly suited for short-distance, high-frequency transfers of long steel pipes within workshops, supporting smart, low-labor, and high-throughput manufacturing environments.

RGV Transfer Carts for Production Line Material Handling

In production lines with high automation demands, RGV transfer carts play a vital role in streamlining material handling across multiple processing stations. These Rail Guided Vehicles operate along fixed tracks to autonomously transport raw materials, semi-finished parts, and finished goods, supporting continuous flow in assembly, machining, and packaging processes.

To meet the precision needs of modern production environments, the RGV system features high-accuracy positioning and automated docking. This ensures efficient loading and unloading with minimal manual intervention, reducing cycle time and improving overall line stability.

Driven by electric motors, the RGV carts offer low-noise, vibration-free operation—ideal for enclosed or space-constrained workshops. Their ability to navigate complex layouts enables smoother logistics and eliminates traffic congestion caused by traditional manual carts or forklifts.

With integrated remote monitoring and real-time control, RGV systems adapt flexibly to shifting production volumes. Their built-in safety systems—including obstacle detection, warning lights, and emergency stop functions—ensure safe operation alongside personnel and other equipment.

These automated transfer carts are widely used in industries such as electronics, automotive, and precision machinery, where high takt time, low labor input, and efficient intra-line logistics are critical. Their seamless integration with MES and warehouse systems also supports intelligent, data-driven production management.

RGV Transfer Carts for Coil Industry

In the steel coil and copper coil industries, efficient and stable material transport is crucial for ensuring safe operations and maintaining a steady production rhythm. The RGV transfer cart, designed for coil handling, offers a dedicated solution that combines high load capacity, smart control, and multi-directional mobility.

Equipped with a maintenance-free battery, the cart operates continuously without cable constraints, and its automatic charging system ensures uninterrupted power during multi-shift operations. Designed to work in harsh environments ranging from -20°C to 50°C, it is ideal for metallurgical workshops with high thermal loads.

The RGV transfer carts with a precision PLC control system that guarantees stable movement and accurate positioning throughout the process. A 360° rotating table allows it to maneuver in narrow aisles and between complex equipment layouts, making it adaptable to tight plant spaces.

To ensure safety during coil transport, the platform comes with a removable V-frame that adjusts to different coil diameters, securing the load and preventing rolling or slippage during transit.

With its zero-emission operation, this rail transfer cart supports green production goals while reducing operating costs and maintenance downtime. It enables fast coil transfer between processing stages and storage areas, greatly improving logistics efficiency and automation in coil manufacturing lines.

RGV Transfer Carts for Long Size Electric Roller Table Industry

The long size electric roller table RGV transfer cart offers an efficient and safe transfer solution for handling large-sized workpieces such as automotive molds and large structural components. Its roller table enables automatic docking and loading/unloading, making it especially suitable for production processes that require frequent mold changes and high positioning accuracy, such as die casting, injection molding, and mold manufacturing.

The equipment supports low-voltage rail power supply and wireless remote control operation, allowing continuous movement between multiple workstations. This ensures an orderly flow of molds through processing, inspection, heat treatment, and other production stages. The automatic roller drive combined with a precise positioning system significantly reduces manual intervention and improves production cycle stability.

Equipped with multiple safety features including tri-color warning lights, laser emergency stop devices, and safety touch edges, the cart ensures both personnel and equipment safety during high-intensity operations. It can be integrated with the plant's MES system to support automated scheduling and real-time status monitoring, enhancing overall workshop intelligence.

This type of RGV is widely used in the automotive manufacturing, mold processing, and heavy machinery assembly industries. It is suitable for medium- to short-distance transfer of long molds and high-value workpieces. By improving mold change efficiency and transfer accuracy, it effectively supports flexible manufacturing with high throughput and reduced labor requirements.

RGV Transfer Carts for High Temperature Environments Industry

In high-temperature environments such as vacuum furnace workshops, the loading, unloading, and transportation of molds have long been a tough challenge in the logistics of metallurgical production. RGV offers a specially designed vehicle model with excellent high-temperature resistance and heavy-load capacity(low voltage rail powered RGV transfer carts), becoming a key solution to address logistics handling issues in high-temperature and heavy-load scenarios.

Tailored for extreme workshop conditions, its cast steel frame and high-temperature-resistant insulated wheels prevent deformation under heat. Equipped with an automatic flipping ladder, it achieves a track with less than 2mm error and 80mm seamless connection, boosting mold transfer efficiency by 60%.

For intelligence and heavy loads, it uses intelligent coding and anti-interference remote control for millimeter-level docking with in-furnace unpowered trolleys and multi-vehicle scheduling. A telescopic drag chain ensures stable power, while a three-color warning light linked to it enhances high-temperature area safety. It handles up to 15 tons and offers customized widened platforms for special-shaped molds.

Its low-voltage track power supply enables 24/7 continuous operation, with one device handling loading, transportation, and unloading. This reduces annual maintenance costs by 45%, enables a metallurgical enterprise to exceed 80 daily mold sets, and triples equipment lifespan in high temperatures, allowing for efficient and eco-friendly logistics in such scenarios.

Global Cases Powered by Dafang Crane RGV Transfer Carts

RGV Transfer Cart Exported to United Arab Emirates

- Power supply: Low Voltage Rail Powered

- Capacity:15 Ton

- Size:2000*1000*600mm

- Running Speed:0-20 m/min

- Application Industry: Metallurgical Vacuum Furnace Mold Handling

- Special Feature: High-temp resistant design with cast-steel frame and insulated wheels; Automatic tilting bridge enables seamless mold transfer with <2 mm rail tolerance.

RGV Transfer Carts Exported to Kyrgyzstan

- Power supply: Battrty Powered

- Capacity: 40 Ton

- Size:6000*1300*450mm

- Running Speed:0-20 m/min

- Application Industry: Coil & Roll Material Handling

- Special Feature: Designed for moving steel, aluminum, paper, and plastic coils along fixed rail routes in high-frequency industrial workshops.

RGV Transfer Carts Exported to Russia

- Power supply: Battrty Powered

- Capacity:15 Ton

- Running Speed:0-20 m/min

- Application Industry: Railway track overhaul

- Special Feature: Equipped with rail detection sensors and onboard inspection systems, enabling real-time monitoring of rail conditions. Supports autonomous navigation, data collection, and fault identification to improve railway maintenance efficiency and reduce manual inspection workload.